John Deere 180 Lawn Tractor Parts Diagram Overview

Understanding the intricacies of your outdoor equipment is crucial for maintaining its longevity and performance. Whether you’re a seasoned professional or a casual user, having a clear reference for the components of your machinery can significantly streamline maintenance tasks and troubleshooting. This section aims to provide valuable insights into the various elements that make up your equipment, facilitating better care and efficient repairs.

By familiarizing yourself with the specific arrangements and functions of each component, you can ensure that your machinery operates at peak efficiency. This knowledge not only helps in identifying potential issues before they escalate but also empowers you to perform necessary adjustments and replacements with confidence. Explore the essential elements that contribute to optimal functionality and discover how a well-informed approach can enhance your overall experience.

Whether you need to replace a worn-out piece or simply wish to understand how everything fits together, having access to a detailed reference guide can prove invaluable. Join us as we delve into the specifics of each component, ensuring that your outdoor equipment remains in top condition for years to come.

John Deere 180 Tractor Overview

This section offers an in-depth look at a popular model known for its reliability and efficiency in outdoor tasks. Designed for various applications, it combines power with user-friendly features, making it a favorite among enthusiasts.

Performance: This model boasts a robust engine, providing ample horsepower for tackling diverse challenges in gardening and landscaping. The thoughtful engineering ensures smooth operation across different terrains.

Features: Equipped with a variety of innovative tools and accessories, this machine enhances productivity. Its ergonomic design allows for comfortable operation, ensuring that users can work for extended periods without fatigue.

Maintenance: Regular upkeep is essential for longevity. Familiarizing oneself with the service requirements can lead to optimal performance and prevent common issues.

Essential Components of the Lawn Tractor

The functionality and performance of a gardening vehicle are heavily dependent on its core elements. Each component plays a pivotal role, ensuring that the machine operates smoothly and efficiently. Understanding these vital parts is crucial for maintenance and troubleshooting, enabling users to keep their equipment in optimal condition.

Key Mechanical Parts

Supporting Features

In addition to the mechanical parts, supporting features such as the chassis, wheels, and control systems are essential. The chassis provides structural integrity, while the wheels ensure stability and ease of movement. Control systems, including steering and braking, allow users to navigate effectively, enhancing the overall user experience. Each of these components must be well-maintained to ensure longevity and reliability.

Engine and Transmission Details

This section explores the essential components that drive performance and efficiency in your machine. Understanding the mechanics behind these systems can greatly enhance maintenance practices and overall longevity.

Power Unit Specifications

The engine serves as the heart of the machine, delivering the necessary power for various tasks. Key specifications include displacement, horsepower, and fuel type, which all contribute to the operational capabilities. Regular inspections and timely oil changes are vital to ensure optimal performance and to prevent potential issues.

Drive Mechanism Overview

The transmission is crucial for translating engine power into movement. Various configurations, such as hydrostatic or gear-driven, dictate how power is transmitted to the wheels. A thorough understanding of the drive system, along with routine maintenance, can significantly improve the efficiency and responsiveness of your equipment.

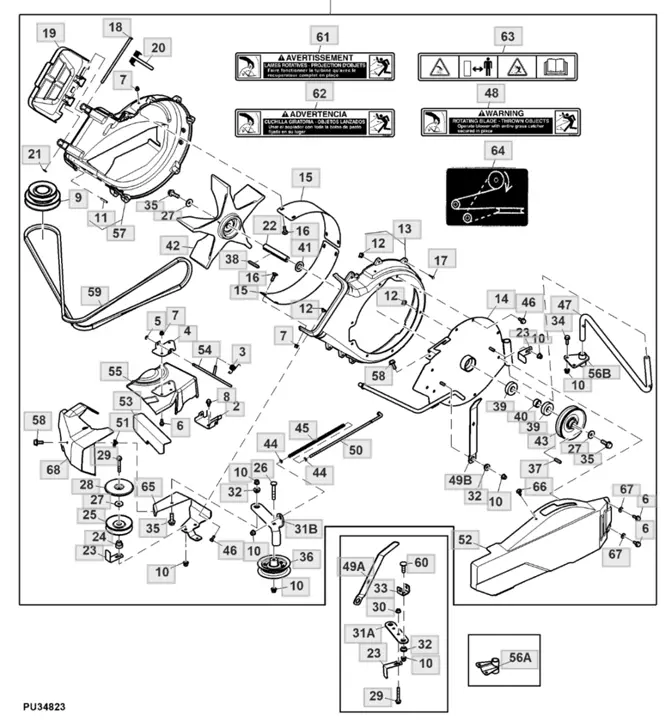

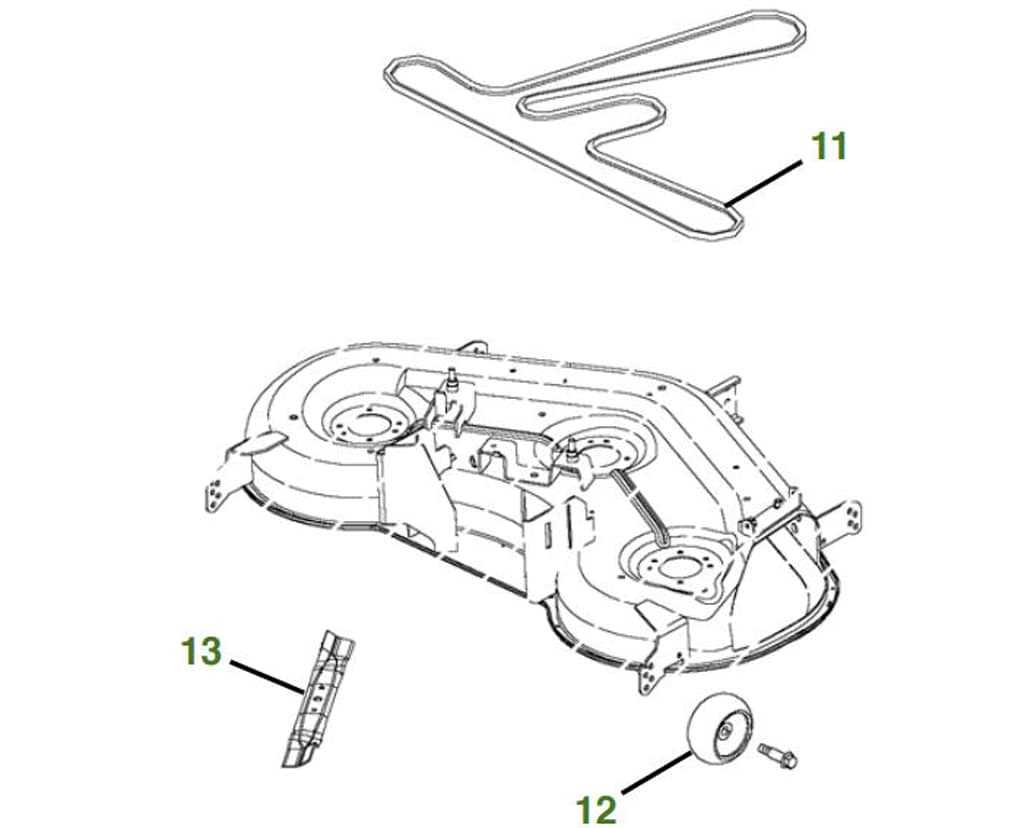

Understanding the Deck Assembly

The deck assembly plays a crucial role in the overall performance and efficiency of a grass-cutting machine. It serves as the foundation for the cutting mechanism, ensuring that grass is trimmed evenly and effectively. Understanding the various components of this assembly can enhance maintenance practices and improve the longevity of the equipment.

Components of the Deck Assembly

The deck assembly consists of several key elements that work in unison. Each part contributes to the functionality and performance of the mowing system.

| Component | Description |

|---|---|

| Deck Housing | The outer shell that protects internal components and supports the cutting blades. |

| Cutter Blades | Sharp edges that rotate to trim grass at the desired height. |

| Spindle Assembly | Holds the blades and allows them to rotate smoothly. |

| Height Adjustment Mechanism | Allows the user to set the cutting height according to preference. |

Maintenance Tips

Regular upkeep of the deck assembly is essential for optimal operation. Keeping the blades sharp and inspecting the housing for wear and tear can prevent potential issues. Additionally, ensuring that all components are securely fastened will contribute to a more effective mowing experience.

Electrical System Breakdown

The electrical system of a garden vehicle is crucial for its functionality, ensuring that various components operate seamlessly. Understanding the intricacies of this system can help in troubleshooting and maintenance, leading to improved performance and longevity.

Key components of the electrical system include:

- Battery: Provides the necessary power to start the engine and operate electrical accessories.

- Wiring Harness: Connects various electrical parts, allowing for communication between them.

- Ignition System: Responsible for starting the engine, it ignites the fuel-air mixture for combustion.

- Lights and Indicators: Enhance visibility and provide feedback on the vehicle’s operational status.

- Starter Motor: Engages the engine to initiate the combustion process.

Common issues that may arise within this system include:

- Weak battery leading to starting difficulties.

- Faulty wiring causing intermittent electrical failures.

- Defective ignition components resulting in misfires.

- Burnt-out bulbs affecting visibility and safety.

Regular inspection and maintenance of the electrical system can prevent these issues, ensuring reliable performance during use.

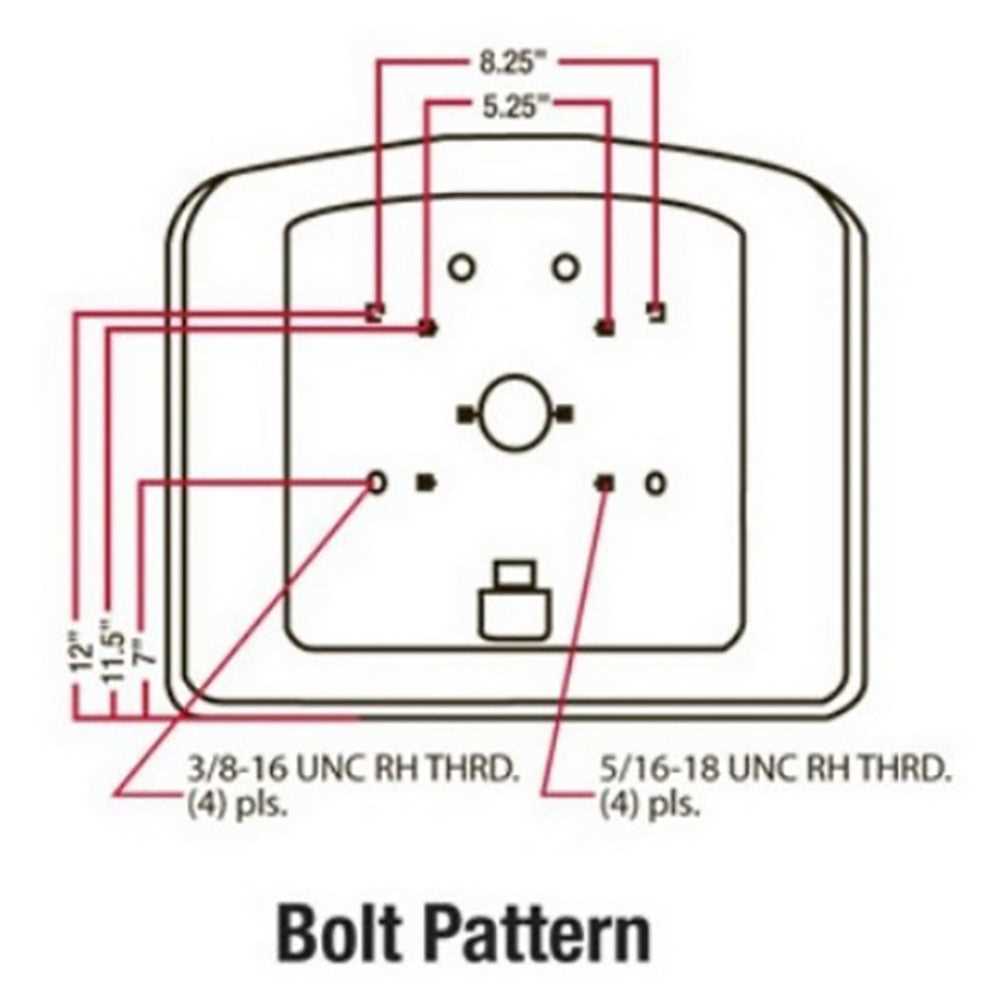

Wheels and Tires Configuration

The arrangement of wheels and tires plays a crucial role in the overall functionality and performance of outdoor equipment. Proper selection and maintenance ensure stability, traction, and maneuverability, enhancing the user experience and extending the lifespan of the machine.

Types of Wheels

- Standard Wheels: Ideal for regular terrain and everyday use.

- All-Terrain Wheels: Designed for uneven surfaces, providing better grip.

- Heavy-Duty Wheels: Suitable for rugged environments and heavy loads.

Tire Specifications

- Width: Affects stability and surface contact.

- Diameter: Influences ground clearance and speed.

- Tread Pattern: Impacts traction and performance on various surfaces.

Understanding these configurations allows users to make informed decisions for optimal functionality in different conditions.

Maintenance Parts for Longevity

Ensuring the durability of outdoor machinery hinges on the quality and upkeep of various components. Regular attention to these essential elements can significantly enhance performance and extend lifespan. By focusing on specific items that require periodic replacement or servicing, users can achieve optimal functionality.

Filters play a critical role in maintaining a clean operational environment. Regularly replacing air and oil filters prevents contaminants from causing damage, ensuring smooth operation.

Belts are another vital aspect. These components endure constant wear and tear, and timely replacement can avert potential breakdowns and maintain efficiency.

Fluids must be regularly checked and changed according to recommendations. Fresh oil and coolant not only enhance performance but also protect internal mechanisms from excessive wear.

Additionally, spark plugs should be monitored and replaced as needed. They are essential for efficient ignition and can significantly impact overall performance when kept in optimal condition.

By delving into these maintenance essentials, users can achieve the ultimate longevity and reliability of their equipment.

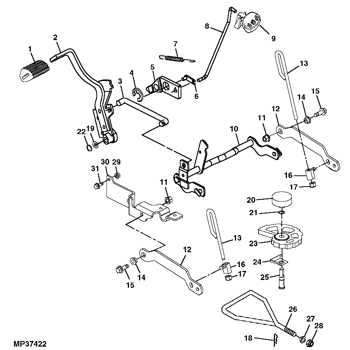

Steering Mechanism and Linkages

The steering system plays a crucial role in maneuvering the vehicle, providing the operator with the ability to navigate various terrains effectively. Understanding its components and how they interact is essential for maintaining optimal performance and ensuring a smooth driving experience.

Key Components

At the core of the steering assembly are the linkages that connect the steering wheel to the wheels. These components include the steering gear, which translates the rotational motion of the wheel into lateral movement, and various rods and joints that facilitate the transfer of force. Regular inspection of these elements is vital to prevent wear and tear that could compromise handling.

Maintenance Tips

To ensure longevity and reliability, it’s important to keep the linkages well-lubricated and free from debris. Additionally, check for any signs of corrosion or damage. Promptly addressing any issues can significantly enhance the overall steering performance and contribute to a more enjoyable operation.

Hydraulic System Insights

The hydraulic mechanism is a vital component of many outdoor machinery, playing a crucial role in their overall functionality. Understanding its intricacies can enhance performance and extend the lifespan of the equipment. This section delves into the essential aspects of hydraulic systems, highlighting key elements and maintenance practices.

Key Components

At the core of any hydraulic setup are the pump, reservoir, and actuator. The pump generates the necessary pressure, while the reservoir stores hydraulic fluid, ensuring a consistent supply. Finally, the actuator translates fluid pressure into mechanical movement, making it essential for optimal operation.

Maintenance Best Practices

Regular maintenance is critical to the functionality of the hydraulic system. Inspecting fluid levels, checking for leaks, and replacing worn seals can prevent costly repairs. Additionally, flushing the system periodically ensures that contaminants do not compromise performance, ultimately enhancing the equipment’s reliability.

Control Levers and Cables Explained

Understanding the mechanisms that govern the movement and functionality of outdoor machinery is crucial for efficient operation and maintenance. Control levers and cables play a pivotal role in allowing users to navigate and manage their equipment effectively. This section delves into their significance and operation.

Functionality of Control Levers

Control levers serve as the primary interface between the operator and the machine. They allow for precise adjustments and commands.

- Facilitate speed adjustments

- Manage directional changes

- Control various attachments

The Role of Cables

Cables connect the control levers to the mechanisms they operate, translating user input into action. Understanding their function is vital for troubleshooting.

- Transmit signals from the lever to the engine

- Enable smooth operation of controls

- Require regular inspection for wear and tear

Fuel and Air Filter Components

Proper filtration of fuel and air is essential for optimal engine performance. These components work together to ensure that the combustion process is efficient, contributing to both power output and fuel economy. Understanding their roles can help maintain equipment longevity and enhance overall functionality.

Fuel Filter

The fuel filter plays a critical role in trapping impurities from the fuel before it reaches the engine. By preventing contaminants from entering the fuel system, it ensures smooth operation and reduces the risk of damage. Regular replacement of this component is vital for maintaining a clean fuel supply.

Air Filter

Similarly, the air filter is essential for keeping dust and debris from entering the engine. A clean air filter allows for proper airflow, which is crucial for the combustion process. Neglecting this part can lead to decreased performance and increased fuel consumption. Routine inspection and replacement can greatly enhance engine efficiency.

Safety Features and Enhancements

Ensuring the well-being of operators and bystanders is paramount in any outdoor equipment. Various enhancements are incorporated to provide a secure experience, minimizing risks and promoting safe usage practices. These innovations not only protect users but also enhance the overall functionality and reliability of the machinery.

| Feature | Description |

|---|---|

| Operator Presence System | Automatically shuts down the machine if the operator leaves the seat, preventing accidents. |

| Roll Over Protection | Structures designed to protect the operator in the event of a rollover, enhancing safety during operation. |

| Secure Footrest | Designed to keep feet securely positioned, reducing the risk of slipping during use. |

| Safety Switches | Multiple switches that prevent the engine from starting under unsafe conditions, ensuring user protection. |