Comprehensive Parts Diagram for John Deere 790 Tractor

In the world of farming equipment, a comprehensive understanding of machinery elements is crucial for optimal performance and maintenance. Each machine consists of various sections that work together seamlessly, ensuring efficiency and durability. By exploring the intricate design of these elements, operators can enhance productivity and reduce downtime.

Visual representations play a vital role in grasping the complexities of any mechanical system. These illustrations not only facilitate better comprehension but also serve as valuable references for troubleshooting and repairs. Knowing how different components interact helps users make informed decisions regarding upkeep and replacements.

By delving into the specifics of each segment, one can appreciate the engineering that goes into crafting reliable equipment. This knowledge empowers users, enabling them to address issues proactively and maximize the lifespan of their machinery. Understanding these intricacies is an essential step for anyone looking to excel in agricultural practices.

Understanding the John Deere 790 Tractor

This section aims to explore the intricate mechanisms and components that make up a popular model in the agricultural machinery sector. By examining these elements, we can appreciate the engineering and design that enhance performance and reliability.

Key Features

- Robust engine capabilities

- User-friendly controls

- Versatile attachment compatibility

- Durable build quality

Maintenance Considerations

- Regular oil changes

- Inspection of hydraulic systems

- Checking tire pressure and condition

- Cleaning air filters

Understanding these aspects not only helps in maintenance but also maximizes the machine’s potential in various agricultural tasks.

Key Features of the 790 Model

This model stands out for its robust construction and efficiency, offering users a blend of power and versatility. Designed to tackle a variety of tasks, it ensures optimal performance across different environments.

Powerful Engine

The heart of this model lies in its strong engine, providing impressive torque and horsepower. This enhances its capability to handle heavy-duty workloads with ease, making it suitable for both agricultural and industrial applications.

Durability and Design

Engineered for longevity, the chassis is crafted from high-quality materials that withstand harsh conditions. The ergonomic design allows for comfortable operation, ensuring users can work efficiently over extended periods without fatigue.

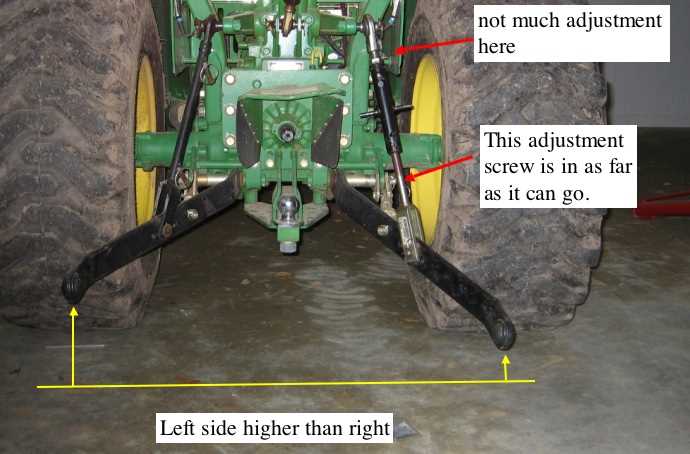

Common Issues with 790 Tractors

Various challenges can arise with agricultural machinery, impacting efficiency and performance. Understanding these common concerns can help operators mitigate issues and enhance longevity.

Engine Performance

One prevalent issue is related to engine functionality. Problems such as overheating or irregular starting can stem from factors like inadequate maintenance or fuel quality. Regular checks and servicing can prevent these complications.

Hydraulic System Failures

Another frequent challenge involves hydraulic systems. Leaks or reduced pressure can hinder operation. Ensuring proper fluid levels and inspecting hoses regularly can significantly improve system reliability.

Parts Replacement for Optimal Performance

Maintaining equipment efficiency requires regular updates and swaps of essential components. Ensuring that each element functions at its best not only prolongs the lifespan of the machine but also enhances its overall productivity. Timely replacements are crucial to prevent unexpected failures and costly repairs.

Benefits of Timely Component Replacement

- Improved Efficiency: Replacing worn-out components boosts overall functionality.

- Cost Savings: Regular maintenance reduces the risk of expensive breakdowns.

- Enhanced Safety: Keeping all elements in optimal condition minimizes risks associated with equipment failure.

Key Components to Monitor

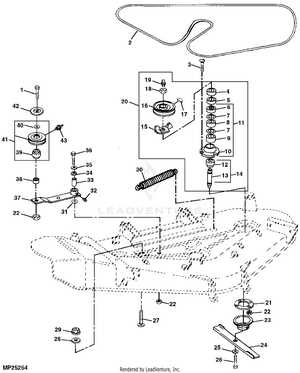

- Filters: Regularly changing air, fuel, and oil filters ensures optimal fluid flow and prevents contaminants from causing damage.

- Belts and Hoses: Inspecting and replacing these elements can prevent unexpected failures and maintain operational efficiency.

- Fluid Levels: Regularly checking and topping off fluids, such as oil and coolant, is vital for smooth operation.

- Worn Parts: Keep an eye on elements that experience high wear and tear, replacing them before they lead to bigger issues.

By prioritizing the replacement of crucial elements, operators can ensure their equipment remains reliable and effective in various tasks. Regular check-ups and updates are a proactive approach to achieving sustained performance.

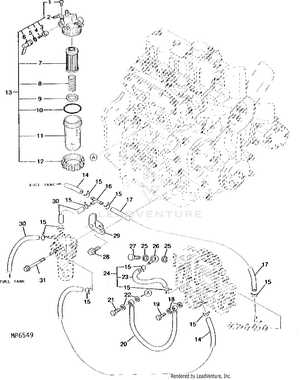

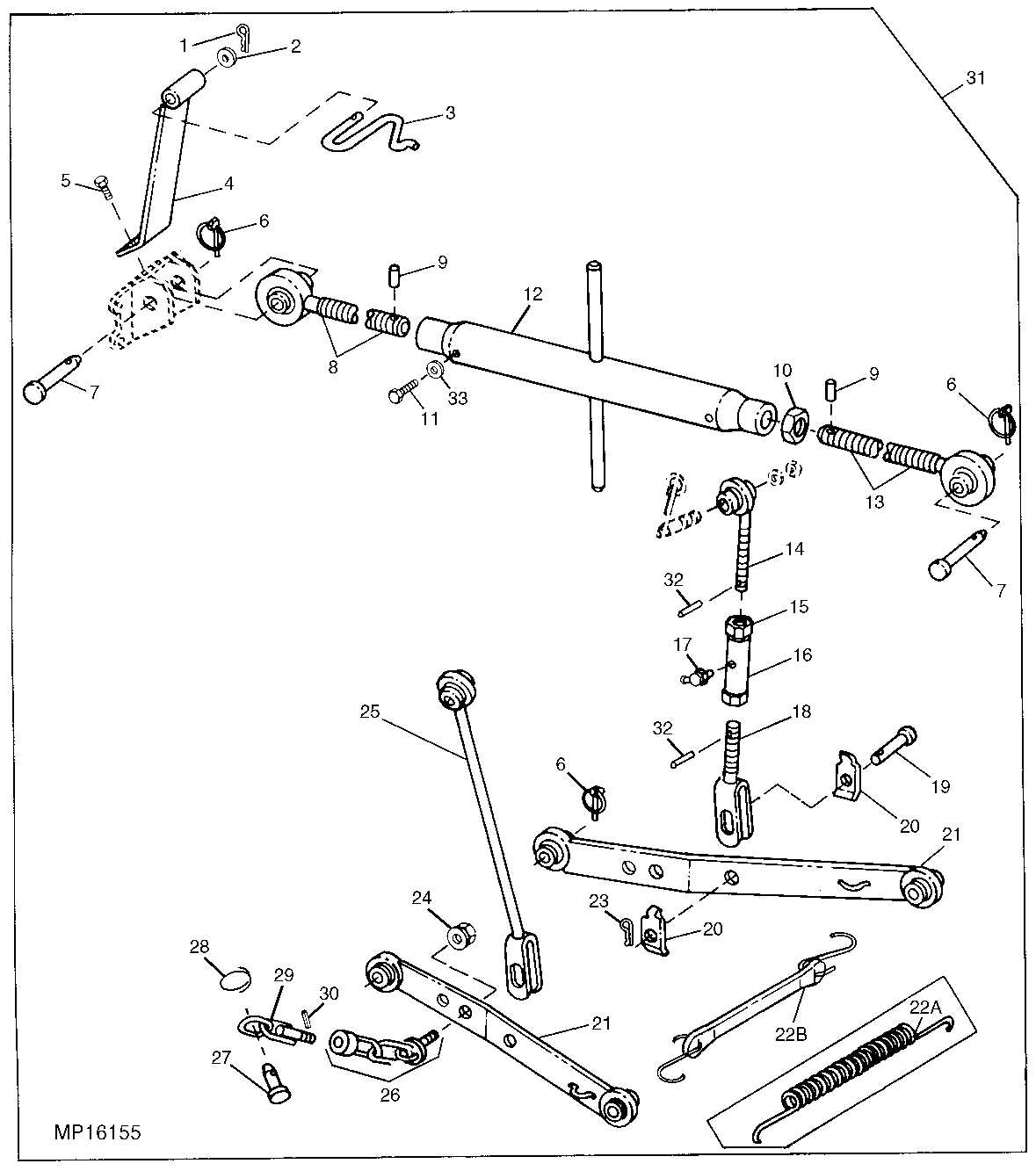

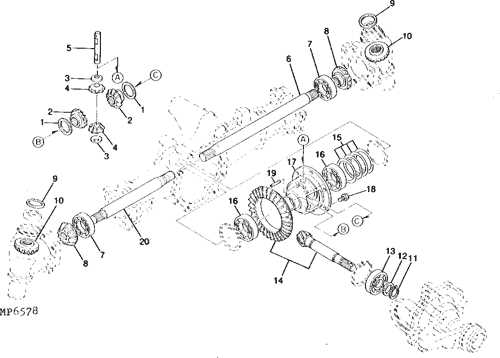

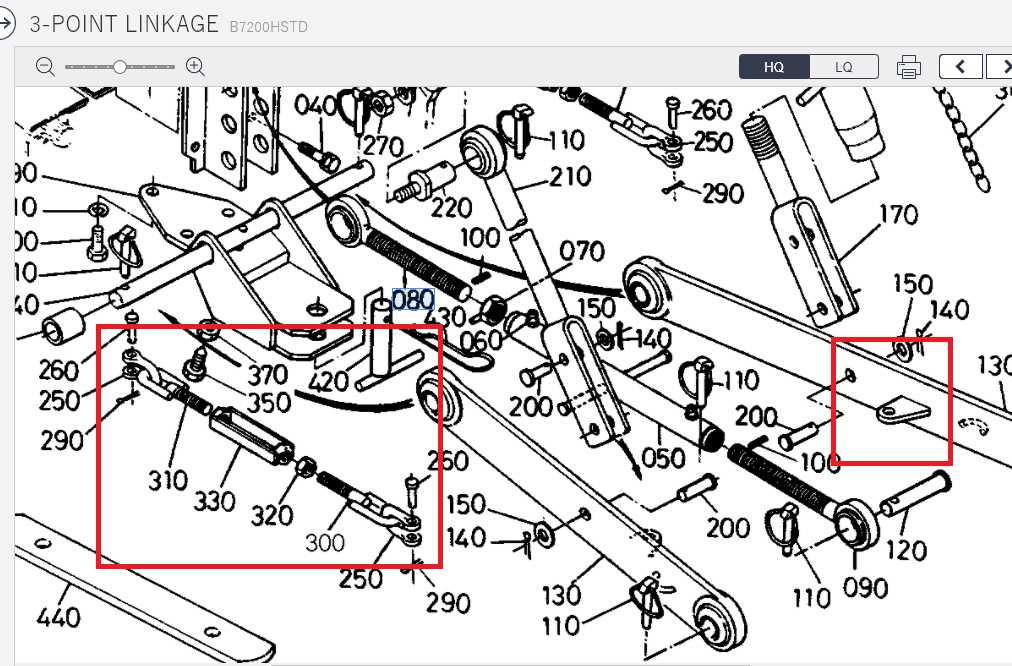

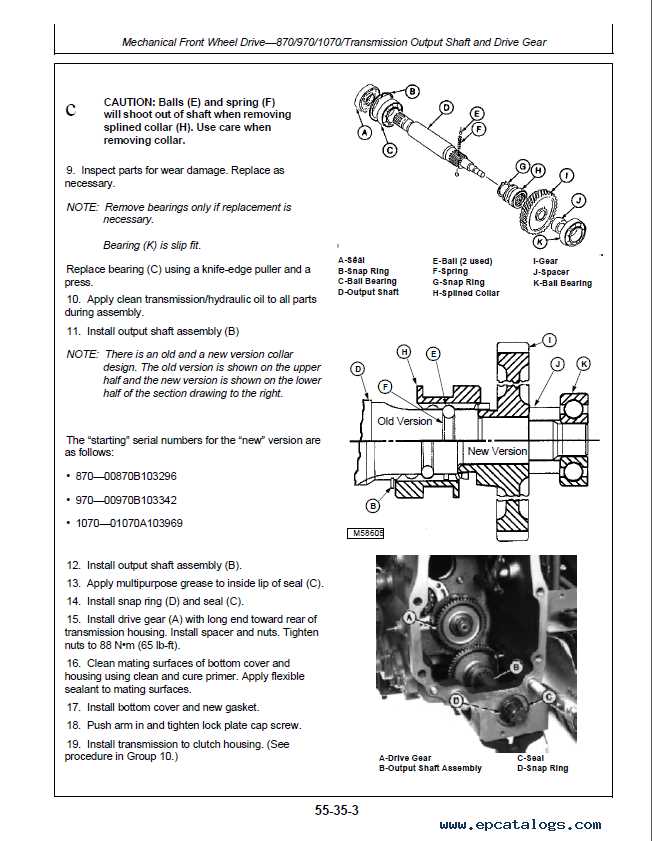

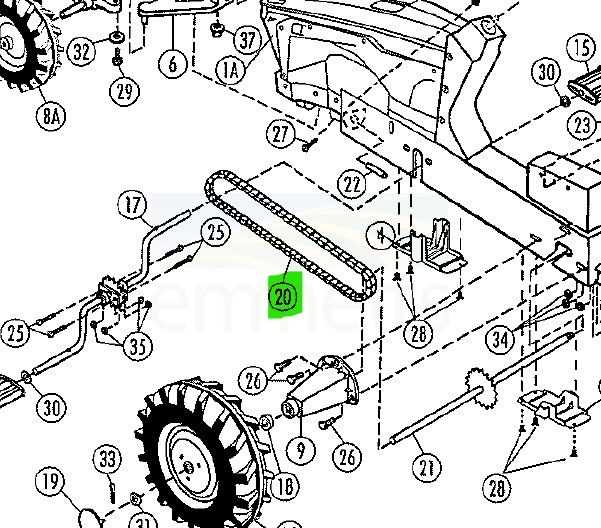

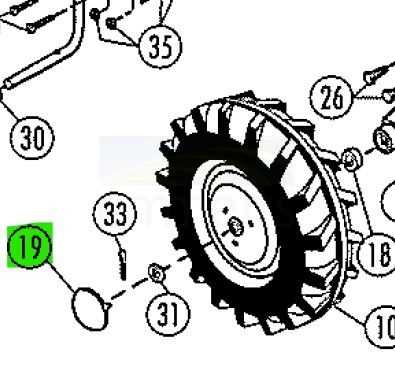

Identifying Components in the Diagram

Understanding the various elements within a technical representation is crucial for effective maintenance and repairs. Each section serves a specific function and contributes to the overall operation of the machinery. By recognizing these components, operators can make informed decisions and ensure optimal performance.

Key Elements to Recognize

Familiarity with the essential units, such as the engine, transmission, and hydraulic systems, allows users to troubleshoot issues efficiently. Each part’s location and relationship to others can significantly influence functionality and serviceability.

Common Issues and Solutions

Identifying wear and tear on specific components can prevent more extensive damage. Understanding how to interpret the layout aids in diagnosing problems early, ensuring timely interventions and prolonging the equipment’s lifespan.

Importance of Regular Maintenance

Regular upkeep is essential for the longevity and efficiency of any machinery. Consistent attention to maintenance not only enhances performance but also prevents unexpected breakdowns, ensuring that equipment operates smoothly over time.

Timely inspections and routine service allow for the early detection of potential issues. By addressing minor problems before they escalate, operators can save time and resources. This proactive approach minimizes downtime, which is crucial in maintaining productivity in any operation.

Additionally, routine care contributes to the overall safety of the equipment. Well-maintained machinery is less likely to malfunction, reducing the risk of accidents and injuries. Furthermore, adhering to a regular maintenance schedule can improve fuel efficiency and reduce operating costs, benefiting the bottom line.

Ultimately, the importance of consistent maintenance cannot be overstated. Investing time and resources into proper care will yield significant returns in terms of performance, safety, and cost-effectiveness.

Where to Find Replacement Parts

Finding the right components for your equipment can be a daunting task, but with the right approach, it becomes manageable. Various sources are available, each offering different benefits, making it essential to explore all options to ensure you obtain quality items at competitive prices.

Online Retailers: Numerous online platforms specialize in machinery components, providing a wide range of products. These websites often feature user reviews, which can guide your purchasing decisions. Look for reputable vendors with detailed descriptions and return policies to protect your investment.

Local Dealers: Visiting local dealerships can be advantageous. They typically stock a selection of essential components and can offer expert advice on compatibility and installation. Establishing a relationship with a nearby dealer may lead to special deals or quicker access to needed items.

Salvage Yards: For those on a budget, salvage yards can be a treasure trove of usable parts. While the selection may vary, it’s possible to find high-quality, pre-owned components at a fraction of the cost. Always inspect items carefully to ensure they meet your requirements.

Online Marketplaces: Websites that host classifieds can be another resource for finding specific components. Sellers may offer new or gently used items, often at lower prices. However, exercise caution and verify the seller’s credibility before making a purchase.

Forums and Community Groups: Engaging with online communities or forums dedicated to equipment maintenance can provide valuable insights. Fellow enthusiasts often share tips on where to find hard-to-locate items or may even have spare components available for sale or trade.

By exploring these avenues, you can streamline your search for necessary replacements and keep your machinery running smoothly.

Benefits of Using Genuine Parts

Utilizing authentic components for machinery maintenance and repair ensures optimal performance and longevity. These original items are designed specifically to fit and function perfectly, providing numerous advantages over generic alternatives.

Quality Assurance

One of the primary benefits of using original components is the guarantee of high quality. These products undergo rigorous testing to meet strict industry standards. Key points include:

- Durability: Authentic components are built to withstand the demands of heavy use.

- Reliability: They are less likely to fail, reducing the risk of costly downtime.

- Consistency: Original items ensure uniform performance across all machinery.

Enhanced Performance

Original components are engineered to work seamlessly with existing systems, leading to improved efficiency. Advantages include:

- Better Compatibility: Genuine items fit perfectly, reducing the risk of installation issues.

- Improved Functionality: They help maintain the machine’s performance, enhancing productivity.

- Extended Lifespan: Using original parts can prolong the life of the machinery, ultimately saving costs in the long run.

DIY Repairs vs. Professional Help

When faced with the challenge of equipment maintenance, individuals often weigh the benefits of tackling repairs themselves against seeking expert assistance. This decision hinges on factors such as skill level, complexity of the task, and the potential for costly mistakes.

Taking on repairs independently can be rewarding, allowing for personal growth and a sense of accomplishment. Engaging in do-it-yourself projects often fosters a deeper understanding of the machinery, making future maintenance easier. However, without adequate knowledge, one risks causing further damage, which can lead to greater expenses down the line.

On the other hand, enlisting the help of professionals ensures that repairs are conducted efficiently and correctly. Experts bring a wealth of experience, often resulting in quicker turnaround times and higher quality outcomes. Yet, this convenience comes at a price, and not everyone may find it feasible to invest in professional services.

Ultimately, the choice between DIY efforts and hiring specialists should consider both the individual’s capabilities and the specific requirements of the task at hand. Balancing these elements will lead to more informed decisions and potentially better results.

Cost Considerations for Tractor Parts

Understanding the financial implications of acquiring machinery components is crucial for maintaining equipment efficiency and longevity. Various factors influence the expenses associated with replacements, repairs, and maintenance.

Key Factors Affecting Costs

- Quality: Higher-quality components often come at a premium but can provide better durability.

- Source: OEM versus aftermarket options can lead to significant price differences.

- Availability: Rarer items may cost more due to limited supply.

Cost-Saving Strategies

- Compare prices from different suppliers to find the best deal.

- Consider purchasing in bulk to reduce overall expenses.

- Regular maintenance can prevent costly repairs in the future.

Upgrading Your John Deere 790

Enhancing the performance and efficiency of your agricultural machine can lead to significant benefits in productivity and ease of operation. By focusing on strategic improvements, you can ensure that your equipment meets your evolving needs and tackles various tasks more effectively.

Investing in superior components can boost your vehicle’s capabilities, such as increasing horsepower or improving fuel efficiency. Consider replacing worn-out elements with upgraded versions that offer enhanced durability and performance.

Additionally, integrating modern technology can transform your experience. From precision farming tools to advanced monitoring systems, these innovations enable you to optimize your operations and achieve ultimate efficiency.

Finally, don’t overlook the importance of regular maintenance. Keeping your machinery in top shape not only extends its lifespan but also maximizes the benefits of any upgrades you implement.

Understanding Warranty and Support Options

When investing in machinery, comprehending the protection plans and assistance available is crucial. These services not only safeguard your investment but also ensure seamless operation and maintenance. A thorough understanding of warranty conditions and support avenues can significantly enhance your ownership experience.

Types of Warranty Coverage

Warranties typically come in various forms, including limited and comprehensive plans. Limited warranties may cover specific components, while comprehensive options often extend protection to a broader range of issues. Knowing the specifics of each can help you make informed decisions about repairs and maintenance.

Accessing Customer Support

Reliable customer service is essential for addressing concerns promptly. Support options can range from online resources to direct assistance via phone or in-person visits. Familiarizing yourself with these channels will ensure that you receive the help you need when facing challenges.

Community Resources for Tractor Owners

Having access to a variety of resources can greatly enhance the experience of those who own and maintain agricultural machinery. Whether you’re seeking advice, replacement components, or simply looking to connect with fellow enthusiasts, community resources provide invaluable support.

Online Forums and Groups

- Participate in discussions on popular platforms to share knowledge.

- Join dedicated social media groups for tips and tricks.

- Engage in Q&A sessions to troubleshoot issues effectively.

Local Workshops and Events

- Attend workshops for hands-on learning opportunities.

- Join local clubs to meet like-minded individuals.

- Participate in community events to expand your network.