Comprehensive Guide to John Deere Lawn Tractor Parts Diagram

Maintaining a machine for outdoor landscaping is essential for optimal performance and longevity. A comprehensive understanding of its inner workings can enhance the efficiency of the equipment and reduce the likelihood of breakdowns. Knowing how each element contributes to the overall functionality empowers users to make informed decisions regarding repairs and upgrades.

In this section, we will explore the intricate layout of essential components, highlighting their roles and interconnections. Whether you are a seasoned operator or a newcomer, familiarizing yourself with these crucial aspects will pave the way for smoother operations and better care of your device.

By delving into the specifics of various assemblies, you can uncover the ultimate potential of your machinery. This knowledge not only facilitates troubleshooting but also enhances your ability to customize and improve your setup for various tasks.

Understanding John Deere Lawn Tractors

This section explores the essential features and components of these versatile outdoor machines. Known for their durability and efficiency, they are designed to tackle various tasks, making them invaluable for maintaining outdoor spaces.

Key Features

These machines often come equipped with powerful engines, advanced cutting systems, and user-friendly controls. Their design allows for easy maneuverability, enabling users to navigate tight areas effortlessly.

Maintenance Essentials

Regular upkeep is crucial to ensure optimal performance. Familiarity with the main components can aid owners in troubleshooting and performing necessary repairs, enhancing the longevity of their equipment.

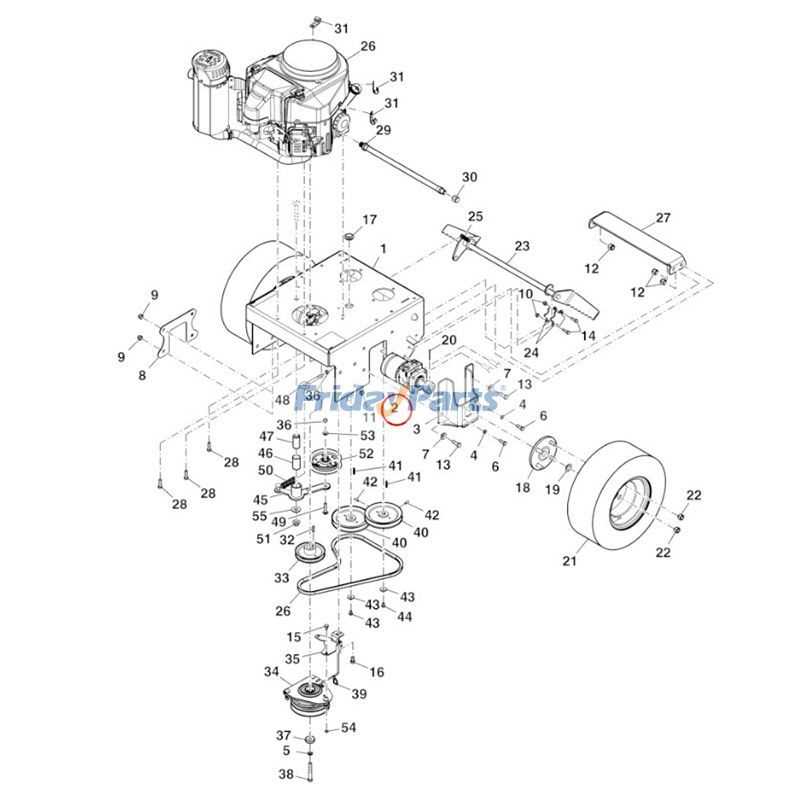

Key Components of Lawn Tractors

Understanding the essential elements of grass cutting machines is crucial for both maintenance and effective operation. Each segment plays a vital role in ensuring optimal performance, contributing to the overall efficiency and longevity of the equipment.

Engine: The heart of the machine, this component provides the necessary power to drive the wheels and operate the cutting mechanism. Engine types can vary, impacting fuel efficiency and performance.

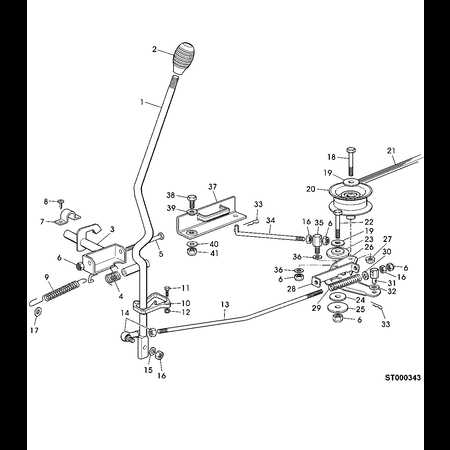

Transmission: This system is responsible for transferring power from the engine to the wheels. Different types of transmissions, such as manual or automatic, affect how smoothly and efficiently the equipment can operate.

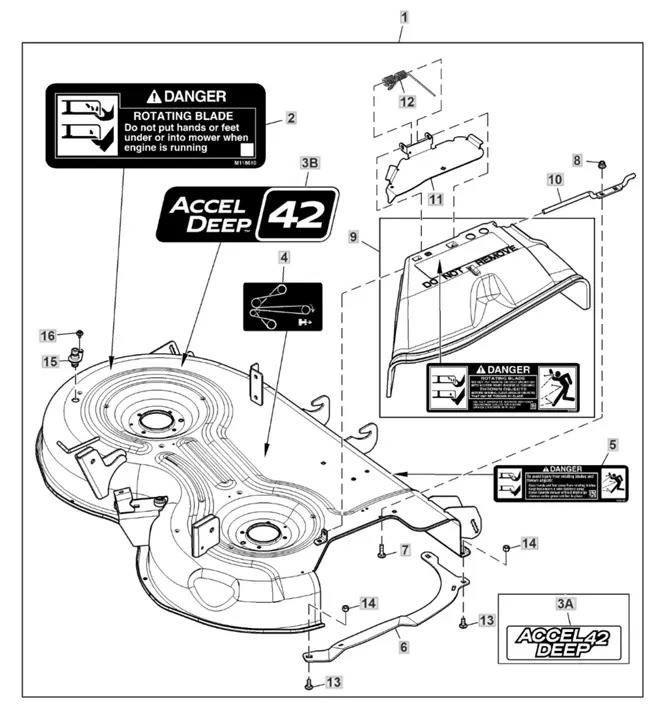

Deck: The cutting deck is where the actual grass trimming occurs. Its design and size determine the width of the cut, influencing how quickly an area can be mowed.

Wheels: The size and type of wheels play a significant role in maneuverability and stability. Larger wheels often provide better traction on uneven terrain, while smaller wheels may allow for tighter turns.

Controls: User interface elements such as levers and pedals are crucial for maneuvering and adjusting the machine’s functions. Ergonomically designed controls enhance user experience and reduce fatigue during operation.

Familiarity with these fundamental components will not only aid in effective use but also in troubleshooting and repairs, ensuring that your equipment remains in top condition for years to come.

Importance of Maintenance for Longevity

Regular upkeep is essential for ensuring the prolonged functionality and reliability of any mechanical device. Neglecting this crucial aspect can lead to decreased performance and premature wear. By adhering to a routine maintenance schedule, one can significantly enhance the lifespan of their equipment, allowing for optimal performance over time.

Engaging in consistent maintenance not only prevents unexpected breakdowns but also ensures that all components function smoothly. This practice helps identify potential issues early, reducing the likelihood of costly repairs in the future. Below is a summary of key maintenance tasks that contribute to longevity:

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Oil Change | Every 50 hours | Reduces engine wear |

| Blade Sharpening | Every 25 hours | Improves cutting efficiency |

| Air Filter Replacement | Every season | Enhances airflow and performance |

| Tire Inspection | Monthly | Ensures proper traction |

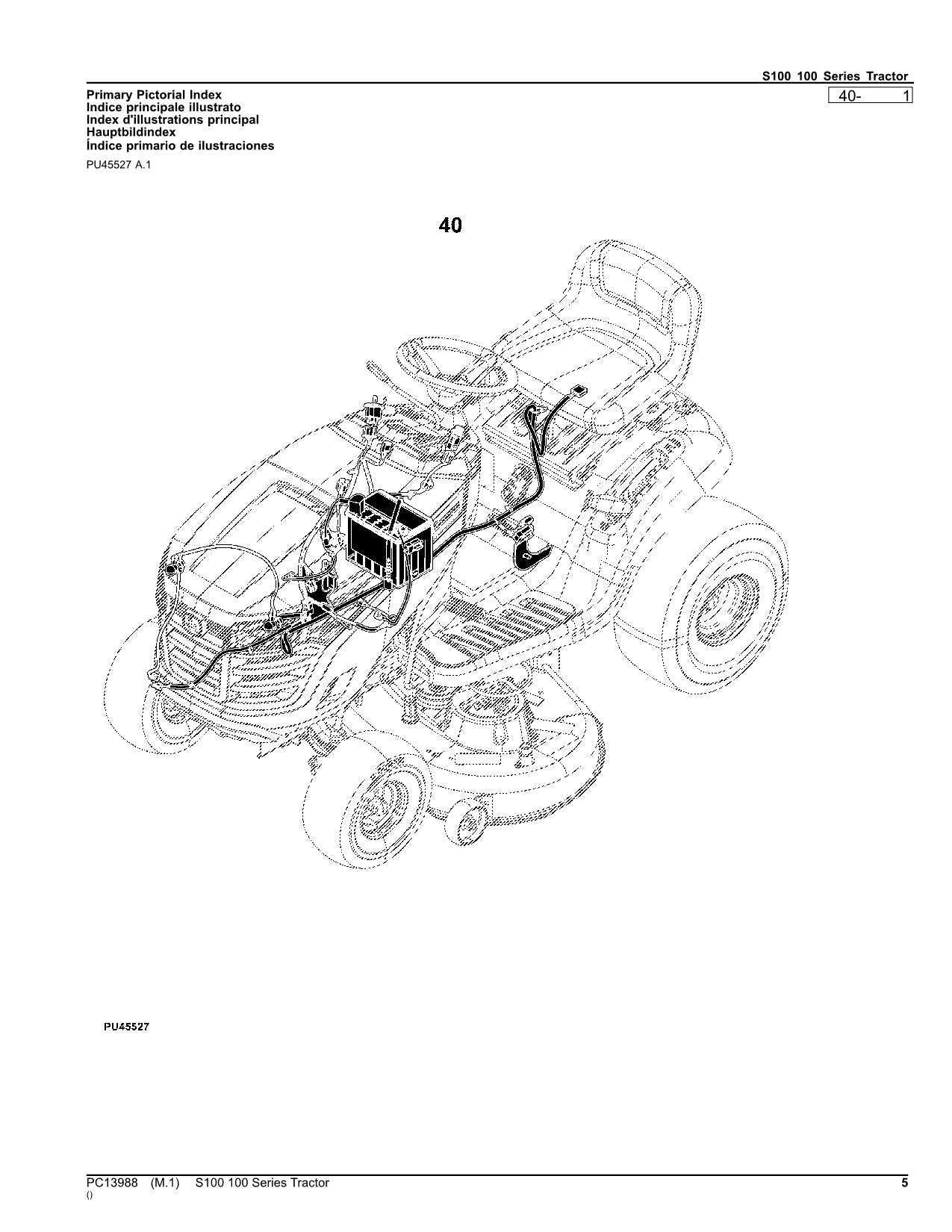

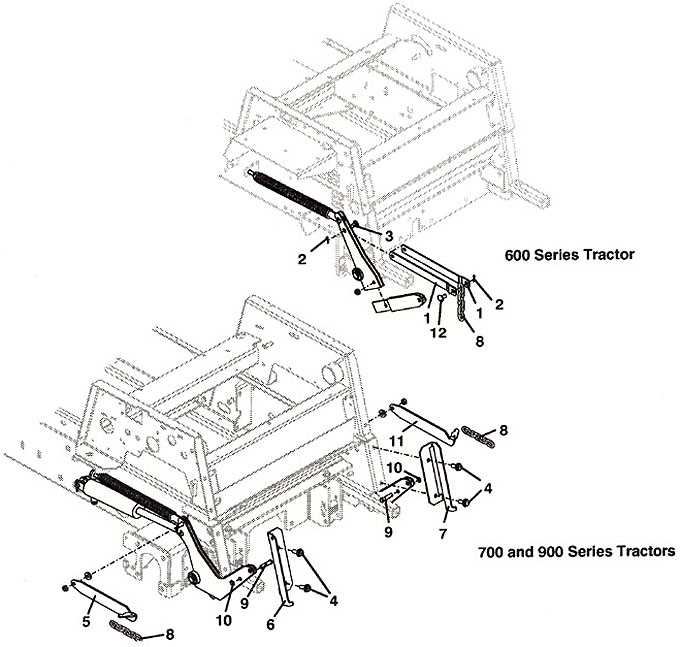

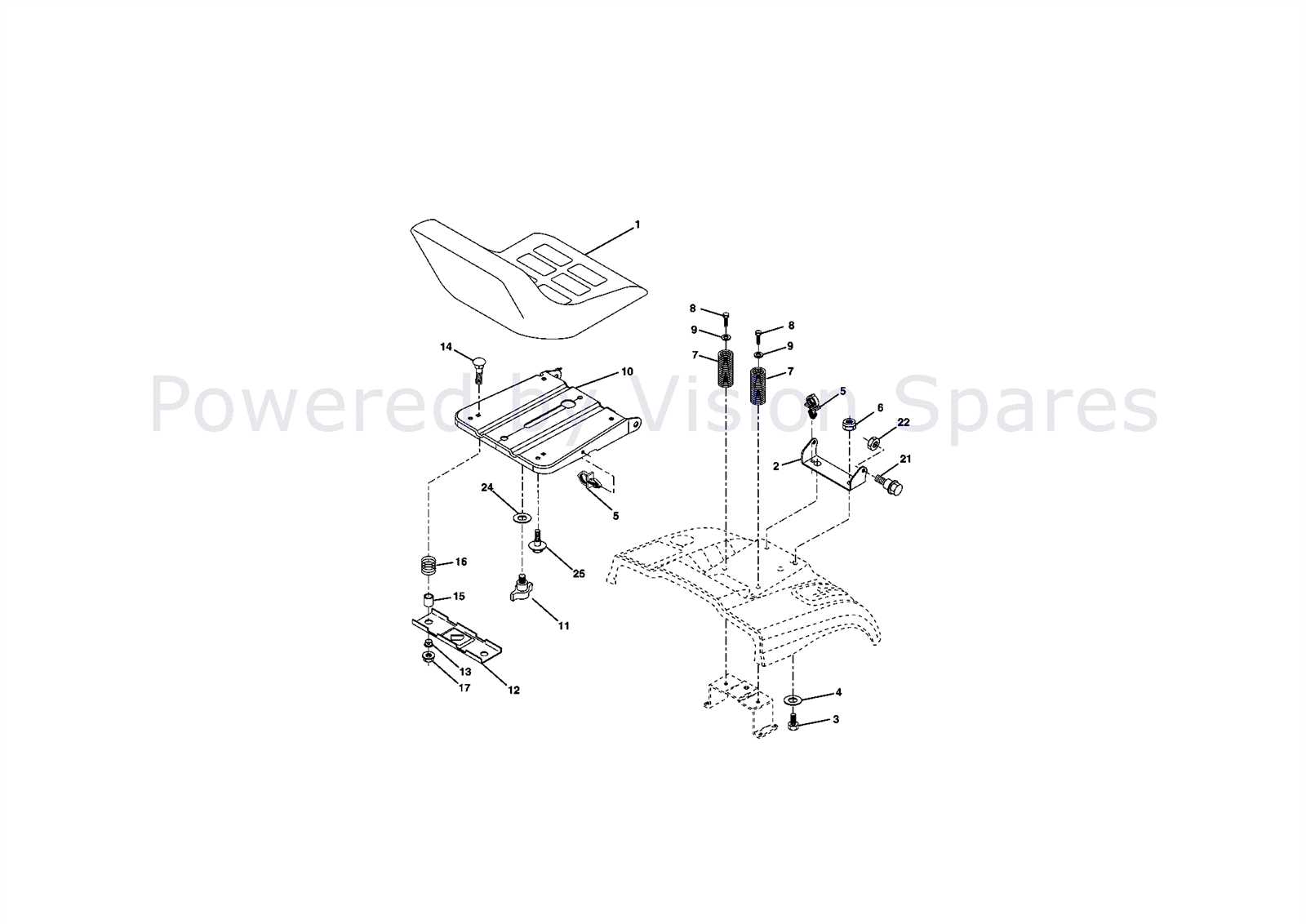

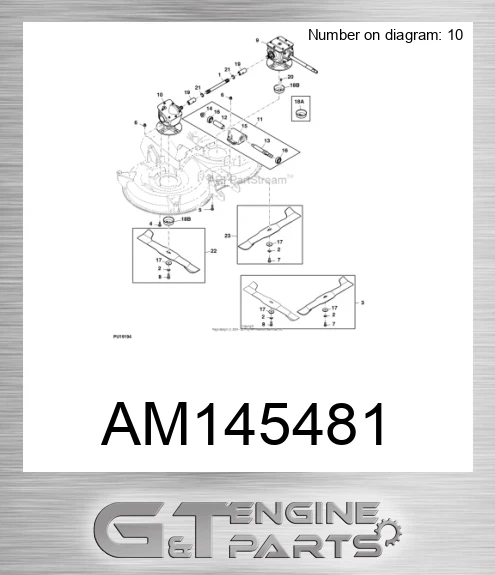

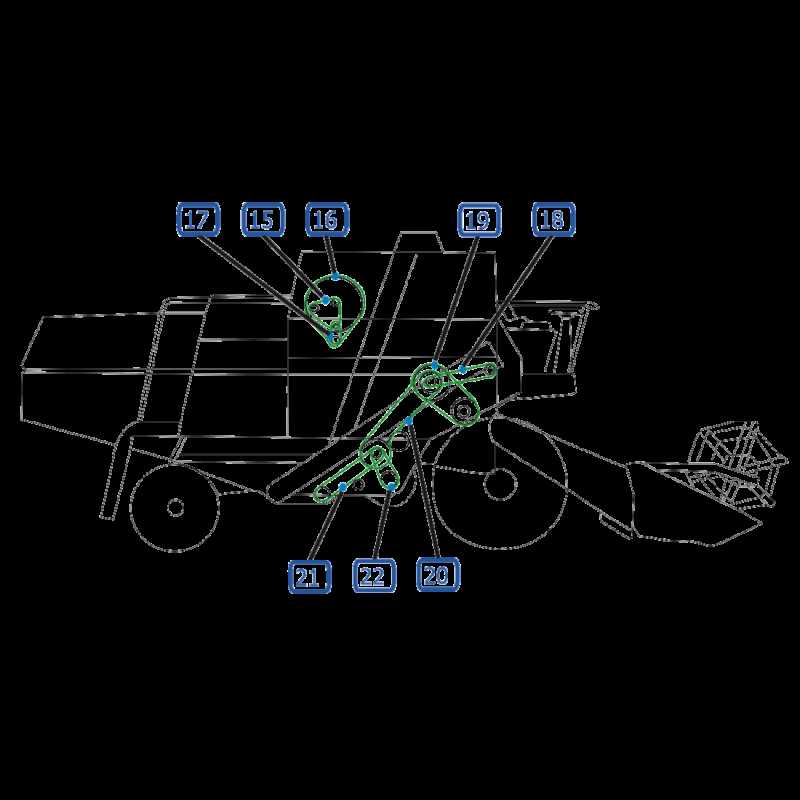

How to Read Parts Diagrams

Understanding illustrations of components is essential for effective maintenance and repair. These visuals provide a clear representation of various elements, helping users identify and locate necessary items.

To effectively interpret these illustrations, consider the following steps:

- Familiarize Yourself with Symbols: Learn the common icons used to represent different components.

- Identify Sections: Break down the illustration into smaller segments for easier navigation.

- Match Numbers with Descriptions: Use the accompanying list to find details on specific components.

- Look for Annotations: Pay attention to notes or arrows that provide additional context.

By following these steps, you can effectively delve into the world of component illustrations, ensuring you have the ultimate understanding for successful repairs.

Common Issues with Lawn Tractor Parts

Maintaining garden machinery can often reveal various complications that users might face over time. Understanding these typical problems can help in identifying and resolving issues effectively, ensuring optimal performance and longevity of the equipment.

Worn Components: Over time, many elements can wear down due to constant use. This deterioration can lead to reduced efficiency and the need for replacement. Regular inspections can help catch these issues early.

Fuel System Troubles: The fuel system is crucial for smooth operation. Common issues include clogged filters and old fuel that can prevent the engine from starting properly. Keeping this system clean is essential for reliability.

Electrical Failures: Electrical components, including batteries and wiring, can be prone to failure. Corrosion and loose connections are frequent culprits that can disrupt functionality. Regular checks can mitigate these problems.

Blade Dullness: The cutting elements are vital for performance. Over time, they can become dull, resulting in uneven cuts. Sharpening or replacing blades as needed ensures a neat appearance for the yard.

Transmission Issues: Problems with gear shifting or slippage can greatly affect maneuverability. Regular maintenance and fluid checks can prevent these complications, allowing for smooth operation.

By staying aware of these common challenges, users can maintain their equipment more effectively and enjoy better results in their outdoor tasks.

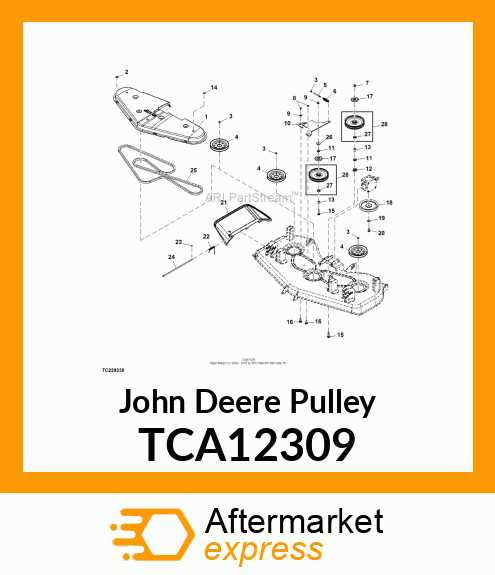

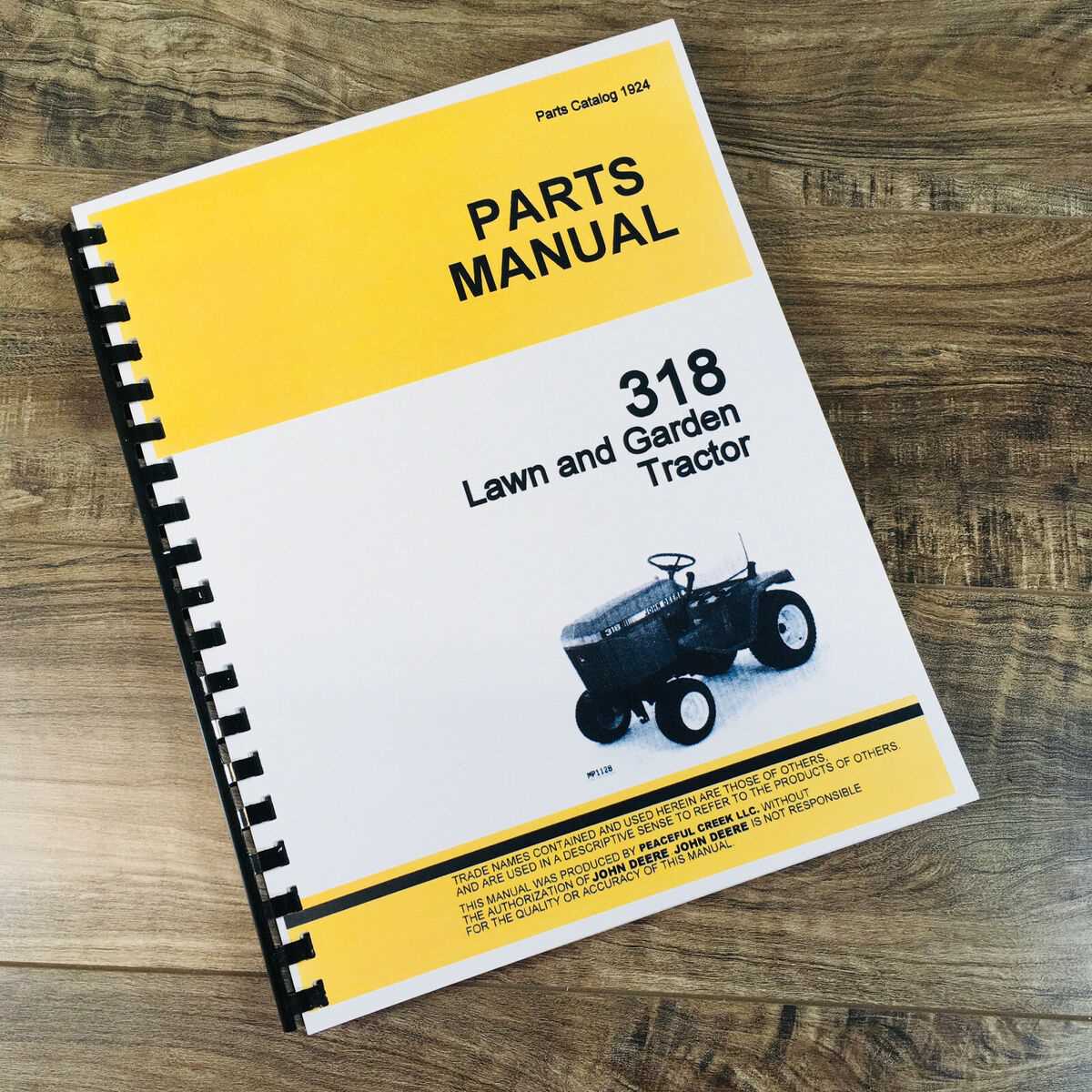

Finding Replacement Parts Easily

Locating suitable components for your equipment can be a straightforward process when you know where to look. Whether you’re maintaining or repairing your machinery, understanding how to access the right resources will streamline your efforts and ensure efficient functionality.

Utilizing Online Resources

Websites dedicated to machinery support offer extensive catalogs and detailed information. Searching for specific items through these platforms not only saves time but also provides valuable insights into compatibility and pricing. Online forums can also connect you with fellow enthusiasts who share tips and experiences.

Consulting Local Dealers

Visiting authorized dealers allows you to receive expert advice and obtain original equipment. Building a relationship with your local supplier can lead to quicker access to essential components, enhancing your maintenance routine and prolonging the life of your machinery.

Step-by-Step Repair Guide

Maintaining your outdoor equipment can be straightforward with the right approach. This guide provides a systematic method to address common issues, ensuring efficient troubleshooting and repairs. By following these steps, you can enhance the longevity of your machine while saving time and money.

Tools and Materials Needed

| Tool/Material | Description |

|---|---|

| Screwdriver Set | Essential for removing and securing screws. |

| Wrench Set | Used for loosening and tightening nuts and bolts. |

| Replacement Parts | Specific components that may need replacement based on wear and tear. |

| Safety Gear | Gloves and goggles to ensure personal protection during repairs. |

Repair Process

Begin by identifying the issue through a thorough inspection. Look for any signs of damage or malfunction. Once the problem is identified, gather the necessary tools and materials. Proceed by disassembling the affected area, carefully noting the arrangement of components. Replace any damaged parts and reassemble the equipment in reverse order. Finally, perform a test run to ensure everything operates smoothly.

Upgrading Your Lawn Tractor Parts

Enhancing your outdoor machinery can significantly improve performance and efficiency. By selecting quality components, you can ensure that your equipment operates at its best, making yard maintenance easier and more enjoyable. Whether you’re looking to boost power, increase durability, or enhance comfort, a thoughtful upgrade strategy can transform your experience.

Before diving into enhancements, assess the current state of your equipment. Identify areas that may benefit from improvement, such as the engine, transmission, or cutting system. Researching compatible enhancements and understanding their impact on overall functionality will help you make informed decisions.

Consider investing in premium alternatives that offer greater reliability and longevity. Components like high-efficiency blades, advanced drive belts, or ergonomic seating can greatly influence both performance and user satisfaction. Additionally, staying current with innovative technologies can provide further advantages, such as fuel efficiency or easier operation.

Regular maintenance and timely upgrades not only extend the lifespan of your machinery but also contribute to a more enjoyable gardening experience. With the right enhancements, you can achieve optimal results, making your outdoor tasks simpler and more efficient.

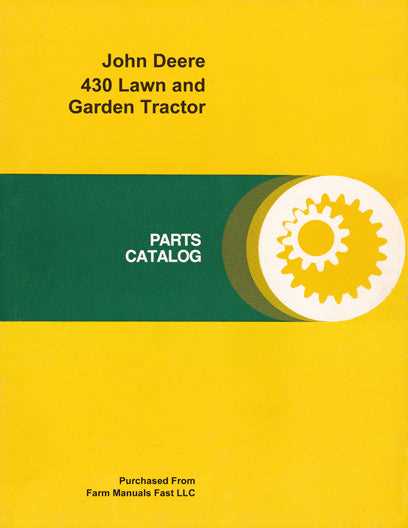

Popular Models and Their Specifications

This section explores a selection of well-regarded machinery and their essential features, catering to various needs in landscaping and maintenance. Understanding the specifications of these models can assist users in making informed decisions for their outdoor tasks.

One popular option is the X350, known for its robust engine and exceptional maneuverability. It boasts a powerful 22-horsepower engine and a 48-inch cutting deck, making it ideal for medium to large areas. Users appreciate its hydrostatic transmission, providing smooth speed adjustments without shifting.

Another frequently chosen model is the D125, designed for homeowners seeking efficiency and comfort. Equipped with a 20-horsepower engine and a 42-inch deck, it effectively tackles smaller yards while maintaining excellent cut quality. Its easy-start feature and ergonomic controls enhance the user experience.

The S240 stands out for those who value versatility and durability. Featuring a 24-horsepower engine and a 48-inch cutting deck, this model is suitable for varied terrains. The twin-blade system ensures a clean cut, while its comfortable seating and easy-to-use controls cater to longer working sessions.

Lastly, the E130 is a budget-friendly choice that does not compromise on performance. With a 22-horsepower engine and a 42-inch cutting width, it delivers reliable results for homeowners. Its automatic transmission simplifies operation, making it accessible for users of all experience levels.

Essential Tools for Repairs

Having the right tools is crucial for any repair task, ensuring efficiency and effectiveness in restoring equipment. Properly equipped, you can tackle various issues that may arise, minimizing downtime and enhancing performance.

Wrenches are fundamental for loosening and tightening bolts, allowing for precise adjustments. Screwdrivers, both flat and Phillips, enable you to handle a variety of fasteners easily. Additionally, pliers provide a strong grip for manipulating components or wires.

Socket sets come in handy for deeper access to fasteners, while torque wrenches ensure that connections are secure without over-tightening. Finally, a good multimeter is essential for diagnosing electrical issues, making it a versatile addition to your toolkit.

Where to Buy Genuine Parts

Finding authentic components for your equipment is crucial for maintaining performance and longevity. Opting for genuine replacements ensures reliability and compatibility, ultimately enhancing your machinery’s efficiency.

Here are some recommended sources:

- Authorized Dealers: Visit local authorized retailers that specialize in your brand.

- Official Website: Explore the manufacturer’s online platform for direct purchases.

- Online Marketplaces: Utilize reputable e-commerce sites, ensuring to filter for genuine items.

- Repair Shops: Seek out professional repair services that stock authentic components.

Always verify authenticity by checking for warranties and manufacturer logos.

DIY vs. Professional Repairs

When it comes to fixing machinery, individuals often face the choice between tackling repairs themselves or hiring a specialist. Each approach has its advantages and challenges, making the decision dependent on various factors, including skill level, time availability, and the complexity of the issue at hand.

Advantages of DIY Repairs

- Cost Savings: Performing repairs independently can significantly reduce expenses associated with labor.

- Learning Experience: Engaging in repairs provides an opportunity to gain hands-on knowledge and skills.

- Convenience: DIY projects can often be done on your schedule, allowing for greater flexibility.

- Satisfaction: Successfully completing a repair can provide a sense of accomplishment and pride.

Benefits of Professional Assistance

- Expertise: Professionals bring specialized knowledge and experience, ensuring repairs are done correctly.

- Time Efficiency: Hiring a specialist can save valuable time, especially for complex issues that require quick resolution.

- Warranty Protection: Many professionals offer warranties on their work, providing peace of mind for future issues.

- Access to Tools: Professionals often have access to advanced tools and technologies that might not be available to the average individual.

Ultimately, the decision between DIY and professional repairs hinges on personal preferences, resource availability, and the specific nature of the repairs needed. Weighing the pros and cons of each approach can help you make an informed choice that best suits your situation.

Tips for Seasonal Maintenance

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By adhering to a seasonal maintenance schedule, you can prevent issues and enhance efficiency throughout the year. Proper care not only saves time but also reduces the risk of unexpected breakdowns.

1. Inspect and Clean: Before each season, thoroughly examine the machine for any debris or wear. Remove grass clippings, dirt, and other materials that could hinder operation.

2. Change Fluids: Regularly replace engine oil and filters according to manufacturer recommendations. Clean oil is crucial for maintaining engine health.

3. Sharpen Blades: Keep cutting implements sharp for effective performance. Dull blades can lead to uneven cuts and increased strain on the engine.

4. Check Tires: Ensure that tires are properly inflated and free from damage. Well-maintained tires enhance traction and stability.

5. Battery Care: Clean battery terminals and ensure secure connections. Consider charging or replacing the battery if it shows signs of weakness.

6. Store Properly: When not in use, store your equipment in a dry, sheltered area to protect it from the elements and prolong its lifespan.