Comprehensive Guide to Tractor Engine Parts Diagram

In the realm of heavy-duty machinery, the intricate workings of powerful vehicles play a crucial role in agricultural efficiency. Comprehending the relationship between various elements is essential for anyone involved in the maintenance or operation of such equipment. This section aims to shed light on the essential constituents that enable these machines to function optimally.

Identifying individual elements is vital for diagnosing issues and ensuring longevity. Each component has a specific function, contributing to the overall performance and reliability of the vehicle. By exploring these constituents, users can better appreciate how they interact and support one another in the machinery’s operation.

Furthermore, a clear visual representation enhances understanding, allowing for easier recognition of each segment’s role within the broader system. This knowledge empowers operators to make informed decisions during maintenance and repairs, ultimately leading to improved productivity and reduced downtime.

Understanding Tractor Engine Components

A deep exploration of the fundamental elements that power heavy machinery reveals their intricate roles and interconnections. Each component contributes significantly to the overall functionality, ensuring efficient operation under various conditions. Grasping these essentials is crucial for effective maintenance and optimization.

Key Elements of the Power System

Every machine consists of critical units that work in unison to generate the required force. Familiarizing oneself with these units aids in recognizing their importance and the potential impact on performance.

| Component | Function |

|---|---|

| Fuel System | Supplies necessary energy sources. |

| Cooling Mechanism | Prevents overheating during operation. |

| Transmission | Transfers power to movement systems. |

| Ignition System | Initiates the combustion process. |

Importance of Regular Maintenance

Maintaining these crucial components ensures longevity and optimal performance. Neglecting any single unit can lead to inefficiencies and costly repairs, underscoring the need for routine checks and timely interventions.

Key Functions of Engine Parts

This section explores the essential roles played by various components within a mechanical power unit. Understanding these functions helps to appreciate how each element contributes to overall performance and efficiency.

Core Components

Each fundamental element serves a unique purpose that facilitates smooth operation. From converting energy to regulating temperature, these functions are critical for optimal functionality.

Overview of Functions

| Component | Function |

|---|---|

| Piston | Converts fuel energy into mechanical motion. |

| Crankshaft | Transforms linear motion into rotational force. |

| Camshaft | Controls the timing of valve openings and closings. |

| Cooling System | Regulates operating temperature to prevent overheating. |

| Fuel Injector | Delivers fuel in precise amounts for combustion. |

Common Types of Tractor Engines

This section explores various classifications of power sources commonly used in agricultural machinery, highlighting their characteristics and applications.

Types of Power Sources

- Diesel: Known for durability and efficiency, these sources are favored for heavy-duty tasks.

- Gasoline: Often utilized in smaller machines, offering quick start and lighter weight.

- Electric: Increasingly popular for their low emissions and quieter operation, suitable for smaller applications.

Performance Characteristics

- Torque: Diesel models typically provide higher torque, ideal for pulling heavy loads.

- Fuel Efficiency: Diesel variants generally consume less fuel compared to gasoline counterparts.

- Maintenance: Electric systems require less upkeep, while diesel engines may need more frequent servicing.

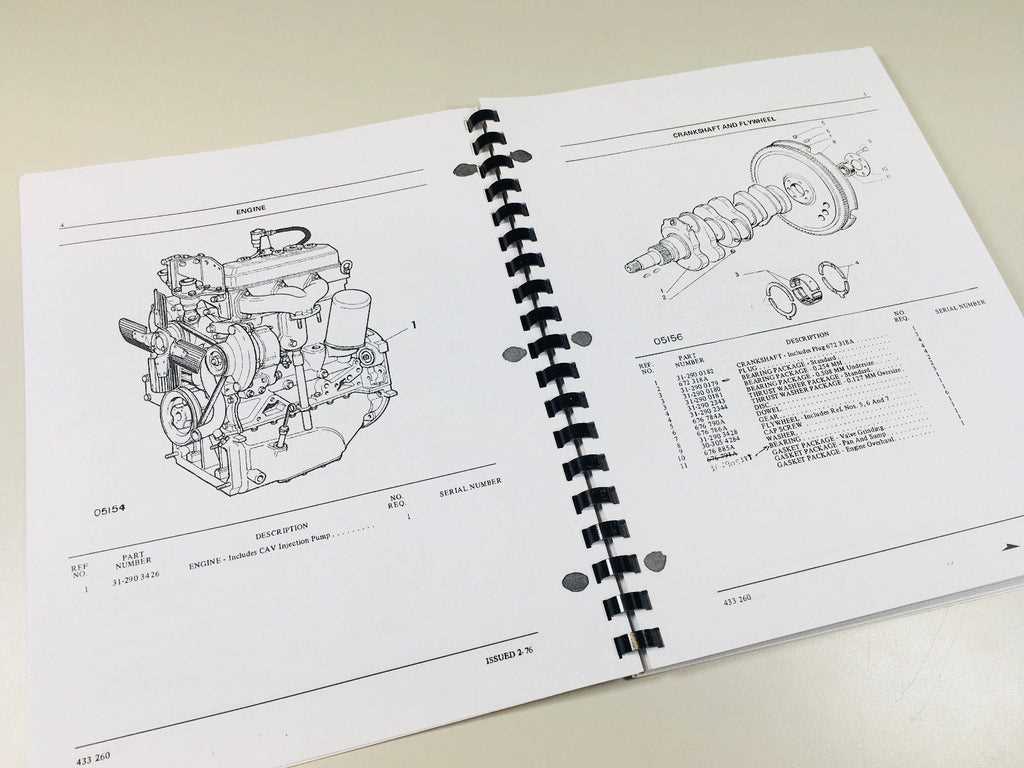

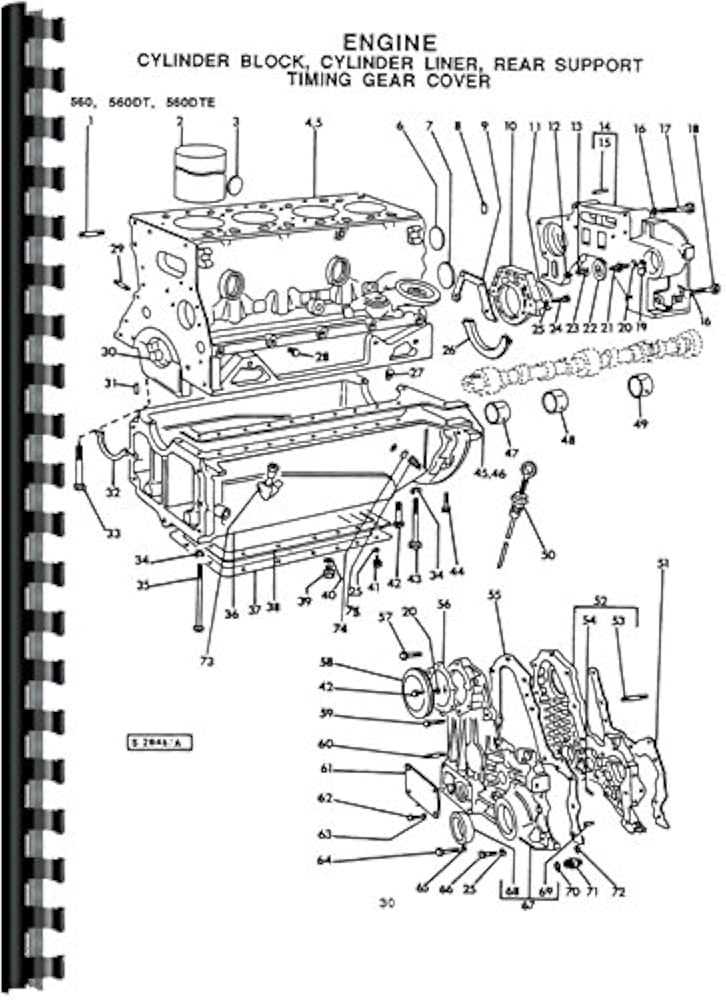

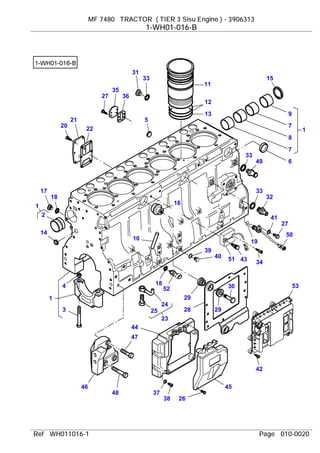

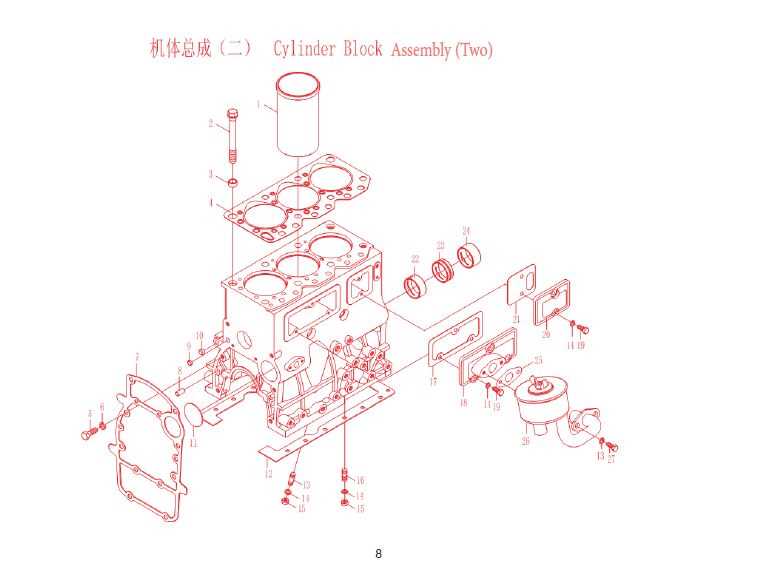

Identifying Major Engine Sections

Understanding the fundamental components of a motor is crucial for effective maintenance and operation. Each section plays a vital role in ensuring optimal performance and longevity.

Main Components

- Cylinder Block

- Crankshaft

- Camshaft

- Valvetrain

- Intake and Exhaust Systems

Functionality Overview

- Cylinder Block: Houses the cylinders and supports other key components.

- Crankshaft: Converts linear motion into rotational force.

- Camshaft: Controls the timing of valve openings and closings.

- Valvetrain: Ensures efficient airflow through the system.

- Intake and Exhaust Systems: Manage the flow of air and gases for combustion.

Importance of Cooling Systems

The cooling mechanism plays a crucial role in maintaining optimal performance and longevity of machinery. It ensures that the operating temperatures remain within safe limits, preventing overheating and potential damage. A well-functioning cooling system contributes to efficiency, reliability, and the overall lifespan of equipment.

Overheating can lead to significant issues, including reduced performance, increased wear, and even catastrophic failures. Therefore, it is essential to understand the components involved in the cooling process and their interdependence. Below is a table outlining the key components and their functions within the cooling mechanism.

| Component | Function |

|---|---|

| Radiator | Dissipates heat from the coolant to the air. |

| Water Pump | Circulates coolant throughout the system. |

| Thermostat | Regulates the flow of coolant based on temperature. |

| Coolant | Absorbs and transfers heat away from components. |

| Cooling Fans | Enhances air flow through the radiator for better heat dissipation. |

Understanding and maintaining the effectiveness of these components is essential for the smooth operation of machinery, ensuring safety and efficiency in various applications.

Fuel Delivery Mechanisms Explained

The process of supplying energy-rich substances to a combustion chamber is critical for optimal performance. Various methods exist to ensure that this vital resource reaches its destination efficiently, influencing both power output and overall functionality.

Types of Fuel Delivery Systems

There are several approaches to delivering fuel, each with unique characteristics:

- Carburetors: These devices mix air and fuel in precise proportions before entering the chamber. They rely on the principle of vacuum to draw fuel from the reservoir.

- Fuel Injectors: Using electronic controls, these injectors deliver fuel directly into the combustion area, allowing for better precision and efficiency.

- Mechanical Pumps: Often found in older systems, these pumps use a diaphragm or gear mechanism to move fuel from the tank to the combustion site.

Factors Influencing Fuel Delivery

Several elements affect the efficiency of fuel delivery mechanisms:

- Pressure: The pressure at which fuel is delivered can greatly impact the atomization and mixing process.

- Temperature: Variations in temperature can affect the viscosity of the fuel, influencing flow rates and combustion quality.

- Fuel Type: Different fuels have distinct properties, which can alter the performance of the delivery system.

Understanding these mechanisms is essential for ensuring effective energy transfer, leading to improved performance and reliability.

Role of the Crankshaft in Engines

The crankshaft serves as a fundamental component within the internal combustion mechanism, playing a crucial role in the conversion of linear motion into rotational movement. This transformation is vital for the overall operation of the power generation system, ensuring that the kinetic energy produced by the combustion process is effectively harnessed.

In essence, the crankshaft acts as the backbone of the system, connecting various elements and facilitating the flow of energy. It works in tandem with other components to ensure smooth operation, balancing forces generated during the combustion cycle. The durability and precision of the crankshaft are paramount, as any imperfections can lead to inefficiencies and potential failure.

Furthermore, the configuration of the crankshaft influences the overall performance characteristics, including power output and fuel efficiency. Its design and material composition are carefully engineered to withstand extreme pressures and temperatures, underscoring its importance in the mechanical landscape.

In summary, the crankshaft is not merely a rotational axis; it embodies the transformation of energy within the system, making it indispensable for optimal functionality and reliability.

How Pistons Operate in Tractors

Pistons play a crucial role in converting fuel energy into mechanical motion. This process involves a series of movements that translate the combustion of fuel into force, enabling the machinery to perform various tasks effectively.

The operation of pistons can be broken down into several key phases:

- Intake Stroke: The piston moves down, creating a vacuum that draws in a fuel-air mixture.

- Compression Stroke: The piston moves up, compressing the mixture to enhance its combustibility.

- Power Stroke: Upon ignition, the explosion forces the piston down, producing power.

- Exhaust Stroke: The piston moves back up, expelling the burnt gases from the chamber.

Each stroke is essential for maintaining efficient operation, and the piston’s movement is synchronized with other components to optimize performance.

Understanding Engine Lubrication Systems

The importance of effective lubrication in machinery cannot be overstated. It plays a critical role in minimizing friction, reducing wear, and ensuring smooth operation of components. A well-designed lubrication system is essential for maintaining optimal performance and longevity of mechanical systems.

Types of Lubrication Systems

Different configurations serve distinct purposes, each suited to various operational needs. The choice between systems can impact efficiency, maintenance requirements, and overall functionality.

| Type | Description |

|---|---|

| Wet Sump | Utilizes a reservoir to collect and circulate lubricant, suitable for many standard applications. |

| Dry Sump | Employs an external reservoir, allowing for better lubrication under extreme conditions. |

| Forced Lubrication | Involves pumps to deliver lubricant, ensuring consistent flow and pressure across components. |

Benefits of Proper Lubrication

Maintaining an efficient lubrication system enhances performance, decreases the likelihood of breakdowns, and prolongs the life of mechanical systems. Regular monitoring and maintenance are crucial to achieving the ultimate effectiveness of these systems.

Maintenance Tips for Engine Longevity

Ensuring the extended life of mechanical systems requires regular attention and care. By implementing a series of best practices, one can enhance performance and reduce the risk of unexpected failures. This section outlines essential strategies to maintain optimal functionality and reliability over time.

Regular Inspections

Conducting routine assessments is crucial for identifying potential issues before they escalate. Check for signs of wear and tear, leaks, or unusual noises. Early detection can prevent costly repairs and prolong operational efficiency. Establish a schedule for these inspections to create consistency in your maintenance routine.

Fluid Management

Maintaining appropriate fluid levels is vital for ensuring smooth operation. Regularly check and replace lubricants and other essential fluids as recommended by the manufacturer. Clean fluids reduce friction and help in cooling systems, contributing significantly to overall performance. Make it a habit to monitor these levels frequently, especially before major tasks.

Impact of Turbochargers on Performance

Turbochargers play a significant role in enhancing the efficiency and output of various types of machinery. By harnessing exhaust gases, they increase air intake, allowing for more fuel combustion and improved power delivery. This boost in performance leads to better acceleration and overall responsiveness, making them a valuable addition in many applications.

Enhanced Power Output

The primary advantage of incorporating a turbocharger is the substantial increase in power. This component enables smaller engines to produce power comparable to larger counterparts, thus optimizing fuel usage while minimizing weight.

Fuel Efficiency

In addition to power gains, turbochargers contribute to enhanced fuel efficiency. By maximizing the amount of air entering the combustion chamber, they allow for more complete combustion, which translates to improved mileage and reduced emissions.

Diagnosing Engine Issues Effectively

Identifying malfunctions in mechanical systems requires a systematic approach. A thorough understanding of potential symptoms and their underlying causes enables technicians to pinpoint problems accurately and implement solutions swiftly.

Common Symptoms to Observe

Watch for unusual noises, fluctuations in performance, or irregular fluid leaks. These indicators often suggest specific malfunctions. For instance, persistent knocking sounds may indicate internal wear, while a sudden drop in power could signal fuel delivery issues.

Utilizing Diagnostic Tools

Employing advanced diagnostic tools can significantly enhance the troubleshooting process. Devices that read error codes and monitor system performance allow for a deeper delve into operational anomalies, ultimately leading to more efficient repairs.

Latest Innovations in Engine Design

The realm of mechanical systems is witnessing groundbreaking advancements that enhance efficiency, performance, and sustainability. These innovations are reshaping how power generation units operate and interact with their environment.

- Hybrid Technology: The integration of electric and traditional systems is revolutionizing performance metrics.

- Alternative Fuels: Utilizing renewable energy sources reduces environmental impact significantly.

- Smart Sensors: Real-time data analytics optimize operational efficiency and predict maintenance needs.

- Lightweight Materials: Advanced composites and alloys contribute to reduced weight and enhanced durability.

As industries strive for the ultimate balance between power and ecological responsibility, these trends mark a significant shift in design philosophy.