Understanding the Key Components of a Tractor Trailer Diagram

The intricate structure of heavy-duty vehicles plays a crucial role in their functionality and efficiency. Each element is designed with a specific purpose, contributing to the overall performance and safety of these robust machines. A comprehensive exploration of these elements unveils the complexity and engineering prowess behind their operation.

From the robust frame that supports the entire assembly to the advanced braking systems that ensure safe stops, every segment is essential. Recognizing how these components interact can enhance both the maintenance and operation of these vehicles. Moreover, understanding these features helps drivers and operators appreciate the engineering that goes into ensuring reliability on the road.

Delving into the various segments reveals a world of mechanical ingenuity. Each section not only fulfills a designated function but also showcases the advancements in technology that drive the industry forward. By examining these integral components, one gains valuable insights into the maintenance, safety, and performance aspects that are vital for efficient transport solutions.

Understanding Tractor Trailer Components

Grasping the intricate workings of heavy-duty vehicles requires a keen awareness of their essential elements. Each component plays a vital role in ensuring safety, efficiency, and overall performance on the road. This section delves into the fundamental structures that enable these massive machines to function effectively.

- Chassis: The backbone of the vehicle, providing support and housing for various systems.

- Engine: The powerhouse that drives the entire unit, crucial for generating the necessary horsepower.

- Transmission: This mechanism facilitates the transfer of power from the engine to the wheels, affecting speed and torque.

- Suspension: Essential for a smooth ride, it absorbs shocks from the road and enhances stability.

- Braking System: A critical safety feature that enables controlled stopping, composed of various types of brakes.

Moreover, understanding how these elements interact can illuminate the complexities of these formidable vehicles.

- Fuel System: Responsible for delivering energy to the engine, ensuring optimal performance.

- Cooling System: Prevents overheating by regulating engine temperature, crucial for longevity.

- Electrical System: Powers lights, signals, and other essential electronics, playing a key role in visibility and communication.

- Tires: The only contact point with the road, their condition is vital for traction and handling.

By familiarizing oneself with these fundamental elements, operators can better appreciate the mechanics of these powerful vehicles and ensure they are well-maintained for safe travel.

Essential Parts of a Tractor Trailer

Understanding the key components of a heavy-duty vehicle used for transporting goods is crucial for both operators and enthusiasts. Each element plays a vital role in ensuring efficiency, safety, and reliability on the road. Here, we will explore the fundamental features that make up this robust machine.

Chassis and Frame

The foundation of any heavy vehicle is its structure, which provides stability and support for all other components. A durable frame ensures that the load is evenly distributed and enhances the overall strength of the vehicle. This base is engineered to withstand significant stress and strain during transit.

Power Unit and Transmission

At the heart of the operation lies the power unit, responsible for generating the necessary force to move the entire assembly. Coupled with a sophisticated transmission system, it allows for smooth gear shifts and optimal performance under various driving conditions. This combination is essential for maintaining control, especially when navigating steep inclines or heavy traffic.

In summary, recognizing the essential features of this transport machine enables better maintenance, operation, and understanding of its capabilities.

Functionality of the Chassis

The framework of a heavy-duty vehicle plays a crucial role in supporting its overall structure and ensuring stability during operation. It serves as the foundation upon which various components are mounted, facilitating the vehicle’s performance and safety on the road.

Key Roles of the Framework

- Support Structure: It provides the necessary strength to withstand loads and stress from both the cargo and road conditions.

- Alignment of Components: The framework ensures proper alignment of critical systems such as suspension, braking, and steering, enhancing functionality.

- Shock Absorption: It absorbs shocks from uneven terrain, contributing to a smoother ride and protecting other components from damage.

- Weight Distribution: Effective design helps distribute weight evenly, which is vital for maintaining control and stability.

Impact on Performance

The design and construction of the framework significantly affect the vehicle’s handling and efficiency. A well-engineered structure enhances maneuverability and reduces wear on tires and other components, ultimately leading to improved longevity and lower maintenance costs.

- Enhanced Control: A rigid framework allows for better steering response, crucial for navigating tight turns and challenging conditions.

- Fuel Efficiency: A lighter yet sturdy design can contribute to lower fuel consumption by minimizing drag and improving aerodynamics.

- Safety Features: Integrating safety mechanisms within the framework enhances overall security for both the operator and cargo.

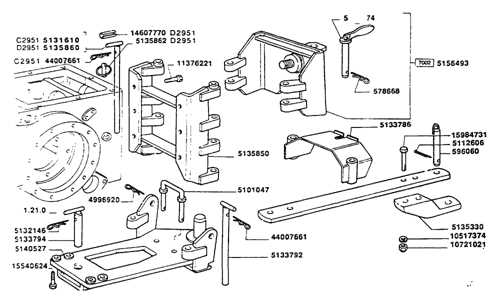

Importance of the Trailer Coupling

The connection mechanism between the towing vehicle and the cargo unit plays a crucial role in ensuring safe and efficient transport. This component not only facilitates the secure attachment but also contributes to the overall stability and maneuverability during transit.

Key Functions

- Stability: A well-designed coupling enhances the balance of the entire setup, reducing swaying and improving handling.

- Safety: It prevents accidental detachment, which could lead to serious accidents on the road.

- Ease of Use: Modern connections are engineered for quick coupling and uncoupling, allowing for efficient loading and unloading.

Factors to Consider

- Weight Capacity: Ensure the mechanism can handle the load being transported.

- Durability: Choose materials that withstand wear and environmental conditions.

- Compatibility: Verify that the connection aligns with both the towing and cargo units.

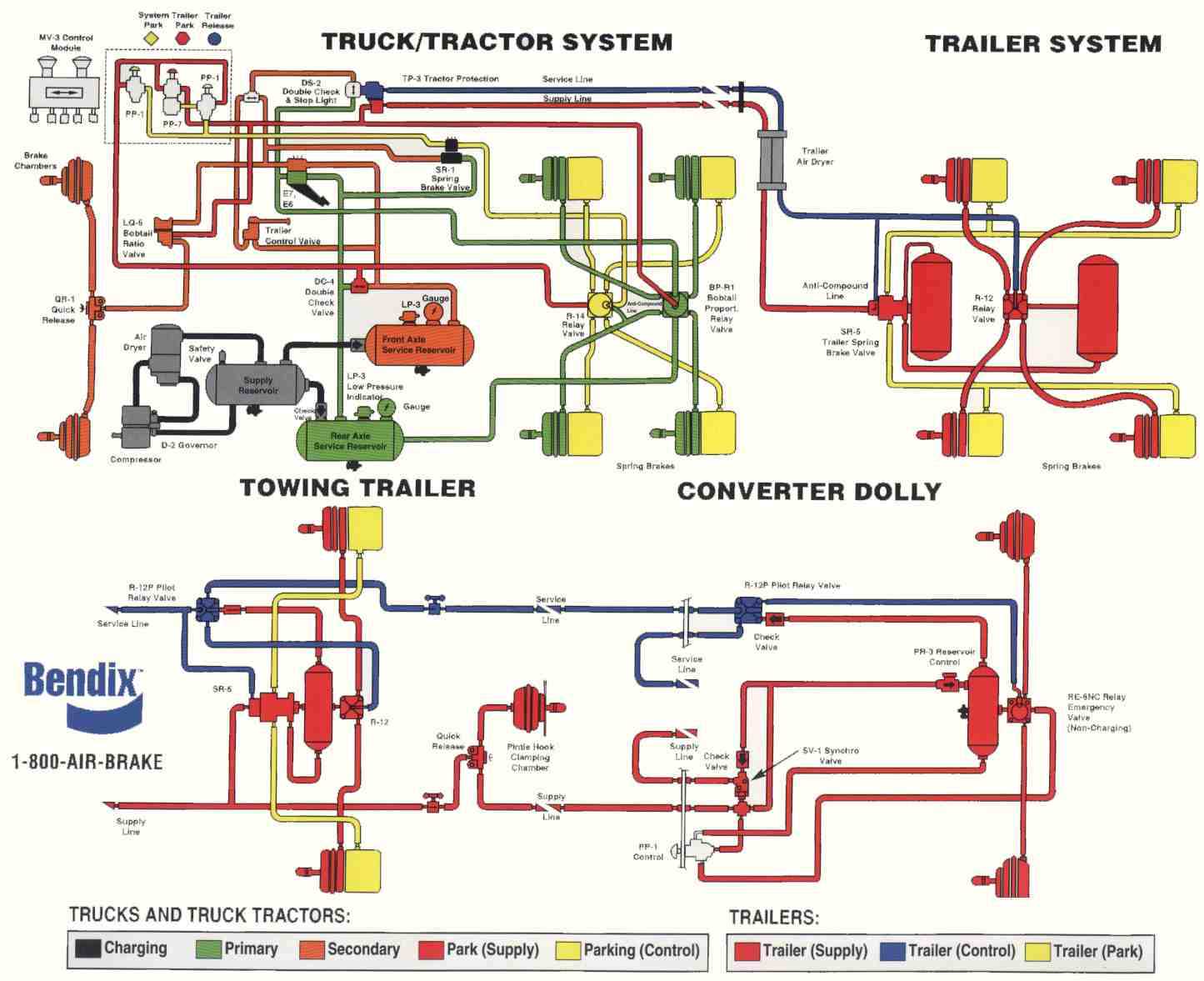

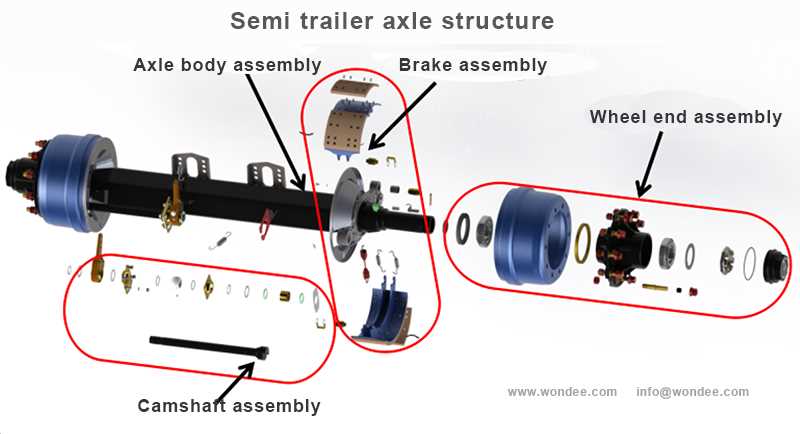

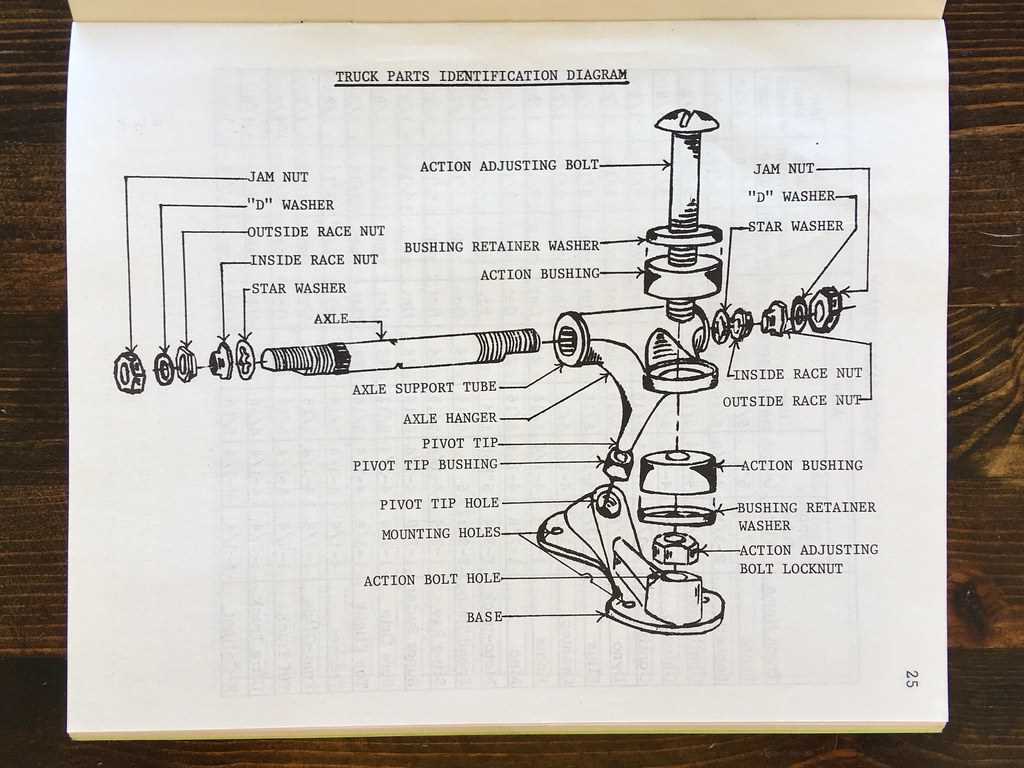

Exploring the Brake System

The braking mechanism is a crucial component of any heavy-duty vehicle, ensuring safety and control during operation. Understanding its elements helps operators maintain optimal performance and address potential issues before they escalate.

This system primarily consists of various key components, each playing a vital role in effective deceleration. The following list outlines the main features:

- Brake Pads: These components create friction against the wheels to slow down the vehicle.

- Brake Drums or Rotors: Essential for housing the brake pads, they facilitate the braking process.

- Air Supply System: A pneumatic mechanism that regulates pressure for effective braking.

- Actuators: Devices that convert energy into mechanical movement, engaging the braking action.

- Hydraulic Lines: Tubing that carries fluid to transmit force from the brake pedal to the brake assembly.

Maintaining these elements is crucial for the longevity and reliability of the entire braking system. Regular inspections can identify wear and tear, ensuring timely repairs and enhancing overall safety.

In summary, a well-functioning braking system is essential for the performance of any heavy vehicle. By familiarizing oneself with its components and maintenance practices, operators can ensure efficient operation and reduce the risk of accidents.

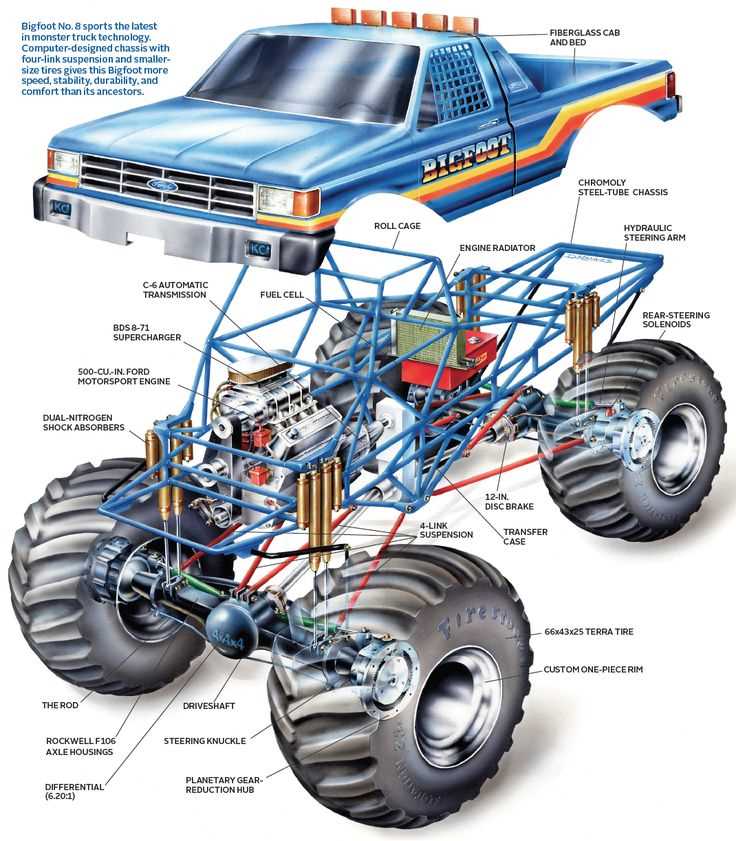

Role of the Suspension System

The suspension system plays a crucial role in ensuring a smooth and stable ride for heavy-duty vehicles. It is designed to absorb shocks from the road, maintaining contact between the wheels and the surface while supporting the overall weight of the vehicle. This balance is essential for both safety and comfort during transport.

One of the primary functions of the suspension system is to minimize the impact of uneven surfaces. By doing so, it protects both the vehicle and its cargo from potential damage. Additionally, it enhances handling and stability, allowing for better control during maneuvers.

| Function | Description |

|---|---|

| Shock Absorption | Dampens the effects of bumps and potholes, ensuring a smoother ride. |

| Weight Distribution | Evenly distributes the load across the axles for improved stability. |

| Handling | Enhances vehicle control during turns and stops, contributing to safety. |

| Load Support | Supports the overall weight, maintaining optimal vehicle posture. |

In conclusion, the suspension system is vital for the efficient operation of large vehicles, ensuring safety, stability, and comfort throughout the journey.

Powertrain and Its Significance

The powertrain is a crucial component of any heavy vehicle, serving as the heart of its operation. It encompasses various systems that work together to deliver the necessary performance and efficiency required for transportation tasks. Understanding the significance of this assembly is essential for optimizing functionality and longevity.

Key functions of the powertrain include:

- Transmitting power from the engine to the wheels.

- Enhancing fuel efficiency and reducing emissions.

- Ensuring smooth acceleration and deceleration.

The importance of a well-designed powertrain can be outlined through the following points:

- Performance: A robust powertrain contributes to better handling and responsiveness, making vehicles more adaptable to various driving conditions.

- Reliability: A durable assembly minimizes maintenance issues, ensuring that the vehicle remains operational for extended periods.

- Cost-effectiveness: Efficient power delivery lowers fuel consumption, ultimately reducing operational costs for fleet owners.

In conclusion, the powertrain plays an indispensable role in the overall efficiency and effectiveness of heavy-duty vehicles, influencing their performance and operational costs significantly.

Overview of Cargo Space Design

The design of the cargo area plays a crucial role in maximizing efficiency and ensuring the safe transport of goods. This space must accommodate a variety of load types while maintaining structural integrity and ease of access. A well-thought-out layout not only enhances storage capabilities but also facilitates the loading and unloading process.

Factors influencing design include the overall dimensions, weight distribution, and the specific requirements of the items being transported. The choice of materials and the configuration of the interior can significantly impact the usability of the cargo area. Optimizing these elements can lead to improved fuel efficiency and reduced operational costs.

Incorporating features such as adjustable shelving, tie-down points, and appropriate ventilation ensures that the cargo remains secure and protected throughout the journey. Ultimately, an effective design is one that balances capacity with practicality, addressing the diverse needs of different industries.

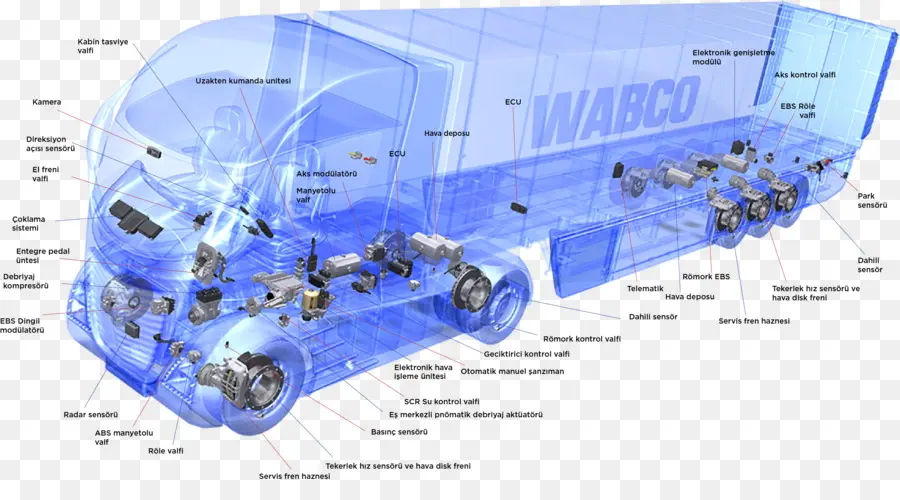

Electrical System in Trucks

The electrical system in large vehicles is essential for various functions that ensure safety, efficiency, and comfort. This intricate network of components powers everything from the ignition and lighting to advanced communication and navigation systems. Understanding how this system operates is crucial for both maintenance and troubleshooting.

Components of the Electrical System

This system consists of several key elements, including the battery, alternator, and wiring harness. The battery serves as the primary power source, providing energy to start the engine and operate electrical devices when the engine is off. The alternator, on the other hand, recharges the battery while the vehicle is running, ensuring a continuous power supply. The wiring harness connects these components, allowing electricity to flow throughout the vehicle.

Importance of Maintenance

Safety Features of Tractor Trailers

Ensuring the safety of large vehicles on the road is paramount for preventing accidents and protecting lives. Modern designs incorporate a range of advanced features aimed at enhancing security for drivers and other road users. These technologies and systems work together to minimize risks and respond effectively in various driving conditions.

- Anti-lock Braking System (ABS): This feature prevents wheel lockup during hard braking, helping maintain steering control.

- Electronic Stability Control (ESC): ESC monitors the vehicle’s movement and assists in maintaining control during skids or sharp turns.

- Blind Spot Detection: Sensors alert the driver to vehicles in adjacent lanes that may not be visible in mirrors.

- Lane Departure Warning: This system provides alerts if the vehicle begins to drift out of its lane without signaling.

- Adaptive Cruise Control: It automatically adjusts speed to maintain a safe following distance from the vehicle ahead.

- Collision Avoidance Systems: These technologies use cameras and radar to detect potential collisions and can even apply brakes autonomously.

- Automatic Emergency Braking (AEB): AEB detects an imminent collision and engages the brakes to prevent or mitigate impact.

Regular maintenance and inspections are also crucial in ensuring that all safety features remain functional and effective. Awareness and training for operators on utilizing these systems can further enhance overall safety on the roads.

Common Issues with Trailer Parts

Understanding the frequent challenges encountered in heavy-duty transport vehicles is crucial for maintaining safety and efficiency. Various components are susceptible to wear and tear, leading to potential operational disruptions. Recognizing these common problems can help ensure timely maintenance and prevent costly repairs.

- Braking System Failures: Issues with the braking mechanism can arise from worn pads, air leaks, or hydraulic failures, affecting stopping power.

- Electrical Malfunctions: Wiring problems, blown fuses, or faulty lights can lead to visibility concerns and increase the risk of accidents.

- Suspension Deficiencies: Components may become misaligned or damaged, resulting in uneven tire wear and affecting ride quality.

- Tire Issues: Common problems include under-inflation, uneven tread wear, and blowouts, all of which can compromise safety.

- Hitch Problems: Wear on the coupling mechanism can lead to instability, making secure attachment critical for safe transport.

Proactive inspections and maintenance of these elements are essential for ensuring reliable operation and enhancing longevity. Regular checks can help identify signs of wear early, allowing for timely interventions.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of heavy-duty vehicles requires consistent care and attention. Implementing a proactive maintenance strategy can significantly extend the lifespan of these essential machines, minimizing downtime and reducing long-term costs. Below are some practical suggestions to keep your equipment in top condition.

Regular Inspections

Conducting routine checks is vital for identifying potential issues before they escalate. Regular inspections can include examining critical systems such as brakes, tires, and engines.

| Inspection Type | Frequency | Key Areas to Check |

|---|---|---|

| Fluid Levels | Weekly | Oil, coolant, transmission fluid |

| Tire Condition | Monthly | Tread depth, pressure, sidewall integrity |

| Brake System | Every 6 months | Pads, rotors, hydraulic fluid |

Proper Storage

Storing equipment correctly is crucial for maintaining its functionality. Keeping vehicles in a sheltered environment protects them from the elements and reduces wear and tear.