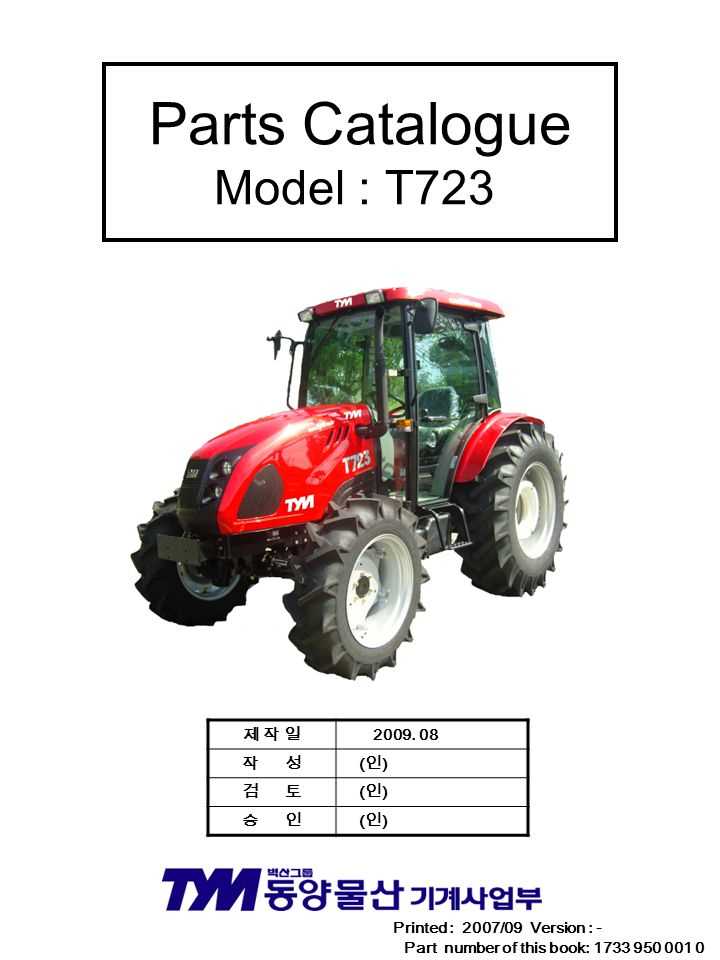

Tym Tractor Parts Layout and Diagrams

The inner workings of heavy equipment are a complex network of interconnected elements that must function in perfect harmony to ensure optimal performance. Each unit is made up of a variety of systems and mechanisms, all designed to support the machine’s operations efficiently.

Identifying the layout and positioning of these components is crucial for those involved in repairs, maintenance, or upgrades. A clear overview of how the various elements are assembled allows for smoother troubleshooting and enhances the overall lifespan of the equipment.

In this guide, we will explore how different mechanical elements come together, focusing on key systems and their placement. This will help in understanding how to keep machinery running smoothly, while minimizing downtime caused by unforeseen issues.

Tym Tractor Component Overview

Understanding the various elements that make up modern agricultural machinery is essential for efficient operation and maintenance. The following section provides a concise look at the primary components commonly found in these machines, highlighting their roles and how they contribute to overall functionality.

- Engine System: The heart of the machine, responsible for powering all operations, from movement to auxiliary functions.

- Transmission: This component ensures smooth shifts between gears, adapting the machine’s speed and torque for different tasks.

- Hydraulic Circuit: This system controls attachments and implements, delivering precise movements and force where needed.

- Axles and Wheels: Critical for stability and mobility, these parts bear the load and provide traction on various terrains.

- Control Console: The operator’s interface, offering access to all machine functions, from basic operation to advanced settings.

Each of these parts plays a pivotal role in ensuring reliable performance, making it crucial to familiarize oneself with their individual functions.

Essential Parts for Tym Tractors

Maintaining reliable equipment requires a deep understanding of its key components. The longevity and performance of agricultural machinery depend on regular upkeep and timely replacement of crucial elements. Understanding which items are most important ensures smoother operations and fewer breakdowns in the field.

Some critical components directly influence functionality and safety, ensuring optimal performance in all conditions. Properly selecting and maintaining these elements is vital for both operational efficiency and long-term durability. Knowing when to inspect and replace them is an essential aspect of maintaining high productivity.

Engine Configuration and Key Components

The engine is the heart of any machine, providing the power needed to drive its various functions. Understanding its structure and essential elements is critical for ensuring optimal performance and longevity. The core components work together harmoniously to facilitate smooth operation, from the combustion process to power transmission.

Key components include the cylinders, where fuel combustion takes place, and the crankshaft, which converts this energy into mechanical motion. Other vital elements, such as the camshaft, valves, and pistons, ensure efficient fuel use and the movement of mechanical parts. Proper maintenance of these critical components is essential for maximizing efficiency and preventing costly repairs.

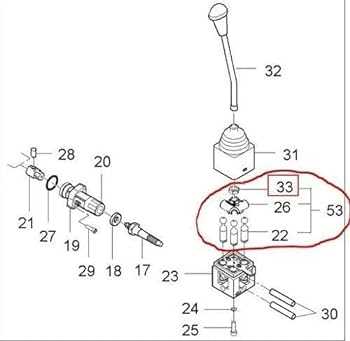

Hydraulic System Layout and Functions

The hydraulic system plays a critical role in powering various essential components and attachments of heavy machinery. This system utilizes pressurized fluid to transmit energy, which enables efficient movement and operation of different parts. Understanding the layout and functions of the hydraulic system is key to maintaining and optimizing performance.

System Components

At the heart of the hydraulic system, a pump generates pressure by moving fluid through hoses and valves. The control valves manage the fluid’s direction, flow rate, and pressure, allowing for precise movement. Actuators, such as cylinders and motors, convert hydraulic pressure into mechanical movement, driving the machinery’s functions.

Fluid Flow and Pressure Control

The flow of hydraulic fluid is controlled to ensure that each component operates smoothly and efficiently. Proper fluid pressure and flow rates are essential for reliable performance. By regulating these elements, the system ensures that every part responds accurately to operator commands, whether lifting, pushing, or pulling heavy loads.

| Component | Function |

|---|---|

| Pump | Generates hydraulic pressure |

| Valve | Controls fluid direction, flow, and pressure |

| Actuators | Convert fluid pressure into mechanical movement |

Transmission Assembly Breakdown

The transmission system is a crucial component in any heavy machinery, ensuring the smooth transfer of power from the engine to the wheels. This assembly contains multiple components working in harmony to manage gear changes and distribute torque efficiently. Understanding the individual elements that make up this system is essential for proper maintenance and troubleshooting.

Key components involved in the transmission assembly include:

- Gears: These play a pivotal role in adjusting speed and torque output.

- Clutch: It allows for smooth engagement and disengagement of gears.

- Shift mechanism: This controls the movement between different gears.

- Bearings: They reduce friction between moving parts and maintain proper alignment.

- Shafts: These transmit the force from the engine to the gears.

- Lubrication system: Ensures that all moving components operate smoothly without excessive wear.

Each component must be properly assembled and maintained to ensure optimal performance and prevent costly repairs. Regular inspections and timely replacements are key to extending the lifespan of the system.

Steering Mechanism and Linkages

The steering system is crucial for the precise control and maneuverability of the vehicle. It encompasses various components that work together to ensure smooth turning and stability during operation. The linkages play a vital role in transmitting the driver’s input from the steering wheel to the wheels, enabling accurate adjustments in direction.

This system involves a series of rods, arms, and joints that connect different sections, allowing for coordinated movement. Each element is designed to handle specific forces and maintain responsiveness, ensuring that the vehicle remains stable and easy to steer under various conditions.

Understanding the structure and function of these linkages is essential for diagnosing issues related to steering performance. Proper maintenance and timely replacement of worn-out parts can prevent more significant mechanical problems and ensure safe and efficient operation.

Chassis Structure and Frame Details

The foundation of any vehicle lies in its structural integrity, with the frame serving as the backbone. The design and construction of this framework play a critical role in ensuring stability, durability, and the efficient transfer of force from various components. A well-engineered chassis ensures that the machine can withstand the pressures of various terrains and working conditions without compromising performance.

Key Elements of the Structure

The frame of the machine is typically constructed from high-strength steel or other robust materials to endure heavy loads. It must be designed with specific geometry to provide balance and support while maintaining optimal flexibility for movement and adaptability during operation.

| Component | Material | Function |

|---|---|---|

| Frame Rails | Steel | Support and distribute load evenly across the chassis |

| Cross Members | Steel or Aluminum | Enhance rigidity and prevent flexing |

| Mounting Brackets | Steel | Provide attachment points for various components |

Structural Reinforcements

To increase strength without adding excessive weight, reinforcements are strategically placed within the frame. These reinforcements ensure that the chassis can withstand both static and dynamic stresses. Whether in high-torque operations or uneven terrain, the integrity of the frame is crucial for smooth and safe functioning.

Fuel System Diagram and Flow

The fuel system is a crucial component of any vehicle, ensuring that the engine receives the proper amount of fuel to operate efficiently. This system is designed to transfer fuel from the tank to the engine, where it is mixed with air and combusted. Proper understanding of how fuel flows through this setup is essential for maintaining performance and troubleshooting issues. The layout typically includes various filters, pumps, and lines that work together to maintain a smooth flow of fuel to the engine.

The process begins when fuel is drawn from the storage tank by a fuel pump. This pump pushes the fuel through a series of filters that remove any impurities or debris, ensuring clean fuel reaches the engine. Once filtered, the fuel travels through the fuel lines, moving toward the engine’s injection system. The fuel is then atomized and mixed with air, ready for combustion.

Each component in this system plays a vital role in ensuring proper fuel delivery, and any issue with one part can impact the overall flow and efficiency. From the moment fuel is drawn from the tank until it combusts in the engine, the system must function without interruptions for optimal performance.

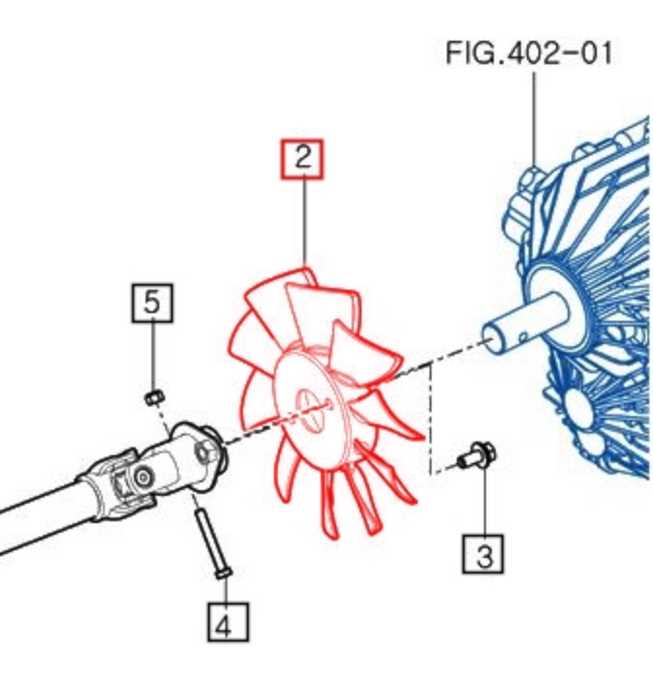

Cooling System Components and Pathways

The cooling system plays a crucial role in maintaining optimal operating temperatures in heavy machinery. It ensures that the engine does not overheat, which could lead to potential damage. Understanding the key elements and how they interact is essential for proper maintenance and performance. This system consists of several interconnected components that facilitate the flow of coolant and regulate heat dissipation effectively.

Key Components of the Cooling System

The heart of any cooling mechanism is the radiator, responsible for transferring heat away from the engine. Coolant flows through the radiator, where heat is dissipated into the atmosphere. Additionally, the water pump circulates the coolant throughout the engine, while the thermostat ensures that the engine operates at a consistent temperature. Hoses and piping are also vital, guiding the coolant between the engine and the various components.

Coolant Pathways and Heat Regulation

The coolant follows a specific pathway through the engine, starting from the pump and passing through the various components. It absorbs heat from the engine and carries it toward the radiator, where it is released. This continuous loop maintains the system’s efficiency and prevents overheating. Proper sealing and regular checks on hoses and connections are vital to avoid coolant leaks, ensuring the system’s smooth operation.

Electrical System Connections

The electrical setup is a vital component that ensures proper operation and functionality of key systems. Understanding the key links and their organization is crucial for maintenance and troubleshooting. Proper connections guarantee that power is distributed efficiently and safely across the entire system.

When working on the electrical system, it is essential to follow a structured approach to ensure each connection is secure and functioning as intended. Below are some important aspects to consider when dealing with the wiring and power distribution:

- Ensure all wires are correctly routed and insulated to prevent short circuits or damage.

- Verify that connectors are properly attached and free of corrosion.

- Check that fuses and relays are rated appropriately for the system’s electrical load.

In addition to these considerations, the following steps can help in securing and maintaining the integrity of the electrical connections:

- Inspect the battery connections regularly to ensure a clean and firm contact.

- Confirm that the ground connections are free from rust and corrosion.

- Use proper tools when handling electrical terminals to avoid damaging the components.

Brake System Arrangement and Parts

The braking mechanism in agricultural vehicles is designed to ensure safe operation under various working conditions. It consists of multiple components working together to provide efficient stopping power when necessary. Understanding how these elements are arranged and interact is crucial for proper maintenance and repair.

Brake discs play a vital role in converting kinetic energy into heat, which is dissipated through friction. These components are usually located within the wheel assemblies and are driven by the vehicle’s movement. Alongside them, brake pads apply pressure to the discs, creating the necessary force to slow down the vehicle.

Other important elements include the hydraulic cylinders, which use fluid pressure to actuate the brake pads, and the brake lines, which transport this fluid. Proper maintenance of these components is essential to avoid potential malfunctions that could affect overall performance.

Regular inspection of the system ensures that all parts are functioning correctly, contributing to both safety and reliability during operation. Keeping each element in good working condition prevents breakdowns and enhances the vehicle’s performance on various terrains.

Maintenance Tips for Tym Tractor Parts

Proper upkeep of your equipment ensures its longevity and optimal performance. Regular inspection and timely repairs can prevent costly breakdowns. Keeping an eye on key components helps maintain efficiency, ensuring smooth operation for years to come.

1. Check fluid levels regularly, including engine oil and hydraulic fluids, to avoid overheating and excessive wear. Low fluid levels can lead to system malfunctions and damage to crucial elements.

2. Inspect belts and hoses for signs of wear or cracks. These components are essential for the smooth functioning of various systems. Replacing damaged parts promptly can prevent more serious issues down the road.

3. Clean filters and screens to avoid clogging. Dust and debris can accumulate, reducing efficiency and increasing strain on the machine. Keeping filters clean is vital for maintaining optimal operation.

4. Lubricate moving parts regularly to ensure smooth movement and reduce friction. Proper lubrication helps prevent unnecessary wear and tear on mechanical components, extending their lifespan.

5. Store the equipment in a dry, sheltered location when not in use to protect it from weather conditions. Exposure to harsh environments can cause rust, corrosion, and deterioration of materials.