Semi Trailer Axle Parts Diagram Explained

In the realm of heavy-duty transport, the intricate assembly of essential elements plays a pivotal role in ensuring efficiency and safety on the road. A thorough comprehension of these vital components not only enhances operational performance but also extends the lifespan of the entire vehicle. Each segment is engineered to withstand significant loads while contributing to overall stability and maneuverability.

Delving into the mechanics of these crucial assemblies reveals a network of interconnected elements that work harmoniously together. From the foundational support structures to the rotating mechanisms, each component has a specific function that influences the vehicle’s handling and responsiveness. Understanding these relationships is key for anyone involved in the maintenance or design of such transport systems.

By visualizing the configuration of these elements, one can appreciate the complexity and precision required in their engineering. This knowledge not only aids in troubleshooting and repair but also empowers operators and technicians to make informed decisions regarding upgrades and enhancements. A clear insight into these systems ultimately fosters greater reliability and safety in transportation operations.

Semi Trailer Axle Overview

This section provides an insightful look into the essential components that support the structure and functionality of heavy transport vehicles. Understanding these elements is crucial for maintaining optimal performance and safety on the road.

These crucial elements serve various functions, including:

- Providing stability and balance during transport

- Distributing weight evenly across the vehicle

- Enhancing maneuverability and handling

- Withstanding significant loads during operation

Typically, these assemblies consist of several key features, such as:

- Wheel bearings for smooth rotation

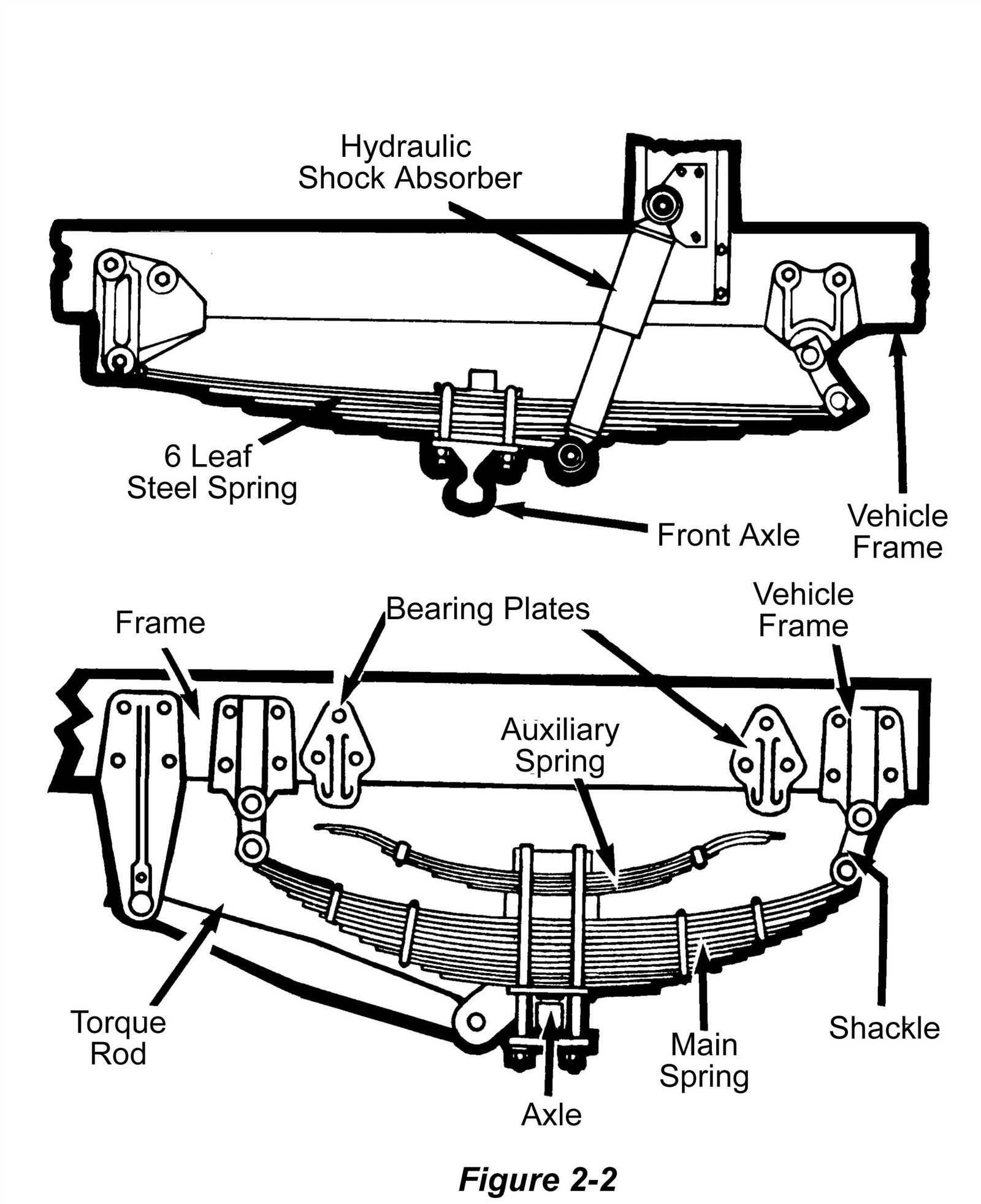

- Suspension systems that absorb shocks

- Brake components for effective stopping power

- Frame structures that support overall integrity

By examining these components in detail, operators can ensure their vehicles are equipped for both durability and efficiency, ultimately leading to safer journeys and reduced maintenance costs.

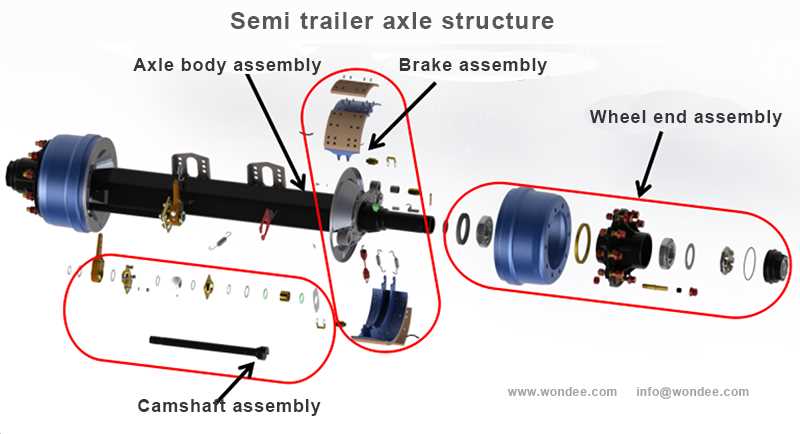

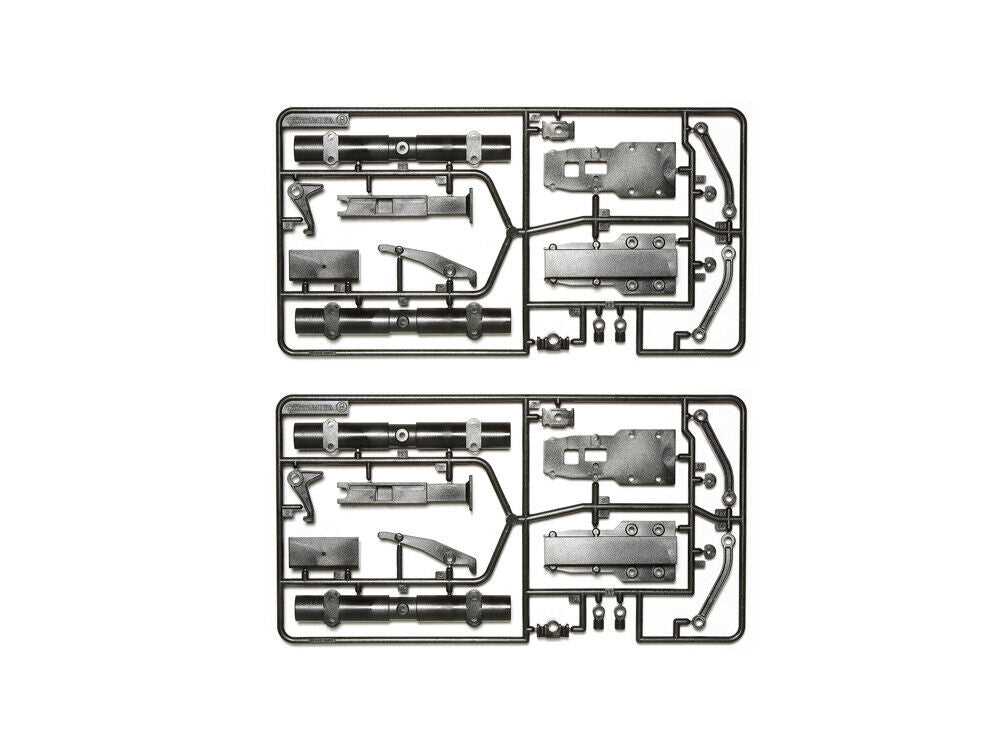

Components of Semi Trailer Axles

The structure that supports heavy loads and facilitates movement on highways consists of various crucial elements. Understanding these components is essential for maintaining performance and ensuring safety.

- Spindle: A critical part that connects the wheel to the suspension system, enabling smooth rotation.

- Hub: This encases the bearings and supports the wheel, allowing for effective load distribution.

- Brake assembly: Essential for slowing down or stopping, it includes pads, drums, and other necessary elements.

- Leaf springs: Provide the necessary support and flexibility, absorbing shocks during transit.

- U-bolts: These secure the suspension components to the frame, ensuring stability and strength.

- Kingpin: Acts as a pivot point for steering and maneuverability, crucial for control.

Each of these elements plays a vital role in the overall functionality and durability of the system, making regular inspections and maintenance imperative.

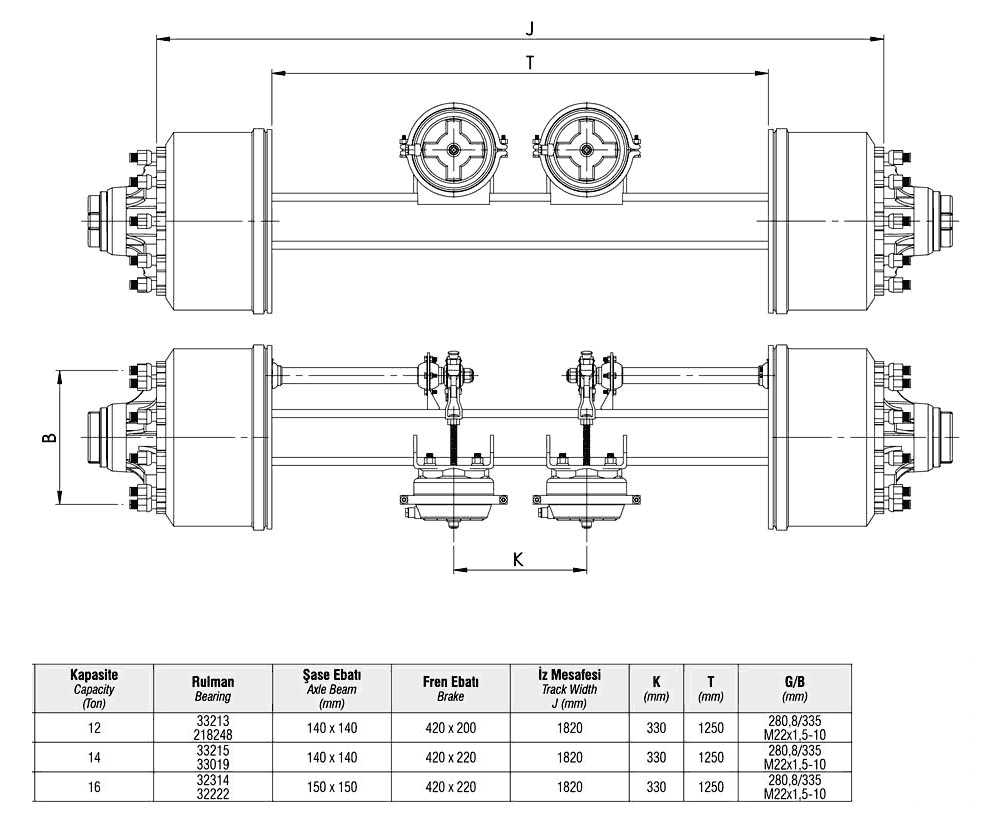

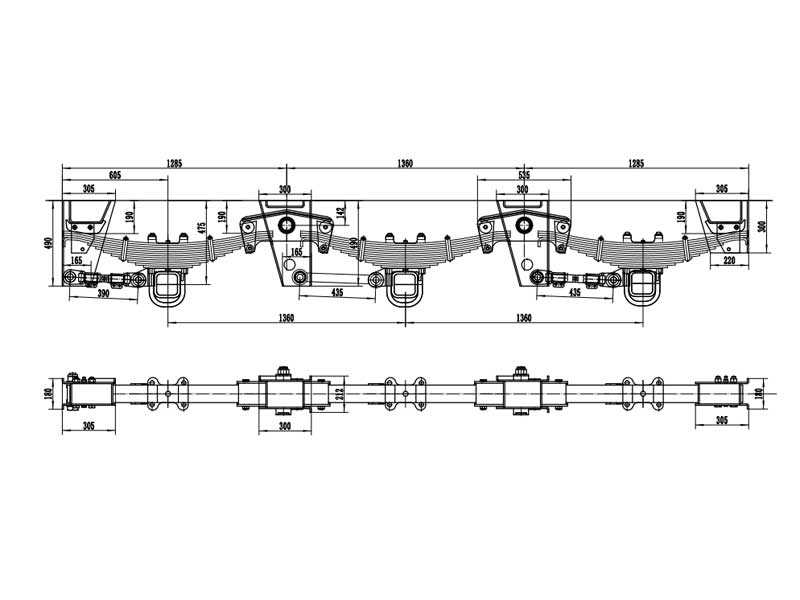

Understanding Axle Types

In the world of heavy-duty vehicles, various support mechanisms play crucial roles in ensuring stability, load distribution, and maneuverability. Each type of support assembly has its unique characteristics, designed to cater to specific operational requirements. Grasping the differences among these mechanisms is essential for optimizing performance and maintenance.

Common Types of Support Mechanisms

Different configurations serve distinct purposes, from enhancing load capacity to improving handling. The most prevalent types include the following:

| Type | Description |

|---|---|

| Single | Designed for light loads, offering simplicity and ease of maintenance. |

| Tandem | Features two assemblies in tandem, allowing for greater weight distribution and stability. |

| Tridem | Involves three assemblies, ideal for heavy loads requiring additional support. |

Choosing the Right Configuration

Selecting the appropriate type is vital for vehicle performance. Consider factors such as load capacity, vehicle design, and intended use to make an informed decision. Each option presents advantages and trade-offs, making it crucial to assess your specific needs before making a choice.

Functionality of Axle Parts

The components that support a vehicle’s weight and enable smooth motion are crucial for overall performance. These elements work together to ensure stability, control, and efficient transfer of power from the engine to the wheels. Understanding how each piece contributes to the whole is essential for maintaining optimal operation and safety.

Key Components and Their Roles

Each element plays a specific role, enhancing the functionality and reliability of the entire system. Below is a table outlining some of the primary components and their respective functions:

| Component | Function |

|---|---|

| Hub | Connects the wheel to the assembly, allowing for rotation and load support. |

| Shaft | Transfers power from the engine to the wheels, facilitating movement. |

| Brake Assembly | Ensures safe stopping by applying friction to the wheels. |

| Suspension System | Absorbs shocks from the road, improving comfort and handling. |

| Kingpin | Allows for steering and turning, providing maneuverability. |

Importance of Maintenance

Regular inspection and maintenance of these components are vital for longevity and performance. Neglecting any single element can lead to operational failures, impacting not only efficiency but also safety on the road. Understanding the individual contributions of each component can help in identifying issues early and ensuring a smoother experience.

Common Issues with Axles

Various challenges can arise with the components that support heavy loads and ensure stability during movement. Understanding these problems can help in maintaining performance and safety.

- Wear and Tear: Over time, components can experience degradation due to constant friction and pressure. Regular inspections are essential.

- Misalignment: If parts are not properly aligned, it can lead to uneven wear and decreased efficiency. This often results from improper installation or wear on other connected elements.

- Corrosion: Exposure to moisture and contaminants can lead to rust and deterioration, compromising the integrity of essential components.

- Overloading: Exceeding the weight limit can strain the system, leading to premature failure. Adhering to weight guidelines is crucial.

Addressing these issues promptly can extend the lifespan of the system and enhance overall performance. Regular maintenance and inspections are key to preventing more serious complications.

Maintenance Tips for Longevity

Ensuring the durability of your transport components requires consistent attention and care. By following a few essential practices, you can significantly extend the lifespan of these vital elements, minimizing the risk of failures and costly repairs.

Regular Inspections: Conduct routine examinations to identify signs of wear or damage. Pay close attention to connections, seals, and fasteners, as these areas are often prone to issues. Early detection can prevent larger problems down the line.

Lubrication: Keep all moving parts well-lubricated to reduce friction and prevent premature deterioration. Use high-quality lubricants suited for the specific conditions in which your equipment operates.

Weight Management: Adhere to weight limits to avoid unnecessary stress on the components. Overloading can lead to accelerated wear and even catastrophic failures, jeopardizing safety and efficiency.

Environmental Protection: Shield your equipment from harsh environmental conditions. Utilize protective covers when not in use and consider treatments that resist corrosion and rust, especially in humid or saline environments.

Timely Repairs: Address any issues immediately. Neglecting minor repairs can lead to more extensive damage and increased downtime, ultimately affecting productivity.

Documentation: Maintain detailed records of maintenance activities, inspections, and repairs. This practice not only helps in tracking performance over time but also assists in identifying recurring problems that may need further attention.

By implementing these strategies, you can ensure that your components remain in optimal condition, providing reliable performance for years to come.

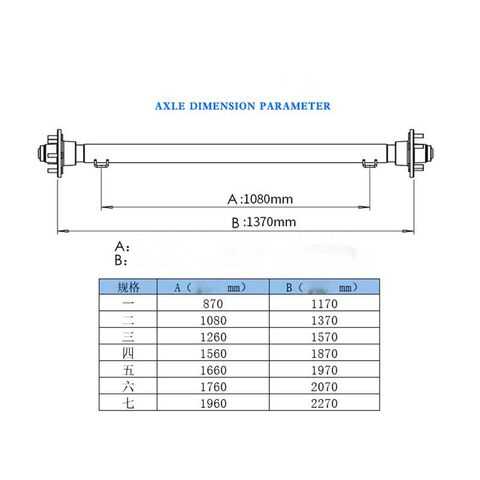

Choosing the Right Axle Size

Selecting the appropriate dimensions for your vehicle’s support system is crucial for ensuring optimal performance and safety. The right size influences load capacity, stability, and maneuverability. Understanding the various factors that affect your choice will help you make an informed decision.

When determining the best size, consider the weight distribution and the intended use of your vehicle. For heavier loads or frequent long-distance travel, a larger configuration may be necessary to maintain balance and reduce wear. Conversely, lighter applications may benefit from a more compact setup for increased agility.

| Factor | Considerations |

|---|---|

| Load Capacity | Assess the maximum weight your vehicle will carry. |

| Vehicle Type | Identify the model and its specifications for compatibility. |

| Terrain | Consider the types of surfaces you will encounter; rough terrains may require sturdier options. |

| Regulatory Compliance | Check local regulations regarding weight limits and specifications. |

Ultimately, making the right choice involves balancing these factors to suit your specific requirements. By carefully evaluating each aspect, you can enhance the efficiency and safety of your vehicle’s operation.

Installation Procedures Explained

This section outlines the essential steps required for the proper assembly and setup of specific vehicle components. A thorough understanding of these procedures ensures optimal performance and longevity of the system, reducing the risk of potential issues during operation.

Before beginning the installation, it is crucial to gather all necessary tools and materials. Ensure that the workspace is clean and organized, allowing for efficient progress. The following table summarizes the key steps involved in the installation process:

| Step | Description |

|---|---|

| 1 | Prepare the workspace by removing any obstructions and gathering tools. |

| 2 | Inspect all components for wear or damage before assembly. |

| 3 | Follow the manufacturer’s instructions for the correct sequence of assembly. |

| 4 | Tighten all fasteners to the specified torque settings to ensure stability. |

| 5 | Conduct a thorough check of all connections and adjustments after installation. |

By adhering to these guidelines, users can ensure a successful setup and enhance the overall reliability of the vehicle components involved.

Impact of Weight Distribution

Effective weight distribution plays a crucial role in the performance and safety of heavy-duty vehicles. When the load is balanced properly, it enhances stability, improves handling, and reduces wear on key components. Conversely, improper distribution can lead to various issues, including decreased maneuverability and increased risk of accidents.

Even weight distribution across all wheels is essential to ensure that the vehicle remains stable during operation. Uneven loading can cause certain wheels to bear more weight than others, leading to premature tire wear and potential tire failure. This can also result in decreased fuel efficiency, as the engine must work harder to compensate for the added strain on specific components.

Moreover, dynamic weight shifts during acceleration, braking, or cornering can significantly affect control. If the load shifts unexpectedly, it may lead to skidding or loss of traction, particularly in adverse weather conditions. Properly managing weight can mitigate these risks and enhance overall safety.

Understanding the effects of weight placement is vital for operators and fleet managers. By ensuring that the load is evenly distributed and secured, vehicles can achieve optimal performance, prolong their lifespan, and maintain a high level of safety on the road.

Upgrading Axle Components

Enhancing the performance and longevity of a vehicle’s undercarriage is a crucial task for any operator. By investing in higher-quality elements, one can significantly improve handling, safety, and overall efficiency. The process involves evaluating existing components and selecting upgraded alternatives that better suit operational needs.

Quality Materials: Transitioning to premium materials can lead to improved durability and reduced wear. Consider options that provide better resistance to stress and environmental factors.

Advanced Technology: Incorporating modern engineering advancements can enhance functionality. For example, using components with superior load distribution or improved braking systems can drastically elevate performance.

Regular Maintenance: Upgrading isn’t solely about new parts; routine inspections and upkeep are vital. Regular maintenance ensures that all enhancements function as intended and extends their lifespan.

By focusing on these aspects, operators can ensure that their vehicles not only meet current demands but also adapt to future challenges, enhancing overall operational success.

Safety Considerations for Trailers

Ensuring the safety of vehicles designed for transporting goods is paramount for both the operator and other road users. Proper maintenance, regular inspections, and adherence to guidelines play critical roles in minimizing risks associated with road transport.

Regular Maintenance and Inspections

Routine checks on various components can prevent accidents caused by mechanical failures. Key areas to focus on include:

- Tires: Ensure adequate tread depth and proper inflation to enhance grip and stability.

- Braking System: Inspect brakes regularly for wear and responsiveness, as they are crucial for stopping effectively.

- Lights and Indicators: Functioning lights are essential for visibility and signaling intentions to other drivers.

Load Security

Properly securing cargo is vital to avoid shifting during transit, which can lead to loss of control. Techniques for effective load management include:

- Using appropriate tie-downs: Invest in high-quality straps and chains that can withstand the weight of the cargo.

- Distributing weight evenly: Ensure that the load is balanced to maintain stability during movement.

By prioritizing these safety measures, operators can enhance road safety and contribute to a safer driving environment for everyone.

Future Trends in Axle Design

The evolution of vehicle support systems is poised to undergo significant transformations driven by technological advancements and changing market demands. Innovations in materials, design methodologies, and manufacturing processes are paving the way for enhanced efficiency, durability, and performance. As industries adapt to new challenges, the focus is shifting toward smarter, lighter, and more sustainable solutions.

Advanced Materials and Manufacturing Techniques

One of the most promising trends is the use of composite materials and additive manufacturing. These approaches allow for the creation of components that are not only lighter but also exhibit superior strength and resistance to wear. The integration of 3D printing technology facilitates rapid prototyping and customization, enabling manufacturers to respond swiftly to evolving needs while reducing production waste.

Integration of Smart Technologies

The incorporation of IoT (Internet of Things) devices into vehicle structures is another significant trend. These smart systems can provide real-time data on performance metrics, enhancing monitoring and maintenance capabilities. By leveraging predictive analytics, operators can anticipate failures and optimize usage, thereby extending the lifespan of critical components and improving overall safety.