Comprehensive Guide to Shelby Trailer Jack Parts Diagram

In the realm of heavy-duty equipment, comprehending the intricate assembly of lifting devices is crucial for both functionality and safety. These mechanisms play a vital role in ensuring that loads are managed effectively, allowing for smooth operation across various applications. A thorough exploration of these assemblies reveals the importance of each individual element in the overall system.

Identifying the specific elements that contribute to the successful operation of these lifting tools can greatly enhance your understanding of their performance. Each component, from the foundational structures to the smaller mechanisms, is designed with a purpose, contributing to the efficiency and reliability of the entire unit. Mastery of these details can empower users to optimize their equipment’s capabilities.

Additionally, visual representations of these assemblies serve as invaluable resources for maintenance and troubleshooting. By studying the layout and function of each segment, users can gain insights that facilitate better care and prolong the lifespan of their machinery. An informed approach to handling these tools not only improves safety but also enhances productivity.

Understanding Shelby Trailer Jacks

When it comes to supporting and stabilizing heavy loads during transportation, certain mechanisms play a crucial role in ensuring safety and efficiency. These essential devices are designed to facilitate easy maneuverability and secure positioning, making them invaluable in various settings. Gaining insight into their components and functionality can greatly enhance their usability and maintenance.

Key Components and Their Functions

Each mechanism comprises several integral elements that work in unison to provide optimal performance. Among these are the lifting mechanism, which enables height adjustment, and the base, which ensures stability on different surfaces. Additionally, components like the handle and mounting hardware contribute to ease of operation and installation.

Maintenance Tips for Longevity

To ensure the durability and effectiveness of these devices, regular maintenance is essential. This includes routine inspections for wear and tear, lubrication of moving parts, and prompt replacement of any damaged elements. By adhering to these practices, users can prolong the life of their equipment and enhance its reliability during critical operations.

Key Components of Trailer Jacks

Understanding the essential elements of lifting mechanisms is crucial for effective usage and maintenance. Each component plays a significant role in ensuring functionality and safety.

Main Elements

- Base: Provides stability and support.

- Legs: Enable height adjustment and load distribution.

- Crank or Handle: Facilitates raising and lowering actions.

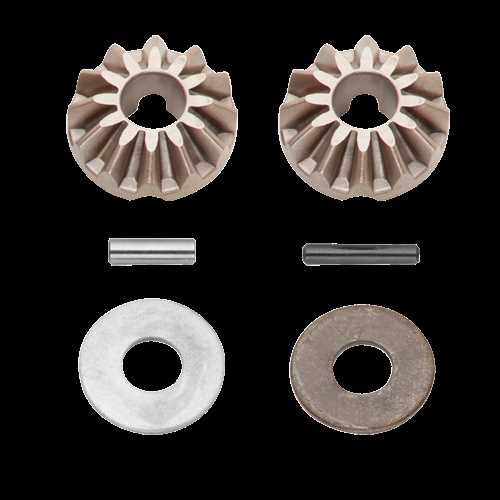

- Gear System: Enhances mechanical advantage for easier operation.

- Wheel or Foot: Offers mobility and ground contact.

Material Considerations

- Steel: Known for durability and strength.

- Aluminum: Lightweight and resistant to corrosion.

- Plastic: Used for components requiring less weight.

Importance of Jack Maintenance

Regular upkeep of lifting mechanisms is crucial for ensuring safety and functionality. Neglecting these components can lead to performance issues and potentially hazardous situations. Routine inspections and maintenance practices help in identifying wear and tear before they escalate into serious problems.

Proper maintenance extends the lifespan of the equipment and ensures optimal performance. This involves checking for rust, lubricating moving parts, and ensuring that all mechanisms operate smoothly. By prioritizing upkeep, users can avoid costly repairs and ensure reliability during critical operations.

Moreover, well-maintained equipment enhances user confidence and minimizes the risk of accidents. Investing time in regular checks ultimately leads to greater efficiency and safety in various applications.

Common Issues with Trailer Jacks

When dealing with lifting mechanisms for trailers, several prevalent challenges can arise, impacting functionality and safety. Understanding these issues is crucial for effective maintenance and ensuring reliable operation.

Wear and Tear: Over time, components may degrade due to exposure to harsh conditions. Regular inspection helps identify wear before it becomes a significant problem.

Corrosion: Rust and corrosion can accumulate, especially in wet environments, leading to operational failures. Keeping parts clean and well-lubricated is essential.

Alignment Problems: Misalignment can hinder proper function, causing difficulties in raising or lowering the mechanism. Ensuring correct alignment during installation is vital.

Hydraulic Issues: For hydraulic models, leaks or pressure loss can severely impact performance. Routine checks of seals and fluid levels can mitigate these risks.

Mechanical Failures: Breakdowns in gears or other moving parts can occur, leading to a complete loss of functionality. Immediate replacement of damaged components is recommended to prevent further issues.

Choosing the Right Jack Size

Selecting the appropriate lifting device is crucial for ensuring safe and efficient handling of loads. A proper fit not only enhances functionality but also minimizes the risk of accidents during use. Understanding the requirements based on the weight and dimensions of the load will lead to a more effective choice.

Understanding Load Capacity

Every lifting tool comes with a specific weight limit that it can handle safely. It’s essential to assess the maximum load you intend to lift and select a device that exceeds this weight to provide a margin of safety. Consulting the manufacturer’s specifications will give you insight into the optimal capacity needed for your tasks.

Height and Reach Considerations

The height required for lifting is another critical factor. Ensure that the chosen device can reach the necessary elevation for your needs. Considering the clearance and overall height will help you avoid complications during operation, ensuring both convenience and safety in your lifting tasks.

Installation Tips for Shelby Jacks

Proper installation of lifting devices is crucial for safety and efficiency. Following specific guidelines can enhance performance and ensure longevity. Here are some essential tips to consider during the setup process.

| Tip | Description |

|---|---|

| Read the Manual | Familiarize yourself with the manufacturer’s instructions to understand the features and requirements. |

| Check Compatibility | Ensure that the device matches the specifications of your vehicle or equipment. |

| Use Proper Tools | Employ the recommended tools for installation to avoid damage and ensure secure fitting. |

| Inspect Components | Examine all components for wear or damage before starting the installation. |

| Secure Fasteners | Tighten all fasteners to the appropriate torque specifications for stability. |

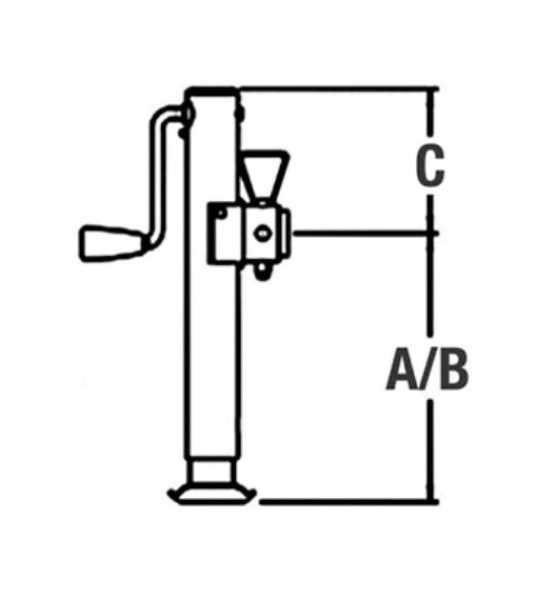

Identifying Parts in Diagrams

Understanding illustrations that depict components is essential for effective maintenance and repairs. These visual representations often include various elements that serve specific functions, making it crucial to recognize each one accurately.

Common Elements to Recognize

- Fasteners

- Connectors

- Support structures

- Control mechanisms

- Power sources

Tips for Effective Identification

- Familiarize yourself with terminology related to the components.

- Use a reference guide for complex systems.

- Take note of labels and annotations in the illustration.

- Practice identifying components in various contexts.

Safety Considerations for Trailer Jacks

Ensuring secure lifting mechanisms is crucial for maintaining safety during operations. Proper understanding and adherence to safety protocols can prevent accidents and injuries while handling heavy loads.

| Safety Tip | Description |

|---|---|

| Inspect Regularly | Check for wear and damage before use to ensure functionality. |

| Use Proper Technique | Follow correct lifting procedures to avoid strain and accidents. |

| Secure the Load | Always ensure that the item being lifted is stable and balanced. |

| Keep Area Clear | Maintain a clutter-free workspace to reduce trip hazards. |

Where to Buy Replacement Parts

Finding components for your equipment can be crucial for maintaining its functionality and ensuring safety. There are several reliable avenues for acquiring these essentials, catering to various preferences and budgets.

- Local Hardware Stores: Often stocked with a variety of essential components, these stores allow for immediate purchases and expert advice.

- Specialized Retailers: Shops that focus on equipment may offer a broader selection, ensuring you find exactly what you need.

- Online Marketplaces: Websites like Amazon, eBay, or specific parts retailers provide convenience and often competitive pricing.

- Manufacturer’s Website: Purchasing directly from the manufacturer can ensure authenticity and quality, along with access to specialized items.

- Repair Shops: Local repair professionals may have spare parts or can direct you to where you can find them.

Each option presents unique advantages, so consider your specific needs and preferences when searching for components to keep your equipment in top condition.

Upgrading Your Trailer Jack System

Enhancing your lifting mechanism can significantly improve functionality and efficiency. By considering various options and components, you can ensure a smoother operation and increased durability for your equipment.

- Assess your current setup for limitations.

- Research modern alternatives that offer better performance.

- Consider weight capacity and ease of use.

When selecting upgrades, keep the following in mind:

- Choose high-quality materials for longevity.

- Look for user-friendly designs that simplify operation.

- Ensure compatibility with your existing equipment.

By investing in a superior lifting system, you can ultimately enhance your overall experience and reliability during use.

Frequently Asked Questions About Jacks

This section addresses common inquiries regarding lifting devices used in various applications. Understanding these mechanisms is crucial for safe and effective use. Below are some frequently asked questions that can help clarify essential aspects and improve your knowledge.

| Question | Answer |

|---|---|

| What are the primary types of lifting devices? | There are several types, including hydraulic, mechanical, and pneumatic, each suited for different tasks and load capacities. |

| How do I determine the right capacity for my needs? | Assess the maximum weight you plan to lift and choose a model with a capacity exceeding that weight to ensure safety. |

| What maintenance is required for optimal performance? | Regular inspections, lubrication of moving parts, and checking for wear and tear are essential for longevity and efficiency. |

| Are there safety precautions I should take? | Always use on a stable surface, ensure the load is secure, and never exceed the maximum weight limit specified by the manufacturer. |

| Can I use these devices for vehicles? | Yes, many models are specifically designed for automotive use, offering stability and safety when lifting vehicles for maintenance. |