Tanker Trailer Components Overview

When delving into the intricate world of specialized transportation vehicles, it is essential to grasp the various elements that contribute to their functionality. Each component plays a vital role in ensuring safe and efficient operations, serving specific purposes that enhance performance and reliability.

In this section, we will explore the assembly of these vehicles, focusing on the interconnections and roles of different elements. By understanding how each part interacts with others, operators and enthusiasts alike can better appreciate the engineering marvels that facilitate the transport of liquids across vast distances.

Equipped with this knowledge, individuals can make informed decisions regarding maintenance, upgrades, and repairs. This insight is invaluable for anyone involved in the industry, as it fosters a deeper connection with the machinery and contributes to overall operational success.

This section provides an outline for understanding the various components involved in a specific type of transport vehicle designed for liquid cargo. By examining the essential elements, readers can gain insight into how these components interact and contribute to the overall functionality and safety of the vehicle.

| Heading Number | Heading Title |

|---|---|

| 1 | Introduction to Liquid Transport Vehicles |

| 2 | Key Structural Elements of the Vehicle |

| 3 | Components for Liquid Handling |

| 4 | Safety Features and Regulations |

| 5 | Maintenance and Inspection Guidelines |

| 6 | Common Issues and Troubleshooting |

| 7 | Understanding Load Distribution |

| 8 | Importance of Material Quality |

| 9 | Technological Advancements in Vehicle Design |

| 10 | Future Trends in Liquid Transport Systems |

Main Components of Tanker Trailers

Understanding the essential elements of specialized transport units is crucial for efficient operation and maintenance. Each element plays a significant role in ensuring safety and functionality, contributing to the overall effectiveness of the transport system. Below are the primary components that define these vehicles.

Chassis and Frame Structure

The foundation of these units consists of a robust chassis and frame structure, designed to withstand heavy loads. This framework provides stability and support, ensuring that the entire system remains intact during transit. A well-engineered frame contributes to durability, enhancing the longevity of the vehicle.

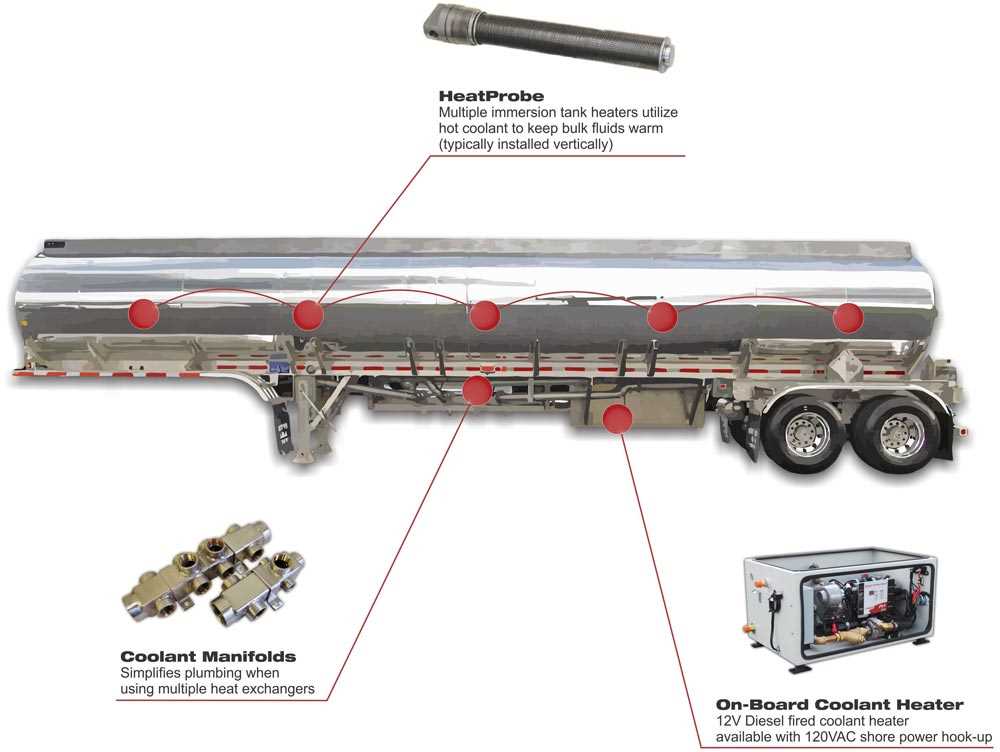

Storage Container and Insulation

The storage container is pivotal for holding liquids securely. It is typically constructed from high-quality materials to resist corrosion and leakage. Adequate insulation is vital to maintain temperature control, preventing the contents from being affected by external conditions. This feature is particularly important for transporting sensitive materials.

Safety features, such as valves and pumps, are integrated into the design to ensure safe loading and unloading procedures, further enhancing operational efficiency.

Understanding Tanker Trailer Functionality

The efficient operation of liquid transport vehicles relies on a range of integrated systems designed to enhance performance and safety. Each component plays a crucial role in ensuring the safe movement of liquids over long distances, while also facilitating effective loading and unloading processes.

Key Components and Their Roles

Each vehicle comprises various elements that contribute to its overall functionality. Understanding these components is essential for anyone involved in their maintenance or operation.

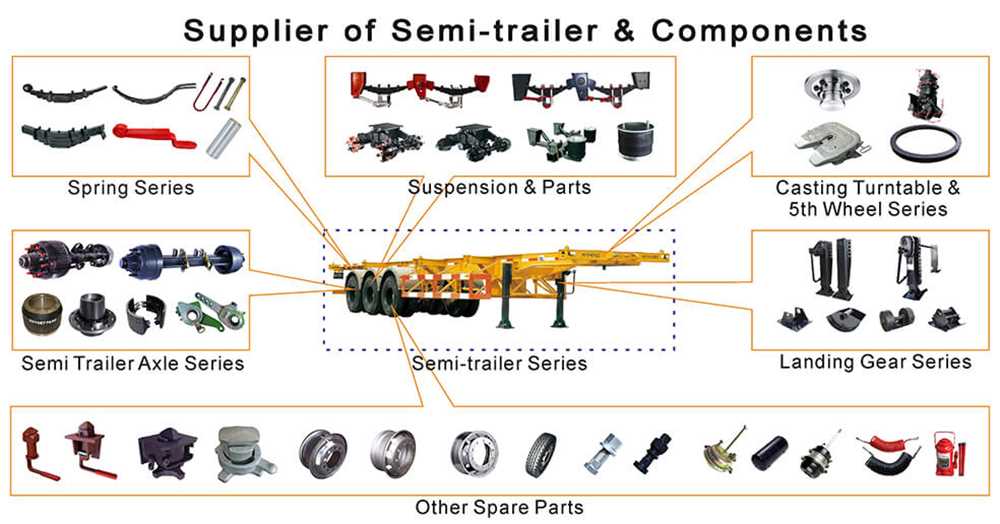

- Chassis: The main structure that supports the entire assembly, providing stability and strength.

- Container: A specially designed vessel that securely holds liquids during transport, preventing spills and leaks.

- Suspension System: A vital system that absorbs shocks and vibrations, ensuring a smooth ride and protecting the cargo.

- Brake Mechanism: Ensures effective stopping power, crucial for safety when transporting heavy liquid loads.

Operational Considerations

When utilizing such vehicles, several operational aspects must be taken into account to maximize efficiency:

- Regular maintenance of all components to prevent malfunctions.

- Monitoring of liquid levels and weight distribution for balance.

- Adherence to safety regulations to minimize risks during transit.

Common Tanker Trailer Accessories

When it comes to enhancing the functionality and safety of transport vehicles, various supplementary components play a crucial role. These additions are designed to improve performance, streamline operations, and ensure compliance with safety regulations, making them indispensable for effective cargo handling.

Essential Safety Equipment

Safety is paramount in the transportation industry. Among the most vital accessories are reflective strips and safety chains. Reflective strips provide visibility in low-light conditions, while safety chains secure connections and prevent accidental detachment during transit.

Operational Enhancements

To maximize efficiency, several tools can be incorporated into the vehicle’s design. For instance, fuel management systems monitor and regulate fuel usage, while load monitoring sensors provide real-time feedback on weight distribution. Proper maintenance of these systems is essential to ensure optimal performance and compliance with industry standards.

Maintenance Tips for Tanker Trailers

Proper upkeep is essential for ensuring the longevity and safety of heavy-duty transport vehicles. Regular attention to various components can significantly enhance performance and reliability, reducing the risk of unexpected breakdowns and costly repairs.

Routine Inspections

Conducting frequent examinations of critical systems is vital. Check for signs of wear and tear, particularly in the suspension and braking systems. Look for any leaks in fluid reservoirs and ensure that all connections are secure. Regular inspections help identify potential issues before they escalate into major problems.

Cleaning and Care

Cleaning plays a crucial role in maintenance. Keeping the exterior and interior free from contaminants prevents corrosion and extends the lifespan of various elements. Use suitable cleaning agents that are gentle yet effective in removing dirt and residues. Thorough cleaning after each journey, especially if transporting corrosive substances, is highly recommended.

Safety Equipment for Liquid Transport Vehicles

The protection of both operators and cargo is paramount in the transportation of liquid materials. Various safety devices and measures are implemented to ensure a secure and efficient transport process. These elements play a crucial role in preventing accidents and ensuring compliance with industry regulations.

Essential Safety Features

- Emergency Stop System: This mechanism allows for immediate cessation of operations in case of an emergency.

- Warning Signals: Visual and auditory alarms alert personnel of potential hazards during loading and unloading.

- Fire Extinguishing Equipment: Portable extinguishers should be readily available to combat any fire incidents.

- Safety Valves: These devices regulate pressure and prevent leaks or spills during transport.

Operational Guidelines

- Conduct regular inspections of all safety equipment to ensure functionality.

- Train personnel in emergency procedures and the proper use of safety devices.

- Maintain a clean and organized work environment to minimize risks.

- Implement strict loading and unloading protocols to prevent accidents.

Choosing the Right Tanker Parts

Selecting appropriate components for fluid transport vehicles is crucial for ensuring efficiency and safety. Various factors influence this decision, including the specific type of liquids being carried, the conditions of transportation, and regulatory standards that must be met. Understanding the essential elements can help streamline the selection process.

When assessing available options, it is important to prioritize durability and compatibility with the substances involved. High-quality materials can significantly enhance the lifespan of the equipment, while proper alignment with the vehicle’s specifications ensures optimal performance. Consideration of these aspects can prevent future issues and costly repairs.

Additionally, consulting with experts in the field can provide valuable insights. Engaging with professionals who specialize in this area can offer recommendations tailored to individual needs, helping to navigate the complexities of selection effectively. Ultimately, thorough research and expert guidance are key to making informed choices.

Assembly Process of Transport Containers

The process of assembling transport containers involves a series of systematic steps that ensure the structure is both functional and secure. Each stage plays a crucial role in achieving a high-quality assembly, emphasizing precision and adherence to safety standards. This intricate procedure requires a blend of skilled labor and efficient techniques to achieve optimal results.

Preparation and Component Inspection

Before beginning the assembly, it is essential to prepare the workspace and inspect all components for defects. Proper organization of tools and materials enhances efficiency and reduces the risk of errors. Each element should be thoroughly examined to guarantee it meets the required specifications, ensuring a seamless assembly process.

Assembly Techniques and Quality Control

Utilizing appropriate assembly techniques is vital for the structural integrity of the container. Techniques may include welding, bolting, and riveting, depending on the materials used. Continuous quality control measures throughout the assembly process help identify any issues early, facilitating prompt corrections and ensuring that the final product adheres to industry standards.

Impact of Trailer Design on Performance

The configuration and structure of a transport unit significantly influence its operational efficiency and stability. Design elements play a crucial role in determining how well the unit can maneuver, carry loads, and endure various road conditions. A well-thought-out design enhances performance, safety, and fuel efficiency, while a poorly designed unit may lead to increased wear and tear, higher maintenance costs, and compromised safety.

Key design features to consider include weight distribution, aerodynamics, and materials used in construction. Each of these elements contributes to how the unit interacts with the vehicle it’s attached to and the environment in which it operates. Understanding these factors can help in selecting or modifying a unit to achieve optimal performance.

| Design Feature | Impact on Performance |

|---|---|

| Weight Distribution | Improves stability and handling during transport |

| Aerodynamics | Reduces drag and enhances fuel efficiency |

| Material Quality | Affects durability and load capacity |

| Suspension System | Ensures a smoother ride and protects cargo |

Troubleshooting Tanker Trailer Issues

When operating a large vehicle designed for transporting liquids, various challenges may arise that require prompt attention. Identifying and resolving these problems is crucial for ensuring safety and efficiency during transportation. This section will explore common complications and provide guidance for effective solutions.

Common Problems and Symptoms

Understanding typical issues can help in diagnosing and addressing malfunctions. Here are some frequent symptoms that may indicate underlying problems:

- Unusual noises during operation

- Leaking fluids or unusual stains

- Poor handling or stability while driving

- Difficulty in braking or excessive wear on brake components

- Warning lights or alerts on the dashboard

Diagnostic Steps

To effectively troubleshoot complications, consider following these steps:

- Conduct a thorough visual inspection for any obvious signs of damage.

- Check fluid levels and inspect for leaks in hoses and connections.

- Test the braking system for responsiveness and unusual sounds.

- Review the suspension components for wear or misalignment.

- Utilize diagnostic tools to read any error codes and address them accordingly.