Understanding the Wabash Dry Van Trailer Parts Diagram

In the realm of logistics, comprehending the intricate elements that compose transport containers is crucial for efficiency and safety. Each segment serves a specific function, contributing to the overall integrity of the structure. Recognizing these components allows operators to ensure optimal performance during transit.

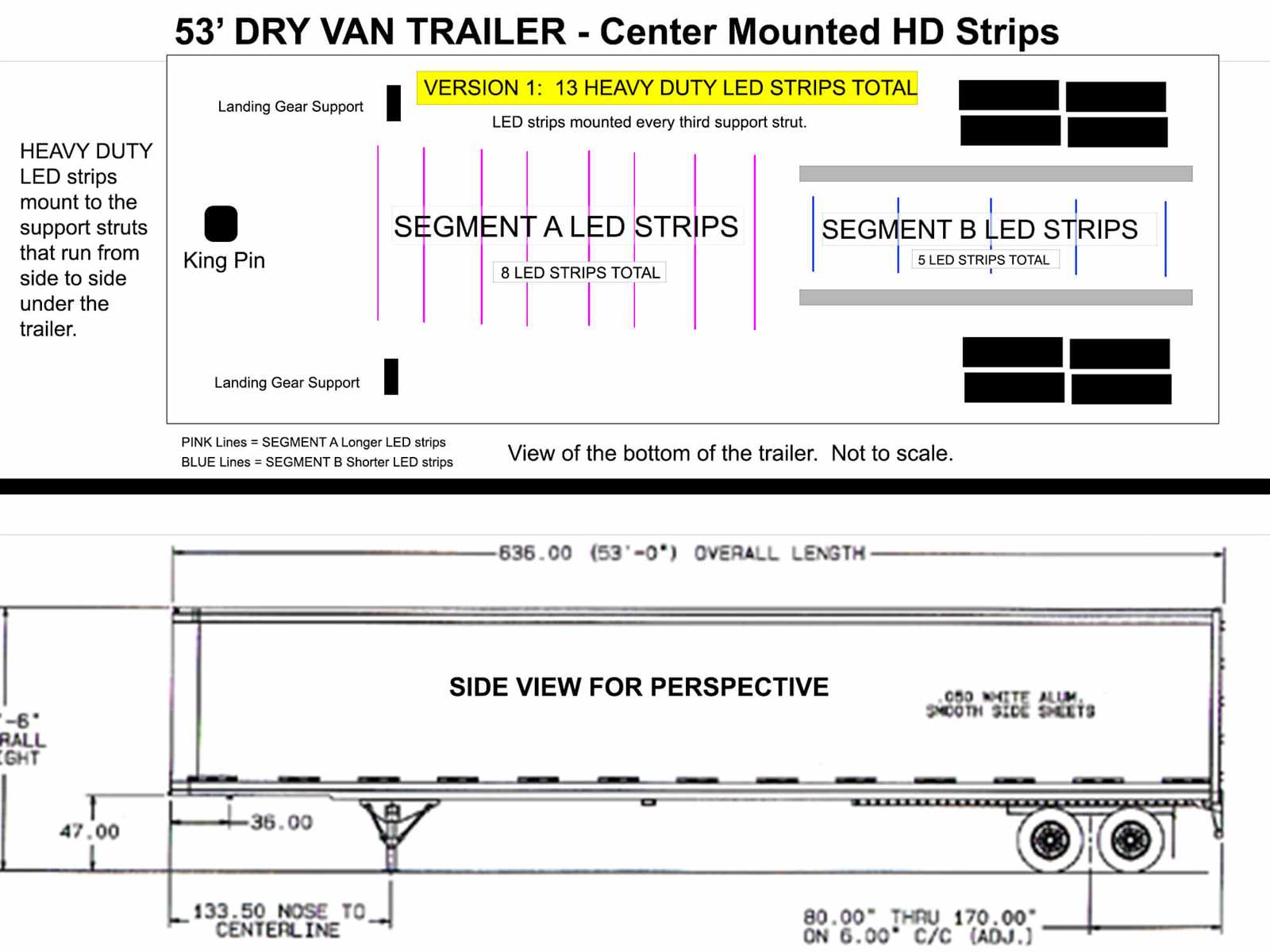

Visual aids play a vital role in illustrating the relationships between these essential features. By examining a detailed representation, one can identify how each part interacts and functions harmoniously within the system. This knowledge is not only beneficial for maintenance but also enhances operational proficiency.

Moreover, a thorough exploration of these components equips professionals with the ultimate understanding needed for effective management. As the industry evolves, staying informed about innovations and updates in design remains paramount for success in transportation logistics.

Understanding Wabash Dry Van Trailers

This section explores essential components and features of a specific type of transport vehicle designed for freight. These structures are crucial for the logistics industry, providing protection and efficiency for cargo transportation. Knowing their design and function enhances operational effectiveness.

| Component | Function |

|---|---|

| Frame | Supports overall structure and load stability. |

| Flooring | Provides a durable surface for cargo placement. |

| Roof | Protects contents from external elements. |

| Doors | Facilitates easy access for loading and unloading. |

Key Components of Dry Van Trailers

The effectiveness and functionality of transport vehicles rely heavily on their fundamental elements. Understanding these essential components can greatly enhance operational efficiency and safety during transit. Each element plays a vital role in ensuring the secure transport of goods across various distances.

One of the primary structures is the chassis, which serves as the backbone, supporting the entire assembly and providing stability. Additionally, the exterior shell, often made of durable materials, protects the cargo from external elements while contributing to aerodynamic efficiency.

Inside, the flooring system is crucial for load distribution, ensuring that weight is evenly spread to maintain balance. Furthermore, various fastening mechanisms, such as tie-downs and lashing points, are essential for securing items in place, preventing movement during travel.

Another important aspect is the lighting system, which enhances visibility and safety, particularly during low-light conditions. Moreover, the braking system is critical for controlling speed and ensuring timely stops, contributing to overall road safety.

Lastly, access points like doors and ramps facilitate the loading and unloading process, making it easier to manage the flow of goods. Each of these components works together harmoniously, highlighting the complexity and precision involved in the design of transport vehicles.

Importance of Quality Trailer Parts

The integrity of any hauling vehicle relies heavily on the components used in its construction. High-quality elements ensure safety, enhance performance, and reduce the likelihood of breakdowns, ultimately leading to a more reliable experience on the road.

Benefits of Using Quality Components

- Enhanced Safety: Durable elements minimize the risk of accidents caused by equipment failure.

- Improved Efficiency: Quality materials contribute to better fuel economy and overall performance.

- Longevity: Premium components often withstand wear and tear, reducing replacement frequency.

Long-Term Cost Savings

- Fewer Repairs: Investing in quality reduces the need for frequent maintenance.

- Higher Resale Value: Well-maintained vehicles with superior elements attract better offers.

- Minimized Downtime: Reliable equipment ensures consistent operation, avoiding costly interruptions.

Common Issues with Wabash Trailers

Owners of these transport vehicles often encounter a variety of challenges that can affect performance and safety. Understanding these common problems is crucial for maintaining the reliability and longevity of the units.

1. Structural Integrity: Over time, the frame may suffer from stress fractures or corrosion due to exposure to harsh environments. Regular inspections can help identify weak points before they lead to significant failures.

2. Door Malfunctions: The access doors can become difficult to operate, often due to misalignment or damaged hinges. Ensuring proper alignment and lubrication can mitigate these issues.

3. Electrical Issues: Wiring problems are prevalent, particularly with lights and sensors. Poor connections or frayed wires can lead to intermittent failures, impacting visibility and safety.

4. Brake Wear: The braking system is crucial for safe operation, yet it is prone to wear and tear. Regular maintenance and timely replacement of brake components can prevent potential accidents.

5. Tire Problems: Uneven wear or improper inflation can lead to tire blowouts, which pose serious risks. Monitoring tire conditions and maintaining appropriate pressure are essential for safe travel.

By staying vigilant and addressing these common concerns, operators can enhance the functionality and safety of their transport equipment.

Maintenance Tips for Trailer Longevity

Ensuring the extended lifespan of your hauling unit involves regular upkeep and attention to detail. Proper maintenance not only enhances performance but also minimizes unexpected breakdowns, ultimately saving you time and money. Here are key strategies to keep your equipment in optimal condition.

Regular Inspections

Conducting frequent checks can help identify potential issues before they escalate. Focus on the following areas during your inspections:

| Component | Inspection Frequency | Notes |

|---|---|---|

| Tires | Weekly | Check for proper inflation and tread wear. |

| Brakes | Monthly | Inspect pads and fluid levels for effectiveness. |

| Lights | Bi-Weekly | Ensure all lights function correctly for safety. |

Proper Lubrication

Lubrication is vital for moving parts to function smoothly. Apply the right type of grease to joints and bearings regularly. This reduces friction and wear, extending the life of your equipment. Consult your manufacturer’s guidelines for specific lubrication schedules and products.

How to Identify Trailer Part Types

Understanding various components of transportation units is essential for effective maintenance and repairs. Each element serves a distinct purpose, contributing to the overall functionality and safety of the unit. By familiarizing yourself with these components, you can ensure optimal performance and longevity.

Common Component Categories

Components can generally be categorized into several groups, such as structural elements, mechanical systems, and electrical systems. Structural elements include the framework and support structures, while mechanical systems encompass braking and suspension features. Electrical systems involve lighting and wiring.

Identification Tips

To effectively recognize these components, start by examining the structure for unique identifiers, like part numbers or manufacturer labels. Consult documentation or guides specific to the unit type for detailed descriptions. This knowledge will assist you in understanding each component’s role and ensure informed decisions during repairs.

Safety Features in Wabash Trailers

Ensuring the security of cargo and the safety of drivers is paramount in the transport industry. Advanced protective measures have been integrated into modern hauling units to address various challenges faced on the road. These features not only enhance safety but also promote operational efficiency.

- Structural Integrity: Reinforced designs contribute to improved durability and resistance to impacts, minimizing the risk of cargo loss.

- Lighting Systems: Enhanced visibility through LED lighting reduces the chances of accidents, especially during low-light conditions.

- Brake Technology: Advanced braking systems offer quicker response times and better control, significantly lowering stopping distances.

In addition to these elements, various monitoring systems have been incorporated:

- TPMS (Tire Pressure Monitoring System): Continuous monitoring helps prevent blowouts and maintains optimal tire conditions.

- GPS Tracking: Real-time location tracking aids in asset recovery and enhances security against theft.

- Camera Systems: Surround-view cameras provide a comprehensive perspective, helping drivers navigate tight spaces and avoid obstacles.

Furthermore, regular maintenance checks and adherence to safety regulations are crucial for sustaining these safety features and ensuring overall reliability on the road.

Choosing the Right Replacement Parts

Selecting appropriate components for your hauling equipment is crucial for maintaining optimal performance and safety. The right choice not only enhances functionality but also extends the lifespan of your vehicle. Understanding the specific requirements of your machinery can help you navigate the variety of options available in the market.

First, consider the compatibility of the components with your existing setup. Always refer to manufacturer specifications to ensure that the replacements align perfectly with your model. Using mismatched parts can lead to inefficiencies and may compromise safety.

Next, assess the quality of the items you intend to purchase. Opt for components made from durable materials that can withstand the rigors of daily use. Investing in high-quality replacements often pays off in the long run, reducing the frequency of repairs and replacements.

Lastly, consider cost-effectiveness. While cheaper options may seem appealing, they often lack the longevity and reliability of higher-priced alternatives. A well-thought-out investment in quality components can save you money and time by minimizing maintenance issues.

In summary, choosing the right replacements involves understanding compatibility, prioritizing quality, and evaluating cost-effectiveness. Making informed decisions will ensure that your hauling equipment operates efficiently and safely.

Benefits of Upgrading Trailer Components

Enhancing vehicle components can lead to significant improvements in performance, safety, and efficiency. Upgrading outdated elements not only boosts operational reliability but also extends the lifespan of the entire unit. The investment in superior materials and technology often results in a smoother experience for both operators and loads.

Improved Safety and Compliance

Modern components are designed with advanced safety features that ensure compliance with current regulations. This reduces the risk of accidents and enhances overall safety on the road.

Enhanced Efficiency and Performance

Upgraded systems often lead to better fuel efficiency and increased payload capacity. These enhancements can translate into lower operational costs and higher profitability.

| Component | Benefit |

|---|---|

| Braking Systems | Shorter stopping distances and improved control |

| Suspension | Better load distribution and ride comfort |

| Lighting | Increased visibility and safety during nighttime operations |

| Tires | Enhanced grip and reduced wear |

Wiring Diagrams for Better Repairs

Understanding the intricacies of electrical systems is crucial for effective maintenance and troubleshooting. Clear visual representations can greatly assist technicians in identifying issues and executing repairs efficiently. This knowledge not only streamlines the repair process but also enhances the overall longevity of the equipment.

Importance of Clarity

Having a well-organized schematic allows for quick reference during repairs. It minimizes confusion and reduces the likelihood of errors, ultimately leading to more reliable outcomes. Technicians can pinpoint connections and troubleshoot problems with greater confidence.

Enhanced Problem-Solving

By utilizing comprehensive illustrations, technicians can delve deeper into the mechanics of the system. This facilitates a better understanding of how components interact, leading to more informed decisions and effective solutions during repairs.

Resources for Wabash Trailer Owners

For those who own specific types of transport equipment, having access to reliable information and resources is crucial. This section provides valuable tools and links to enhance your experience and ensure the longevity of your investment.

Useful Online Platforms

- Manufacturer’s Official Website

- Dedicated Forums for Equipment Owners

- Social Media Groups for Networking

Maintenance and Support

- Regular Inspection Checklists

- Online Repair Guides and Tutorials

- Local Repair Shops and Service Providers