Complete Guide to 2006 Ford F150 Transmission Parts Diagram

In the intricate world of automotive engineering, the efficient functioning of a vehicle’s power transfer mechanism is crucial for optimal performance. This complex assembly ensures that the engine’s power is effectively transmitted to the wheels, facilitating smooth acceleration and deceleration. For enthusiasts and mechanics alike, comprehending the various elements involved in this system is essential for maintenance and repair tasks.

Among the myriad of components, certain key elements play a pivotal role in ensuring reliability and efficiency. A visual representation of these components can significantly aid in grasping their interrelations and functionalities. By exploring the layout of this system, individuals can enhance their understanding of how each part contributes to the overall operation of the vehicle, paving the way for informed troubleshooting and modifications.

Whether you are a seasoned mechanic or a curious owner, delving into the structure of this vital assembly offers valuable insights. Knowing the specific functions of each component not only facilitates better repair practices but also fosters a deeper appreciation for the engineering marvels behind modern automobiles. In this discussion, we will explore the essential elements and their configurations, providing a comprehensive overview of this integral aspect of vehicle design.

Overview of 2006 Ford F150 Transmission

This section provides a comprehensive examination of the crucial assembly responsible for the power transfer in a light-duty pickup truck. Understanding the function and components of this intricate system is essential for proper maintenance and repairs, ensuring optimal performance and longevity of the vehicle.

Key Functions

- Facilitates the transfer of engine power to the wheels.

- Regulates gear shifting to optimize performance and efficiency.

- Enhances the vehicle’s handling characteristics.

- Contributes to fuel economy through effective power management.

Common Components

- Gear assembly: Responsible for different speed ratios.

- Fluid pump: Ensures proper lubrication and hydraulic pressure.

- Torque converter: Allows smooth gear transitions and power multiplication.

- Valve body: Directs fluid flow and regulates gear changes.

Knowledge of these functions and components is vital for troubleshooting issues and performing necessary repairs, which can significantly enhance the vehicle’s reliability and performance.

Key Components of the Transmission System

The mechanism responsible for transferring power from the engine to the wheels is a crucial aspect of any vehicle’s operation. Understanding the main elements of this system can enhance performance and reliability. Each component plays a vital role in ensuring smooth gear shifts and effective torque management, contributing to the overall driving experience.

Main Elements

Several fundamental components work together within this system to facilitate its functioning. Each part has a specific purpose, and their interaction is essential for optimal performance. Recognizing these elements aids in comprehending how the entire system operates and the importance of regular maintenance.

Component Overview

| Component | Description |

|---|---|

| Gear Set | Responsible for varying the torque and speed transmitted to the wheels. |

| Clutch Assembly | Engages and disengages the engine from the drivetrain to allow for gear changes. |

| Fluid Pump | Circulates hydraulic fluid necessary for the operation of various components. |

| Valve Body | Directs hydraulic fluid to different parts of the system based on the selected gear. |

| Torque Converter | Transfers engine power to the transmission and allows for smooth acceleration. |

Transmission Types for 2006 F150

This section explores the various systems responsible for power transfer in vehicles designed in that year. Understanding these mechanisms is essential for owners and enthusiasts alike, as it impacts performance, efficiency, and overall driving experience.

Types of Systems

- Automatic Gearbox

- Manual Gearbox

- Continuously Variable Transmission (CVT)

Key Features

-

Automatic Gearbox:

Offers seamless gear shifting without driver intervention, enhancing convenience during operation.

-

Manual Gearbox:

Provides a more engaging driving experience, allowing the operator to select gears based on preference and conditions.

-

Continuously Variable Transmission:

Utilizes a system of belts and pulleys to offer a smooth acceleration curve without distinct gear shifts.

Each of these mechanisms presents unique advantages and considerations, allowing users to choose based on their driving habits and preferences.

Common Issues with F150 Transmissions

The vehicle’s shifting mechanism plays a crucial role in its overall performance and reliability. However, certain problems may arise over time, leading to undesirable symptoms that can affect driving experience and safety. Understanding these common complications can help owners identify issues early and seek appropriate solutions.

Frequent Problems

- Slipping Gears: One of the most prevalent issues is the unexpected disengagement of gears, causing a sudden loss of power. This may occur due to worn components or fluid leaks.

- Delayed Engagement: Drivers might experience a lag when shifting from park to drive or reverse. This can indicate low fluid levels or malfunctioning valves.

- Overheating: Excessive heat can lead to severe damage, often resulting from low fluid levels, clogged coolers, or heavy towing.

Maintenance Tips

- Regularly check fluid levels and top up as necessary.

- Change the fluid according to the manufacturer’s recommended intervals.

- Inspect for leaks and address them immediately to prevent further damage.

- Have routine check-ups to ensure all components are functioning correctly.

By being aware of these typical concerns and following preventative measures, vehicle owners can enhance the longevity and performance of their shifting mechanisms.

Importance of Regular Maintenance

Consistent upkeep of automotive components is crucial for ensuring optimal performance and longevity. Regular inspections and servicing can prevent minor issues from escalating into significant problems, ultimately saving both time and money. Maintaining your vehicle in top condition fosters reliability, enhances safety, and improves fuel efficiency.

Benefits of Routine Care

Routine care not only extends the lifespan of the vehicle but also boosts its resale value. A well-maintained machine is more appealing to potential buyers, as it signifies reliability and reduced risk of future repairs. Additionally, regular maintenance can help identify potential safety hazards before they pose a threat to the driver or passengers.

Key Maintenance Tasks

| Task | Frequency | Benefits |

|---|---|---|

| Oil Change | Every 5,000 miles | Reduces engine wear and improves efficiency |

| Fluid Checks | Monthly | Ensures all systems operate smoothly |

| Tire Rotation | Every 6,000 miles | Promotes even tire wear and extends lifespan |

| Brake Inspection | Every 12,000 miles | Enhances safety and performance |

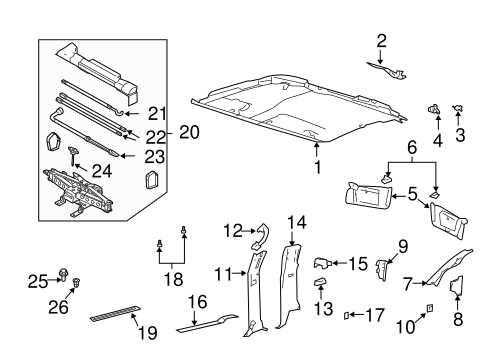

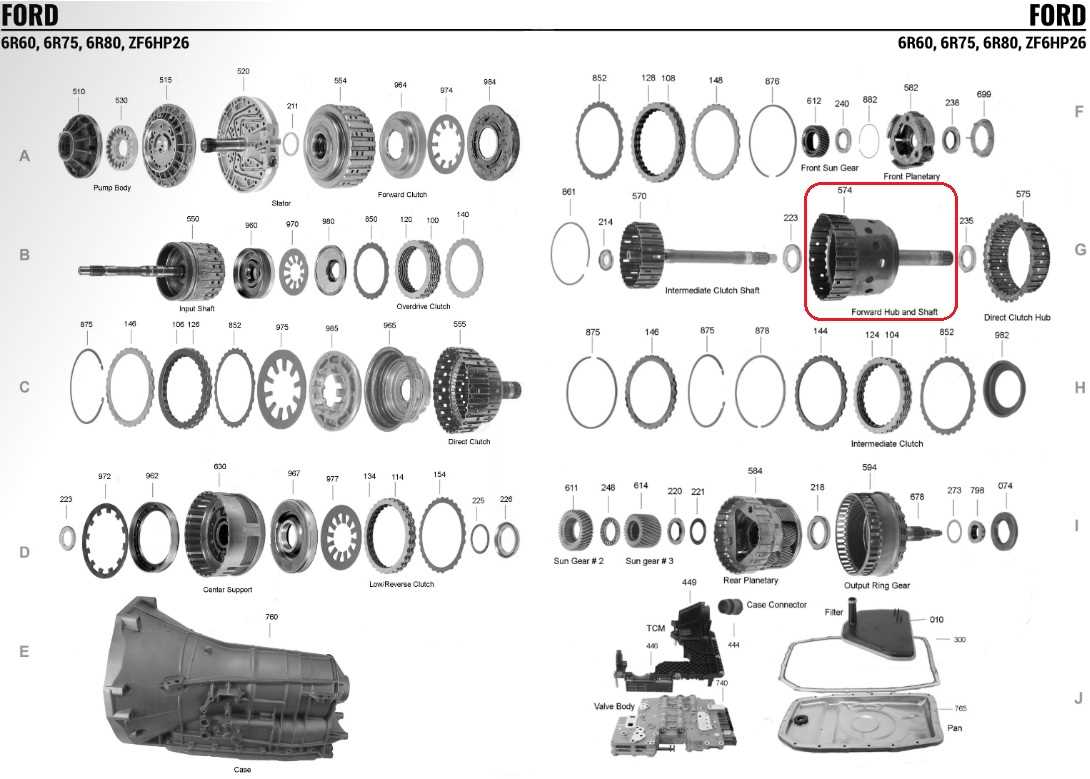

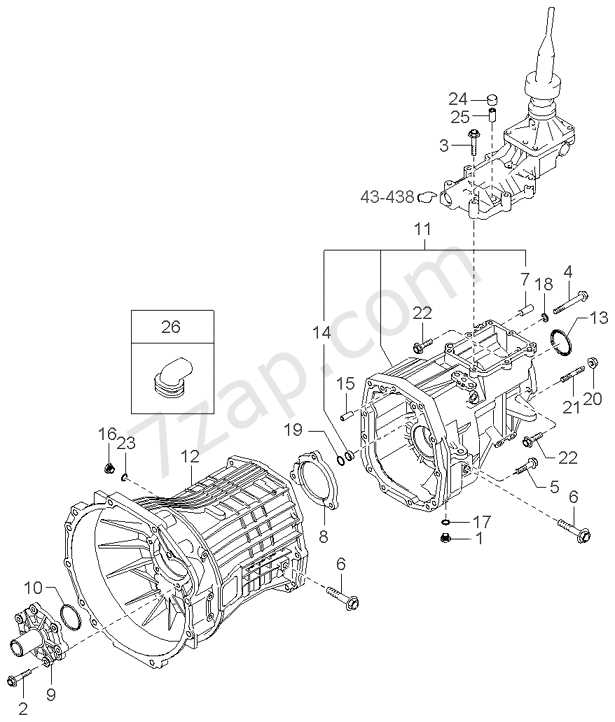

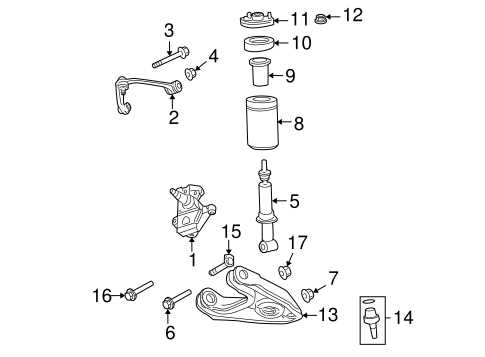

Identifying Transmission Parts by Diagram

Understanding the intricate components of a vehicle’s gear system is crucial for maintenance and repair. Utilizing visual representations can significantly aid in recognizing and differentiating each element, ensuring that mechanics and enthusiasts alike can approach repairs with confidence. By examining illustrations that showcase the arrangement and function of each component, individuals can enhance their knowledge and streamline their work processes.

Importance of Visual Guides

Visual aids serve as essential tools for anyone working with complex machinery. They provide clear depictions of various components, allowing users to easily pinpoint locations and functions. This approach not only simplifies troubleshooting but also facilitates effective communication among professionals and hobbyists. By referencing these guides, individuals can accurately identify issues and make informed decisions about repairs.

Key Components and Their Functions

Every assembly contains numerous elements, each with specific responsibilities. Recognizing these roles through detailed illustrations can be particularly beneficial. For instance, understanding how a particular gear interacts with others can clarify the overall operation of the assembly. Additionally, the ability to identify each section’s contribution to the system’s performance is essential for successful diagnostics and repairs. The emphasis on visual recognition fosters a deeper appreciation for mechanical engineering and encourages a more hands-on approach to vehicle maintenance.

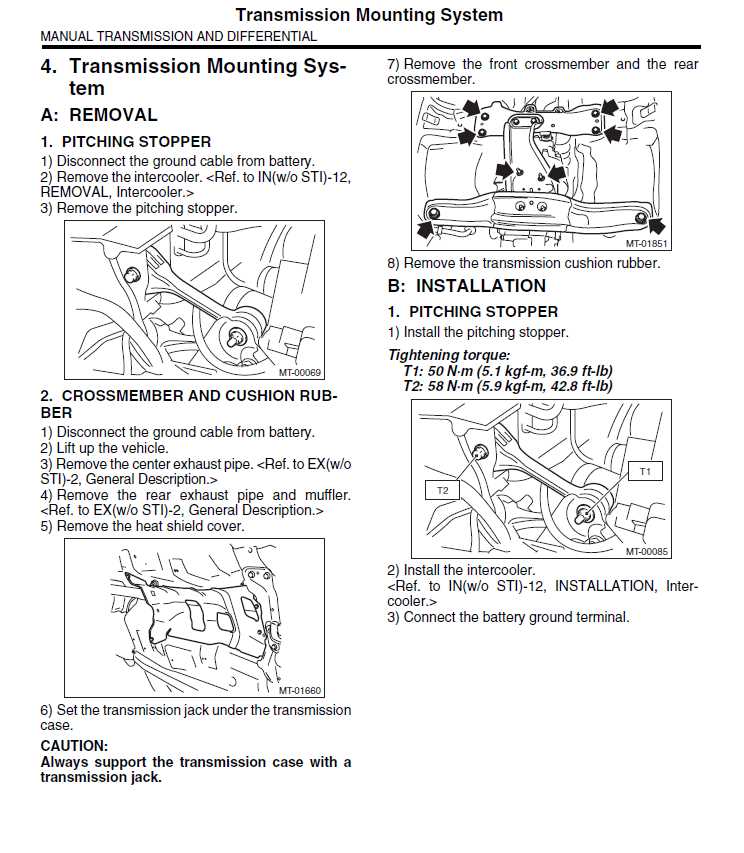

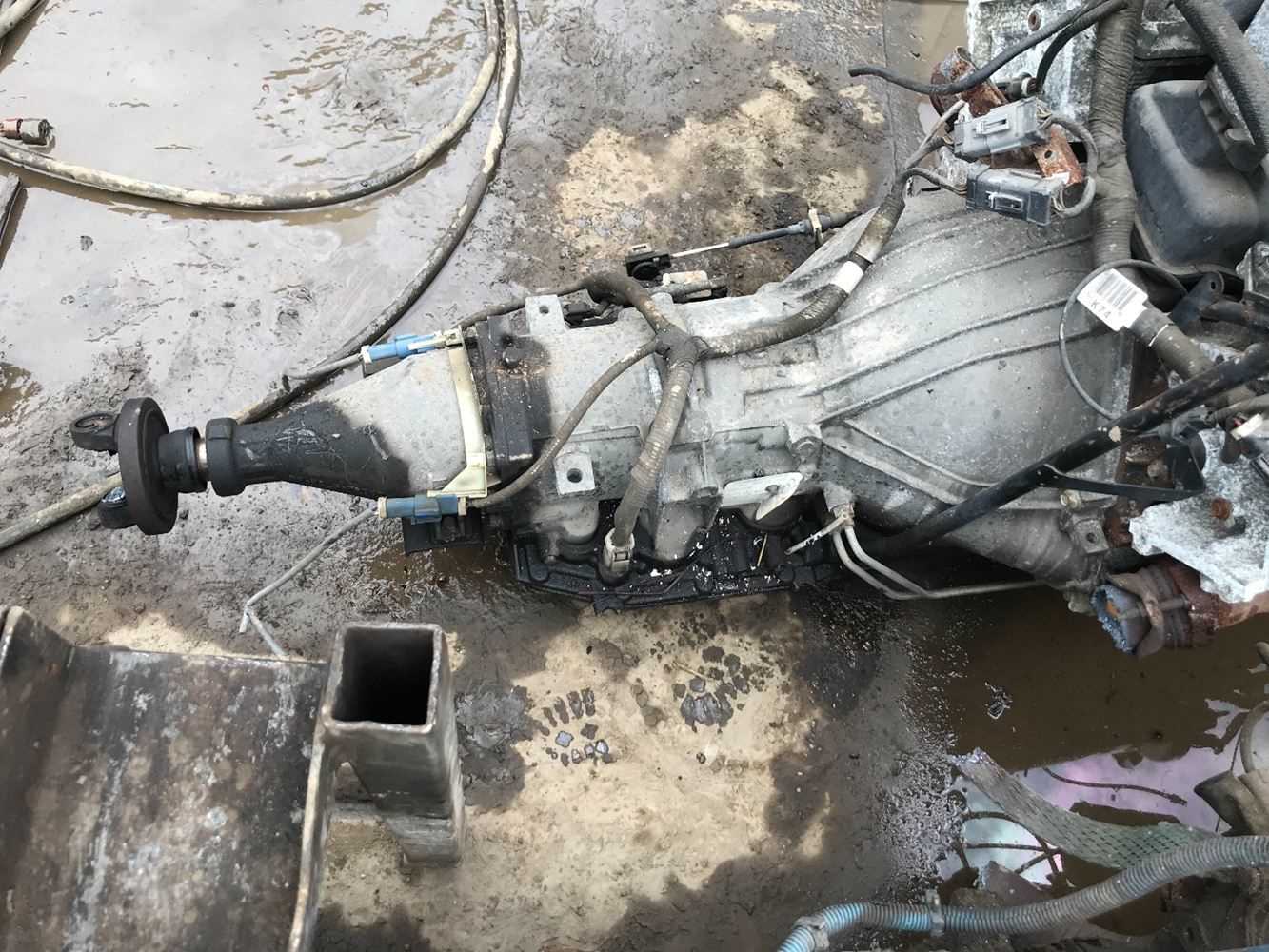

Replacing Faulty Transmission Components

When experiencing issues with your vehicle’s shifting system, addressing defective elements is crucial for maintaining performance and safety. Identifying the source of problems often requires a thorough examination of the system’s various components. Ensuring timely replacements not only enhances vehicle reliability but also prevents further damage and costly repairs in the future.

Identifying the Problem

Recognizing the signs of malfunction is the first step in resolving any issues. Symptoms may include unusual noises, slipping gears, or fluid leaks. Once these indicators are noted, a systematic approach to diagnose the issue can be implemented. Using tools such as diagnostic scanners can help pinpoint specific areas that require attention.

Replacement Process

After identifying the faulty components, the replacement process begins. This involves removing the defective element carefully and installing a new one. It is essential to use high-quality replacements to ensure longevity and optimal performance. Additionally, consulting the service manual or a reliable resource can provide guidance on proper installation procedures, ensuring everything is correctly aligned and secured.

Regular maintenance is key to preventing future issues. Regular checks of fluid levels, connections, and overall system performance can help detect potential problems early on, ultimately saving time and resources.

Tools Needed for Transmission Repair

Effective repair of vehicle gear systems requires a well-equipped workspace and the right tools. Having the appropriate instruments not only ensures accuracy but also enhances safety and efficiency during the repair process. Below is a list of essential tools that will aid in the successful execution of any repair task related to gear mechanisms.

Essential Hand Tools

- Socket Set: A complete set of sockets in various sizes will allow you to tackle different bolt types and sizes.

- Wrenches: Adjustable and fixed wrenches are vital for loosening or tightening various fasteners.

- Screwdrivers: Both flathead and Phillips screwdrivers are essential for accessing and securing various components.

- Pliers: Needle-nose and locking pliers can help in grasping and manipulating small parts.

- Hammer: A rubber mallet can be useful for gently persuading components without causing damage.

Specialized Tools

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications.

- Gear Puller: A gear puller is necessary for removing components without damage.

- Fluid Transfer Pump: This tool aids in draining and refilling fluid effectively.

- Diagnostic Scanner: A scanner helps in identifying issues by reading error codes and providing insights into the system’s functionality.

Equipping yourself with the right tools is crucial for a successful repair job. Investing in quality tools can save time, enhance precision, and ultimately lead to a more efficient repair process.

Transmission Fluid: Selection and Benefits

Choosing the right fluid for a vehicle’s powertrain system is crucial for optimal performance and longevity. This specialized fluid plays a significant role in facilitating smooth operation, providing necessary lubrication, and maintaining system efficiency. Understanding the characteristics and advantages of different types of fluids can help vehicle owners make informed decisions that enhance the overall driving experience.

Selection of the appropriate fluid depends on various factors, including the specific requirements outlined by the manufacturer, environmental conditions, and driving habits. It is essential to consider the viscosity, additives, and compatibility with the existing fluid. Synthetic options often offer superior protection and stability under extreme temperatures, making them a popular choice among enthusiasts.

The benefits of using the right fluid are numerous. Proper fluid selection can lead to improved fuel efficiency, reduced wear on components, and enhanced overall reliability. Additionally, high-quality fluids are formulated to resist breakdown, ensuring that the system remains clean and free from harmful deposits. Regular fluid changes and adherence to manufacturer guidelines further contribute to a vehicle’s performance and longevity.

Understanding Transmission Codes and Diagnostics

Modern vehicles are equipped with advanced systems that monitor performance and detect issues through various codes. These codes are essential for understanding the operational state of a vehicle’s shifting mechanism. By interpreting these codes, technicians can quickly identify problems and implement the necessary repairs, ensuring optimal functionality.

Each vehicle’s system generates a set of alphanumeric codes that correspond to specific malfunctions. These codes can provide insight into sensor failures, mechanical issues, or electronic malfunctions, allowing for targeted diagnostics. Accurate interpretation of these codes is crucial for effective troubleshooting and maintenance.

| Code | Description |

|---|---|

| P0700 | Transmission Control System Malfunction |

| P0720 | Output Speed Sensor Circuit Malfunction |

| P0730 | Incorrect Gear Ratio |

| P0740 | Torque Converter Clutch Circuit Malfunction |

| P0750 | Shift Solenoid A Malfunction |

When diagnosing issues, it is essential to use an appropriate scanning tool that can retrieve these codes. Following the retrieval, a systematic approach to interpretation and troubleshooting is necessary. Understanding each code’s significance allows for a more efficient repair process, ultimately enhancing vehicle performance and longevity.

DIY Transmission Repairs: A Guide

Taking on vehicle repairs can be an empowering experience, especially when it comes to the intricate systems that keep your ride functioning smoothly. Understanding the inner workings and being equipped with the right knowledge can save you both time and money. This guide will walk you through essential steps for handling repairs on critical components of your vehicle’s drivetrain.

Before diving into any repair project, it’s crucial to gather the necessary tools and create a conducive workspace. Adequate preparation will facilitate a smoother process and minimize the chances of mistakes. The following table outlines some essential tools that you might need for your repair tasks:

| Tool | Purpose |

|---|---|

| Socket Set | For removing and tightening bolts and nuts. |

| Torque Wrench | Ensures bolts are tightened to the manufacturer’s specifications. |

| Fluid Pump | For transferring fluids efficiently during service. |

| Oil Catch Pan | To collect old fluids during maintenance. |

| Seal Puller | Helps in the removal of old seals without damage. |

When undertaking repairs, always refer to your vehicle’s manual for specific instructions related to your model. Familiarize yourself with the components involved to make the process less daunting. Break down the repairs into manageable steps, ensuring each task is completed thoroughly before moving on to the next.

Lastly, safety should always be a priority. Wearing protective gear and working in a well-ventilated area will help safeguard against accidents and health risks. With patience and diligence, you can successfully navigate the challenges of vehicle repairs and keep your machine in optimal condition.

Where to Source Replacement Parts

Finding reliable components for your vehicle can significantly enhance its performance and longevity. Whether you’re engaged in a full rebuild or simply replacing a single element, it’s crucial to know where to look for high-quality alternatives. There are various avenues available, each offering distinct benefits and challenges.

Online Retailers: E-commerce platforms provide an extensive selection of components at competitive prices. Websites dedicated to auto supplies often feature user reviews, which can help gauge the reliability of the items. Make sure to verify the seller’s reputation before making a purchase.

Local Auto Parts Stores: Visiting a physical store can be advantageous when you need a component urgently. Knowledgeable staff can assist you in selecting the right item and may even provide installation tips. It’s also a great way to support local businesses.

Salvage Yards: For those on a budget, exploring salvage yards can yield excellent finds. You can often obtain used components in good condition for a fraction of the cost. However, it’s essential to inspect each item carefully to ensure it meets your standards.

Manufacturer Dealerships: Purchasing directly from a dealership guarantees that you’re getting original equipment. While this option tends to be pricier, it provides peace of mind regarding the quality and compatibility of the components.

Forums and Community Groups: Online communities often share valuable insights about sourcing components. Engaging with fellow enthusiasts can lead to recommendations for reliable suppliers or even opportunities to buy directly from other users.

Cost Considerations for Transmission Work

When addressing issues related to the shifting mechanism in vehicles, understanding the financial implications is crucial. The expenses associated with repair or replacement can vary significantly based on multiple factors, including the extent of the damage, the type of vehicle, and labor costs. Being aware of these elements can help vehicle owners make informed decisions about their maintenance and repair options.

Factors Influencing Costs

Several key components affect the overall expenses for repair work on the shifting mechanism. These include parts quality, labor rates, and any additional services required. Additionally, geographic location can play a role in determining costs, as some regions may have higher average rates for mechanics and parts. Below are some factors to consider:

| Factor | Description |

|---|---|

| Quality of Components | OEM parts tend to be more expensive but offer better reliability compared to aftermarket alternatives. |

| Labor Rates | Mechanic hourly rates can differ widely, impacting total service costs. |

| Geographic Location | Costs can vary based on local market conditions and competition among repair shops. |

| Complexity of Repair | More intricate repairs may require specialized tools or techniques, increasing labor time and cost. |

Budgeting for Repairs

To effectively budget for repair work, vehicle owners should consider setting aside a dedicated maintenance fund. Researching average costs in advance and obtaining multiple quotes can help in managing expenses. Additionally, regular maintenance can prevent costly repairs down the line, making it a wise investment for vehicle longevity.