2007 Ford F150 Transmission Parts Overview

Exploring the intricacies of a pickup truck’s gear assembly reveals a complex network essential for optimal performance. This system plays a pivotal role in the vehicle’s functionality, ensuring smooth operation and enhancing overall driving experience.

To fully appreciate this mechanical marvel, one must examine the various elements that come together to create a seamless flow of power. Each component, from the core gears to the auxiliary mechanisms, contributes significantly to the efficiency and durability of the vehicle.

In this section, we will delve into the essential components that constitute this system, highlighting their functions and interconnections. Understanding these aspects not only aids in maintenance but also empowers enthusiasts to make informed decisions when it comes to upgrades or repairs.

Overview of 2007 Ford F150 Transmission

This section provides a comprehensive look into the intricate system responsible for power transfer within a specific vehicle model. Understanding this mechanism is essential for both maintenance and performance enhancement.

Key Components: The assembly consists of various crucial elements that work in harmony to ensure smooth gear shifts and optimal efficiency.

Functionality: This system not only facilitates acceleration but also plays a vital role in managing engine power, ensuring that the vehicle responds appropriately to driver input.

Common Issues: Identifying potential problems early can prevent costly repairs and enhance the longevity of the vehicle.

Maintenance Tips: Regular inspections and timely fluid changes are pivotal for maintaining the reliability of this essential system.

Common Transmission Issues in F150

Vehicles often experience a range of mechanical challenges, particularly in their shifting mechanisms. Understanding these common complications can help owners maintain their vehicles more effectively and recognize when professional assistance is necessary.

Signs of Malfunction

One prevalent issue is difficulty in shifting gears. Drivers may notice a delayed response or harsh engagement, which can indicate underlying problems. Additionally, unusual noises, such as grinding or whining sounds, may signal that components are wearing down or misaligned. Fluid leaks can also point to serious issues, as proper lubrication is essential for optimal function.

Preventative Measures

Regular maintenance is key to preventing issues. Checking fluid levels and quality, along with replacing worn-out components, can enhance longevity. Employing the use of quality fluids and ensuring the system is free of contaminants will also contribute to smoother operation. In case of any signs of distress, consulting with a specialist promptly can prevent further damage and costly repairs.

Essential Transmission Components Explained

The inner workings of an automotive power transfer system are vital for seamless vehicle operation. Understanding the key elements that contribute to this complex mechanism can enhance your knowledge of vehicle performance and maintenance.

One crucial element is the assembly responsible for shifting gears, enabling the driver to adjust power and speed effectively. This component ensures smooth transitions, allowing the vehicle to adapt to various driving conditions.

Another significant piece is the fluid pump, which circulates hydraulic fluid throughout the system. This action provides the necessary pressure for gear engagement, making it essential for the proper functioning of the overall mechanism.

The control module serves as the brain of the operation, utilizing sensors to monitor performance and optimize shifts. Its ability to adjust parameters in real-time ensures a responsive and efficient driving experience.

Additionally, clutch packs play a critical role in engaging and disengaging different gears. Their functionality directly impacts acceleration and deceleration, making them integral to the system’s performance.

Lastly, the torque converter enhances power transfer from the engine to the wheels, allowing for a smoother ride. It aids in maintaining engine efficiency while providing the necessary torque for acceleration.

Familiarity with these essential components not only aids in troubleshooting but also empowers vehicle owners to make informed decisions regarding maintenance and repairs.

Step-by-Step Transmission Repair Guide

This guide provides a comprehensive approach to fixing the complex mechanisms of your vehicle’s shifting system. Understanding the intricacies involved can help you efficiently navigate the repair process, ensuring a smoother ride once completed.

Preparation and Tools Needed

Before starting the repair, gather essential tools such as wrenches, screwdrivers, and a jack. It’s crucial to have a clean workspace and a reliable manual specific to your vehicle’s model. Familiarizing yourself with the components will make the process more manageable.

Disassembly and Inspection

Begin by safely elevating the vehicle and removing the protective coverings. Take care to document each step through photographs or notes, which will aid in reassembly. As you disassemble the unit, inspect each element for wear and damage. Replace any worn-out components to prevent future issues. After cleaning all parts, prepare them for reinstallation.

Following these steps will enhance your understanding and skills, paving the way for effective maintenance and longevity of your vehicle’s mechanisms.

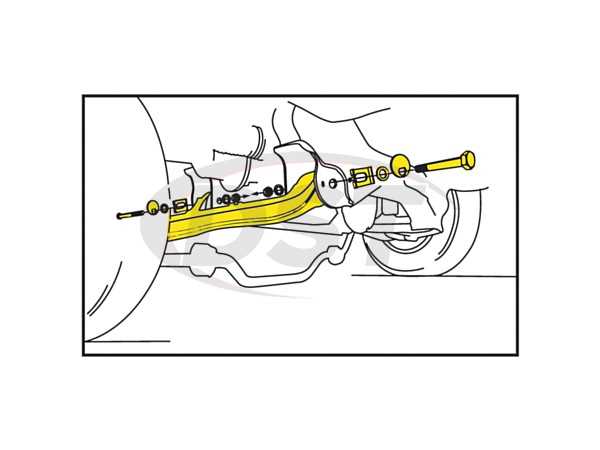

Understanding Transmission Diagrams

Comprehending visual representations of automotive mechanisms is essential for effective repairs and maintenance. These illustrations provide clarity on how components interact, ensuring that enthusiasts and technicians alike can navigate complex systems with confidence.

Key Components to Identify

- Gear Sets

- Shifter Mechanisms

- Linkage Systems

- Fluid Pathways

Benefits of Using Visual Guides

- Enhanced comprehension of mechanical functions.

- Streamlined troubleshooting processes.

- Improved assembly and disassembly efficiency.

- Reduced risk of errors during repairs.

Parts Replacement for Optimal Performance

Maintaining peak functionality in vehicles requires regular evaluation and timely upgrades of crucial components. Ensuring each element operates seamlessly contributes significantly to overall efficiency and longevity.

Key reasons to consider replacements include:

- Enhanced Reliability

- Improved Fuel Efficiency

- Minimized Wear and Tear

- Increased Safety

When planning replacements, focus on the following elements:

- Filters: Regular changes keep systems clean.

- Fluids: High-quality lubricants enhance performance.

- Seals: Prevent leaks and maintain pressure.

- Gears: Upgrading to higher quality reduces stress.

Ultimately, prioritizing these enhancements ensures your vehicle operates at its best, prolonging its lifespan and delivering a smooth driving experience.

Identifying Transmission Fluid Types

Understanding the different types of fluid used in vehicles is crucial for optimal performance and longevity. Each type serves a specific purpose, contributing to the overall functionality of the machinery. Recognizing the characteristics of these liquids can help ensure proper maintenance and prevent potential issues.

Fluids are typically categorized by their viscosity and chemical composition. The main types include mineral, synthetic, and blended varieties. Mineral fluids, derived from refined petroleum, offer basic protection but may break down more quickly under extreme conditions. Synthetic options, engineered for enhanced performance, provide better thermal stability and resistance to oxidation. Blended fluids aim to combine the benefits of both types, offering a middle ground.

Color and smell can also serve as indicators. For instance, fresh fluid is usually red or pink, while older fluid may appear darker or even brown. An unusual odor could signal contamination or degradation, warranting further investigation. Regular checks and fluid changes according to the manufacturer’s recommendations can prevent costly repairs down the line.

Tips for Maintaining Your F150

Proper upkeep of your vehicle not only enhances performance but also extends its lifespan. Regular maintenance can help you avoid costly repairs and ensure a smooth driving experience. Here are some essential tips to keep your truck in top shape.

Regular Inspections

- Check fluid levels monthly, including oil, coolant, and brake fluid.

- Inspect belts and hoses for signs of wear or damage.

- Examine tires for tread depth and proper inflation.

Scheduled Services

- Follow the manufacturer’s recommended service intervals.

- Change the oil and filter every 5,000 to 7,500 miles.

- Replace air filters as needed to ensure optimal airflow.

By adhering to these guidelines, you can maintain the performance and reliability of your vehicle, ensuring it remains a trusted companion on the road.

Aftermarket vs. OEM Parts Comparison

The choice between alternative and original components is a critical decision for vehicle maintenance and performance. Each option presents distinct advantages and drawbacks that can impact overall functionality and longevity.

Alternative components often provide cost savings and a wider selection, appealing to budget-conscious consumers. They may also offer enhancements not available through original sources. However, quality can vary significantly, requiring careful research to ensure reliability.

Original components, on the other hand, are designed to meet specific manufacturer standards, ensuring compatibility and performance. While typically more expensive, they often come with warranties that offer peace of mind. Ultimately, the decision hinges on individual needs, budget constraints, and desired performance outcomes.

Diagnostic Tools for Transmission Problems

Identifying issues within a vehicle’s gear system requires specialized equipment and techniques. Utilizing the right diagnostic tools can significantly streamline the troubleshooting process, ensuring accurate assessments and timely repairs.

Essential Diagnostic Equipment

- OBD-II Scanner: Reads error codes from the vehicle’s computer.

- Pressure Gauge: Measures hydraulic pressure within the system.

- Multimeter: Assesses electrical components and circuits.

- Diagnostic Software: Provides in-depth analysis and live data streaming.

Steps for Effective Diagnosis

- Connect the OBD-II scanner to retrieve any stored codes.

- Inspect fluid levels and quality for signs of contamination.

- Test electrical connections and sensors using a multimeter.

- Use a pressure gauge to verify operational pressure during gear shifts.

Importance of Regular Transmission Check-ups

Maintaining a vehicle’s essential systems is crucial for optimal performance and longevity. Regular assessments of critical components help prevent potential issues, ensuring smooth operation and reducing the risk of costly repairs.

Benefits of Regular Inspections

- Identifies wear and tear early

- Improves overall vehicle efficiency

- Enhances safety on the road

- Increases resale value

Recommended Frequency

- Annual check-ups for standard use

- Bi-annual assessments for heavy usage

- Before long trips or significant weather changes