Comprehensive Guide to 2008 Ford Escape Transmission Parts Diagram

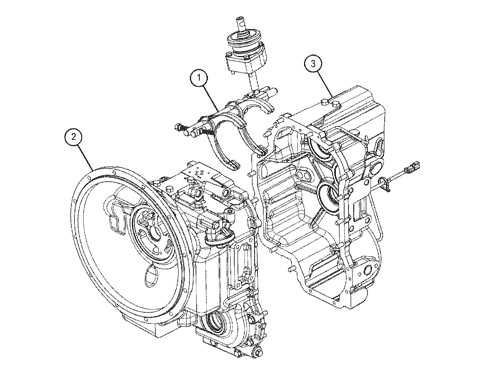

In the intricate world of automotive engineering, the functionality of a vehicle relies heavily on the various elements that work in harmony within its gear mechanism. This complex assembly not only facilitates smooth motion but also ensures optimal performance under diverse driving conditions. Understanding these individual components is essential for both enthusiasts and professionals alike.

Exploring the intricate layout of the gear arrangement can reveal the essential role each piece plays in the overall efficiency of the system. From the primary gears to the intricate linkages, every element contributes to the seamless operation of the vehicle, providing a blend of power and control. A clear representation of these components can aid in troubleshooting and maintenance, making it a valuable resource for anyone engaged in automotive care.

As we delve deeper into the specifics of these mechanisms, we will uncover the interconnections that make up the assembly. Whether you are looking to repair, replace, or simply understand how these components function together, having a visual reference can significantly enhance your comprehension and proficiency in dealing with automotive issues.

Overview of 2008 Ford Escape Transmission

This section provides a comprehensive look at the mechanism responsible for power transfer within a specific vehicle model. Understanding this component is crucial for maintaining optimal performance and ensuring smooth operation. The functionality, design, and key features play a significant role in driving dynamics.

The assembly in question utilizes advanced engineering to manage the flow of power from the engine to the wheels. Its intricate design comprises several critical elements that work together seamlessly. Regular maintenance and awareness of potential issues can enhance longevity and reliability.

With various configurations available, this system offers different performance characteristics suited for diverse driving conditions. Knowing the specifications and common challenges associated with this assembly can aid in troubleshooting and repairs, ultimately contributing to a better driving experience.

Understanding Transmission Components

Grasping the various elements within a vehicle’s shifting mechanism is essential for both enthusiasts and professionals. These components work together to ensure seamless power transfer from the engine to the wheels, enhancing performance and efficiency. A deeper comprehension of these parts can aid in maintenance and troubleshooting.

Main Components Overview

The primary elements of a shifting system include gears, clutches, and hydraulic systems. Each part plays a crucial role in the overall functionality and effectiveness of the mechanism. Understanding how these pieces interact can lead to improved vehicle performance and longevity.

| Component | Function |

|---|---|

| Gears | Control the speed and torque delivered to the wheels. |

| Clutches | Engage and disengage power flow between the engine and gears. |

| Hydraulic System | Facilitates the operation of clutches and gears through fluid pressure. |

Importance of Regular Maintenance

Regular upkeep of these components is vital for optimal performance. Neglecting maintenance can lead to premature wear and potential failure, resulting in costly repairs. Understanding the importance of each part can empower vehicle owners to take proactive steps in preserving their machinery.

Importance of Transmission Diagrams

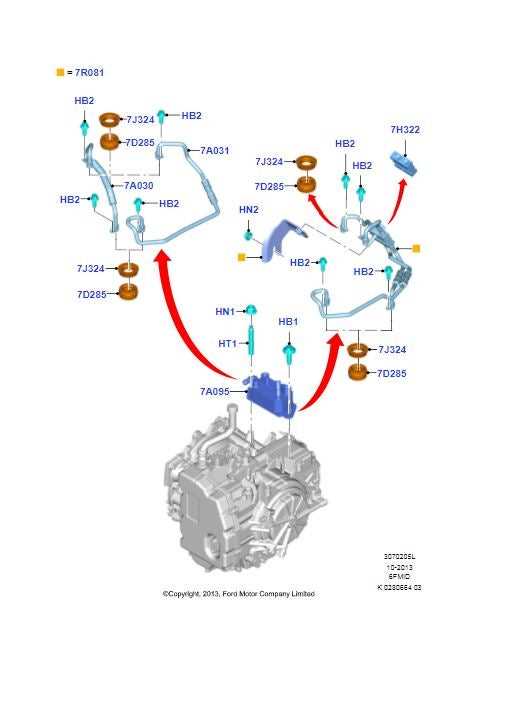

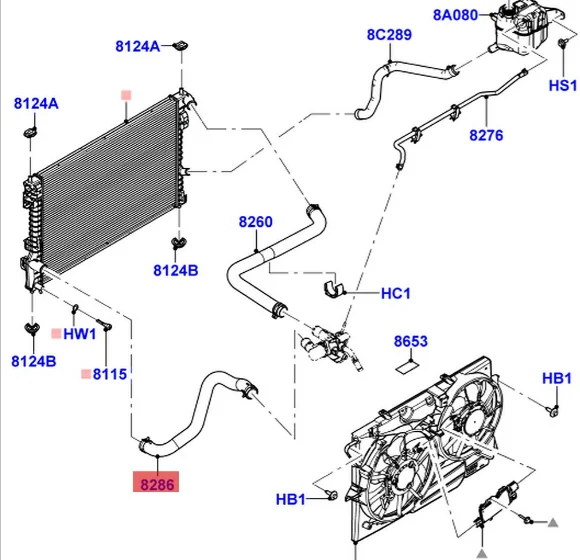

Understanding the layout and functionality of vehicle components is crucial for both mechanics and enthusiasts. Detailed schematics serve as invaluable tools that illustrate the relationships and interactions between various elements within the system. They provide clarity, enabling users to visualize complex assemblies and troubleshoot issues effectively.

These visual aids facilitate efficient repairs and maintenance by highlighting critical connections and pathways. With a well-structured representation, individuals can pinpoint potential failure points, making diagnostics quicker and more accurate. Additionally, they assist in the assembly and disassembly processes, ensuring that each part is correctly positioned and aligned.

Moreover, comprehensive schematics support learning and training. For newcomers to the automotive field, they serve as educational resources that enhance understanding of mechanical principles and system operations. By studying these illustrations, aspiring technicians can develop a deeper appreciation for the intricacies of vehicle engineering.

Ultimately, the availability of clear and precise illustrations not only aids in practical applications but also fosters a greater respect for automotive design and technology. This knowledge empowers individuals to maintain their vehicles effectively and make informed decisions about repairs and modifications.

Common Issues with 2008 Escape Transmissions

The vehicle’s shifting mechanism can encounter several challenges that impact performance and reliability. Understanding these issues can help owners anticipate problems and maintain their vehicles more effectively.

Frequent Problems

Drivers often report a range of difficulties, including slipping gears, delayed engagement, and unusual noises. These symptoms can arise from various factors, such as fluid leaks or worn components.

| Issue | Symptoms | Potential Causes |

|---|---|---|

| Slipping Gears | Loss of power, engine revs increase | Low fluid levels, worn clutches |

| Delayed Engagement | Hesitation when shifting | Contaminated fluid, valve body issues |

| Unusual Noises | Grinding, whining sounds | Faulty bearings, low lubrication |

Maintenance Tips

Regular inspections and fluid changes can mitigate many of these issues. Keeping an eye on fluid levels and listening for unusual sounds can help catch problems early, ensuring smoother operation and extending the life of the system.

Parts Replacement and Maintenance Tips

Ensuring the longevity and reliability of your vehicle requires a keen focus on its components and regular upkeep. Understanding when and how to replace essential elements can prevent significant issues down the road, ultimately saving time and money.

Regular Inspection: Conduct routine checks on vital components to catch wear and tear early. Look for signs of damage or excessive wear, such as leaks or unusual noises, which can indicate that a replacement is necessary.

Quality Components: Always opt for high-quality replacements. Using subpar materials can lead to further complications and reduce the lifespan of your vehicle. Research brands and consult reviews to make informed choices.

Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule outlined in the owner’s manual. This includes specific intervals for inspections and replacements, ensuring that each component remains in optimal condition.

Proper Tools: Utilize the correct tools for installation and removal. Using inappropriate equipment can cause additional damage and complicate the replacement process.

Seek Professional Help: If you’re uncertain about any aspect of the maintenance process, don’t hesitate to consult a professional. Their expertise can prevent mistakes and provide peace of mind.

By implementing these strategies, you can ensure that your vehicle operates smoothly and efficiently, enhancing both performance and safety on the road.

How to Read Transmission Diagrams

Understanding schematic representations of complex mechanical systems is essential for effective maintenance and repair. These visual aids provide insight into the arrangement and functionality of various components, making it easier to troubleshoot issues or plan upgrades.

Here are some key steps to help you interpret these visual representations:

- Familiarize Yourself with Symbols: Different symbols represent specific elements. Learning these will make it easier to understand the overall layout.

- Identify the Main Components: Focus on the primary parts illustrated, such as gears, levers, and fluid pathways. Recognizing their roles will aid in understanding how they interact.

- Follow the Flow: Many diagrams depict the direction of fluid movement or mechanical force. Tracing these paths can clarify the sequence of operations.

Consider the following tips for deeper comprehension:

- Use a Legend: Most diagrams come with a key that explains the symbols used. Refer to it frequently.

- Practice with Real Examples: Hands-on experience with physical systems alongside diagrams can solidify your understanding.

- Consult Technical Manuals: Additional documentation can provide context and detail that enriches your interpretation.

By developing these skills, you will enhance your ability to work with intricate mechanical systems efficiently and effectively.

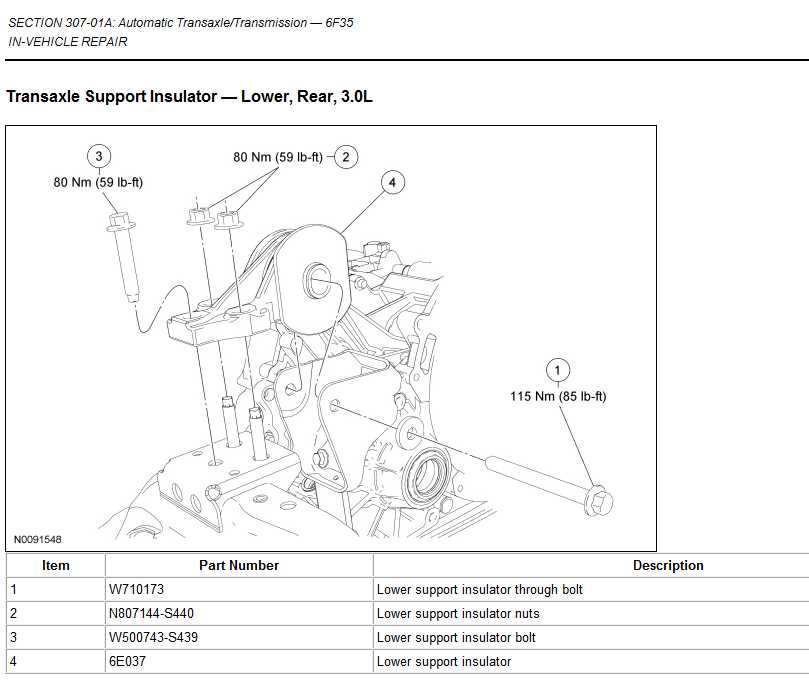

Step-by-Step Repair Process

This section provides a comprehensive guide to addressing issues related to a specific vehicle’s shifting mechanism. Following a systematic approach ensures that each step is executed efficiently, resulting in a successful restoration of functionality.

1. Preparation: Begin by gathering all necessary tools and components. Ensure that you have a clean workspace and adequate lighting to facilitate the repair process.

2. Diagnosis: Identify the underlying problem through a thorough inspection. Check for any leaks, unusual noises, or warning lights that may indicate specific faults.

3. Disassembly: Carefully remove the components surrounding the mechanism. Document the order of removal to aid in reassembly later. Use appropriate safety measures, such as gloves and goggles.

4. Component Inspection: Examine each part for wear and damage. Pay close attention to seals, gears, and electrical connections. Replace any defective items as necessary.

5. Cleaning: Clean all disassembled parts using suitable solvents to remove dirt and debris. Ensure all surfaces are free from contaminants before reassembly.

6. Reassembly: Follow the documentation created during disassembly to reassemble the mechanism. Ensure all components fit securely and are aligned correctly.

7. Testing: Once reassembled, conduct tests to verify proper functionality. Check for leaks, responsiveness, and overall performance.

8. Final Inspection: Perform a thorough check of the entire assembly to confirm everything is in order. Make any necessary adjustments before closing up the workspace.

Tools Needed for Transmission Work

When tackling the complexities of vehicle gear systems, having the right equipment is essential for a successful and efficient process. Proper tools not only enhance accuracy but also ensure safety throughout the task. Below is a list of must-have instruments that will aid in the disassembly, inspection, and reassembly of gear assemblies.

- Wrenches: A variety of sizes, including adjustable and socket wrenches, are crucial for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for accessing components secured with screws.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

- Pliers: Needle-nose and regular pliers can help grip and manipulate small parts effectively.

- Fluid Extraction Pump: Essential for removing old fluids and replacing them with new ones, maintaining system efficiency.

- Safety Equipment: Gloves, goggles, and a mechanic’s apron to protect against debris and harmful substances.

Utilizing the correct tools will streamline the procedure and reduce the risk of errors, ultimately leading to a more reliable outcome. Preparing in advance will save time and effort, allowing for a smoother experience.

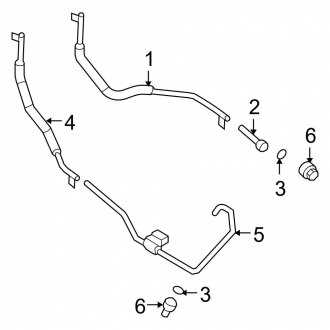

Identifying Transmission Fluid Leaks

Detecting fluid leaks is crucial for maintaining the health of your vehicle’s drivetrain. Over time, various components can wear out or become damaged, leading to potential issues that may affect performance and safety. Recognizing the signs of leakage early can save you from costly repairs and ensure smooth operation.

Common Indicators: Look for reddish-brown stains under the vehicle, especially after it has been parked. These stains are often indicative of fluid seepage. Additionally, a distinct burnt smell or difficulty in shifting gears can signal an underlying problem.

Visual Inspection: Regularly check the area around the gearbox and adjacent seals for any signs of fluid accumulation. If you notice a residue, it could point to a failing gasket or a loose connection. A flashlight can help illuminate hard-to-reach areas for a more thorough examination.

Fluid Levels: Monitoring the fluid levels is essential. If you find yourself needing to top off frequently, this might suggest a leak. Always ensure that you are using the correct type of fluid, as specified by the manufacturer, to maintain optimal functionality.

Professional Assistance: If you’re uncertain about diagnosing the issue, it’s advisable to seek help from a qualified mechanic. They can perform a detailed inspection and address any potential concerns, providing peace of mind and ensuring your vehicle remains in excellent condition.

Upgrading Parts for Better Performance

Enhancing your vehicle’s capabilities often involves a strategic approach to improving specific components. By focusing on key elements of your drive system, you can achieve a noticeable boost in efficiency, responsiveness, and overall enjoyment of the ride. Below are some areas to consider when aiming for optimal performance.

- Improved Gear Set: Switching to a more efficient gear ratio can enhance acceleration and fuel economy.

- Enhanced Cooling Systems: Upgrading to a high-performance cooler helps maintain optimal operating temperatures, reducing wear and tear.

- High-Quality Fluids: Using specialized lubricants can lower friction and extend the life of crucial components.

Additionally, consider the following modifications to further refine performance:

- Lightweight Flywheel: This upgrade can decrease rotational mass, allowing for quicker revs and improved throttle response.

- Stronger Torque Converter: A high-stall converter can provide better power transfer, especially during acceleration.

- Performance Modifications: Tweaking the ECU for enhanced tuning can optimize power delivery and efficiency.

Investing in these enhancements not only improves performance but also contributes to a more exhilarating driving experience. Careful consideration of each component’s role will lead to a more cohesive and responsive vehicle.

Comparing Automatic and Manual Transmissions

When it comes to choosing the right drivetrain for a vehicle, the decision often boils down to the type of gear-shifting mechanism. Each system offers distinct characteristics that cater to different driving preferences and styles. Understanding these differences can help drivers make an informed choice suited to their needs.

Here are some key points of comparison between the two systems:

- Driving Experience:

- Automatic systems provide a more relaxed and hands-free driving experience.

- Manual systems offer a sense of control and engagement with the vehicle.

- Fuel Efficiency:

- Modern automatic systems have improved fuel efficiency, often rivaling manuals.

- Manual systems traditionally offer better fuel economy in certain conditions.

- Maintenance:

- Automatic systems may require more frequent servicing due to their complexity.

- Manual systems are generally simpler, which can lead to lower maintenance costs.

- Performance:

- Automatic systems can shift gears faster, benefiting performance in many scenarios.

- Manual systems allow for more driver control, which can enhance performance in skilled hands.

- Cost:

- Vehicles with automatic systems tend to be more expensive initially.

- Manual-equipped vehicles can be more affordable both in purchase price and repair costs.

Ultimately, the choice between these two types depends on personal preference and driving habits. Understanding the strengths and weaknesses of each can aid in selecting the most suitable option for your driving lifestyle.

Resources for Further Learning

For those interested in deepening their understanding of automotive systems, a variety of resources are available. These materials encompass books, online courses, forums, and technical manuals, providing a well-rounded foundation for both beginners and seasoned enthusiasts. Exploring these options can enhance your knowledge and skills significantly.

Below is a table highlighting some valuable resources:

| Resource Type | Description | Recommended Links |

|---|---|---|

| Books | Comprehensive guides covering various automotive topics. | Amazon |

| Online Courses | Interactive courses designed for practical learning. | Udemy |

| Forums | Community-driven platforms for sharing knowledge and troubleshooting. | AutoTrader Forums |

| Technical Manuals | In-depth documentation for specific vehicle models. | Haynes |

Utilizing these resources can provide a comprehensive understanding of vehicle mechanics and enhance problem-solving abilities, making it easier to tackle automotive challenges effectively.