Understanding the 41TE Transmission Parts Diagram

The intricate mechanisms that drive modern vehicles often go unnoticed by the average driver. Yet, these components play a crucial role in ensuring smooth operation and overall performance. Gaining insight into these systems can greatly enhance one’s appreciation for automotive engineering.

In this exploration, we will delve into various essential elements that contribute to the functionality of a specific automotive assembly. By examining their arrangement and interaction, we can uncover the ultimate significance of each segment within the whole.

Whether you’re a seasoned mechanic or an enthusiastic hobbyist, understanding these components can empower you with knowledge for better maintenance and repair. Join us as we dissect this fascinating subject and illuminate the paths through which power is transmitted within the vehicle.

Understanding the 41TE Transmission

This section explores the intricacies of a specific automotive component crucial for smooth vehicle operation. Its design plays a vital role in enhancing performance and efficiency, allowing seamless gear shifts and contributing to overall drivability. Understanding its functionality and construction is essential for both enthusiasts and professionals alike.

Key Components and Their Functions

A variety of elements work in harmony within this system, each serving a distinct purpose. Key components include clutches, gears, and hydraulic systems, which interact to facilitate the transfer of power from the engine to the wheels. Mastery of these elements allows for improved maintenance and repair strategies.

Troubleshooting Common Issues

Recognizing typical malfunctions can prevent more significant problems down the road. Symptoms such as slipping or unusual noises may indicate underlying concerns requiring immediate attention. Familiarity with these indicators can lead to timely interventions, ensuring the longevity and reliability of the entire assembly.

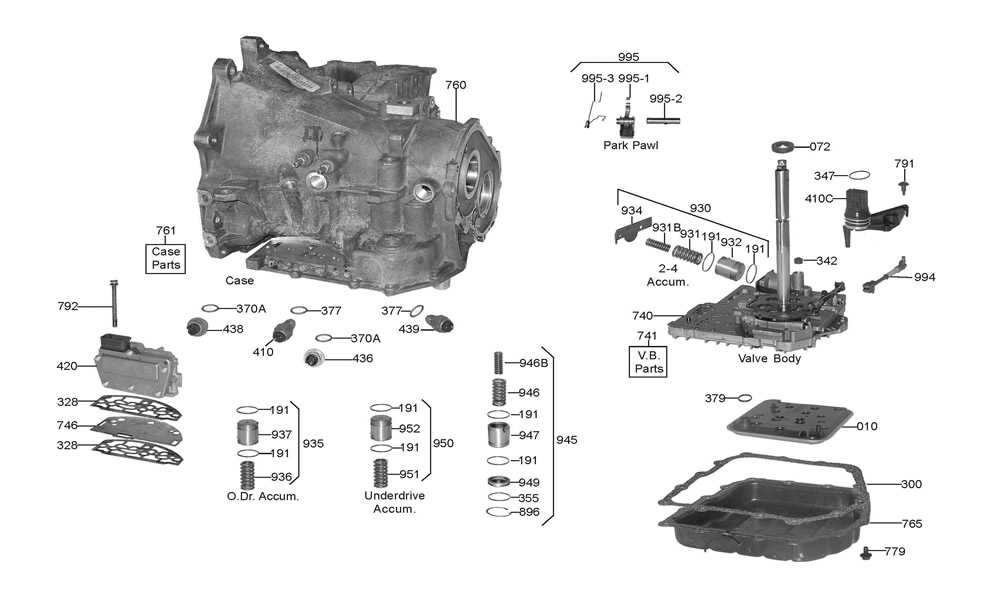

Overview of Transmission Components

This section provides a comprehensive understanding of the essential elements involved in the mechanism responsible for power transfer in vehicles. Each component plays a vital role in ensuring efficient operation, enabling smooth shifts and optimal performance.

Key Elements

- Gear Sets: These are crucial for altering torque and speed, allowing for adjustments based on driving conditions.

- Clutches: They facilitate the engagement and disengagement of gears, ensuring seamless transitions during acceleration or deceleration.

- Sensors: Modern systems rely on various sensors to monitor parameters like speed and load, helping to optimize performance.

- Control Modules: These electronic units process data and command the system to function efficiently.

Supporting Elements

- Fluid Pump: Responsible for circulating hydraulic fluid, which is essential for pressure generation.

- Valve Body: Acts as a central hub that directs fluid flow to different components.

- Filters: Maintain fluid cleanliness, protecting the system from debris and contaminants.

Understanding these components helps in diagnosing issues and enhancing the overall efficiency of the power delivery system in vehicles.

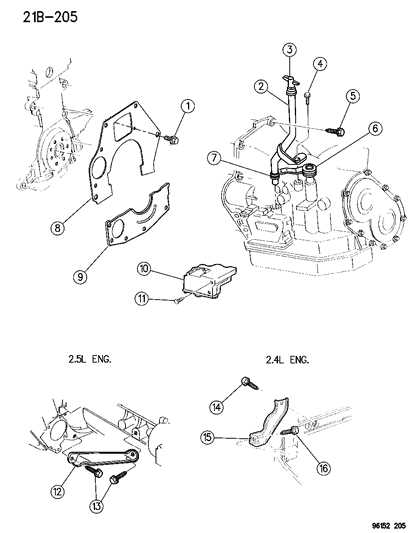

Key Features of 41TE Design

The design of this particular mechanism encompasses a range of innovative attributes that enhance performance and reliability. These characteristics are integral to its functionality, contributing to smoother operation and increased durability under various conditions.

Compact Structure: One of the most notable aspects is its compact architecture, which allows for efficient use of space while maintaining robust performance. This design choice facilitates easier installation and integration into diverse vehicles.

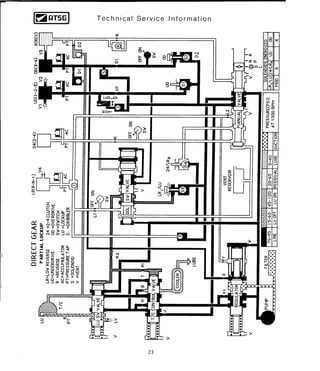

Advanced Fluid Dynamics: The system incorporates sophisticated fluid management techniques, optimizing hydraulic performance. This advancement ensures precise shifting and contributes to the overall efficiency of the unit.

Durability and Strength: The materials selected for construction emphasize resilience, enabling the unit to withstand high-stress scenarios. This characteristic significantly extends the lifespan of the mechanism, reducing the frequency of repairs.

Smart Control Systems: Integration with modern electronic control units enhances adaptability. These smart systems allow for real-time adjustments, improving response times and overall driving experience.

Maintenance Accessibility: Designed with user convenience in mind, the layout promotes straightforward access for maintenance tasks. This feature simplifies servicing, leading to reduced downtime and operational costs.

Importance of Transmission Diagrams

Understanding the intricate mechanics of a vehicle’s system is essential for effective maintenance and repair. Visual representations serve as invaluable tools, providing clear insights into the components and their interrelations. These illustrations not only simplify complex structures but also enhance the overall comprehension of how each element functions together.

Enhanced Problem Solving

When encountering issues, having a visual reference can significantly streamline troubleshooting processes. Technicians can quickly identify potential failures or misalignments by examining the layout. This approach not only saves time but also reduces the likelihood of errors during repairs, ensuring a more efficient workflow.

Educational Value

For learners and professionals alike, these graphical representations serve as educational resources. They facilitate a deeper understanding of mechanics, allowing individuals to visualize the interaction between various components. This knowledge is crucial for anyone aiming to master vehicle maintenance or repair.

In summary, graphical representations are essential in the automotive field, promoting efficient problem-solving and enhancing educational experiences.

Common Parts in 41TE Systems

Understanding the components of a specific power delivery system is essential for efficient operation and maintenance. This system relies on various elements that work in tandem to ensure smooth functionality. Each part plays a crucial role in the overall performance and longevity of the mechanism.

| Component Name | Description |

|---|---|

| Planetary Gear Set | Facilitates gear ratio changes for different driving conditions, enhancing torque and speed. |

| Torque Converter | Enables smooth acceleration by multiplying engine torque and providing a fluid coupling between the engine and the drivetrain. |

| Clutch Packs | Engage and disengage various gears, allowing for seamless transitions during shifting. |

| Control Module | Monitors system performance and coordinates the operation of various components for optimal efficiency. |

| Oil Pump | Supplies hydraulic pressure necessary for the operation of the clutch packs and other hydraulic components. |

Familiarity with these elements aids in troubleshooting and enhancing the overall reliability of the system. Regular maintenance and understanding of their functions can prevent potential failures and ensure a smoother driving experience.

Functionality of Transmission Gears

Gears play a crucial role in the mechanism that facilitates the transfer of power within a vehicle. Their primary function is to adjust the torque and speed, enabling the engine’s output to be effectively utilized across various driving conditions. This allows for smoother acceleration, enhanced fuel efficiency, and improved overall performance.

Types of Gears and Their Roles

Different types of gears serve specific purposes within the system. For instance, reduction gears increase torque while decreasing speed, making them essential for heavy loads or steep inclines. Conversely, overdrive gears allow for higher speeds with reduced engine strain, optimizing fuel consumption during highway driving.

Interplay Between Gears

The interaction between various gear ratios is vital for achieving seamless shifts and maintaining engine efficiency. By selecting the appropriate gear, the driver can ensure that the vehicle responds effectively to varying demands, whether accelerating quickly or maintaining a steady pace. This intricate balance enhances both performance and drivability.

Transmission Fluid and Its Role

Fluids play a crucial role in the smooth operation of various mechanical systems, ensuring efficiency and longevity. Among these, a specific type of liquid is essential for facilitating movement and reducing friction between components. Understanding its function helps in maintaining the overall health of the machinery.

This vital liquid serves several key purposes:

- Lubrication: It minimizes wear and tear by providing a slippery coating between moving parts.

- Cooling: It dissipates heat generated during operation, preventing overheating and potential damage.

- Hydraulic Function: It enables the transfer of force within the system, allowing for efficient operation.

- Contaminant Removal: It helps to flush out debris and particles, maintaining cleanliness within the assembly.

Choosing the right type of liquid is essential for optimal performance. Various formulations exist, each designed to cater to specific requirements:

- Standard Fluids: Suitable for general use in most systems.

- High-Performance Options: Engineered for demanding applications, offering enhanced protection and longevity.

- All-Season Formulations: Designed to perform well under varying temperature conditions.

Regular maintenance and monitoring of fluid levels are critical to ensure continued efficiency. Neglecting this aspect can lead to significant issues, including reduced performance and increased risk of failure. Therefore, understanding the role of this essential liquid is fundamental for anyone looking to maintain their mechanical systems effectively.

Identifying Wear and Tear Issues

Recognizing signs of deterioration is crucial for maintaining optimal performance and longevity of your vehicle’s mechanical systems. Regular inspections can reveal subtle changes that, if left unaddressed, might lead to more significant problems down the line.

Common Indicators of Deterioration

Look for unusual noises, vibrations, or fluid leaks as initial warnings. Unusual sounds, such as grinding or whining, often signal that components are struggling. Fluid leaks can indicate seal failures or improper functioning, necessitating immediate attention.

Inspection Techniques

Regular visual assessments, combined with tactile checks, can uncover wear patterns that are not immediately visible. Ensure to examine surfaces for cracks and deformations, which may suggest excessive wear. Documenting your findings will help track changes over time, aiding in proactive maintenance.

Replacement Parts for 41TE

When it comes to maintaining the functionality of your vehicle’s shifting system, ensuring the right components are in place is crucial. Over time, wear and tear can affect performance, leading to the need for specific replacements. This section focuses on the essential elements necessary for restoring optimal operation, highlighting options for quality substitutions that guarantee reliability.

Key elements include the hydraulic mechanisms, electronic controls, and structural supports that collectively influence efficiency. When selecting new components, it’s vital to consider both compatibility and durability. Original equipment manufacturers and trusted aftermarket suppliers offer a variety of choices, making it easier to find the perfect fit for your vehicle’s needs.

Regular maintenance checks can help identify potential issues early, allowing for timely replacements that prevent more significant problems down the line. Always consult professional resources or experienced technicians to ensure the right choices are made, keeping your vehicle running smoothly for years to come.

Maintenance Tips for Longevity

Ensuring the durability of your mechanical systems requires consistent care and attention. Implementing effective maintenance practices can significantly extend the lifespan of crucial components, preventing costly repairs and replacements. By focusing on regular inspections and timely servicing, you can optimize performance and reliability.

Regular Inspections

Conducting routine assessments of key elements can help identify potential issues before they escalate. Look for signs of wear and tear, and address them promptly to maintain efficiency.

Fluid Management

Maintaining appropriate fluid levels and quality is essential for optimal function. Regularly check and change fluids as recommended to ensure smooth operation.

| Tip | Frequency | Action |

|---|---|---|

| Inspect components | Monthly | Look for damage or leaks |

| Check fluid levels | Weekly | Top up or replace as necessary |

| Professional service | Annually | Schedule comprehensive check-up |

Diagnosing Transmission Problems

Identifying issues within the shifting mechanism of a vehicle can be complex, requiring attention to various symptoms. Understanding the signs can lead to quicker resolutions and improved performance.

- Unusual Noises: Grinding, whining, or clunking sounds may indicate internal damage.

- Fluid Leaks: Puddles or spots beneath the vehicle can signal leaks, potentially leading to severe issues.

- Slipping Gears: If the vehicle unexpectedly changes gears, it may suggest worn components.

- Warning Lights: Dashboard alerts can provide early warnings of underlying problems.

To delve deeper, it’s essential to observe driving habits and the conditions under which issues arise. Regular checks can ultimately prevent larger repairs.

Resources for Further Study

Expanding your knowledge in automotive systems can be greatly enhanced by exploring a variety of materials and references. This section provides valuable resources that will help deepen your understanding of mechanical components and their functions.

Books

Consider the following titles for comprehensive insights:

| Title | Author |

|---|---|

| Automotive Technology: A Systems Approach | Jack Erjavec |

| Fundamentals of Automotive Technology | William Crouse |

Online Resources

Utilize these websites for tutorials and articles:

| Resource | Description |

|---|---|

| HowStuffWorks | Detailed explanations of mechanical operations. |

| SAE International | Technical papers and industry standards. |