Understanding the 5 Speed Peerless Transmission Parts Diagram

The intricacies of mechanical assemblies often captivate those interested in engineering and automotive design. A comprehensive examination of a specific five-gear system reveals essential elements that contribute to its functionality. By delving into the various components, one can appreciate how they work together to achieve optimal performance.

Identifying the individual elements within this mechanism is crucial for anyone looking to enhance their understanding or carry out repairs. Each component serves a unique purpose, playing a vital role in the overall operation. Grasping the relationship between these elements offers valuable insights into the mechanics at play.

In this article, we will explore a detailed breakdown of the five-gear assembly, highlighting its unique characteristics and functionalities. By visualizing the arrangement and interaction of these components, you can gain a deeper understanding of how they contribute to seamless operation.

Understanding 5 Speed Peerless Transmissions

This section delves into the mechanics of a specific type of gear system commonly used in various machinery. By exploring its fundamental components and their interactions, we can gain insights into how these systems enhance performance and efficiency.

Key features of this system include:

- Multiple gear ratios allowing for versatility in operation.

- A compact design that maximizes space utilization.

- Robust construction ensuring durability and reliability.

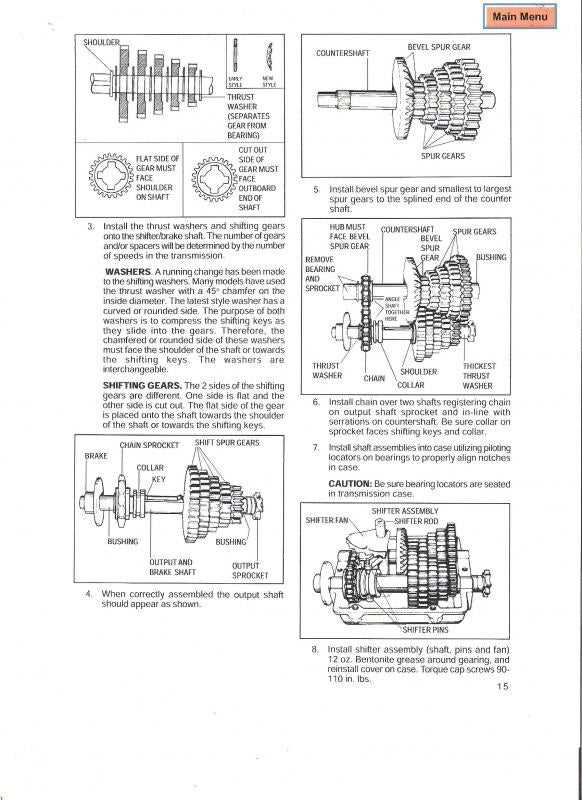

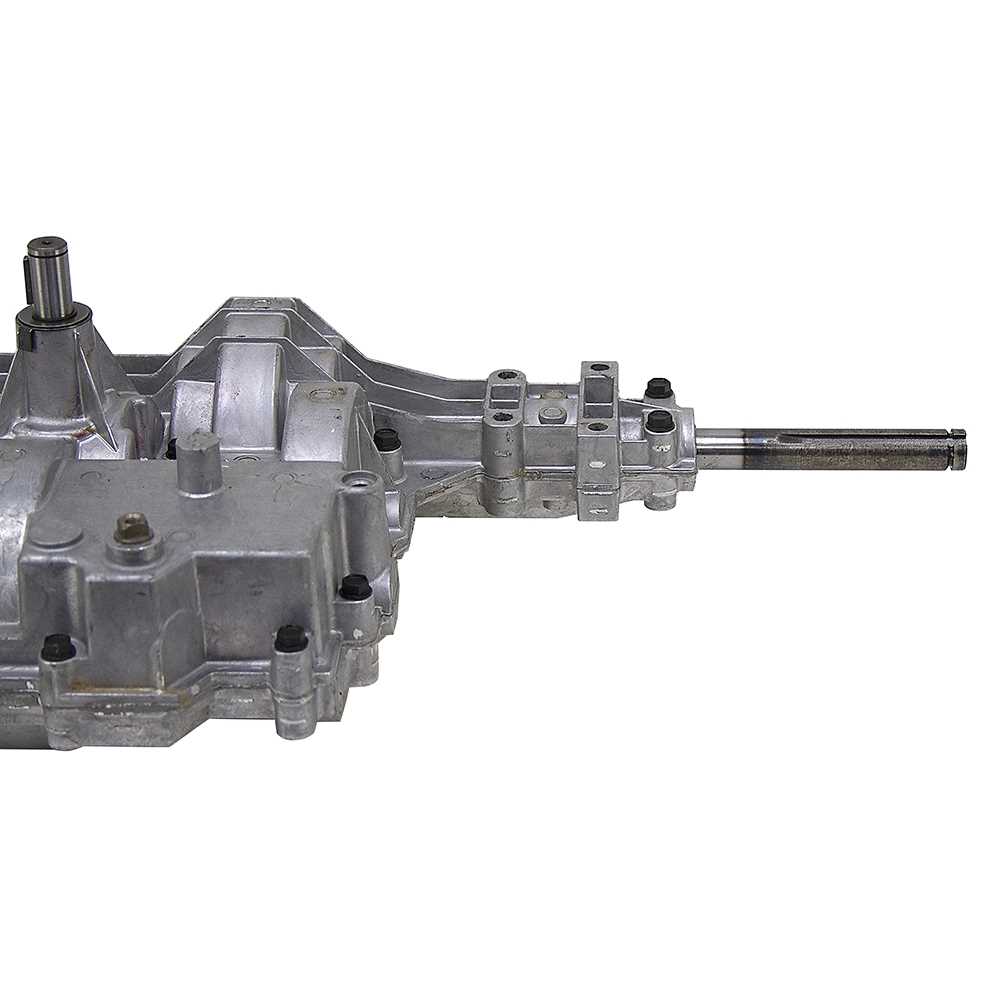

To fully appreciate the functionality of this system, it is essential to understand its major elements:

- Input Shaft: The entry point for power, crucial for initiating movement.

- Gear Cluster: A set of gears that engage to change the torque and velocity transmitted.

- Output Shaft: The component that delivers power to the wheels or other machinery.

- Shifting Mechanism: Allows the operator to select different gear ratios smoothly.

Understanding these components and their functions will provide a comprehensive overview of how this mechanical system operates efficiently in various applications.

Key Components of Peerless Transmissions

The essential elements that contribute to the functionality of a drive system are crucial for understanding how power is transmitted efficiently. Each component plays a significant role in ensuring smooth operation and optimal performance.

Gear Mechanisms are fundamental, as they facilitate the transfer of energy from the engine to the wheels. The arrangement of these gears determines the torque and rotational speed delivered to the output.

Shafts are integral for connecting various components within the assembly. They provide a stable pathway for motion and ensure that power is effectively directed throughout the system.

Bearings support the rotating shafts, reducing friction and wear. Their quality directly affects the longevity and reliability of the mechanism, making them vital for sustained performance.

Clutch Systems enable the engagement and disengagement of power flow. This functionality is essential for smooth operation, particularly during shifting and stopping.

Housing serves as the protective shell for all components, safeguarding them from external elements and providing structural integrity. Its design also aids in the efficient dispersal of heat generated during operation.

Understanding these components enhances the ability to troubleshoot issues and improve performance, ultimately leading to a more reliable and efficient drive experience.

Common Issues with Transmission Parts

Mechanical systems often encounter various challenges that can hinder their performance. Understanding these common difficulties is crucial for effective maintenance and repair. Below are some frequent issues observed in the components of these systems.

- Wear and Tear: Over time, certain elements may degrade due to friction and usage.

- Fluid Leaks: Seals and gaskets can fail, leading to fluid loss which affects functionality.

- Overheating: Insufficient lubrication or cooling can cause overheating, resulting in damage.

- Noise Issues: Unusual sounds may indicate misalignment or component failure.

- Shifting Difficulties: Problems with engagement can arise from worn components or hydraulic issues.

Regular inspection and timely intervention can mitigate these problems, ensuring optimal performance and longevity of the system.

Benefits of Upgrading Transmission Components

Enhancing the internal mechanisms of your vehicle can lead to significant improvements in performance and efficiency. This process not only boosts the overall driving experience but also contributes to the longevity of the entire system. Below are key advantages of investing in upgraded components.

- Improved Performance: Higher quality components can lead to better responsiveness and acceleration, making your vehicle more enjoyable to drive.

- Increased Durability: Upgrading to robust materials can enhance the lifespan of your vehicle’s internal systems, reducing the need for frequent repairs.

- Enhanced Efficiency: Advanced technology often results in improved fuel efficiency, allowing for longer distances on less fuel.

- Smoother Operation: Newer components often reduce friction and wear, leading to a more seamless driving experience.

- Customizability: Upgraded mechanisms allow for tailored modifications, letting drivers optimize performance based on their individual needs.

In summary, upgrading critical components can transform the overall functionality and enjoyment of your vehicle, making it a worthwhile investment for any car enthusiast.

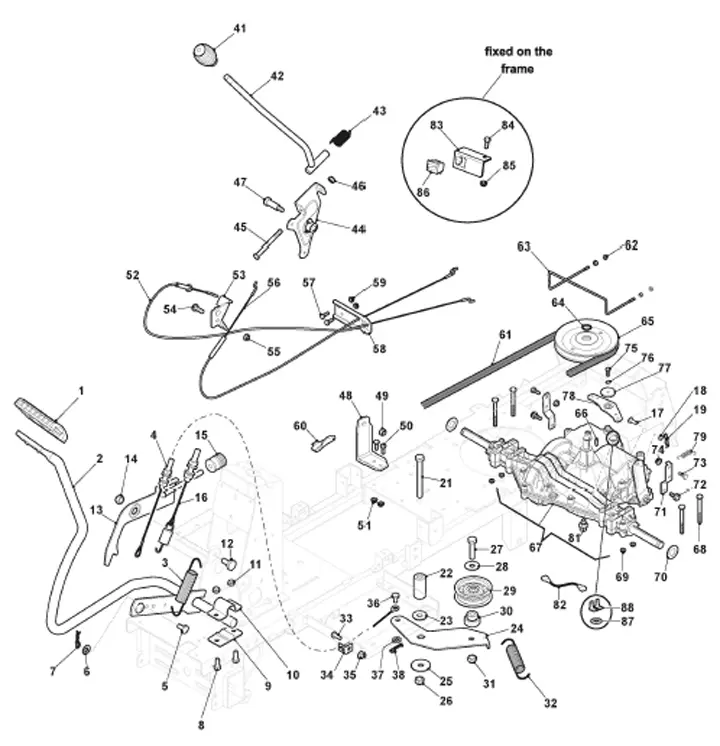

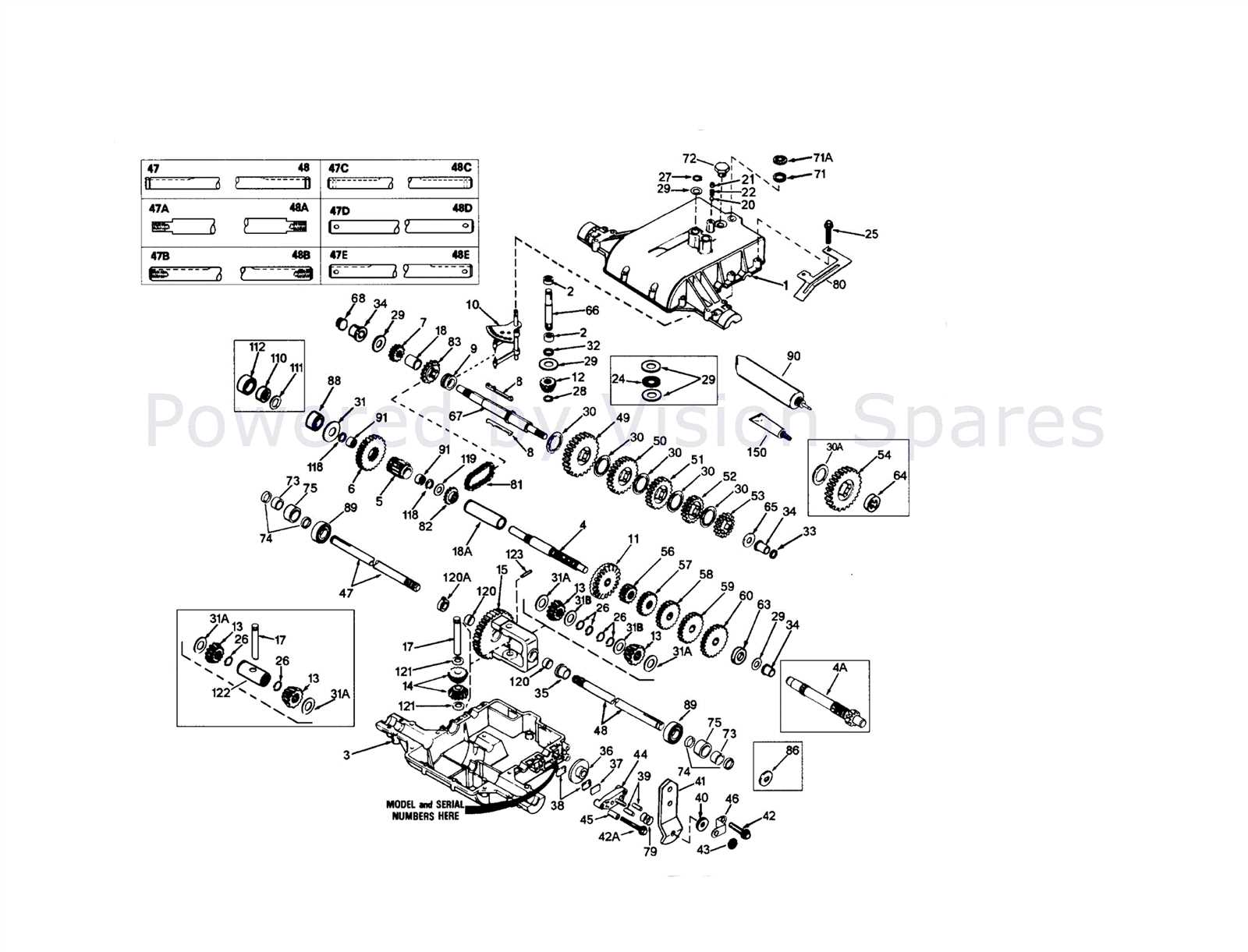

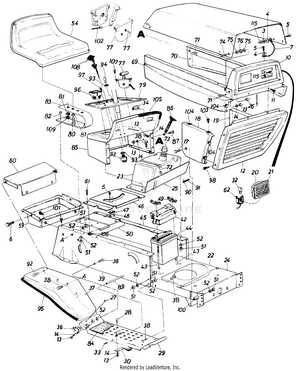

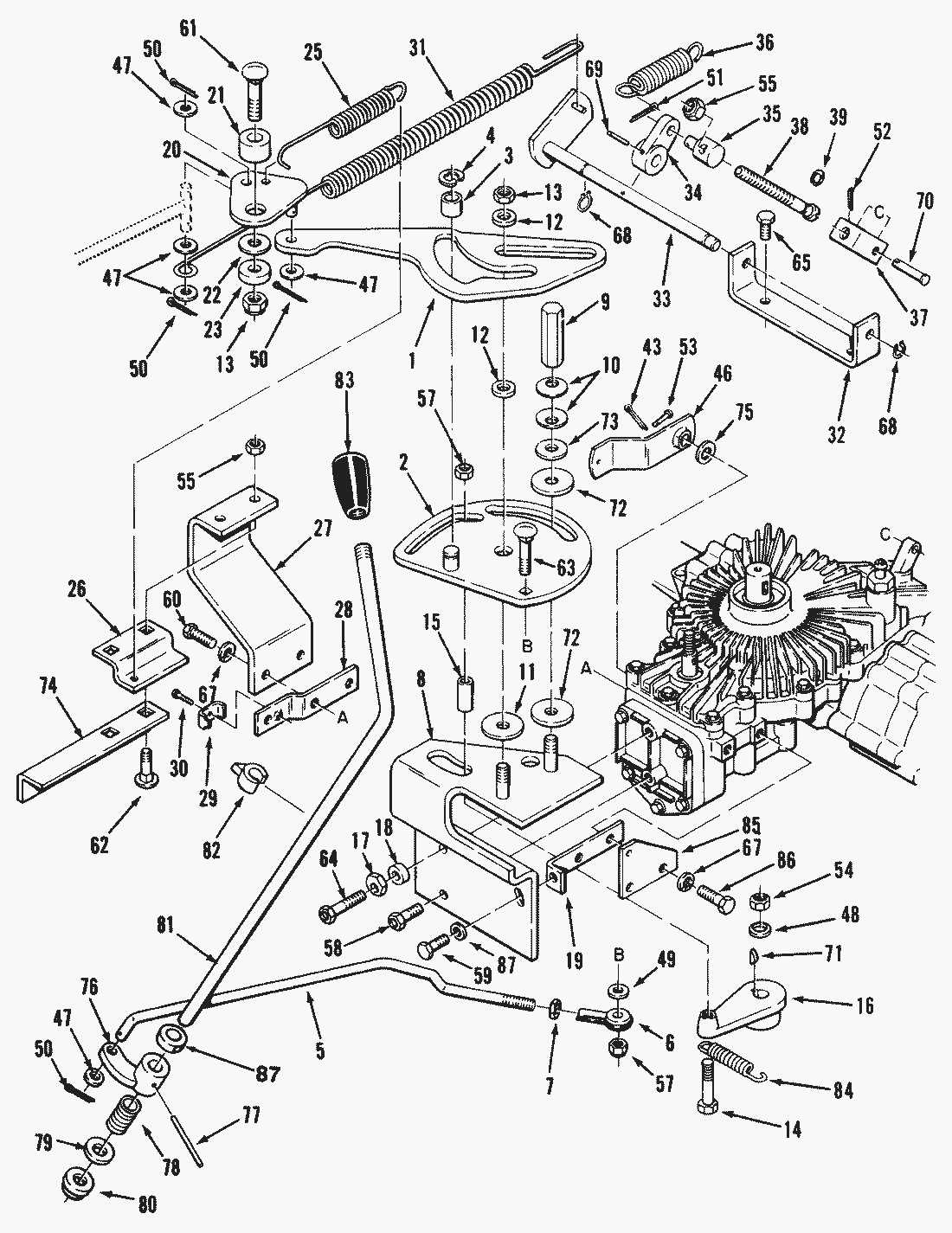

How to Read a Parts Diagram

Understanding an illustration of components can significantly enhance your ability to troubleshoot and repair machinery. By familiarizing yourself with the layout and symbols used, you can efficiently identify each element and its function, making your work much more manageable.

Key Elements to Note

- Labels: Each component typically has a label or number that corresponds to a list or key, providing clarity on what each part is.

- Connections: Look for lines or arrows that indicate how different elements interact or fit together.

- Grouping: Parts may be grouped based on their function or location, helping to organize the information logically.

Steps to Follow

- Start by reviewing the key or legend to understand the symbols used.

- Identify major sections of the assembly to orient yourself within the overall structure.

- Trace connections between components to comprehend their relationships and roles.

- Refer to the accompanying documentation for additional details on each item.

By mastering the interpretation of these illustrations, you can enhance your repair skills and improve the overall maintenance process.

Maintenance Tips for Transmission Longevity

Ensuring the durability of your vehicle’s essential components requires consistent care and attention. A well-maintained system enhances overall performance and reduces the likelihood of costly repairs. Following specific guidelines can significantly extend the lifespan of these intricate mechanisms.

Regular Fluid Checks

Frequent inspections of the lubricant levels are crucial. Maintaining the proper fluid ensures optimal functioning and reduces wear on internal elements. Replace the fluid at recommended intervals, as contamination can lead to serious issues over time.

Timely Inspections and Adjustments

Conduct routine examinations for signs of wear or damage. Addressing minor issues promptly can prevent more significant problems from developing. Additionally, periodic adjustments can help maintain proper alignment and functionality, contributing to the overall health of the system.

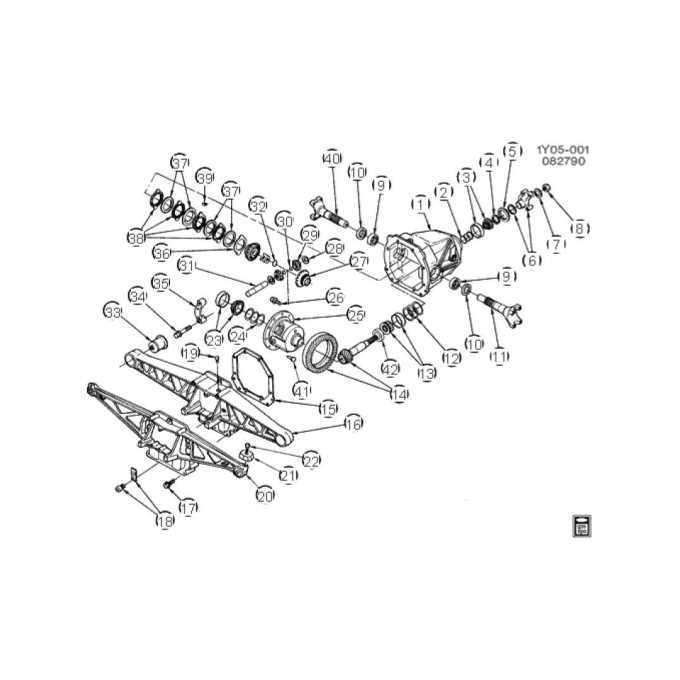

Identifying Wear and Tear in Parts

Understanding the signs of degradation in mechanical components is crucial for maintaining optimal performance and longevity. Regular inspection can reveal subtle changes that indicate the need for replacement or repair, ultimately preventing further damage and ensuring efficiency.

Visual Inspection is the first step in identifying deterioration. Look for signs of friction, such as discoloration or surface irregularities, which may suggest excessive wear. Cracks or chips can also indicate that a component has been subjected to undue stress.

Measurement Techniques play an important role in assessing the condition of components. Using tools like calipers or micrometers allows for precise measurements of critical dimensions, helping to identify any deviations from specifications that could lead to performance issues.

Operational Testing is essential for evaluating functionality. Unusual noises or vibrations during operation can be telltale signs of underlying problems. Monitoring performance metrics can also highlight inefficiencies caused by worn components.

Material Analysis provides deeper insights into wear patterns. Techniques such as hardness testing can reveal changes in material properties that indicate fatigue or degradation. Understanding these changes can guide decisions on maintenance and replacement.

By staying vigilant and employing these methods, one can effectively identify issues before they escalate, ensuring reliable operation and extending the life of critical components.

Choosing Quality Replacement Parts

When it comes to maintaining the performance of your machinery, selecting high-quality components is crucial. The longevity and efficiency of your equipment often depend on the reliability of these replacements. Opting for inferior substitutes can lead to premature failures, increased costs, and downtime, ultimately affecting your overall productivity.

Research is key to making informed choices. Before purchasing any component, it’s essential to investigate the manufacturer’s reputation. Look for brands that are known for their commitment to quality and durability. Customer reviews and testimonials can provide valuable insights into the experiences of others who have used these components.

Another factor to consider is compatibility. Ensure that the replacements you choose are specifically designed to fit your equipment. Mismatched components can result in inefficiencies and even damage to the machinery. Always verify specifications and consult your equipment’s documentation when necessary.

Price should not be the sole deciding factor. While it may be tempting to go for cheaper options, investing in quality components can save you money in the long run by reducing the need for frequent replacements and repairs. Assess the value each option brings and weigh it against its cost.

Lastly, consider the availability of customer support and warranties. Reputable manufacturers often provide assurances and assistance, which can be invaluable in case of issues. Choosing suppliers that stand behind their products can enhance your confidence in the components you select.

DIY Repair Guide for Transmission Issues

When faced with mechanical challenges in your vehicle’s shifting system, addressing them yourself can save both time and money. This guide aims to empower you with essential knowledge and steps to troubleshoot common malfunctions effectively. Understanding the underlying components and their functions will enhance your ability to diagnose and fix issues with ease.

1. Identify Symptoms: Begin by recognizing the signs of trouble. Unusual noises, difficulty in engaging gears, or slipping can all indicate underlying problems. Pay attention to any changes in performance to narrow down potential issues.

2. Gather Necessary Tools: Equip yourself with the right tools for the job. A socket set, wrenches, and a torque wrench are typically required. Additionally, having a repair manual specific to your vehicle can provide valuable insights.

3. Disassemble with Care: Once you have identified the issue, carefully disassemble the relevant components. Take photos or notes to remember the arrangement, which will help during reassembly. Keep track of all screws and small pieces to avoid losing them.

4. Inspect and Clean: Thoroughly examine the disassembled parts for wear or damage. Clean all components to remove debris and old lubricant, ensuring everything is free from contaminants. Replace any damaged items with new or refurbished ones as necessary.

5. Reassemble and Test: After making repairs, reassemble the system carefully, ensuring all parts fit snugly and securely. Once reassembled, conduct a test run to verify that the issues have been resolved. Monitor for any recurring symptoms.

By following these steps, you can tackle mechanical issues confidently and efficiently. With patience and attention to detail, many challenges can be addressed without professional assistance.

Expert Insights on Transmission Performance

Understanding the mechanics behind vehicle efficiency and functionality is essential for both enthusiasts and professionals in the automotive field. This section delves into various elements that influence the overall efficacy of gear systems, highlighting key considerations and innovations that can enhance performance.

Key Factors Affecting Performance

- Design and Engineering: The structural integrity and engineering precision of gear systems play a pivotal role in determining their operational effectiveness.

- Material Selection: High-quality materials can significantly reduce wear and tear, contributing to longevity and reliability.

- Calibration: Proper tuning and calibration ensure optimal functionality, aligning the system’s capabilities with vehicle requirements.

Innovations and Best Practices

- Regular Maintenance: Routine inspections and timely servicing can prevent issues before they escalate, maintaining peak performance.

- Advanced Lubrication: Utilizing superior lubricants reduces friction and heat, enhancing the lifespan of gear assemblies.

- Technological Integration: Implementing modern technologies, such as electronic controls and adaptive systems, can significantly improve responsiveness and efficiency.

By focusing on these essential aspects, automotive experts can better understand how to optimize gear configurations, ensuring vehicles perform at their best while meeting the demands of modern driving.

Comparing Peerless to Other Brands

When evaluating different manufacturers in the field of mechanical systems, it is crucial to examine their respective strengths and weaknesses. Each brand offers unique features, performance levels, and reliability, which can significantly impact the end-user experience. Understanding these differences allows for informed decisions when selecting the most suitable option for specific applications.

Quality and Durability: One of the primary factors to consider is the quality of materials and construction techniques employed by various brands. Some companies prioritize robust designs that withstand harsh conditions, while others may focus on lightweight components that enhance efficiency. This choice affects longevity and performance under different operational scenarios.

Performance Efficiency: Another important aspect is how well each manufacturer optimizes their devices for performance. Brands that implement advanced engineering solutions may provide superior functionality, leading to better energy efficiency and output. Conversely, alternatives might sacrifice performance for cost, which could influence operational costs over time.

Maintenance and Support: The level of customer service and maintenance support can also vary significantly. Some brands offer extensive resources, including detailed manuals and readily available replacement components, ensuring that users can maintain their systems with ease. Others may lack sufficient support, which can lead to challenges during troubleshooting or repairs.

In summary, a thorough comparison of different brands reveals essential insights into quality, performance, and support. This knowledge empowers users to choose a solution that aligns with their specific needs and expectations.