Comprehensive Guide to Automatic Transmission Parts Diagram

The intricate design of gear shifting systems plays a crucial role in the overall functionality and efficiency of vehicles. By examining the various elements involved, one can appreciate how these components work together to ensure seamless operation and optimal performance. This exploration not only highlights the mechanical sophistication but also underscores the importance of each segment in the entire assembly.

Each element within the shifting mechanism has a specific function, contributing to the overall harmony of the system. From the control devices to the hydraulic systems, understanding their interplay is essential for anyone looking to delve deeper into automotive engineering. This knowledge empowers both enthusiasts and professionals to appreciate the complexity of modern machinery.

Moreover, a comprehensive overview of these components facilitates better maintenance and troubleshooting. Recognizing how each segment interacts allows for more effective diagnostics and repairs, ultimately leading to enhanced longevity and reliability of the vehicle. Whether you are an aspiring technician or a curious car owner, gaining insight into these mechanical wonders opens up a new realm of understanding.

Understanding Automatic Transmission Basics

Grasping the fundamentals of gear-shifting systems in vehicles is essential for both enthusiasts and everyday drivers. These intricate mechanisms allow for smooth acceleration and efficient power delivery without the need for manual gear changes. Familiarity with how these systems operate can enhance maintenance knowledge and improve overall vehicle performance.

Key Components and Functions

At the core of these systems are various elements that work in harmony to enable seamless gear transitions. Key components include hydraulic systems, clutches, and electronic controls. Each of these plays a vital role in determining how power is managed between the engine and the wheels, ensuring that the vehicle operates efficiently under different driving conditions.

Importance of Regular Maintenance

Maintaining the health of these complex systems is crucial for longevity and optimal performance. Regular fluid changes, inspections of key components, and timely repairs can prevent costly breakdowns and enhance driving comfort. Understanding the importance of upkeep can lead to better vehicle management and an enjoyable driving experience.

Key Components of Automatic Transmissions

The intricate system within modern vehicles operates through a series of essential elements, each playing a crucial role in facilitating seamless gear shifts and enhancing driving efficiency. Understanding these fundamental components is vital for grasping how vehicles function and maintain optimal performance under varying conditions.

| Component | Function |

|---|---|

| Planetary Gear Set | Provides multiple gear ratios for efficient power distribution and speed control. |

| Torque Converter | Transmits power from the engine, allowing for smooth acceleration and deceleration. |

| Clutch Packs | Engage and disengage different gear sets, enabling changes in drive ratios. |

| Valve Body | Acts as the control center, directing hydraulic fluid to various components to manage gear shifts. |

| Hydraulic Pump | Maintains pressure in the system, ensuring proper operation of the hydraulic components. |

How Transmission Fluid Works

The fluid plays a crucial role in the functionality of a vehicle’s drive system, ensuring smooth operation and optimal performance. Its unique properties allow for efficient energy transfer and heat management, which are essential for the entire mechanism’s reliability.

Key functions of the fluid include:

- Lubrication: It reduces friction between moving components, preventing wear and tear.

- Cooling: It dissipates heat generated during operation, maintaining optimal temperatures.

- Hydraulic pressure: It facilitates the transfer of power by enabling various elements to engage and disengage smoothly.

- Contaminant removal: It helps to carry away debris and contaminants, keeping the system clean.

The properties of the fluid are critical for maintaining performance. Key characteristics include:

- Viscosity: This affects how well the fluid flows and its ability to create a lubricating film.

- Thermal stability: This ensures the fluid can withstand high temperatures without breaking down.

- Oxidation resistance: This prolongs the life of the fluid by preventing degradation over time.

Regular maintenance of the fluid is essential for prolonging the life of the system. Over time, the fluid can degrade, leading to compromised performance. Routine checks and timely replacements can help ensure everything functions as intended.

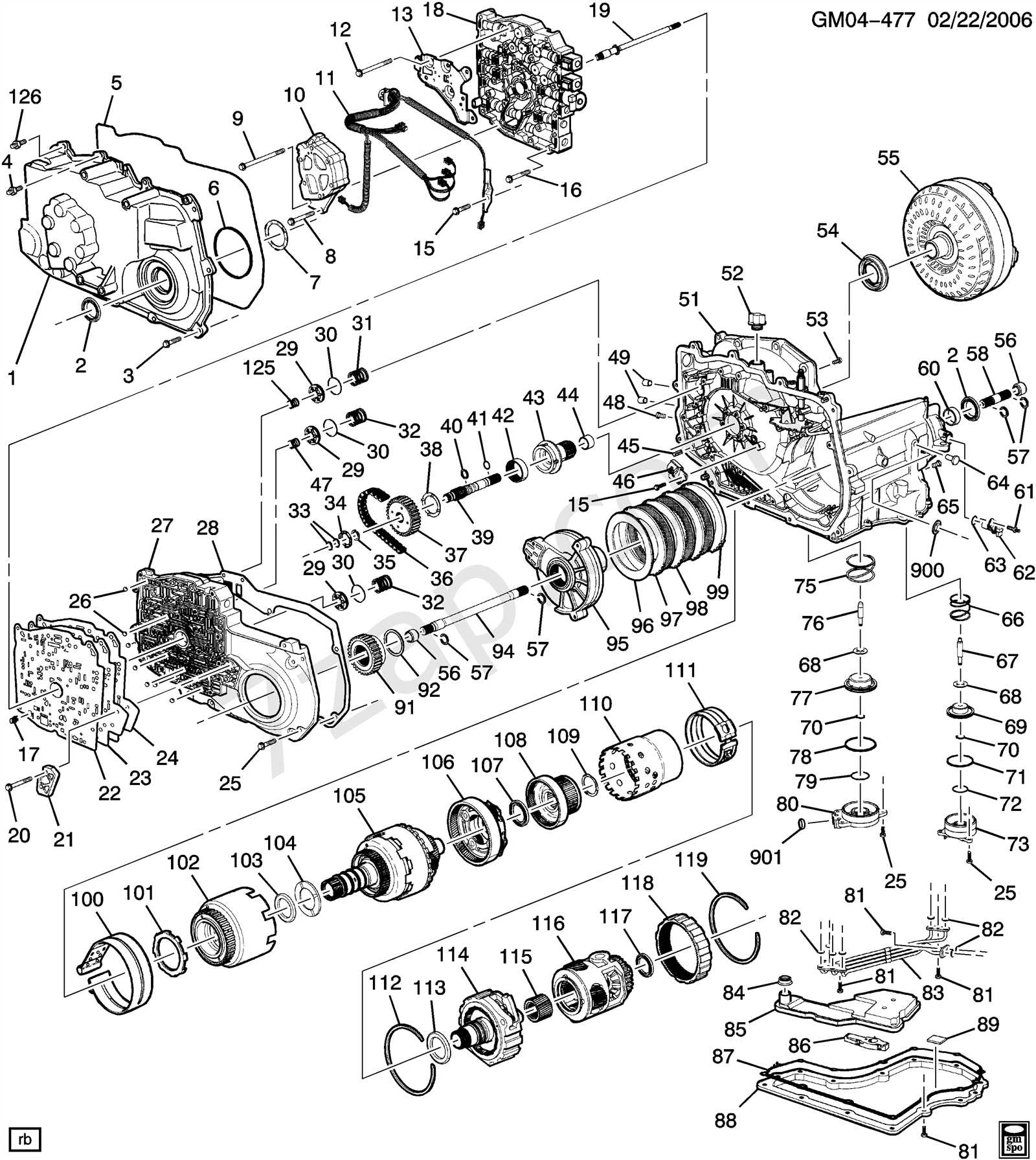

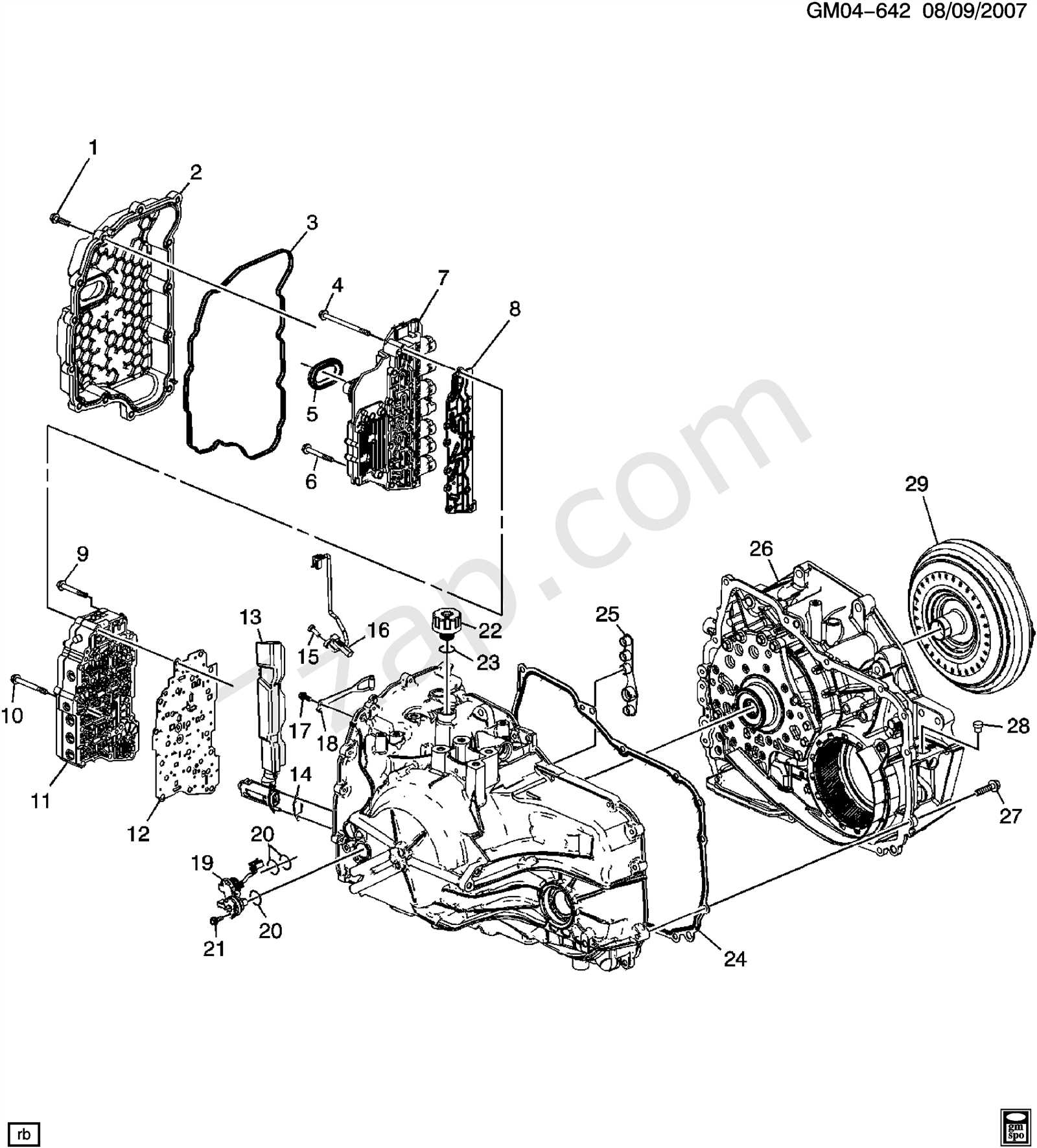

Diagram Overview of Automatic Systems

This section provides a comprehensive look at the components and their arrangement within sophisticated gear-shifting mechanisms. Understanding how these elements interact is essential for diagnosing issues and optimizing performance.

Key Components and Their Functions

The intricate system consists of several critical elements that work in unison to ensure smooth operation. Each component plays a vital role, from managing fluid flow to regulating pressure. Below is a summary of these components:

| Component | Function |

|---|---|

| Fluid Pump | Circulates hydraulic fluid throughout the system. |

| Valve Body | Controls the flow of fluid to various components. |

| Clutch Pack | Engages and disengages gears based on system demands. |

| Torque Converter | Transfers engine power and allows for smooth acceleration. |

System Interaction

The seamless collaboration between these elements ensures that the entire mechanism functions efficiently. Each part responds to inputs and adjusts accordingly, facilitating smooth transitions and optimal performance under various conditions.

Common Problems with Automatic Transmissions

Vehicles equipped with complex shifting mechanisms often experience various issues that can affect their performance and reliability. Identifying these common malfunctions is essential for maintaining optimal functionality and ensuring a smooth driving experience.

Frequent Issues

Several key problems tend to arise with these systems, which can manifest in different ways. Understanding these issues can help drivers take preventive measures and seek timely repairs.

| Problem | Description |

|---|---|

| Slipping Gears | This occurs when the vehicle unexpectedly shifts out of gear, leading to a loss of power. |

| Fluid Leaks | Leaks can result from damaged seals or gaskets, causing a drop in fluid levels and potential overheating. |

| Unusual Noises | Grinding or whining sounds may indicate issues with internal components, requiring immediate attention. |

| Delayed Engagement | A noticeable lag when shifting from park to drive can signal problems with the hydraulic system. |

| Warning Lights | Illuminated indicators on the dashboard can suggest malfunctions that need diagnostics. |

Preventive Measures

Regular maintenance and timely inspections are crucial for preventing these issues. Keeping an eye on fluid levels and scheduling routine check-ups can prolong the lifespan of the system and enhance driving safety.

Importance of Regular Maintenance

Consistent upkeep is essential for ensuring the longevity and efficiency of any mechanical system. By adhering to a scheduled maintenance routine, users can prevent minor issues from escalating into significant problems, thereby enhancing overall performance.

Benefits of Routine Care

- Improved Performance: Regular check-ups can enhance functionality and responsiveness.

- Increased Lifespan: Systems that receive frequent attention tend to have a longer operational life.

- Cost Savings: Preventive measures can help avoid costly repairs and replacements.

- Safety Assurance: Routine inspections help identify potential hazards before they become serious risks.

Key Maintenance Practices

- Fluid Checks: Regularly monitor and replace essential fluids to ensure optimal operation.

- Filter Replacements: Change filters periodically to maintain cleanliness and efficiency.

- Component Inspections: Conduct thorough checks of all essential elements to detect wear and tear.

- Software Updates: Keep any related technology up to date for improved functionality.

Incorporating these practices into a regular schedule not only safeguards the system’s integrity but also contributes to a more enjoyable and reliable experience for users.

Differences Between Automatic and Manual Transmissions

Understanding the distinctions between different types of gear-shifting mechanisms is essential for car enthusiasts and everyday drivers alike. Each system offers unique features, advantages, and driving experiences, influencing vehicle performance and driver engagement.

Here are some key differences:

- Operation:

- One system allows the driver to change gears without input, relying on electronic controls.

- The other requires the driver to manually select gears using a clutch and gear stick.

- Driver Engagement:

- One type offers a more hands-on experience, appealing to those who enjoy control and precision.

- The alternative focuses on convenience and ease of use, making it accessible for all drivers.

- Fuel Efficiency:

- Typically, one mechanism can provide better fuel economy under certain conditions.

- Advancements in technology have improved efficiency in the other option as well.

- Maintenance:

- One system generally requires more frequent servicing due to its complexity.

- The other may be simpler and less costly to maintain over time.

Ultimately, the choice between these two systems depends on personal preferences, driving style, and the specific requirements of the vehicle. Each has its own set of characteristics that cater to different needs and tastes.

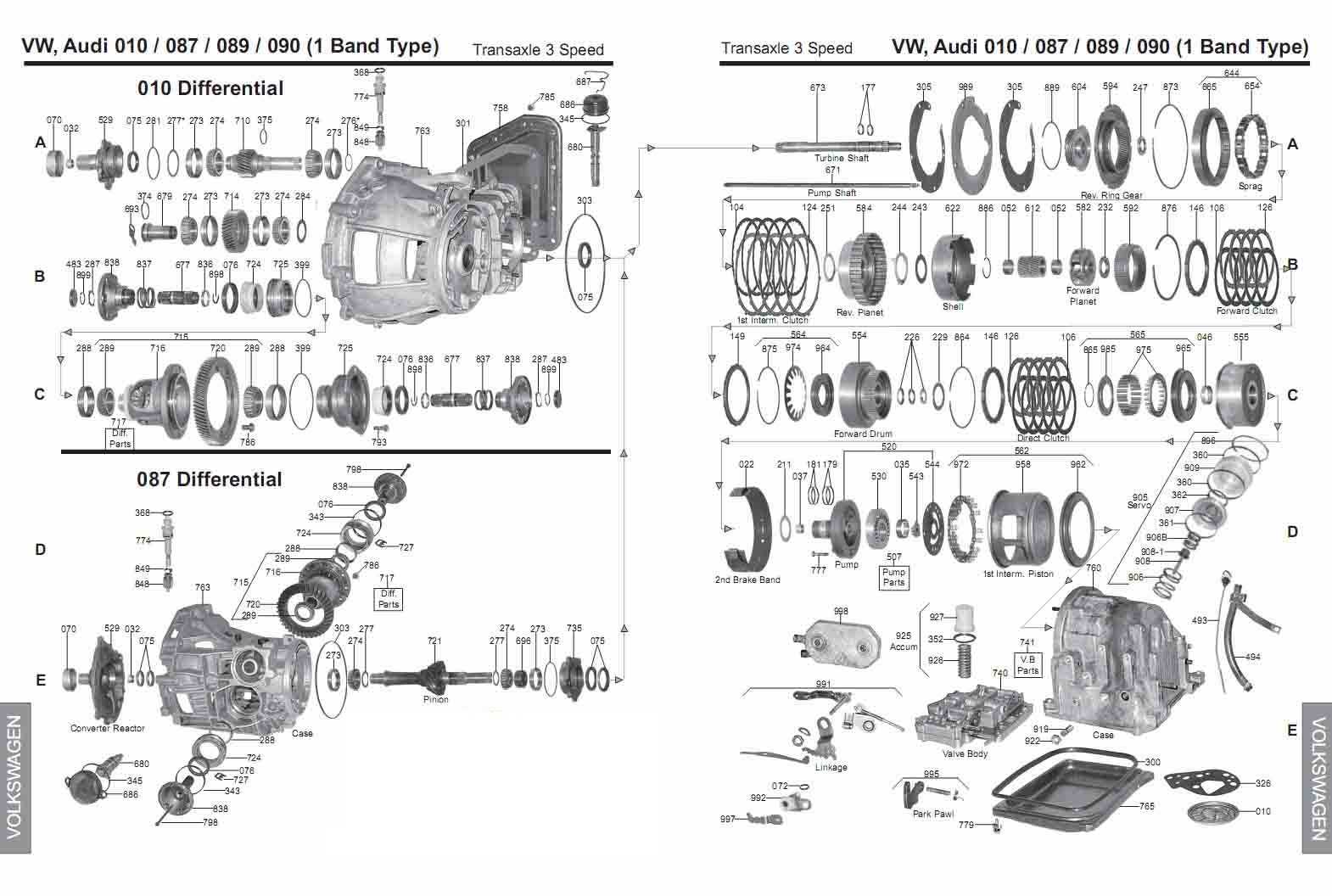

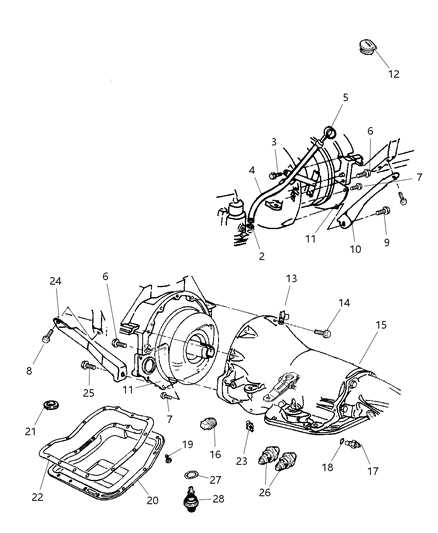

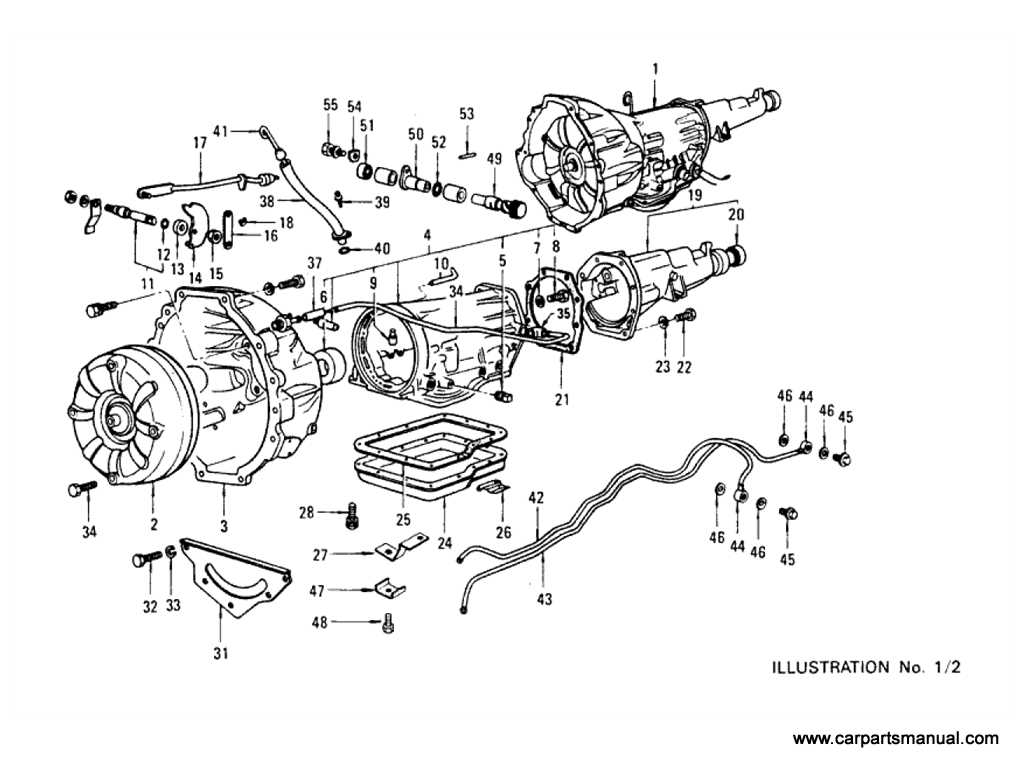

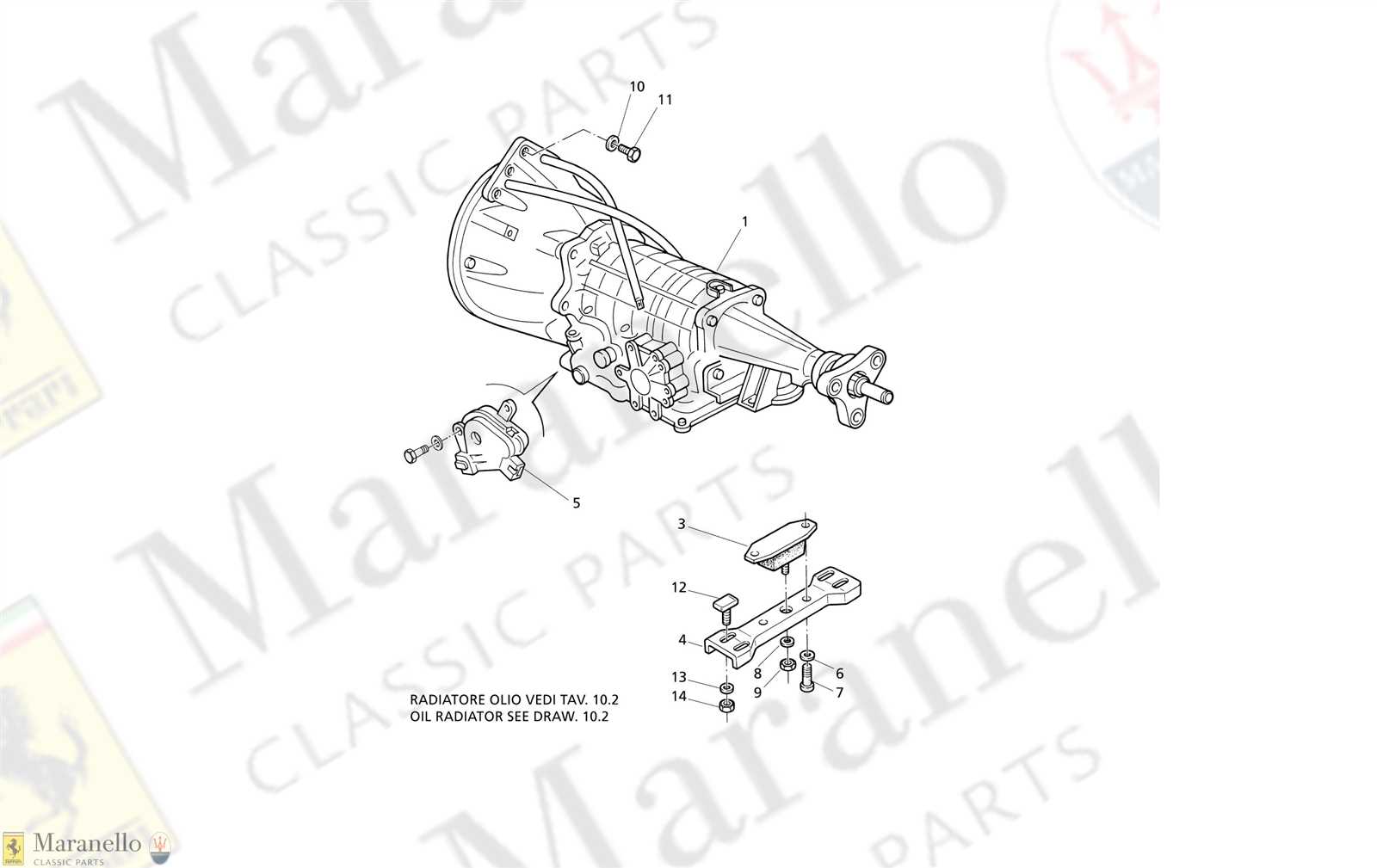

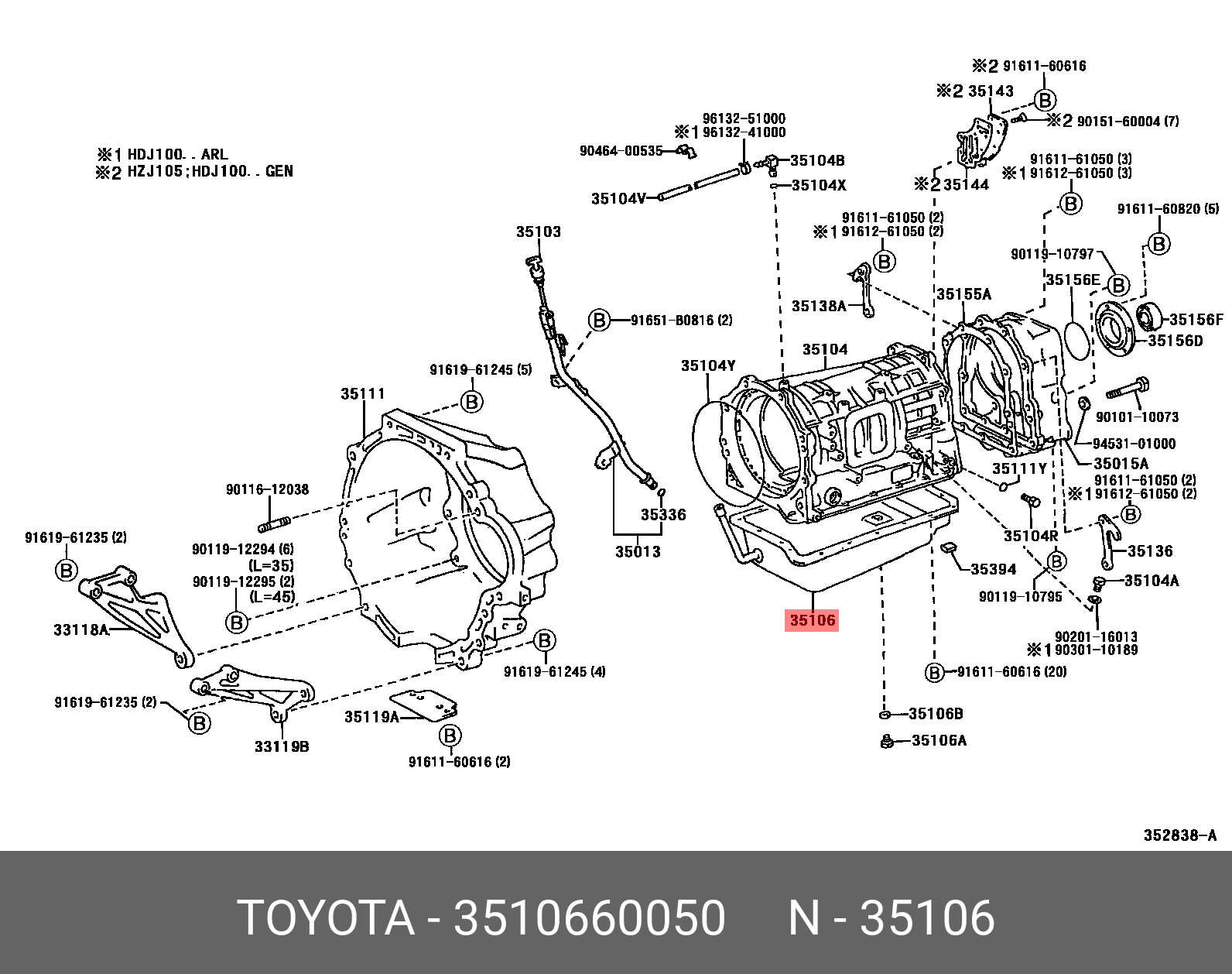

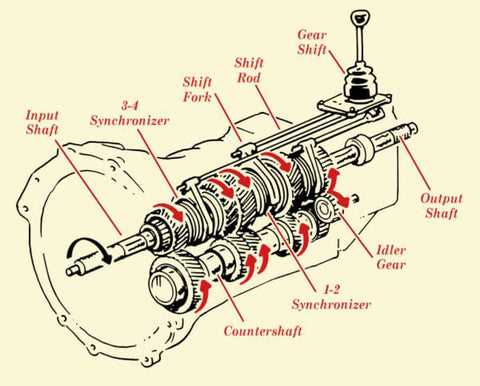

Identifying Parts in Transmission Diagrams

Understanding the various components illustrated in schematic representations is crucial for effective maintenance and repair. These visuals serve as a guide, allowing one to grasp the relationships and functions of each element within the system. By familiarizing yourself with these illustrations, you can enhance your ability to diagnose issues and perform necessary interventions.

Key Elements to Recognize

Begin by identifying the main components typically represented in these visual aids. Valves, gears, and clutches are often highlighted, each serving a specific purpose. Valves regulate fluid flow, while gears facilitate power transfer. Recognizing these elements helps you understand their roles in the overall mechanism.

Interpreting Symbols and Notations

Another important aspect is interpreting the symbols and notations used in the illustrations. Different manufacturers may employ various symbols to represent similar components. Familiarizing yourself with these symbols will enhance your comprehension and enable you to navigate through different schematics with ease. Pay attention to the legends or keys provided, as they often clarify the meaning behind the symbols.

Transmission Fluid Types and Functions

Understanding the various liquids used in gear systems is essential for optimal performance and longevity. Each type serves distinct purposes, contributing to the smooth operation and efficiency of the entire mechanism. Knowing these differences helps in selecting the right fluid for maintenance and ensuring the system runs flawlessly.

Types of Fluids

There are several categories of fluids, each tailored to specific applications and conditions. Synthetic fluids are engineered to offer enhanced protection and performance, particularly in extreme temperatures. Mineral-based liquids, derived from refining crude oil, provide basic lubrication but may lack the advanced properties found in their synthetic counterparts. Blend fluids combine both types, aiming to deliver a balance between cost-effectiveness and performance.

Functions of Fluids

The primary roles of these liquids include lubrication, which reduces friction between moving components, and cooling, helping to dissipate heat generated during operation. Additionally, they assist in cleaning by suspending contaminants and preventing deposits. Proper fluid maintenance is crucial, as degraded liquids can lead to increased wear and potential system failures.

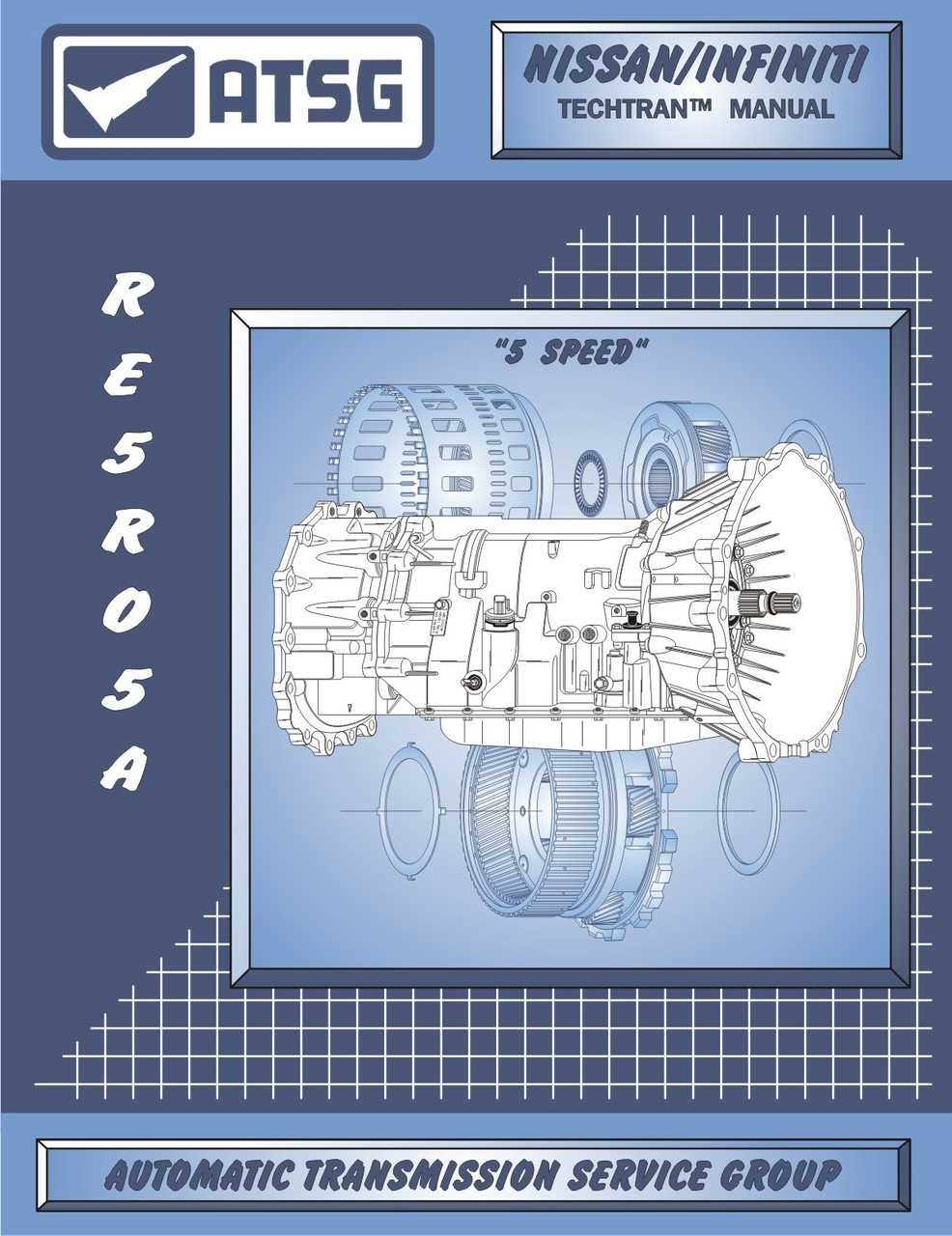

Tips for DIY Transmission Repairs

Engaging in do-it-yourself repairs for your vehicle’s shifting system can be both rewarding and challenging. Understanding the essentials can help you save money and gain valuable skills. Here are some practical suggestions to ensure a successful repair process.

Essential Tools and Equipment

- Wrenches and sockets: Invest in a quality set to tackle various fasteners.

- Jack and stands: Ensure safe access to the undercarriage for inspection and repairs.

- Fluid pumps: Useful for draining and refilling essential fluids.

- Repair manual: Obtain a detailed guide specific to your vehicle model for reference.

Steps for a Successful Repair

- Assess the Issue: Begin by diagnosing the symptoms thoroughly to identify the root cause.

- Gather Supplies: Collect all necessary tools and replacement components before starting the repair.

- Follow Procedures: Adhere to the step-by-step guidelines in your repair manual to avoid mistakes.

- Test Thoroughly: After repairs, conduct a series of tests to ensure everything functions smoothly.

- Seek Help if Needed: Don’t hesitate to consult a professional if you encounter complex problems.