E40D Transmission Parts Diagram Overview

The intricate workings of modern automatic gear systems involve a complex assembly of elements that work harmoniously to ensure smooth vehicle operation. Each component plays a vital role in the overall functionality, contributing to performance, efficiency, and reliability. A thorough grasp of these individual elements is essential for both enthusiasts and professionals in the automotive field.

As we delve into this topic, we will explore the key sections and how they interact within the larger mechanism. Recognizing the significance of each segment can aid in maintenance, troubleshooting, and upgrades, allowing for enhanced driving experiences. This exploration will also illuminate the engineering marvels behind seamless gear transitions.

Whether you are aiming to perform repairs, upgrades, or simply expand your knowledge, understanding the layout and function of these components will provide valuable insights. Let’s embark on a journey through the essential features of these complex systems and uncover the critical roles they play in automotive technology.

E40D Transmission Overview

This section provides a comprehensive look into a specific automatic gearbox widely utilized in various vehicle models. Designed for enhanced performance and durability, this mechanism is essential for optimal power distribution from the engine to the wheels, ensuring a smooth driving experience.

Key Features

Among its notable characteristics, the system incorporates advanced electronic controls, allowing for precise gear shifts and improved fuel efficiency. The construction is robust, utilizing high-quality materials to withstand the stresses of regular use. Additionally, it offers a range of gear ratios, enabling versatility in various driving conditions.

Maintenance Considerations

Regular upkeep is crucial for longevity and reliability. This involves monitoring fluid levels and ensuring cleanliness to prevent wear and tear. Utilizing the correct lubricants and adhering to service intervals can significantly extend the lifespan of this essential assembly.

Key Components of E40D Transmission

The efficiency and performance of an automatic shifting system are largely determined by its fundamental elements. Understanding these critical components provides insights into how power is managed and transferred, ensuring smooth operation and responsiveness in various driving conditions.

Main Elements

At the heart of this system lies the gearset, which determines the range of speeds and torque characteristics. This assembly interacts with other components to facilitate the vehicle’s acceleration and deceleration. Additionally, the clutch pack plays a vital role in engaging and disengaging gears, allowing for seamless transitions during operation.

Supporting Mechanisms

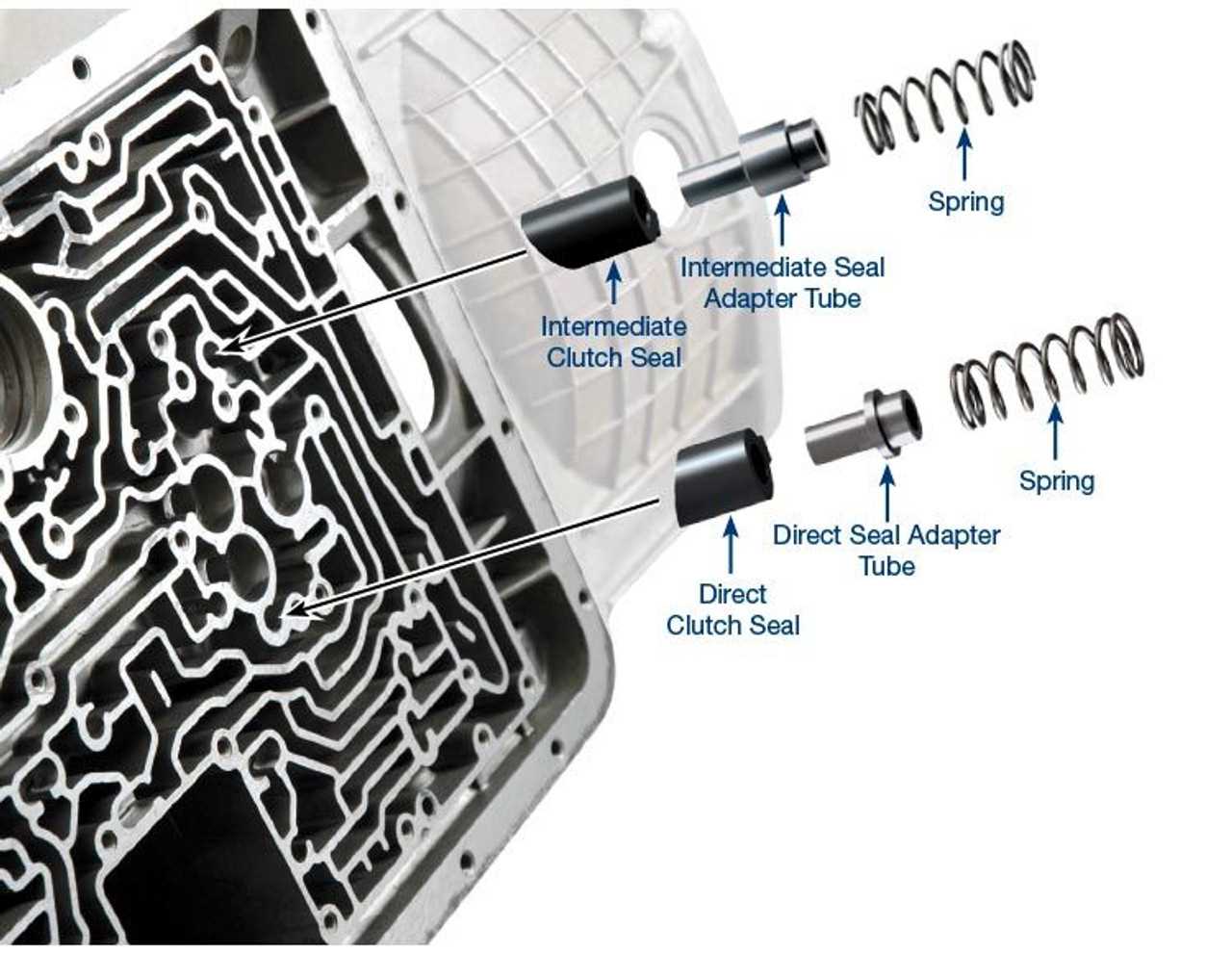

Equally important are the valve body and the control module. The valve body serves as a central hub for fluid distribution, managing hydraulic pressure to engage the necessary elements at the right time. Meanwhile, the control module utilizes electronic signals to optimize shifting patterns based on driving conditions, enhancing both performance and fuel efficiency.

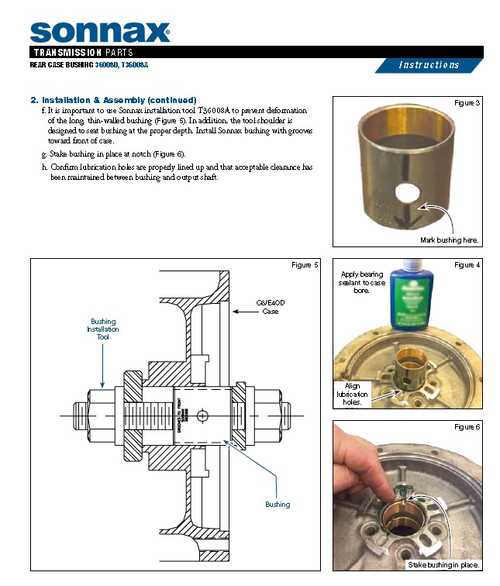

Understanding Transmission Diagrams

Grasping the intricacies of mechanical layouts is crucial for anyone involved in automotive maintenance or repair. These visual representations serve as essential guides, showcasing the arrangement and interaction of various components within a system. By analyzing these schematics, one can gain valuable insights into functionality and troubleshooting processes.

The Importance of Visual Representations

Visual aids simplify complex information, making it easier to comprehend how different elements work together. They allow technicians to identify specific units quickly and understand their roles, facilitating effective repairs and modifications. Moreover, these illustrations often highlight the assembly sequence and operational flow, which are vital for successful service interventions.

Decoding the Symbols and Notations

Each schematic employs standardized symbols and annotations that convey important information about the components and their relationships. Familiarity with these symbols is essential for accurate interpretation. Understanding the meaning behind each icon can significantly enhance one’s ability to diagnose issues and implement corrective measures efficiently.

Common Issues with E40D Parts

When dealing with automatic systems in vehicles, various challenges can arise that affect performance and reliability. Understanding these common complications can help in diagnosing issues early and ensuring smooth operation.

- Fluid Leaks:

One of the most prevalent problems is leakage of hydraulic fluid, which can lead to inadequate lubrication and overheating. Regular checks can prevent significant damage.

- Overheating:

Excessive heat can cause critical components to fail. This often results from poor cooling or extended use under heavy loads.

- Worn Clutches:

Clutch wear is a common concern, especially in systems that endure heavy driving conditions. Symptoms include slipping and delayed engagement.

- Electrical Failures:

Malfunctions in the electronic control units can lead to erratic shifting or complete system failure. Regular diagnostics are essential to identify issues.

- Filter Blockages:

A clogged filter can restrict fluid flow, causing inadequate operation. Periodic replacement of filters is crucial for maintaining efficiency.

Addressing these issues promptly can extend the lifespan of the assembly and enhance overall vehicle performance.

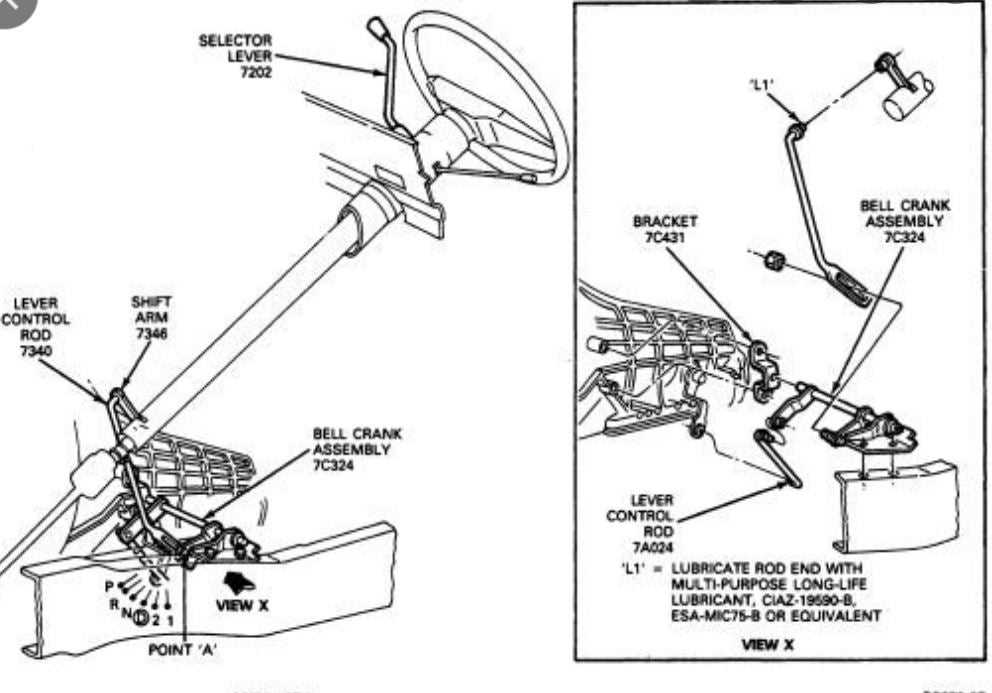

How to Read Transmission Schematics

Understanding the layout of mechanical systems is crucial for effective maintenance and repair. Schematics serve as visual representations that simplify complex arrangements into more digestible formats. By breaking down the components and their relationships, one can easily identify parts and their functions within the overall mechanism.

Key Elements of Schematics

When examining these visual guides, it’s important to familiarize yourself with common symbols and notations. Each symbol typically represents a specific component, while lines indicate connections or interactions between them. Familiarity with these elements helps in navigating the schematic with confidence.

Interpreting Connections and Flow

Beyond recognizing individual components, understanding how they interact is essential. Arrows may denote the direction of fluid movement or electrical flow, while annotations often provide additional context. Analyzing these connections allows for a comprehensive grasp of how the entire system operates, aiding in troubleshooting and repairs.

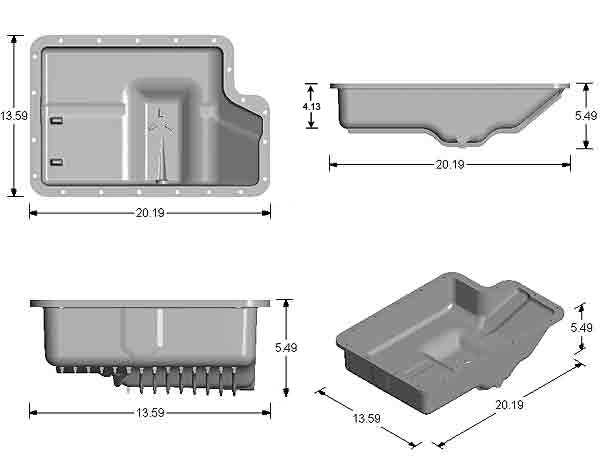

Maintenance Tips for E40D Transmission

Regular upkeep of your vehicle’s shifting mechanism is essential for ensuring optimal performance and longevity. By adhering to specific maintenance practices, you can prevent issues before they arise and enhance overall functionality.

Routine Fluid Checks

- Inspect fluid levels regularly to ensure they are within the recommended range.

- Look for any signs of contamination, such as discoloration or a burnt smell.

- Replace fluid according to the manufacturer’s guidelines, typically every 30,000 to 60,000 miles.

Component Inspections

- Examine seals and gaskets for leaks or wear.

- Check electrical connections for corrosion or damage.

- Inspect the cooling system to ensure it effectively regulates temperatures.

By implementing these maintenance tips, you can significantly reduce the risk of costly repairs and enhance the performance of your vehicle’s shifting system.

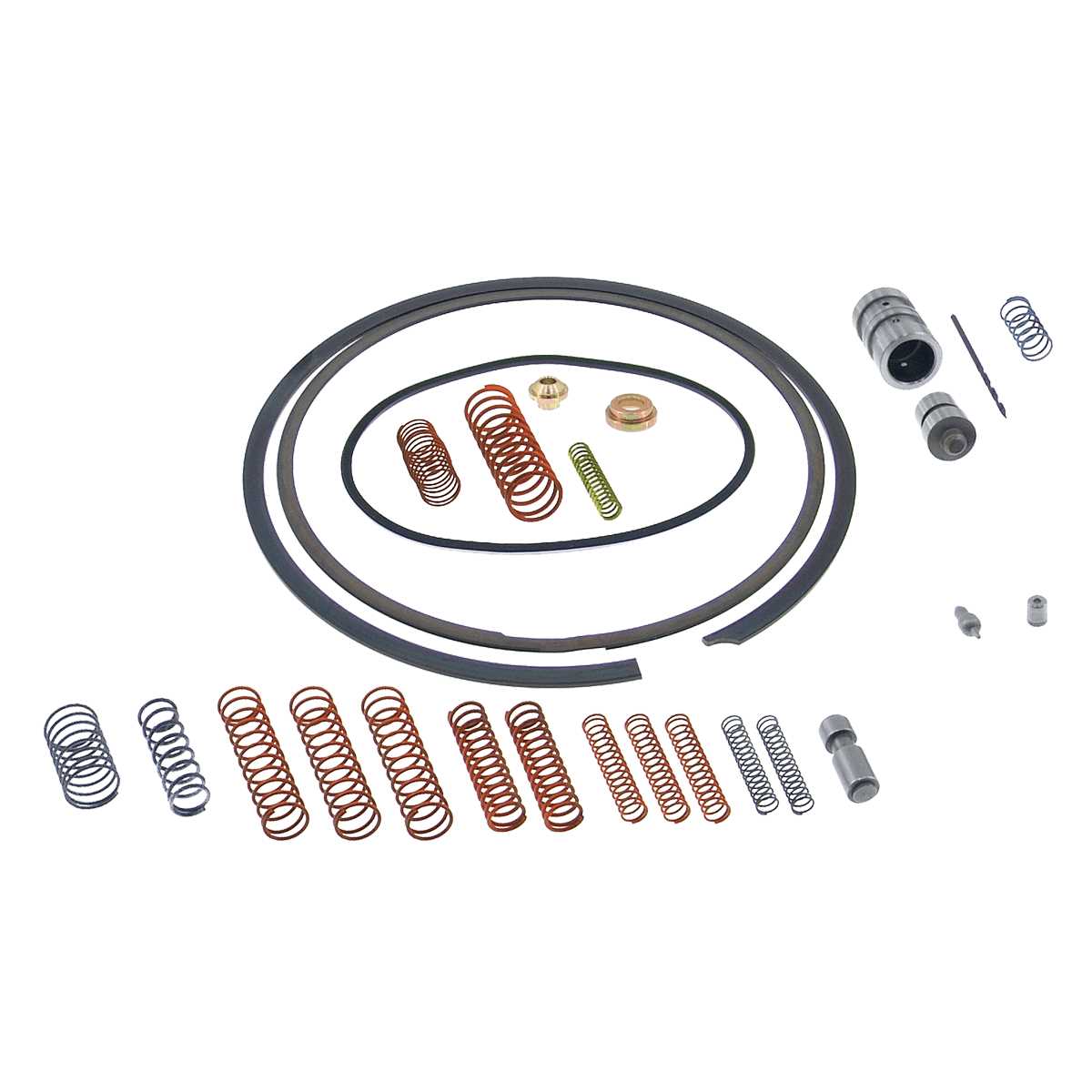

Upgrading E40D Transmission Components

Enhancing the efficiency and performance of your vehicle’s shifting system can significantly improve driving experience and durability. By carefully selecting and upgrading various elements within this complex assembly, you can achieve smoother gear changes, increased power handling, and greater overall reliability. Understanding the components involved and their interplay is essential for any successful enhancement project.

Key Components for Upgrades

Several critical elements should be considered when planning upgrades. Focusing on high-quality materials and modern technology can yield substantial improvements.

| Component | Upgrade Options | Benefits |

|---|---|---|

| Clutch Plates | High-performance friction materials | Improved grip and heat resistance |

| Valve Body | Aftermarket performance valve bodies | Faster shifting response and better pressure control |

| Torque Converter | High-stall converters | Increased torque multiplication and efficiency |

Choosing the Right Upgrades

When selecting components for enhancement, consider your vehicle’s specific needs and your driving style. Consulting with experts and utilizing quality aftermarket products can lead to substantial gains in performance and reliability. Prioritize components that complement each other to create a balanced system, ensuring all upgrades work in harmony for optimal results.

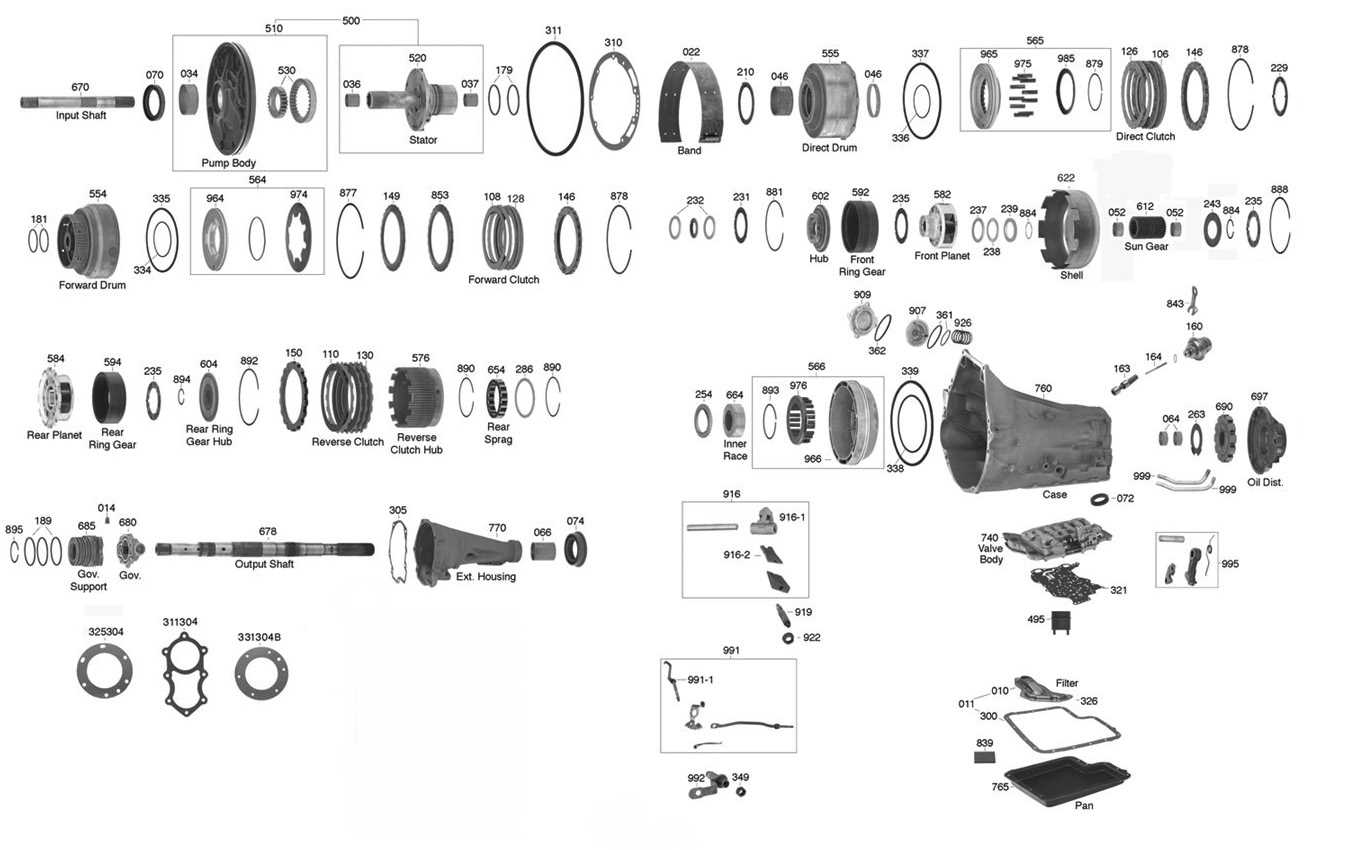

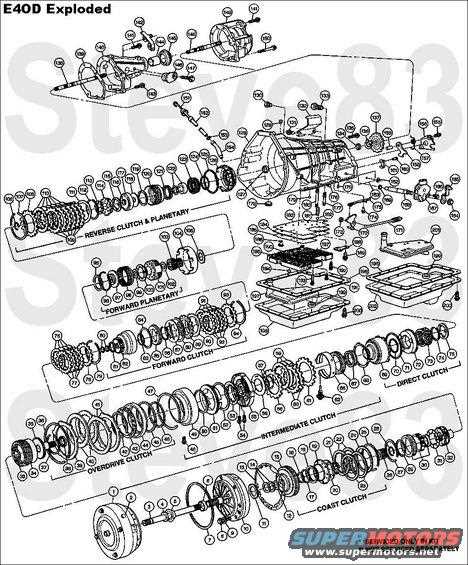

Identifying Parts in E40D Diagram

Understanding the various components within a specific mechanical system is crucial for effective maintenance and repair. Familiarity with the layout and function of each element allows for better troubleshooting and enhancement of performance. This section aims to guide users in recognizing and interpreting the different components shown in the provided schematic.

Each component plays a unique role, contributing to the overall functionality. Familiarizing oneself with these elements helps streamline repairs and ensures optimal operation. Below is a table that outlines common components, their functions, and associated features.

| Component Name | Function | Key Features |

|---|---|---|

| Fluid Pump | Circulates hydraulic fluid | Maintains pressure for operation |

| Valve Body | Directs fluid flow | Houses solenoids for gear shifting |

| Clutch Packs | Engages and disengages gears | Facilitates smooth transitions |

| Filter | Cleans hydraulic fluid | Prevents debris buildup |

| Sensors | Monitor operational parameters | Provide data for electronic control |

By studying the characteristics of these components, users can develop a deeper understanding of the system’s mechanics and enhance their ability to maintain or repair the unit effectively.

Importance of OEM Parts

When it comes to vehicle maintenance and repairs, opting for original equipment manufacturer components is crucial. These elements are designed specifically for your vehicle, ensuring a perfect fit and reliable performance. Using these components guarantees that your vehicle will function as intended, maintaining its efficiency and longevity.

Quality Assurance: OEM components are manufactured to the highest standards, often exceeding aftermarket alternatives in durability and reliability. This ensures that your vehicle operates smoothly and reduces the risk of future issues.

Compatibility: Original parts are engineered to work seamlessly with the specific make and model of your vehicle. This compatibility minimizes the chances of installation problems and ensures that all systems function harmoniously.

Warranty Protection: Many manufacturers offer warranties on their original components, providing peace of mind. If a problem arises, you have the security of knowing that you are covered, which is often not the case with generic alternatives.

Investing in original components is not just about immediate repairs; it’s about safeguarding your vehicle’s future performance and value.

Repairing E40D Transmission Problems

Addressing issues within your vehicle’s shifting mechanism requires a methodical approach to ensure optimal performance. Many drivers encounter a range of complications that can stem from various components within the system. Understanding how to identify and rectify these issues is crucial for maintaining the vehicle’s functionality.

Common challenges include:

- Slipping gears

- Unresponsive shifting

- Fluid leaks

- Unusual noises during operation

To effectively tackle these problems, follow these essential steps:

- Diagnosis: Start by assessing symptoms. Look for warning lights, listen for irregular sounds, and check for fluid levels.

- Fluid Inspection: Examine the hydraulic fluid for contamination. Clean fluid is vital for proper function.

- Visual Inspection: Check for any visible wear or damage to components. Look for signs of leakage around seals and gaskets.

- Component Testing: Utilize diagnostic tools to test electronic sensors and solenoids for accuracy and responsiveness.

- Repair or Replace: Based on your findings, repair damaged elements or replace them as needed. Ensure all components are compatible with your vehicle’s specifications.

Maintaining a regular service schedule can also prevent many of these issues from arising. By staying proactive, you can enhance the longevity and performance of your vehicle’s system.