Understanding the G56 Transmission Parts Diagram

The intricacies of a manual gearbox reveal a complex interplay of mechanisms that ensure seamless power transfer. A comprehensive overview of these elements not only enhances understanding but also aids in effective maintenance and troubleshooting.

In this section, we will delve into the essential constituents of this system, illustrating how each component contributes to the ultimate performance. By examining their relationships and functions, readers can gain valuable insights into the workings of these vital mechanisms.

With the right knowledge, enthusiasts and professionals alike can appreciate the sophistication of manual gear systems, paving the way for improved handling and longevity. This exploration serves as a foundation for deeper technical engagement and informed decision-making.

Understanding G56 Transmission Components

The intricacies of a vehicle’s mechanical system are vital for its performance and longevity. A deeper understanding of these components allows for better maintenance, troubleshooting, and enhancement of driving experience. This section delves into the essential elements that make up the gear mechanism, highlighting their functions and significance.

- Gear Set: The heart of the mechanism, facilitating the transfer of power from the engine to the wheels.

- Synchronizers: These elements ensure smooth engagement of gears, preventing grinding and enhancing shifting efficiency.

- Clutch Assembly: A crucial component that allows the driver to disengage the engine from the drivetrain for smoother gear changes.

- Shifter Linkage: The system connecting the gear lever to the internal mechanism, allowing the driver to select the desired gear.

- Bearings: These reduce friction between moving parts, ensuring longevity and smooth operation of the assembly.

- Housing: The protective shell that encases all internal components, providing structural integrity and protection from external elements.

Understanding these components not only aids in effective repairs but also enhances the overall driving experience by allowing for informed modifications and optimizations.

Overview of G56 Transmission System

The complex system designed for gear shifting plays a vital role in the overall functionality of heavy-duty vehicles. It facilitates the transfer of power from the engine to the wheels, ensuring smooth acceleration and deceleration under various driving conditions. Understanding the intricacies of this mechanism is essential for both enthusiasts and professionals alike.

This mechanism is renowned for its durability and efficiency, making it a preferred choice in modern trucks. Its design incorporates a series of gears and components that work in harmony to optimize performance. By efficiently managing power distribution, it enhances driving experience and vehicle handling.

In addition to its robust construction, the system offers a variety of gear ratios. These ratios allow for tailored performance based on load requirements and terrain, making it adaptable to different operational scenarios. Maintenance and care of this assembly are crucial to ensure longevity and optimal performance over time.

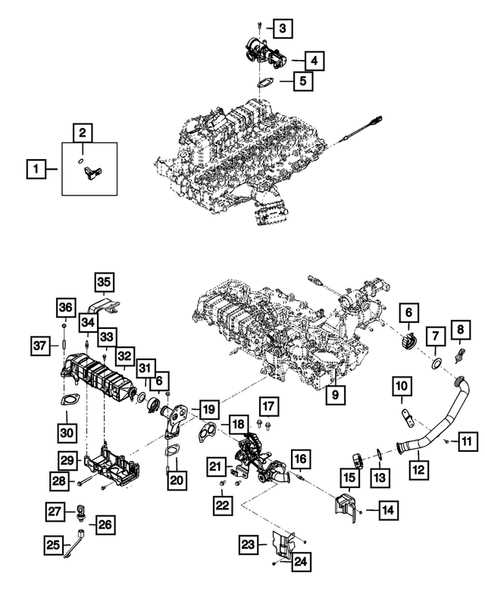

Main Parts of the G56 Transmission

This section explores the essential components that work in harmony to facilitate efficient gear shifting and power transfer. Understanding these elements is crucial for anyone looking to maintain or enhance performance.

Core Components

The primary elements include the gear set, which enables various speed adjustments, and the synchronizers that ensure smooth engagement between gears. Additionally, the input shaft plays a vital role by connecting to the engine, while the output shaft delivers power to the drivetrain.

Supporting Elements

Other notable components consist of the housing that protects internal mechanisms, the shift fork that guides gear selection, and the bearing assemblies that minimize friction. Together, these crucial parts contribute to the overall functionality and reliability of the system.

Functionality of Key Components

Understanding the essential elements of a mechanical system is crucial for appreciating how they work together to facilitate performance and efficiency. Each component plays a vital role in the overall operation, contributing to the seamless functionality of the entire assembly.

- Input Shaft: This element transmits power from the engine, initiating the movement that will eventually be transferred to the output.

- Gear Sets: Different gear ratios are utilized to manage speed and torque, allowing for adaptability under various driving conditions.

- Clutch Assembly: This component engages and disengages power flow, enabling smooth transitions between different gear settings.

- Shift Mechanism: The mechanism facilitates gear changes, providing the driver with control over the system’s performance.

- Output Shaft: Responsible for delivering the final drive to the wheels, ensuring that the vehicle moves as intended.

By recognizing the individual functions of these critical components, one can gain a deeper insight into the complexities of mechanical design and the importance of each part in achieving optimal performance.

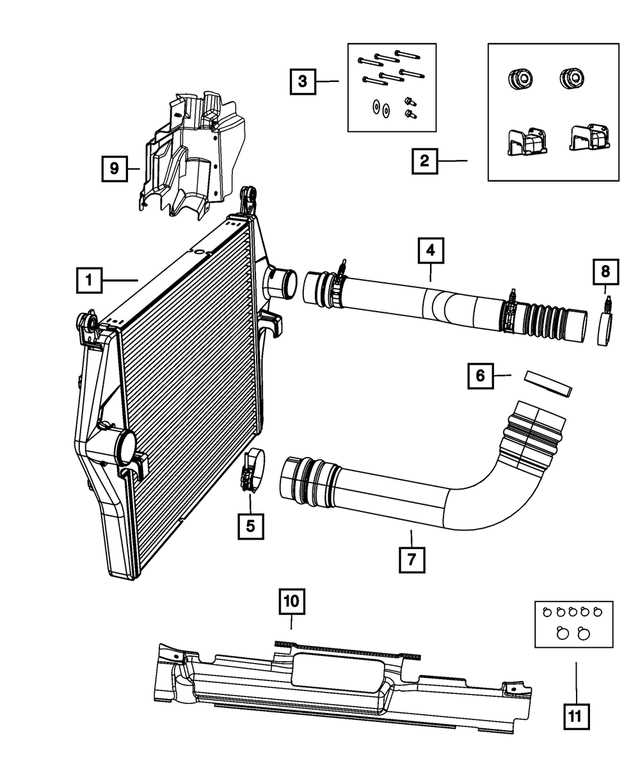

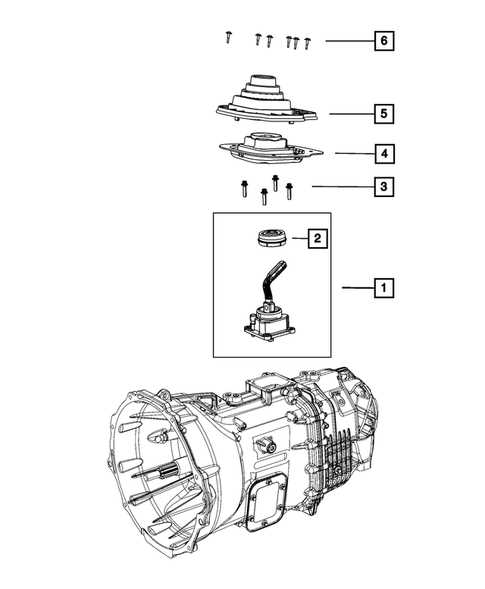

Transmission Diagrams Explained

Understanding the intricate workings of a vehicle’s mechanical components is essential for both enthusiasts and professionals. Visual representations provide clarity and insight into the relationships and functions of various elements within the system.

These illustrations serve multiple purposes:

- They simplify complex concepts, making it easier to grasp how components interact.

- They assist in identifying specific elements, which can aid in troubleshooting and maintenance.

- They can guide assembly and disassembly processes, ensuring that each piece is correctly positioned.

When examining these visual guides, it’s helpful to be aware of the common symbols and terminology used:

- Components: Each part is usually labeled, allowing for quick identification.

- Connections: Lines and arrows indicate how elements are linked and the direction of movement.

- Groupings: Related parts may be shown together, highlighting their function within the larger assembly.

Familiarity with these visuals not only enhances understanding but also empowers users to engage more effectively with their vehicles. Whether for repair, modification, or pure curiosity, these representations are invaluable resources in the automotive field.

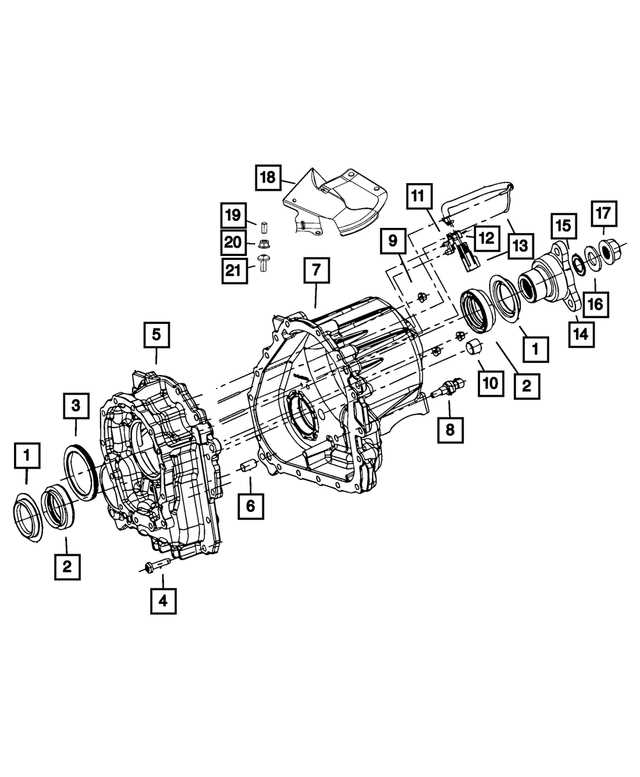

G56 Transmission Assembly Process

The assembly procedure of a heavy-duty gearbox involves meticulous attention to detail and a systematic approach. Each component must be carefully fitted to ensure optimal functionality and performance. Understanding the sequence of operations is crucial for achieving a reliable and efficient mechanism.

Initially, it’s vital to prepare all necessary components, ensuring they are clean and free of debris. The first step typically involves assembling the main housing, where precision alignment is essential. Following this, gears and bearings are installed with specific torque specifications to maintain structural integrity.

Next, the installation of the shifting mechanism occurs, allowing for seamless gear changes. This stage requires careful calibration to ensure smooth operation. Afterward, seals and gaskets are applied to prevent fluid leakage, which is critical for durability.

Finally, a thorough inspection is performed to confirm that everything is correctly assembled. Testing the complete unit under various conditions guarantees that it meets performance standards. This comprehensive approach ensures that the final product operates at its peak efficiency.

Common Issues with G56 Parts

When dealing with the complex mechanisms of heavy-duty gear systems, certain challenges frequently arise that can affect performance and longevity. Understanding these common problems is essential for maintaining optimal functionality and ensuring smooth operation over time.

Typical Problems Encountered

Users often report issues related to wear and tear, resulting in suboptimal engagement and responsiveness. Additionally, improper lubrication can lead to overheating, while misalignment may cause excessive noise and vibration.

Preventative Measures

Regular inspections and proper maintenance can help mitigate these issues. Ensuring correct installation and using quality lubricants will contribute to the durability and efficiency of the system.

| Issue | Description | Preventative Action |

|---|---|---|

| Wear | Degradation of components leading to reduced performance. | Routine checks and timely replacements. |

| Overheating | Excessive heat due to insufficient lubrication. | Use high-quality lubricants and check levels frequently. |

| Misalignment | Components not aligned correctly, causing noise. | Ensure precise installation and adjustment. |

Maintenance Tips for G56 Transmission

Regular upkeep is essential for ensuring optimal performance and longevity of your vehicle’s gear system. Proper maintenance not only enhances efficiency but also prevents costly repairs down the line. Adopting a few key practices can greatly extend the life of this crucial component.

1. Regular Fluid Checks: Keep an eye on the fluid levels. Low or contaminated fluid can lead to overheating and wear. Check for any discoloration or strange odors, which may indicate the need for a change.

2. Timely Fluid Changes: Follow the manufacturer’s recommendations for fluid replacement intervals. Fresh fluid ensures smooth operation and protects internal components from damage.

3. Inspect for Leaks: Regularly inspect the area around the system for any signs of leaks. Addressing leaks promptly can prevent further damage and loss of efficiency.

4. Monitor Performance: Pay attention to how your vehicle shifts. Any unusual noises, hesitations, or grinding sensations can signal potential issues that need immediate attention.

5. Professional Inspections: Schedule routine check-ups with a qualified technician. They can identify wear and tear that might go unnoticed and recommend necessary repairs.

6. Avoid Overloading: Be mindful of the load you carry. Exceeding weight limits can put extra strain on the system, leading to premature wear and failure.

By incorporating these maintenance tips, you can ensure the efficiency and reliability of your vehicle’s gear mechanism for years to come.

Replacement Parts for G56 System

Maintaining the efficiency and reliability of a vehicle’s powertrain often requires replacing specific components. Understanding the necessary elements can enhance performance and extend the lifespan of your equipment. This section outlines essential replacements that contribute to optimal functionality.

Key Components to Consider

- Clutch Assembly

- Gear Shift Forks

- Synchronizers

- Bearings

- Seals and Gaskets

Choosing Quality Replacements

When selecting new components, it’s crucial to prioritize quality over cost. High-grade materials and precision engineering significantly affect overall performance. Here are some tips:

- Research reputable manufacturers.

- Read customer reviews and testimonials.

- Verify compatibility with your specific model.

Investing in quality replacements not only enhances performance but also minimizes the risk of future failures. Regular maintenance and timely updates are key to a well-functioning system.

Comparing G56 with Other Transmissions

This section delves into the nuances of various gear systems, highlighting the strengths and weaknesses of each option. By examining key characteristics, we can better understand how one system measures up against another, providing insight into performance, reliability, and user experience.

Performance Characteristics

When evaluating performance, it’s essential to consider factors such as gear ratios, shifting smoothness, and torque capacity. Some systems excel in high-torque applications, while others offer quicker shifts and better responsiveness. Users seeking enhanced acceleration may prefer options with a different configuration, making it crucial to align choices with specific driving needs.

Durability and Maintenance

Longevity and ease of upkeep are pivotal when selecting a suitable gear assembly. Certain designs are renowned for their robust construction, minimizing the frequency of repairs. In contrast, others may require regular maintenance to ensure optimal functionality. Understanding these differences can aid in making an informed decision based on anticipated usage and maintenance commitment.

Tools Required for G56 Repairs

When undertaking repairs on heavy-duty mechanical systems, having the right equipment is crucial for efficiency and precision. The appropriate tools not only facilitate the repair process but also ensure that each component is handled correctly, minimizing the risk of damage and ensuring longevity.

| Tool Type | Purpose |

|---|---|

| Socket Set | For loosening and tightening fasteners. |

| Torque Wrench | To apply the correct torque specifications. |

| Pry Bar | Assists in removing stubborn components. |

| Fluid Pump | For efficient fluid transfer and maintenance. |

| Seal Puller | Helps in removing seals without damage. |

| Cleaning Brushes | Essential for maintaining cleanliness of components. |

| Magnetic Tray | To keep small fasteners organized and secure. |

| Safety Gear | Protects the technician during the repair process. |

Equipping yourself with these essential tools will enhance the effectiveness of your repair tasks, ensuring that each job is completed to a high standard.

Upgrades for G56 Transmission Performance

Enhancing the functionality of your vehicle’s gear-shifting system can significantly improve driving dynamics and efficiency. Various modifications are available to boost performance, offering both reliability and increased power handling. These upgrades can be tailored to meet specific needs, whether for daily driving or high-performance applications.

Clutch Upgrades: Upgrading to a high-performance clutch can provide better engagement and durability, enabling the system to handle increased torque. Options include ceramic or organic materials that enhance grip and heat resistance.

Gear Ratio Modifications: Altering the gear ratios can optimize power delivery, allowing for quicker acceleration and improved throttle response. This can be particularly beneficial for those seeking a sportier driving experience.

Shift Forks and Bushings: Replacing standard components with performance-grade forks and bushings can reduce play and enhance precision during gear changes. This results in smoother transitions and a more connected driving feel.

Fluid Upgrades: Utilizing high-quality lubricants designed for performance applications can reduce friction and improve thermal stability. This ensures better longevity and consistent operation under stress.

Electronic Enhancements: For modern systems, tuning the electronic control unit (ECU) can unlock additional performance features, improving shift points and responsiveness, tailored to your driving style.

Resources for G56 Transmission Owners

For those who own a specific model of manual gear system, having access to the right materials and information is essential for maintenance and upgrades. This section provides valuable resources that can enhance your understanding and ensure optimal performance of your equipment.

Online Communities and Forums

- Dedicated automotive forums: Engage with fellow enthusiasts to share experiences and troubleshoot issues.

- Social media groups: Join Facebook or Reddit communities where owners discuss tips and modifications.

- Specialized websites: Explore platforms focusing on performance enhancements and repairs.

Technical Manuals and Guides

- Manufacturer’s manuals: Obtain official documents for specifications and maintenance procedures.

- Aftermarket repair guides: Find detailed instructions for repairs and upgrades from third-party publishers.

- Video tutorials: Watch step-by-step guides on platforms like YouTube for visual assistance.