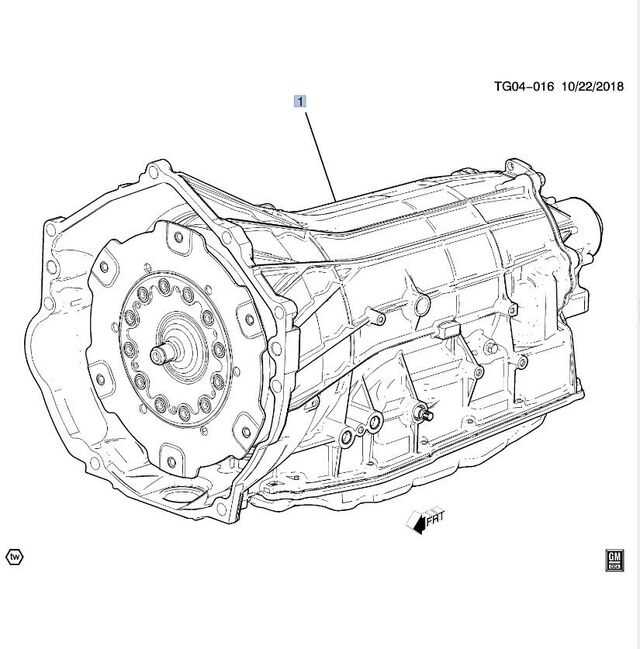

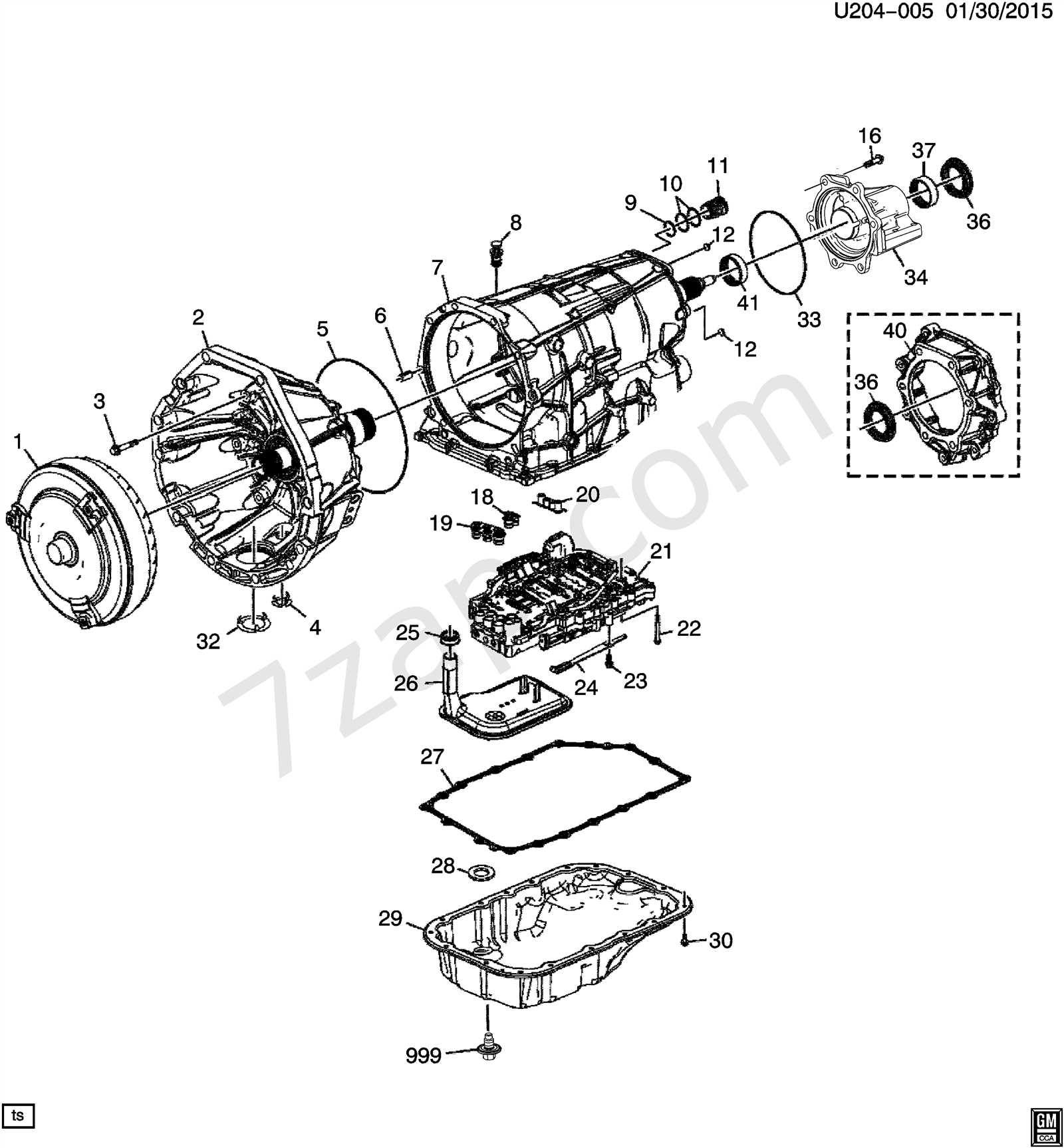

Understanding the Gm Transmission Parts Diagram

In the intricate world of automotive engineering, the mechanics that govern power transfer are crucial for optimal vehicle performance. A comprehensive grasp of these elements not only enhances repair and maintenance efforts but also empowers enthusiasts and professionals alike to make informed decisions. This exploration delves into the various elements that play a significant role in the seamless operation of a vehicle’s power delivery system.

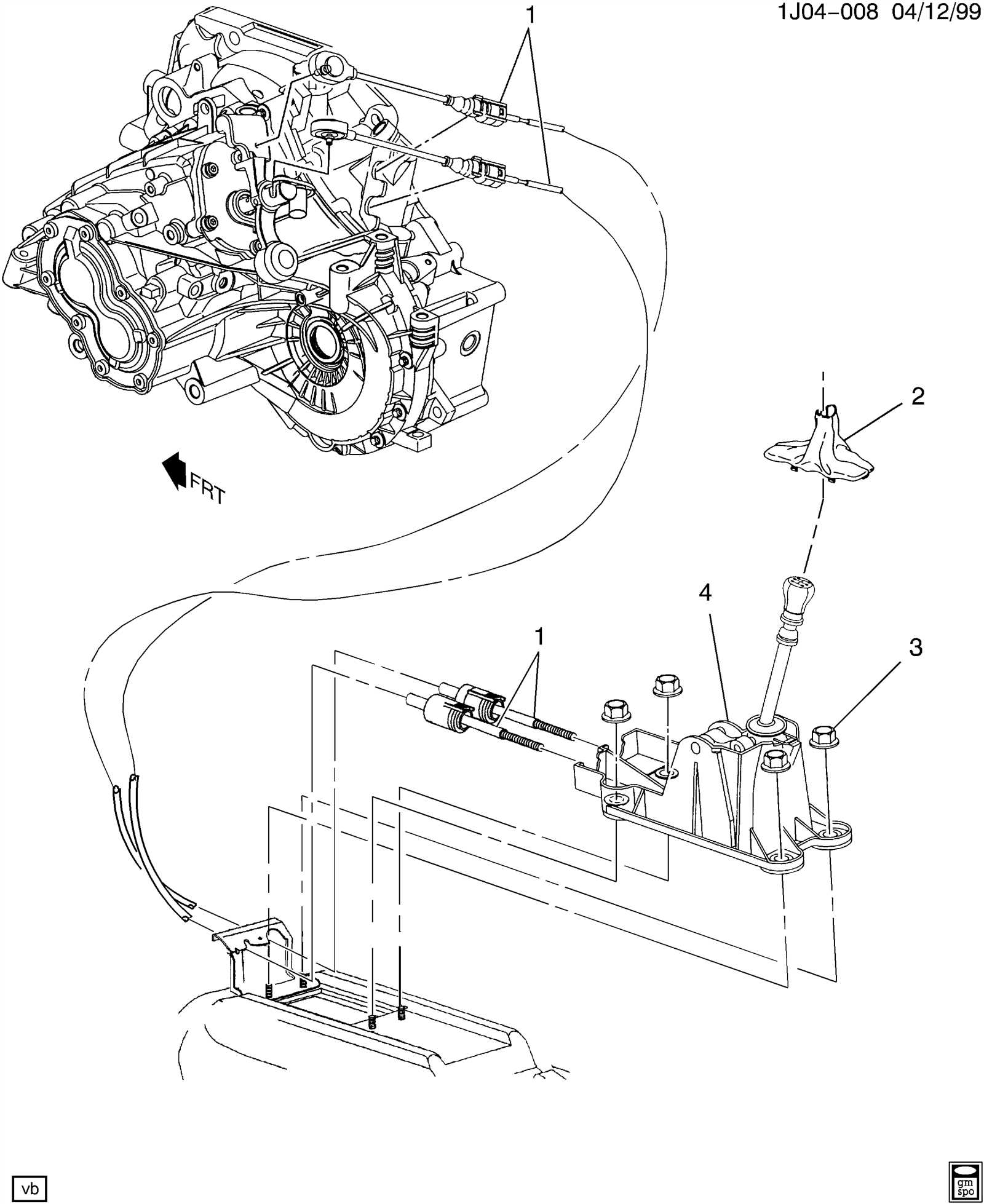

Visual representation of these components can serve as an invaluable tool for understanding their arrangement and functionality. By examining the layout and interconnections, one can gain insight into how each piece interacts within the overall system. This knowledge is essential for diagnosing issues and implementing effective solutions.

Moreover, a clear depiction of these integral mechanisms fosters a deeper appreciation for the engineering marvels that drive our automobiles. From the initiation of power from the engine to its final delivery to the wheels, recognizing the structure and role of each element is vital for anyone involved in automotive repair or modification.

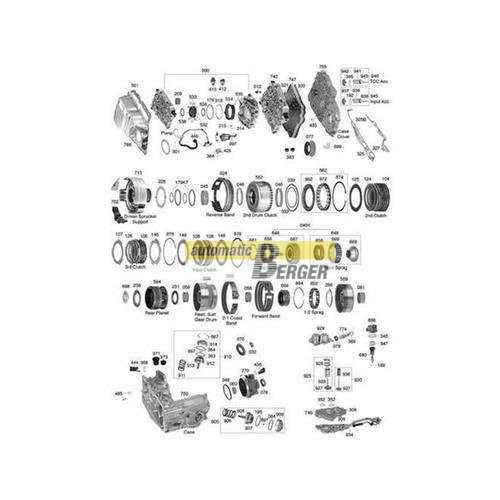

Understanding GM Transmission Components

Exploring the intricate mechanisms that facilitate vehicle movement reveals a complex interplay of elements, each contributing to the overall functionality. A comprehensive understanding of these essential components allows for better maintenance, performance optimization, and troubleshooting.

At the core of these systems lies a variety of crucial elements that work together to ensure smooth gear shifts and efficient power delivery. Familiarity with the roles and interactions of these components can enhance both vehicle performance and longevity.

| Component | Function |

|---|---|

| Clutch | Engages and disengages the engine from the drivetrain, allowing for gear changes. |

| Gear Set | Transfers power from the engine to the wheels, altering torque and speed. |

| Hydraulic System | Controls fluid pressure to facilitate automatic shifting and component engagement. |

| Planetary Gear Assembly | Enables multiple gear ratios in a compact design, allowing for smooth acceleration. |

| Valve Body | Directs hydraulic fluid to the appropriate components for shifting sequences. |

Understanding these crucial elements not only empowers vehicle owners but also aids in diagnosing issues and implementing effective solutions, ensuring optimal vehicle operation.

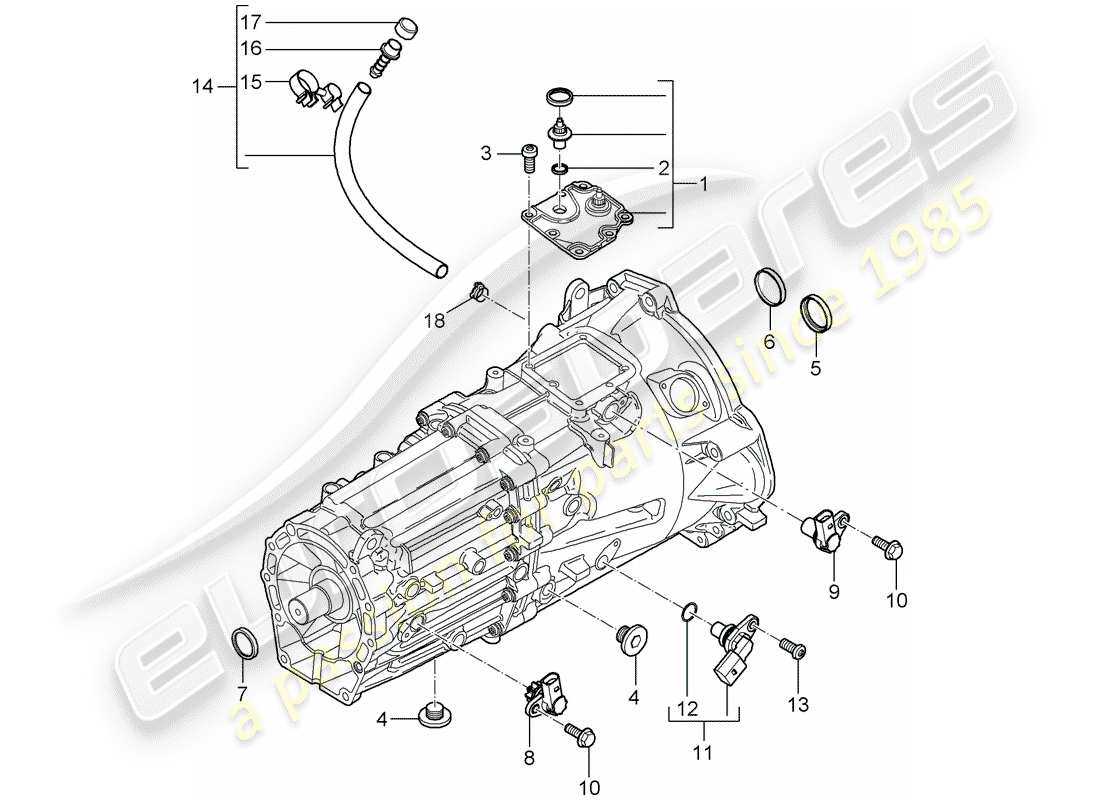

Key Parts of GM Transmissions

Understanding the essential components of GM systems is crucial for both enthusiasts and professionals. These elements work in harmony to ensure optimal performance, durability, and efficiency. Each component plays a vital role, contributing to the overall functionality and reliability of the drivetrain.

- Torque Converter: This device facilitates the transfer of power from the engine to the drivetrain, allowing for smooth acceleration and deceleration.

- Clutch Packs: These assemblies engage and disengage various gears, ensuring a seamless transition between different driving modes.

- Planetary Gear Set: A complex arrangement that allows for multiple gear ratios, enabling a balance between power and efficiency.

- Valve Body: This critical component directs hydraulic fluid to various systems, controlling gear changes and overall operation.

- Oil Pump: Responsible for circulating fluid throughout the system, the oil pump ensures that all components receive the necessary lubrication.

- Filter: This element keeps contaminants out of the fluid, prolonging the life of the entire system.

Each of these components is designed with precision, reflecting the engineering excellence that GM is known for. Regular maintenance and understanding how these elements work together can greatly enhance vehicle longevity and performance.

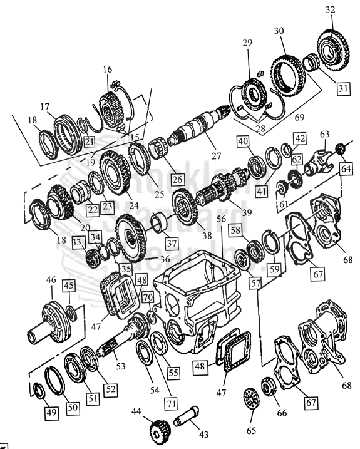

Functions of Transmission Gears

Gears play a crucial role in the efficient operation of a vehicle’s drive system. They manage the relationship between engine power and wheel movement, enabling optimal performance across various driving conditions. By adjusting the rotational speed and torque, these components ensure that a vehicle can accelerate, maintain speed, and navigate different terrains effectively.

Speed Adjustment

One of the primary functions of gears is to modify speed. By engaging different gear ratios, the system allows for a balance between high-speed travel and necessary torque for acceleration. Lower ratios provide increased force for starting and climbing, while higher ratios enable efficient cruising at elevated speeds.

Torque Management

Another vital function is torque distribution. Gears are designed to amplify the engine’s torque, translating it into usable power for the wheels. This transformation is essential for overcoming resistance, whether it’s from inclines, heavy loads, or varying road conditions. The ability to manage torque effectively contributes to the overall performance and drivability of the vehicle.

In summary, the functionality of gears is fundamental in achieving a harmonious balance between speed and power, allowing for a smoother and more controlled driving experience.

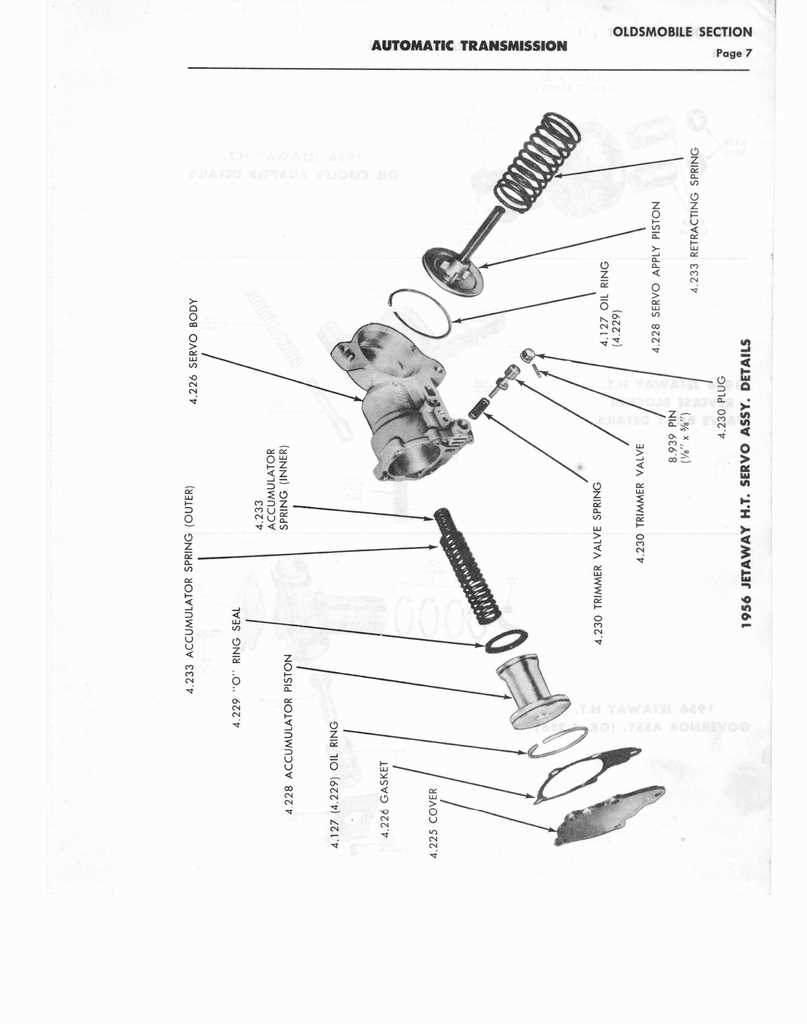

How to Read Transmission Diagrams

Understanding complex schematics can significantly enhance your ability to repair and maintain vehicle mechanisms. These illustrations provide a visual representation of components and their interconnections, enabling a clearer understanding of how everything operates together.

When approaching these visuals, consider the following steps:

- Familiarize Yourself with Symbols: Different components are represented by unique symbols. Knowing what each symbol stands for is crucial for accurate interpretation.

- Identify the Layout: Look for a clear layout that shows how parts are organized. This can help you grasp the relationship between various elements.

- Follow the Flow: Pay attention to the direction of movement indicated by arrows. This will help you understand how energy or power is transmitted throughout the system.

Additionally, here are some tips to enhance your comprehension:

- Use a Legend: Most schematics include a legend that explains the symbols used. Refer to it as needed.

- Break it Down: Tackle one section at a time instead of trying to absorb the entire illustration at once.

- Consult Resources: Utilize manuals or online guides for additional context and explanations.

With practice and patience, you’ll find that these illustrations become an invaluable tool in understanding the intricate systems of your vehicle.

Common Issues with GM Transmissions

Many vehicle owners encounter a range of challenges when it comes to the mechanisms responsible for power delivery in their GM models. Recognizing these problems early can save time and expense, ensuring smoother operation and longevity of the vehicle.

Frequent Problems

- Slipping Gears

- Unusual Noises

- Delayed Engagement

- Fluid Leaks

- Overheating

Causes and Solutions

- Slipping Gears: This can be due to worn components or low fluid levels. Regular checks and replacements can help maintain optimal function.

- Unusual Noises: Grinding or whining sounds often indicate internal damage. Immediate inspection is recommended to prevent further issues.

- Delayed Engagement: Hesitation when shifting can stem from a range of issues, including faulty sensors or low hydraulic pressure. Diagnosing the exact cause is crucial.

- Fluid Leaks: Leaks can lead to inadequate lubrication. Checking seals and gaskets regularly can prevent significant damage.

- Overheating: This issue may arise from low fluid levels or a faulty cooler. Ensuring the cooling system is functioning properly is essential.

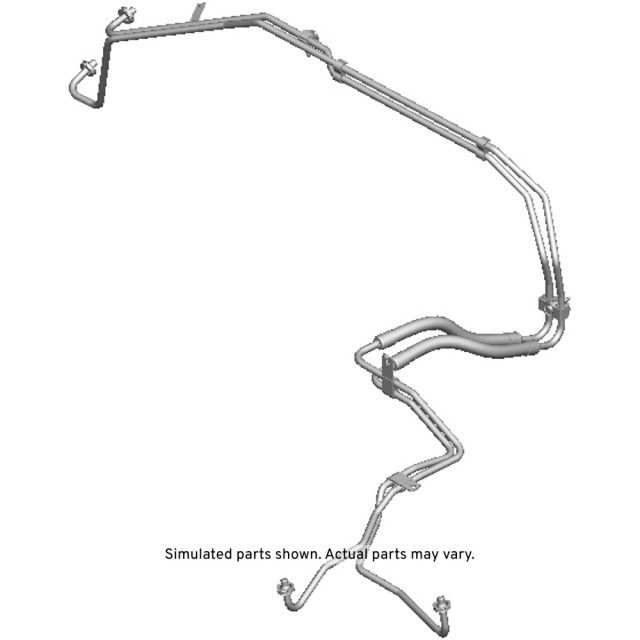

Importance of Transmission Fluid

Fluids play a crucial role in the functionality and longevity of any vehicle’s internal mechanisms. They serve multiple purposes, including lubrication, heat dissipation, and facilitating smooth movement. Ensuring that these liquids are in optimal condition is essential for the overall performance and reliability of your automobile.

Functions of the Essential Fluid

This vital liquid not only reduces friction between moving components but also acts as a coolant, preventing overheating during operation. Additionally, it aids in the efficient shifting of gears, contributing to a seamless driving experience. Regular checks and maintenance of this fluid can prevent costly repairs and ensure that your vehicle operates at its best.

Signs of Deterioration

Monitoring the condition of this crucial fluid is important. Various indicators can suggest that it may need replacement or replenishment. Understanding these signs can help in timely interventions, thus avoiding potential issues down the road.

| Indicator | Possible Issue |

|---|---|

| Dark or dirty color | Contamination |

| Burnt smell | Overheating |

| Difficulty shifting | Low level or degraded fluid |

| Unusual noises | Insufficient lubrication |

Maintenance Tips for GM Transmissions

Proper care and regular upkeep are essential for ensuring the longevity and performance of your vehicle’s drivetrain components. Adopting a few key practices can help prevent issues and enhance efficiency, ultimately leading to a smoother driving experience.

Regular Fluid Checks

One of the most crucial aspects of upkeep is monitoring the quality and level of the fluid. Check for discoloration or a burnt smell, which can indicate the need for a change. Ensuring that the fluid is at the appropriate level helps maintain optimal functionality and prevents unnecessary wear on internal elements.

Routine Inspections

Conducting periodic inspections can catch potential problems early. Look for any signs of leaks, unusual noises, or vibrations while driving. Addressing these issues promptly can save you from costly repairs down the line. Consult your vehicle’s manual for recommended inspection intervals to stay on track with maintenance.

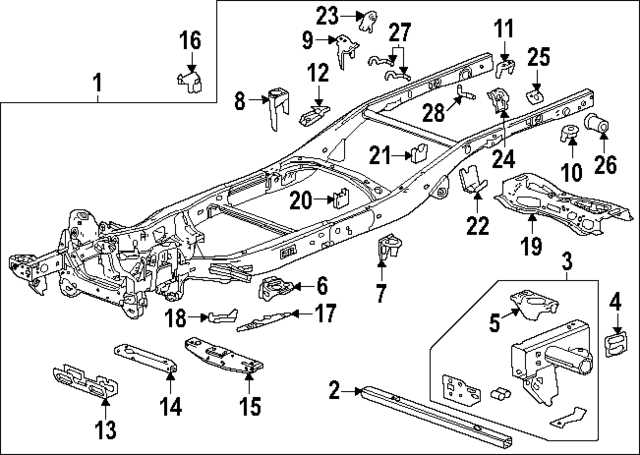

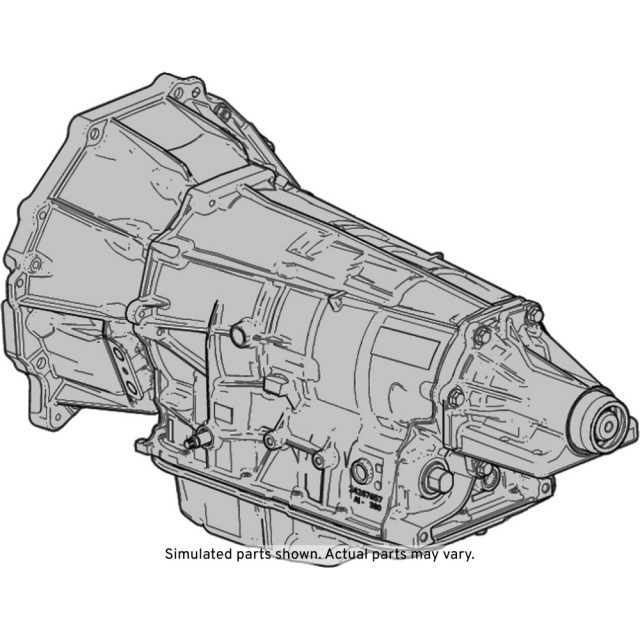

Transmission Assembly Process Explained

The process of assembling complex mechanical systems involves meticulous attention to detail and a thorough understanding of each component’s function. This intricate task requires precision and a methodical approach to ensure that every element interacts seamlessly, contributing to the overall efficiency and performance of the machinery.

Key Steps in the Assembly Process

The assembly journey typically unfolds in several crucial stages, each designed to enhance the effectiveness and reliability of the entire unit. Below are the primary steps involved:

| Step | Description |

|---|---|

| Preparation | Gather all necessary components and tools, ensuring everything is clean and free of defects. |

| Alignment | Carefully align components to guarantee proper fit and function, minimizing wear and tear. |

| Fastening | Secure components using appropriate fasteners, applying the correct torque specifications. |

| Testing | Conduct functional tests to verify that all systems operate as intended, identifying any issues early on. |

Quality Control Measures

Throughout the assembly, rigorous quality control protocols are essential. These measures not only ensure that each section meets industry standards but also help prevent future malfunctions. Regular inspections, combined with adherence to manufacturer guidelines, contribute to a successful assembly process, yielding a robust and reliable mechanical unit.

Aftermarket Parts vs. OEM Components

The choice between third-party components and those provided by the original manufacturer can significantly impact performance and longevity. Each option comes with its own set of advantages and drawbacks, influencing both the functionality and the overall experience of vehicle ownership.

Third-party components are often seen as budget-friendly alternatives, providing similar functionalities at a reduced cost. Many enthusiasts appreciate the variety available, as these options can enhance performance and offer unique features not found in standard offerings. However, quality can vary widely among manufacturers, making it essential to research and select reputable brands to avoid potential issues.

On the other hand, original manufacturer components ensure compatibility and reliability, having been designed specifically for the vehicle in question. While these options may come at a premium price, their durability and performance consistency often justify the investment for many drivers. Additionally, they typically come with warranties that provide peace of mind in case of defects or failures.

Ultimately, the decision between aftermarket and original components hinges on individual priorities, whether they be cost, performance, or reliability. Weighing these factors carefully can lead to a more informed choice that best suits one’s driving needs.

Diagnostic Tools for Transmission Problems

Identifying issues within a vehicle’s gear system requires specialized equipment and methods. Utilizing the right diagnostic tools can streamline the process, helping mechanics and vehicle owners pinpoint malfunctions efficiently. This section will explore essential instruments and techniques to assist in diagnosing complications in the powertrain.

Effective diagnostic tools include:

- OBD-II Scanners: These devices read error codes generated by the vehicle’s onboard computer, providing insights into potential faults.

- Pressure Gauges: Measuring hydraulic pressure helps determine if the system is functioning within the required specifications.

- Digital Multimeters: Useful for checking electrical connections and components related to the gear system.

- Fluid Analyzers: Assessing the condition of the lubricant can reveal issues like contamination or degradation.

Additionally, some advanced tools provide detailed analyses, such as:

- Scan Tools: More comprehensive than standard OBD-II scanners, these can display live data and perform tests on specific components.

- Data Loggers: These devices capture information over time, allowing for trend analysis and more precise diagnostics.

- Vibration Analyzers: These can identify mechanical imbalances or wear that may not be apparent through traditional methods.

Utilizing these tools effectively can save time and resources, ensuring that issues are addressed promptly and accurately. By investing in proper diagnostic equipment, both professionals and DIY enthusiasts can enhance their ability to maintain vehicle performance.

Upgrading Your GM Transmission System

Enhancing the performance of your vehicle’s shifting mechanism can lead to improved efficiency, increased power delivery, and an overall better driving experience. Whether you’re looking to boost acceleration or optimize fuel consumption, focusing on this crucial system can yield significant benefits.

Choosing the Right Components

When considering enhancements, it’s essential to select high-quality components that match your vehicle’s specifications. Investing in robust clutches, improved gears, and upgraded fluids can make a substantial difference. High-performance alternatives often provide better durability and efficiency, ensuring your setup can handle increased demands.

Installation and Maintenance

Proper installation is key to reaping the rewards of your upgrades. Engaging a professional can help ensure that everything is aligned and functioning optimally. Regular maintenance, such as fluid changes and inspections, will also prolong the lifespan of your enhancements. Keeping a close eye on performance metrics allows you to address any issues before they escalate.