Comprehensive Guide to John Deere JS63 Transmission Parts Diagram

In the world of farming equipment, the intricacies of machinery play a crucial role in enhancing efficiency and productivity. A comprehensive look at the various components and their functions allows operators to maintain optimal performance, ensuring that the machinery runs smoothly during demanding tasks.

Familiarity with the essential elements that contribute to the overall operation is vital for any machinery user. By exploring the layout and relationships between different components, one can uncover the ultimate insights necessary for effective maintenance and troubleshooting.

In this article, we will delve into a detailed exploration of the inner workings of a specific model, focusing on how each segment interacts and contributes to the machinery’s functionality. Understanding this will empower operators to take informed actions for repairs and upgrades.

Overview of John Deere JS63 Transmission

This section provides a comprehensive look at the essential mechanisms involved in the operation of the mower’s drive system. Understanding these components is crucial for effective maintenance and repair.

Key Components

- Gear assembly

- Drive belts

- Linkages

- Fluid systems

Maintenance Tips

- Regularly check fluid levels.

- Inspect belts for wear and tear.

- Ensure all connections are secure.

- Clean components to prevent debris buildup.

Importance of Transmission Parts

The functionality of any machinery heavily relies on its internal components. These essential elements work in unison to ensure smooth operation and efficiency, playing a critical role in the overall performance of equipment.

Understanding the significance of these components empowers users to make informed decisions regarding care and upgrades, ultimately leading to improved performance and user satisfaction. Investing in quality replacements ensures that equipment continues to function optimally over time.

Key Components in Transmission Systems

The efficiency and reliability of machinery heavily depend on the intricate systems that facilitate power transfer. Understanding the essential elements of these mechanisms is crucial for optimal performance and maintenance. Each component plays a vital role, contributing to the overall functionality and durability of the equipment.

| Component | Function |

|---|---|

| Gearbox | Adjusts speed and torque, allowing for better control of machinery operations. |

| Clutch | Engages and disengages power flow, enabling smooth transitions during operation. |

| Shifter | Facilitates gear changes, providing the operator with control over speed and power delivery. |

| Drive Shafts | Transmits rotational power from the engine to the wheels or other components. |

| Bearings | Reduce friction and support rotating elements, enhancing the overall efficiency of the system. |

Each of these elements is integral to the seamless operation of machinery, ensuring that power is effectively harnessed and utilized. Regular inspection and maintenance of these components can significantly extend the lifespan of equipment and improve its performance.

Identifying JS63 Transmission Issues

Understanding potential problems within the power delivery system is essential for ensuring optimal performance. Recognizing early signs of malfunction can help in mitigating extensive repairs and maintaining efficiency.

Common Symptoms of Malfunction

Several indicators can signal issues within the system. These symptoms may include unusual noises, difficulty shifting gears, or decreased power transfer. Observing these signs promptly can facilitate timely intervention.

Diagnostic Checklist

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Unusual Noises | Worn components | Inspect and replace damaged parts |

| Difficulty Shifting | Fluid issues | Check and refill fluid levels |

| Loss of Power | Blocked filters | Clean or replace filters |

Regular maintenance and observation can prevent severe damage and enhance the longevity of the equipment. Addressing any irregularities immediately will ensure reliable operation and avoid costly repairs in the future.

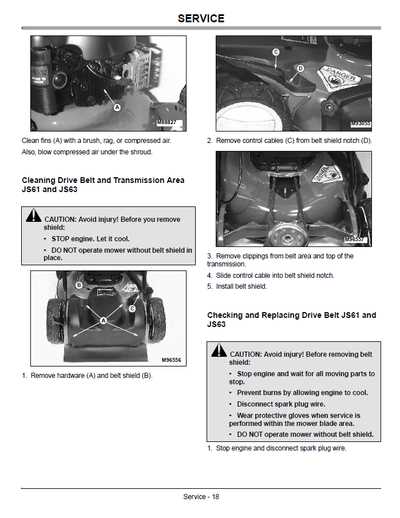

Maintenance Tips for JS63 Models

Proper upkeep is essential for enhancing the longevity and performance of your equipment. Regular attention to specific components can prevent costly repairs and ensure efficient operation. Here are some key strategies to maintain your model effectively.

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Replace oil to ensure smooth functioning and prevent engine wear. |

| Filter Inspection | Every 100 hours | Check air and fuel filters for clogs to maintain optimal performance. |

| Grease Bearings | Every 25 hours | Lubricate bearings to reduce friction and extend service life. |

| Battery Check | Monthly | Inspect connections and charge level to ensure reliable starting. |

Implementing these practices will ultimately contribute to the reliability and efficiency of your equipment.

Common Repair Procedures Explained

This section outlines prevalent methods for addressing mechanical issues commonly encountered in agricultural machinery. Understanding these techniques can streamline maintenance and enhance equipment longevity.

Routine Maintenance Steps

- Inspecting components for wear and tear.

- Changing fluids regularly to ensure optimal performance.

- Cleaning filters to prevent blockages.

Troubleshooting Techniques

- Identifying symptoms of malfunction.

- Using diagnostic tools for precise analysis.

- Implementing corrective measures based on findings.

Replacement Parts Availability and Sources

Finding components for machinery maintenance is essential for optimal performance. Various suppliers offer a range of options to ensure that equipment remains in top condition.

Where to Look

- Authorized Dealers

- Online Retailers

- Local Hardware Stores

- Specialized Machinery Outlets

Factors to Consider

- Quality of the components

- Availability of inventory

- Pricing and shipping options

- Customer service and support

Understanding the Parts Diagram

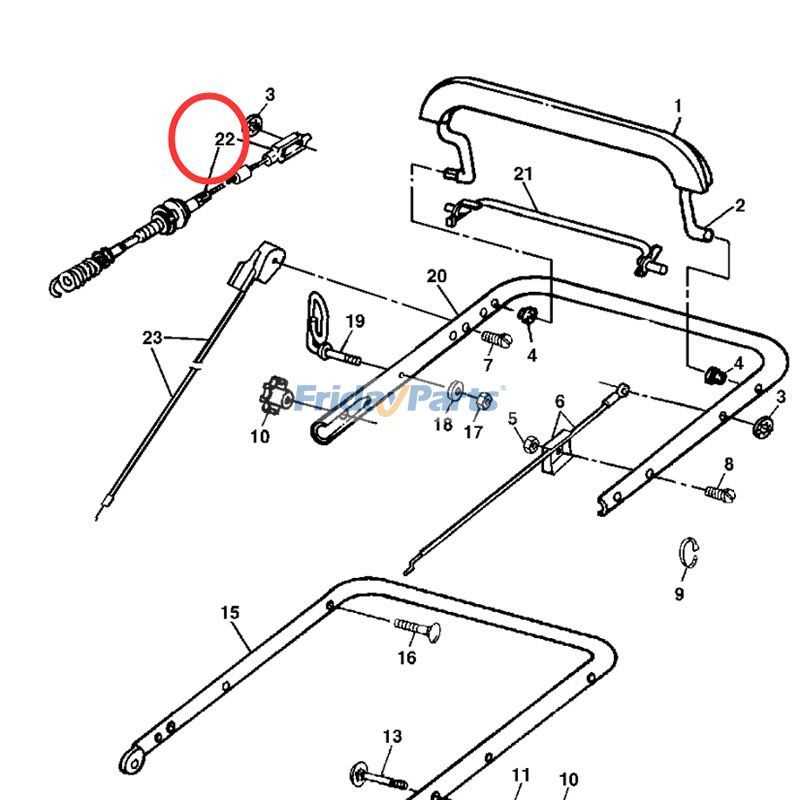

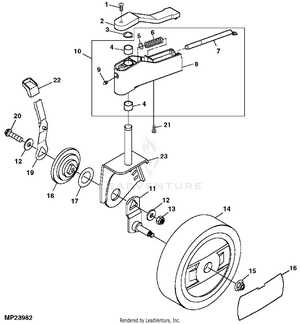

When analyzing a visual representation of mechanical components, it is essential to grasp the structure and layout of the image. This type of guide provides a clear view of each element, helping identify their positions and roles within the system. By studying the arrangement, users can better understand how various elements interact and contribute to the overall function.

Deciphering Component Placement

The layout typically includes numerous elements, each marked with reference numbers or labels. These indicators help

How to Read a Transmission Diagram

Understanding the layout of a technical illustration can be a valuable skill for anyone involved in machinery maintenance. These visual guides provide insights into the internal components and their arrangement, enabling users to identify specific elements and comprehend how they interact within the system.

To begin, it’s important to familiarize yourself with the labels and symbols typically used in such illustrations. Each component is usually marked with a unique identifier, making it easier to distinguish one part from another. Pay attention to the lines connecting the elements, as these often represent the flow of motion or the transfer of power within the mechanism.

Next

Tools Required for Transmission Repair

When it comes to fixing mechanical issues, having the right equipment is crucial for achieving the best results. Properly selected tools not only make the process easier but also help to ensure the components are handled correctly, reducing the risk of damage or mistakes.

One essential category includes wrenches and sockets of various sizes, which are used for loosening and tightening bolts. It’s important to have both standard and metric measurements to cover different hardware types. A reliable ratchet with an extension can also

Upgrading vs. Replacing Transmission Parts

When it comes to mechanical maintenance, one often faces a choice between enhancing existing components or opting for complete replacements. Each approach has its own advantages and potential drawbacks, which largely depend on the condition of the equipment and the desired outcome. Deciding which path to take involves careful evaluation of factors such as cost, expected lifespan, and the availability of improved alternatives.

Benefits of Upgrading Components

Upgrading individual elements can be a cost-effective way to improve performance without the expense of a full replacement. Modern enhancements may offer higher durability or efficiency compared to older versions, resulting in a more reliable operation. Additionally,

FAQs About JS63 Transmission Repairs

When it comes to maintaining your lawn equipment, issues related to mechanical systems can be a frequent concern. Knowing what to look out for and how to address common problems can help prevent larger issues from arising. Here are some frequently asked questions regarding the repair and maintenance of your mower’s drive system.

What Are Common Issues to Watch For?

- Unusual noises during operation, which may indicate wear or damage to internal components.