Mack T2180 Transmission Parts Diagram Explained

In the realm of heavy machinery, the intricate network of mechanisms that facilitate power transfer plays a crucial role in performance and efficiency. This section delves into the essential elements that comprise these complex systems, shedding light on their functionality and interconnections. Each component serves a specific purpose, contributing to the overall operation of the vehicle.

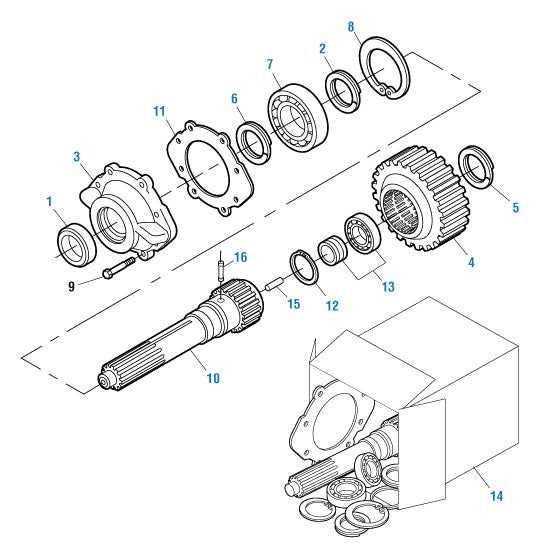

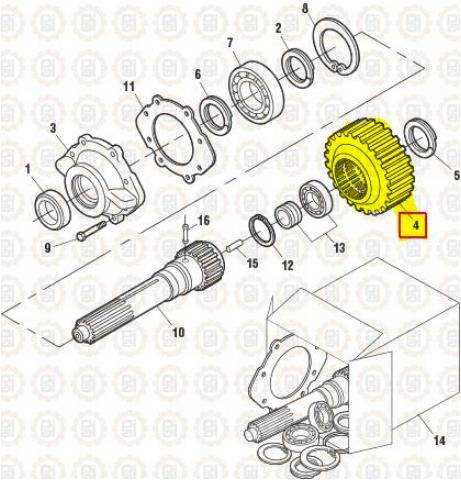

Visualizing these elements can significantly enhance comprehension, allowing operators and technicians to identify and troubleshoot issues with greater ease. By examining the layout and relationships between different units, one can gain insights into maintenance practices and potential enhancements. Understanding this intricate assembly not only aids in repairs but also promotes optimal functionality.

Additionally, knowledge of the arrangement and characteristics of these components empowers users to make informed decisions when it comes to upgrades and replacements. As machinery continues to evolve, familiarizing oneself with the foundational aspects of these systems is essential for anyone involved in their operation or maintenance.

Understanding Mack T2180 Transmission Parts

The intricacies of vehicle gear systems are vital for their optimal performance. A thorough knowledge of the individual components involved is essential for maintenance and repair. This section delves into the essential elements that make up a specific type of gear mechanism, shedding light on their functions and interactions.

Key Components and Their Functions

At the heart of any gear assembly lies a series of crucial elements, each with a specific role. The housing serves as the protective shell, while the gears facilitate the transfer of power. Bearings reduce friction and allow smooth movement, ensuring longevity and efficiency. Clutches enable seamless engagement and disengagement, making gear shifts smooth and reliable.

Importance of Regular Maintenance

Regular inspection and upkeep of these components are vital for the overall health of the vehicle. Neglecting even minor issues can lead to significant complications, affecting performance and safety. Understanding how each element works together not only aids in timely repairs but also enhances the lifespan of the entire system.

Components of the Mack T2180 System

This section delves into the essential elements that constitute the intricate assembly of the vehicle’s powertrain. Understanding these components is crucial for effective maintenance and performance enhancement. Each part plays a vital role in ensuring the overall functionality and efficiency of the system.

Main Components

- Power Input Shaft

- Gear Assembly

- Clutch Mechanism

- Output Shaft

- Fluid Pump

Auxiliary Elements

- Filters

- Seals and Gaskets

- Control Valves

- Sensors

- Cooling System

Each of these components works in unison to deliver optimal performance, ensuring smooth operation and longevity of the vehicle’s overall system.

Functionality of Each Transmission Part

The intricate assembly of components within a shifting mechanism plays a crucial role in ensuring optimal performance and efficiency. Each element is designed with a specific function, contributing to the overall operation and responsiveness of the vehicle.

Gear Set: The gear set is responsible for modifying the torque and speed delivered to the wheels. By varying the gear ratio, it allows for smooth acceleration and deceleration, adapting to different driving conditions.

Clutch: The clutch enables the driver to engage and disengage the engine from the drivetrain, allowing for seamless gear changes. Its proper functioning is essential for preventing gear clash and ensuring smooth transitions.

Shifter: The shifter serves as the interface between the driver and the gear assembly. It provides the necessary control to select the desired gear, influencing the vehicle’s speed and power output.

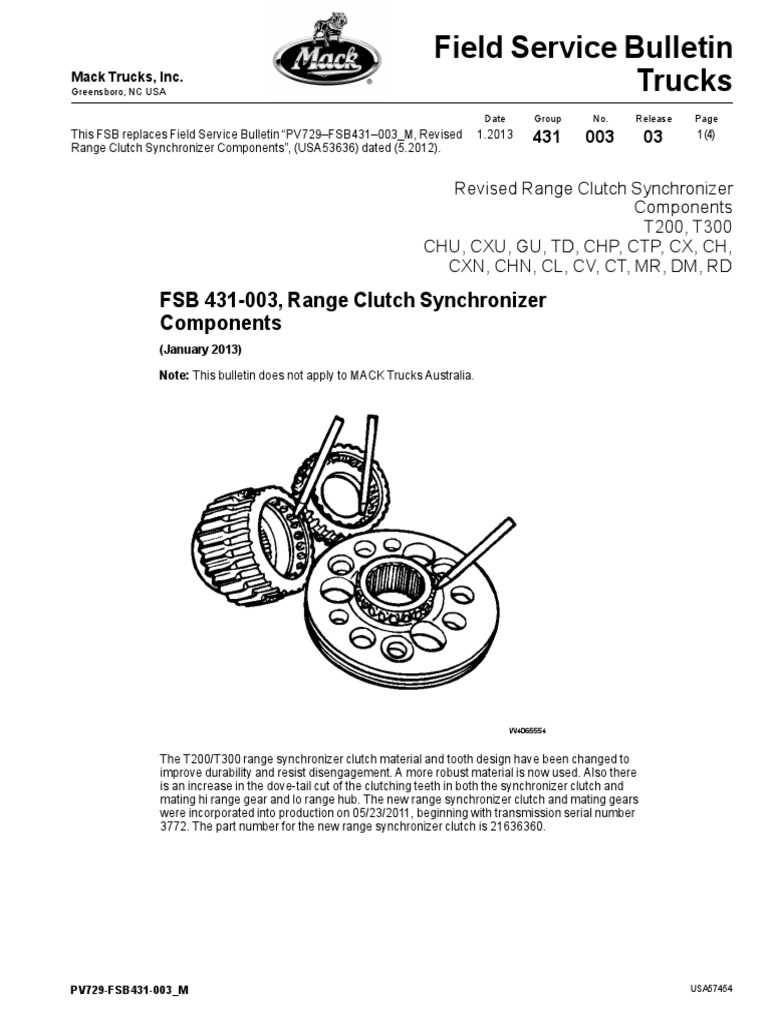

Synchronizers: These components facilitate smooth engagement of gears by matching their rotational speeds. This reduces wear and tear, enhancing longevity and ensuring a quiet operation.

Bearings: Bearings support rotating elements, minimizing friction and wear. They are critical in maintaining the alignment and stability of various moving parts, ensuring efficient power transfer.

Hydraulic System: The hydraulic mechanism plays a vital role in actuating the clutch and shifting gears. It utilizes fluid pressure to facilitate smooth transitions, providing responsiveness and control.

Understanding the functionality of each component helps in diagnosing issues and optimizing performance, ultimately leading to a more enjoyable driving experience.

Common Issues with Mack T2180 Parts

When dealing with heavy-duty machinery, understanding the frequent challenges that arise with components is essential for effective maintenance and operation. Many users encounter specific issues that can lead to performance setbacks, ultimately affecting productivity.

Wear and Tear

One of the most prevalent concerns involves the natural degradation of components over time. Frequent usage can result in friction-related damage, leading to malfunctions. Regular inspections are vital to identify early signs of wear.

Fluid Leaks

Another significant problem is the occurrence of leaks. These can stem from improper seals or connections, which may lead to reduced efficiency. Addressing these leaks promptly can prevent more serious complications down the line.

How to Maintain Transmission Efficiency

Ensuring optimal performance of your vehicle’s mechanism requires regular attention and care. By adopting specific practices, you can enhance longevity and functionality, preventing potential issues before they escalate. A proactive approach is key to preserving the efficiency of this crucial system.

Regular Fluid Checks

Monitoring fluid levels is essential. Consistent inspections can help identify leaks or degradation, ensuring that the necessary lubrication is always present. Change the fluid according to the manufacturer’s recommendations to maintain peak performance.

Routine Inspections

Conducting frequent examinations of components for wear and tear is vital. Look for signs of damage or unusual wear, and replace any worn items promptly. Keeping everything in optimal condition will significantly contribute to overall efficiency.

Step-by-Step Repair Guide for T2180

This guide offers a comprehensive approach to addressing common issues associated with a specific vehicle component. By following these instructions, you will enhance your understanding of the assembly and improve your ability to perform effective repairs.

Preparation and Tools

Before beginning the repair process, ensure you have all necessary tools at hand. This may include wrenches, screwdrivers, and specialized equipment. Additionally, a clean workspace is essential to keep track of components and prevent contamination.

Repair Process

Start by safely removing the unit from the vehicle. Document each step to aid in reassembly. Once detached, inspect all elements for wear or damage. Replace any faulty parts with high-quality replacements to ensure longevity. Follow the manufacturer’s specifications for reassembly, ensuring that each component is correctly positioned. Finally, conduct tests to verify that the repairs have resolved the issues.

Regular maintenance is crucial for optimal performance. Keeping a close eye on wear and tear can prevent more significant problems down the line. Remember, proper tools and techniques are your best allies in maintaining the functionality of your vehicle’s components.

Replacement Parts: What You Need to Know

Understanding the essentials of component replacements is vital for maintaining optimal vehicle performance. Ensuring the right fit and functionality can significantly enhance the lifespan and efficiency of your machinery.

Quality vs. Cost

When selecting new components, consider the balance between quality and affordability. Higher-quality options may offer greater durability, while budget-friendly alternatives can save initial costs. Always evaluate long-term benefits versus short-term savings.

Compatibility and Specifications

Verify that the chosen components meet specific compatibility criteria for your vehicle model. Referencing manufacturer specifications will help ensure seamless integration and performance, ultimately leading to a smoother operation.

Importance of Accurate Parts Diagram

Having a precise representation of components is crucial for effective maintenance and repair operations. Such visual aids serve as invaluable resources, allowing technicians to identify each piece accurately, ensuring that replacements or adjustments are performed correctly.

Here are several reasons why these representations are essential:

- Clarity: Clear illustrations eliminate ambiguity, making it easier for technicians to understand complex assemblies.

- Efficiency: Quick reference to detailed visuals speeds up the diagnostic process, reducing downtime.

- Training: Accurate visuals are vital for training new staff, providing them with a solid foundation for understanding component interactions.

- Reduction of Errors: A well-constructed reference can help minimize mistakes during assembly or disassembly, ultimately saving time and resources.

- Inventory Management: Precise visual references assist in managing stock, ensuring that necessary items are always available.

In summary, having accurate visual representations of mechanical components significantly enhances both operational efficiency and the overall effectiveness of maintenance tasks.

Tools Required for Transmission Work

When undertaking the complex task of servicing a vehicle’s power transfer system, having the right equipment is essential for success. The appropriate tools not only enhance efficiency but also ensure safety and precision during the process. Below is a list of essential implements that aid in the maintenance and repair of these intricate assemblies.

| Tool | Description |

|---|---|

| Socket Set | Essential for removing bolts and fasteners with various sizes and shapes. |

| Torque Wrench | Ensures bolts are tightened to the manufacturer’s specifications. |

| Fluid Pump | Facilitates the transfer of lubricants and fluids for proper operation. |

| Seal Installer | Helps in accurately positioning seals without damage. |

| Diagnostic Scanner | Assists in identifying issues through electronic monitoring. |

Upgrading Your Mack T2180 System

Enhancing the performance of your vehicle’s system can lead to significant improvements in efficiency and power. By focusing on key components, you can unlock the full potential of your machinery, ensuring a smoother operation and extended lifespan. Whether you’re looking to boost functionality or simply replace outdated elements, careful selection and installation are crucial.

Identifying Key Components

Start by assessing which elements are underperforming or outdated. Upgrading these key components can provide the ultimate enhancement. Consider aspects such as durability, compatibility, and performance when making your choices.

Installation and Maintenance

Once you’ve chosen the right components, proper installation is essential for optimal performance. Follow guidelines closely and consult professionals if needed. Regular maintenance post-upgrade will ensure longevity and efficiency, keeping your system operating at its best.

Comparison with Other Mack Transmissions

This section explores the distinctions and similarities among various gear systems produced by the brand, focusing on their performance, design, and usability. Understanding these differences can help users make informed decisions based on their specific needs.

Durability is a key factor when comparing different models. Some systems are engineered for heavy-duty applications, while others prioritize efficiency and fuel economy.

Additionally, shifting mechanisms vary significantly. Certain models feature advanced automation, enhancing user experience, whereas others maintain a more traditional manual approach, appealing to purists.

Another aspect to consider is serviceability. Some designs allow for easier access to components, simplifying maintenance tasks and reducing downtime.

Ultimately, evaluating these factors provides valuable insights into which option best suits various operational requirements.

Resources for Further Learning and Support

Exploring the intricacies of mechanical systems can be both challenging and rewarding. Access to the right resources is crucial for enhancing knowledge and troubleshooting effectively. This section provides valuable information to support your learning journey and foster a deeper understanding of the subject.

Online Forums and Communities

Engaging with online forums and communities dedicated to mechanical engineering can offer insights and real-world advice from experienced professionals and enthusiasts. Platforms like Reddit and specialized forums provide spaces to ask questions, share experiences, and find solutions to specific issues.

Educational Materials and Manuals

Comprehensive manuals and educational resources are essential for anyone looking to deepen their understanding. Books, online courses, and instructional videos can provide step-by-step guidance and detailed explanations, making complex concepts more accessible and easier to grasp.