Comprehensive Guide to Peerless Transmission Parts Diagram

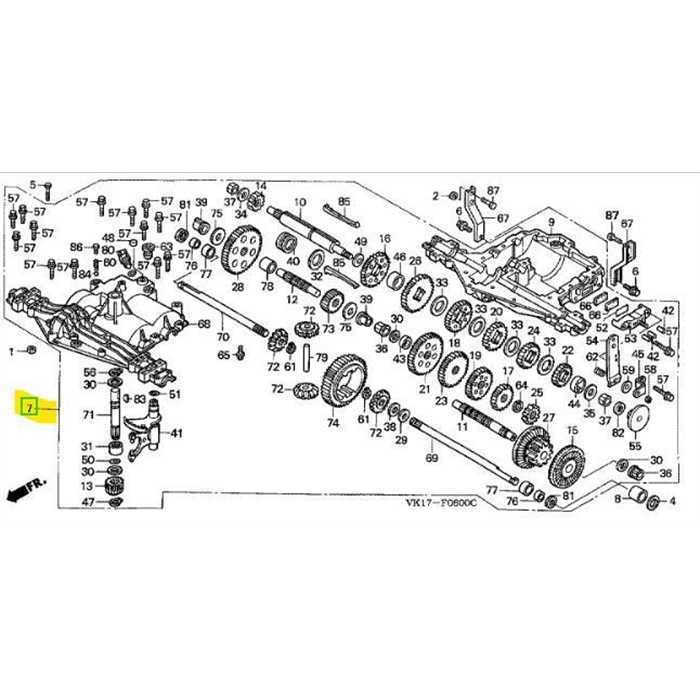

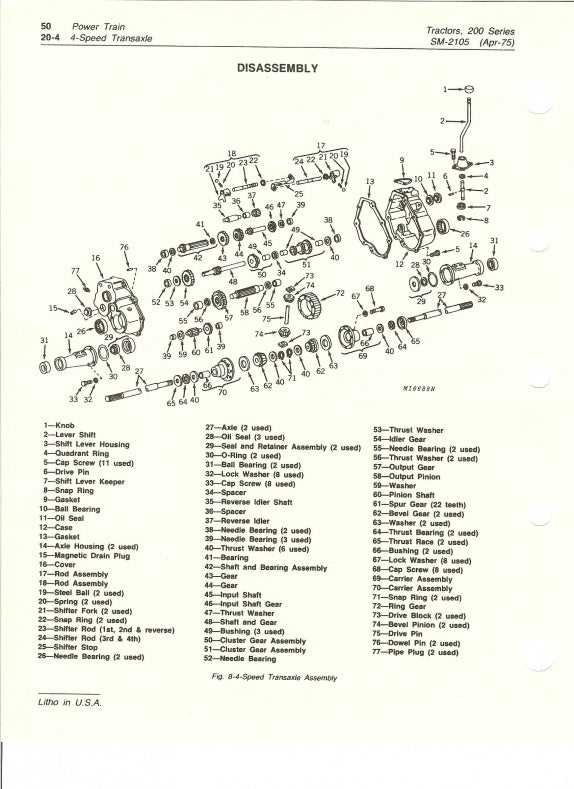

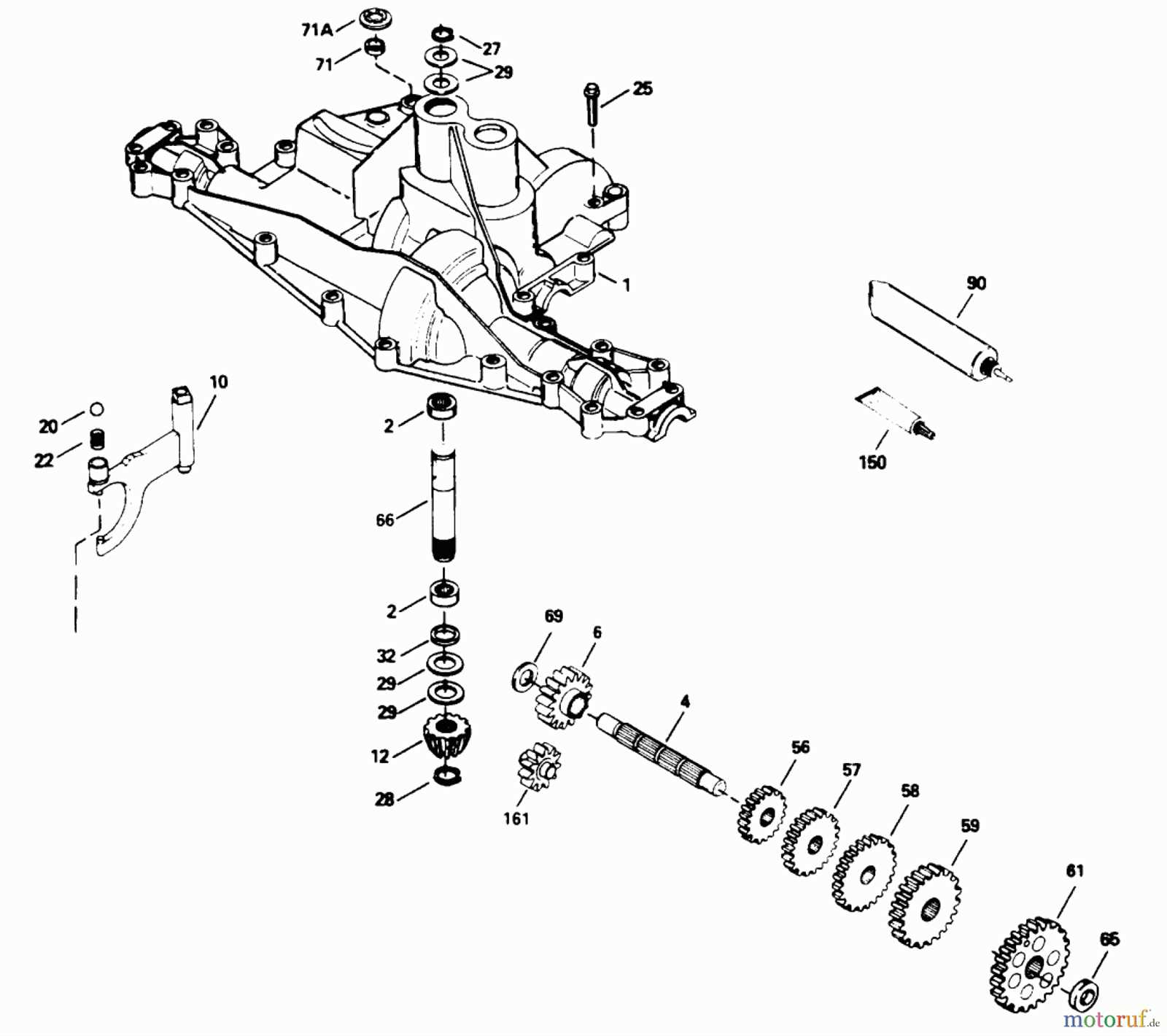

In the realm of machinery, the intricate workings of gear systems play a crucial role in ensuring efficient operation. This section delves into the essential components that contribute to the seamless interaction between various mechanical elements. By examining these vital elements, one can gain insight into the overall functionality and performance of complex systems.

Throughout this exploration, we will highlight the various structures that facilitate motion transfer and energy conversion. Each component, from the most basic to the more complex, serves a unique purpose, working harmoniously to achieve the desired outcomes. A thorough understanding of these mechanisms is key for anyone involved in engineering, maintenance, or design.

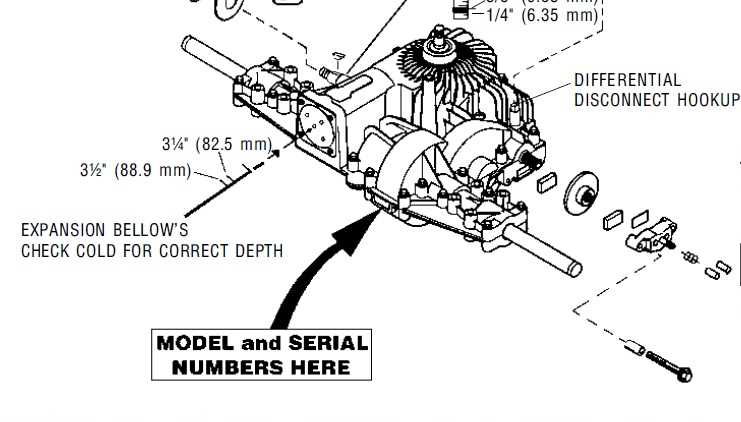

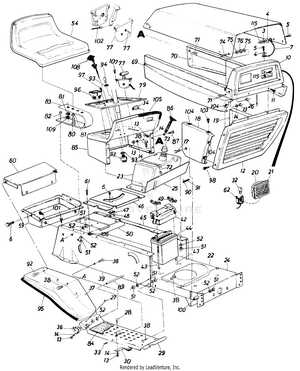

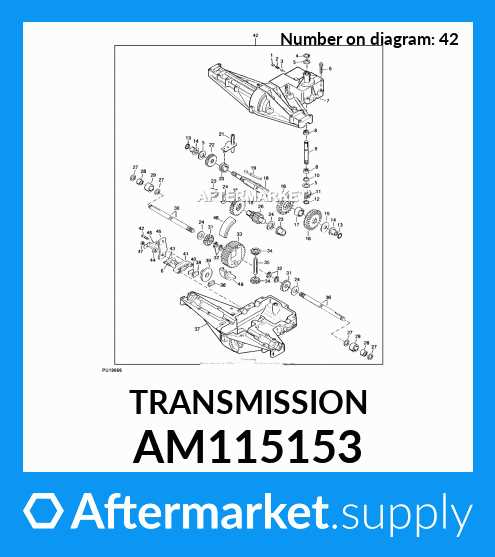

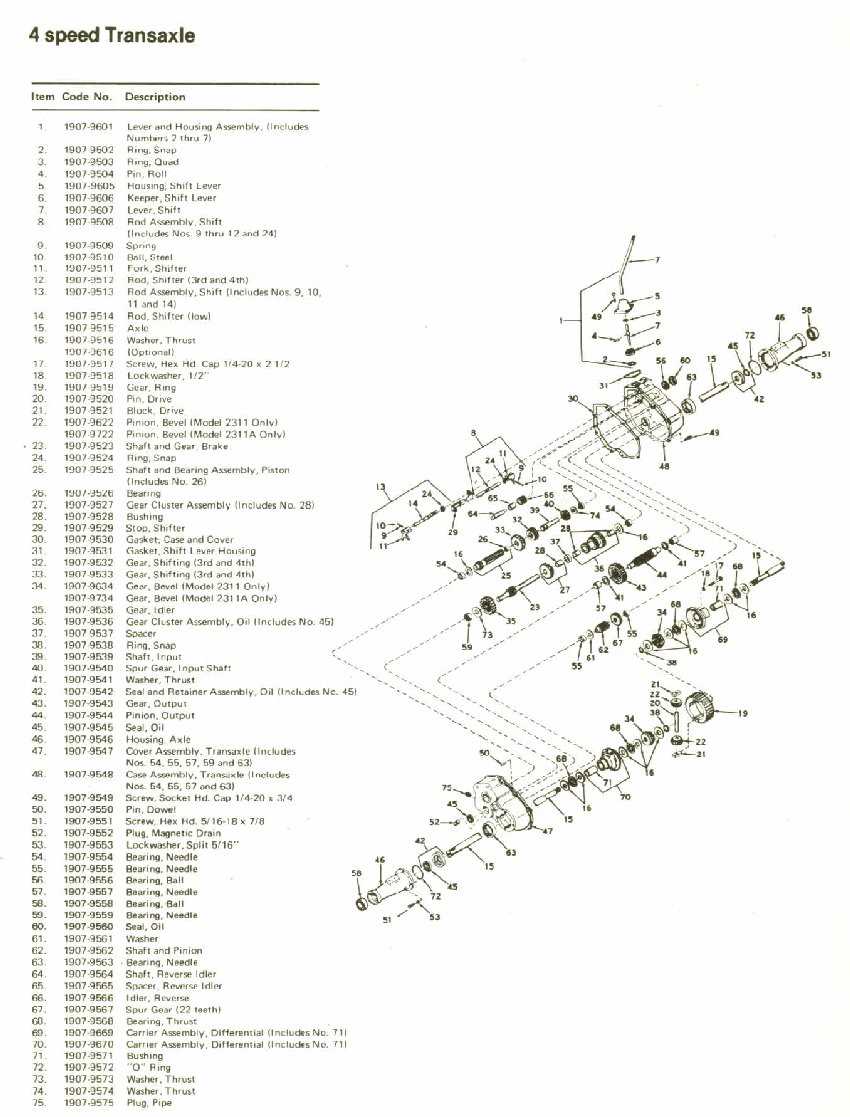

Moreover, we will discuss the significance of visual representation in understanding these systems. A well-crafted illustration can clarify the relationships between components, making it easier to identify issues and optimize performance. By mastering these visual aids, one can enhance both theoretical knowledge and practical skills, leading to greater success in the field.

Understanding Peerless Transmission Components

This section delves into the intricate elements that play a crucial role in the operation of mechanical systems. By exploring the various components, one can gain insights into their functions, interrelationships, and overall significance in enhancing performance and reliability.

The assembly consists of several key components, each serving a unique purpose. Understanding these elements is essential for anyone involved in maintenance or repair. Below are the primary categories:

- Gears: These are essential for transferring motion and torque between different parts of the system.

- Shafts: They facilitate the movement and connection between various components, ensuring smooth operation.

- Bearings: These reduce friction and support rotational elements, enhancing durability and efficiency.

- Linkages: These connect different sections, allowing for coordinated movement and flexibility.

Each of these components interacts in a complex manner, making it crucial to understand their functions and relationships. Below is an outline of their importance:

- Ensuring optimal performance through efficient energy transfer.

- Reducing wear and tear, thereby extending the lifespan of the entire system.

- Facilitating repairs by identifying specific elements that may require attention.

By comprehending these fundamental elements, individuals can make informed decisions regarding maintenance and enhancements, ultimately leading to improved functionality and longevity of mechanical systems.

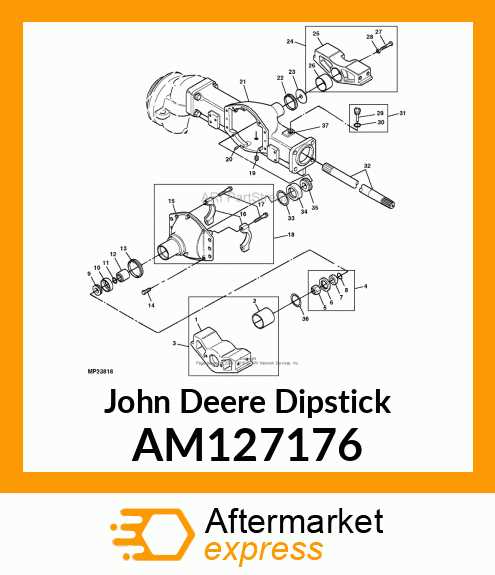

Diagram Overview and Importance

Visual representations serve as crucial tools in understanding complex mechanical systems. They illustrate relationships and functions within various components, enhancing both comprehension and communication among professionals. Such representations provide clarity, ensuring that intricate designs can be easily interpreted and analyzed.

Significance of Visual Representations

The value of these illustrations can be summarized in several key points:

- Facilitate communication among engineers and technicians.

- Provide a clear roadmap for assembly and disassembly procedures.

- Help in diagnosing issues by highlighting potential problem areas.

- Enhance training for new personnel through simplified visuals.

- Allow for efficient documentation and referencing in maintenance records.

Applications in Various Industries

These visual aids are widely used across multiple sectors, including:

- Automotive engineering for vehicle assembly.

- Aerospace for aircraft design and maintenance.

- Manufacturing processes to optimize production lines.

- Robotics for programming and troubleshooting.

In conclusion, effective visual representations play a pivotal role in the successful operation and understanding of mechanical systems, making them indispensable in various fields.

Types of Peerless Transmission Models

Understanding the variety of models available is crucial for selecting the right system for specific applications. Each type is designed with unique features that cater to different performance requirements and operational environments.

Standard Models

Standard variations are typically employed in common machinery, providing reliable performance and ease of maintenance. These systems are well-suited for various general tasks.

High-Performance Models

High-performance versions offer enhanced efficiency and durability, ideal for demanding applications. They incorporate advanced technology to meet rigorous operational standards.

| Model Type | Key Features | Applications |

|---|---|---|

| Standard | Reliable, easy maintenance | General machinery |

| High-Performance | Enhanced efficiency, durability | Heavy-duty applications |

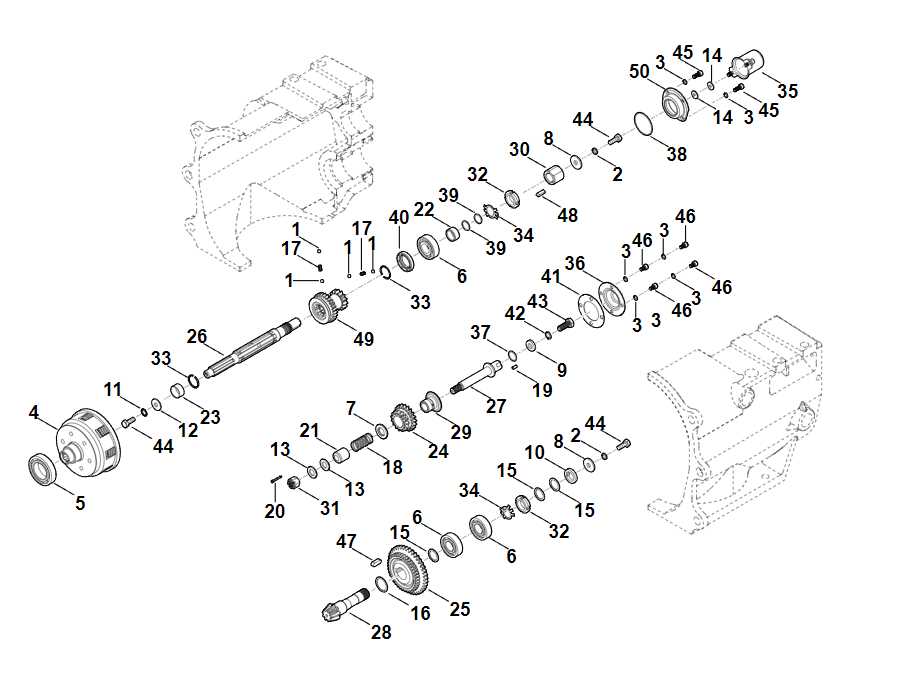

Key Functions of Each Part

Understanding the essential roles of various components in a mechanical system is crucial for optimal performance and maintenance. Each element serves a specific function that contributes to the overall efficiency and reliability of the mechanism.

Core Components

Gears play a vital role in transferring motion and adjusting torque. They enable the system to achieve different speeds and levels of power output, ensuring smooth operation across various conditions.

Support Elements

Bearings are critical for reducing friction and wear between moving parts. Their presence enhances longevity and functionality, allowing for smoother movement and better alignment within the assembly.

Common Issues with Transmission Parts

Mechanical systems often face a variety of challenges that can impact their performance and efficiency. Understanding these challenges is crucial for maintenance and longevity. This section explores some prevalent concerns that can arise in these components, providing insights into their causes and potential solutions.

Frequent Challenges

One of the main issues encountered is wear and tear over time. Components may degrade due to constant friction and stress, leading to malfunctions. Another common problem is fluid leakage, which can significantly affect the operation of the entire system. Additionally, improper installation or alignment can result in various complications, causing inefficient functioning.

Symptoms and Solutions

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Excessive Wear | Unusual noises, slipping | Regular inspections, timely replacements |

| Fluid Leakage | Puddles under the vehicle, low fluid levels | Seal replacements, checking connections |

| Misalignment | Vibration, uneven wear | Realignment, ensuring proper installation |

Maintenance Tips for Longevity

Ensuring the durability and efficiency of mechanical systems requires consistent care and attention. By following a few fundamental guidelines, you can significantly enhance their lifespan and performance.

| Tip | Description |

|---|---|

| Regular Inspections | Conduct frequent assessments to identify wear and tear early on. |

| Lubrication | Apply appropriate lubricants to reduce friction and prevent overheating. |

| Cleanliness | Keep components clean from debris and contaminants that can cause damage. |

| Timely Repairs | Address any issues immediately to avoid further complications. |

| Proper Storage | Store equipment in a suitable environment to protect it from the elements. |

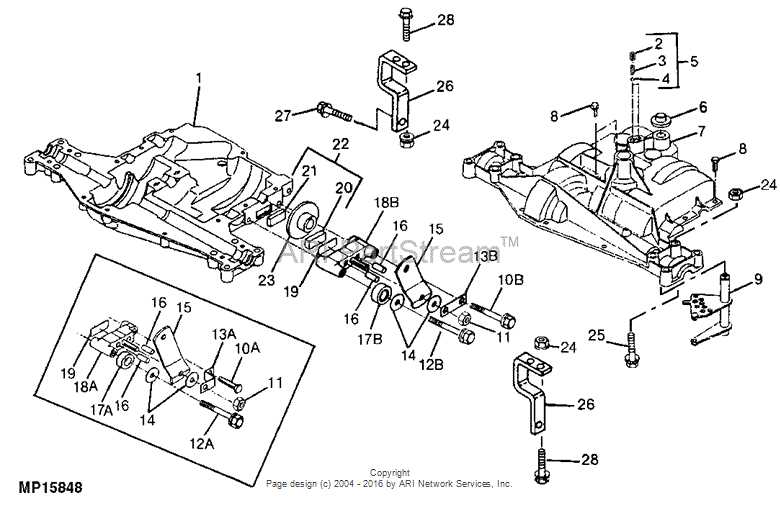

How to Read Transmission Diagrams

Understanding complex visual representations is essential for anyone working with mechanical systems. These illustrations convey vital information about the interrelationships and functionalities of various components. Mastering the ability to interpret these graphics can significantly enhance both efficiency and accuracy in maintenance and repair tasks.

1. Familiarize Yourself with Symbols: Every schematic utilizes specific symbols to represent different elements. Take the time to learn what each icon means, as this will be crucial for deciphering the overall layout and operation.

2. Analyze the Flow of Energy: Observe how power is transmitted throughout the system. Identifying the direction and path of energy flow will help you understand how components interact and function together.

3. Identify Key Components: Look for major elements such as gears, shafts, and couplings. Recognizing these components will allow you to comprehend their roles and how they influence the entire assembly.

4. Understand Relationships: Pay attention to how different parts are connected. The way components are linked often provides insights into their operational dependencies and potential failure points.

5. Use a Legend: Many illustrations include a legend that explains symbols and notations. Refer to this guide to clarify any uncertainties you may have as you work through the schematic.

By applying these strategies, you can enhance your skills in reading complex illustrations, leading to improved troubleshooting and repair outcomes in your mechanical projects.

Comparing Peerless to Other Brands

When evaluating various manufacturers in the mechanical components sector, it is essential to consider factors such as durability, efficiency, and cost-effectiveness. Different brands offer unique advantages, influencing the decision-making process for consumers and businesses alike. This analysis aims to highlight key differences that may impact performance and user satisfaction.

Performance and Durability

One of the most critical aspects to assess is how different manufacturers stack up in terms of performance and longevity. Reliability under various operating conditions is paramount for any mechanical system. The following table outlines a comparison of notable brands based on these criteria.

| Brand | Performance Rating | Durability Rating |

|---|---|---|

| Brand A | 8/10 | 7/10 |

| Brand B | 9/10 | 9/10 |

| Brand C | 7/10 | 8/10 |

| Brand D | 8/10 | 6/10 |

Cost and Availability

Price is another significant factor when comparing different brands. Some may offer more economical options without sacrificing quality, while others may provide premium products that come at a higher cost. Assessing availability in local markets is equally important, as this can affect both procurement and maintenance timelines.

Assembly Techniques for Peerless Transmissions

Understanding the methods involved in constructing complex machinery is essential for ensuring optimal performance and longevity. This section explores effective techniques that can enhance the assembly process, focusing on precision and reliability.

Preparation Steps

- Gather all necessary components and tools.

- Clean each piece to remove debris or contaminants.

- Inspect all elements for signs of wear or damage.

Assembly Process

- Begin with the foundational components, ensuring proper alignment.

- Secure elements using appropriate fasteners, following torque specifications.

- Incorporate lubrication where necessary to reduce friction.

- Conduct a thorough inspection once assembled to ensure all connections are secure.

Safety Precautions During Repairs

When engaging in maintenance or repair tasks, it is crucial to prioritize safety to prevent accidents and ensure a successful outcome. Proper preparation and awareness of potential hazards can significantly reduce risks associated with the work environment and tools involved. Adhering to safety guidelines fosters a more efficient workflow and protects both the individual and the equipment.

Essential Safety Gear

Always wear appropriate personal protective equipment (PPE) such as gloves, safety goggles, and sturdy footwear. These items serve as a barrier against various hazards, including sharp objects, chemical splashes, and falling debris. Furthermore, ensure that your clothing is fitted properly to avoid any entanglement with machinery.

Work Environment Considerations

Maintain a clean and organized workspace to minimize the risk of accidents. Clear away any unnecessary tools and materials that could create tripping hazards. Additionally, ensure proper ventilation when working with chemicals or substances that may release harmful fumes. Finally, be aware of your surroundings and avoid distractions while performing tasks to maintain focus and attention.

Resources for Further Learning

Understanding complex mechanisms requires access to a variety of educational materials and references. This section provides valuable resources to enhance your knowledge and skills in the field, offering different formats to cater to diverse learning preferences.

Books and Publications

- Technical Manuals: Comprehensive guides that offer in-depth information and step-by-step instructions.

- Industry Journals: Peer-reviewed articles discussing the latest advancements and innovations.

- Reference Books: Detailed texts covering fundamental concepts and applications.

Online Courses and Tutorials

- Video Tutorials: Visual demonstrations that simplify complex topics and enhance understanding.

- Webinars: Interactive sessions led by experts that allow for real-time Q&A.

- MOOCs: Massive Open Online Courses that provide structured learning on specific subjects.

Utilizing these resources will significantly aid in deepening your comprehension and practical application in the field.