Comprehensive Guide to SM420 Transmission Parts Diagram

In the realm of automotive engineering, the intricate workings of gear mechanisms play a crucial role in ensuring efficient vehicle operation. These systems are designed to facilitate the transfer of power, enabling optimal performance across various driving conditions. A comprehensive grasp of these components is essential for enthusiasts and professionals alike.

The study of these mechanical assemblies involves exploring the numerous elements that contribute to their functionality. Each piece has a specific purpose, working in harmony with others to achieve seamless gear shifts and robust torque management. Understanding how these components interact provides valuable insights into maintenance and troubleshooting.

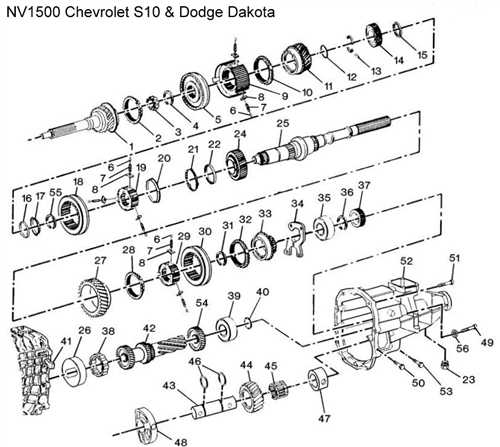

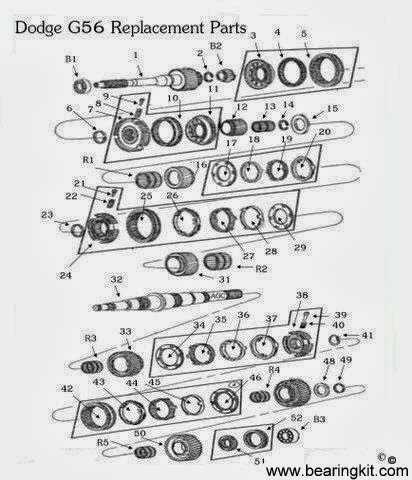

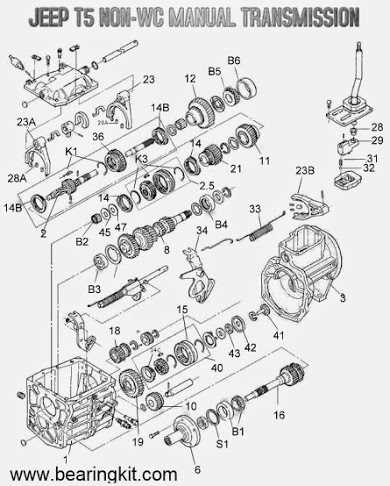

Visual representations of these mechanical structures can significantly enhance comprehension, offering a clear view of how each element fits together. This clarity not only aids in learning but also empowers individuals to engage in repairs and upgrades with confidence. Delving into the specifics of these assemblies fosters a deeper appreciation for automotive design and engineering excellence.

Understanding SM420 Transmission Overview

This section delves into a well-known mechanism that plays a crucial role in transferring power from the engine to the wheels of a vehicle. It is essential for achieving the desired performance and efficiency, adapting to various driving conditions while providing the necessary torque and speed. A closer examination reveals its intricate design and functionality, which are vital for optimal vehicle operation.

Key Features and Design

The mechanism in question boasts several distinctive characteristics that enhance its performance. It typically includes a series of gears and shafts, allowing for smooth shifts and effective torque distribution. The robust construction ensures durability, making it suitable for heavy-duty applications, while the gear ratios are designed to optimize both acceleration and fuel efficiency.

Applications and Compatibility

This system is widely used in various types of vehicles, particularly in trucks and off-road models, where reliability and strength are paramount. Its versatility allows it to be compatible with multiple engine types, making it a popular choice among automotive enthusiasts and professionals alike. Understanding its capabilities can aid in selecting the right components for specific needs, ensuring a seamless integration with the vehicle’s overall mechanics.

Key Components of SM420 Transmission

The mechanical system consists of various interconnected elements that work together to ensure smooth operation. Understanding these key elements is essential for proper maintenance and functionality. Below is an overview of the crucial pieces that make up this robust system.

- Main Gear Set: This set of gears is responsible for the smooth shifting of the system, transferring power efficiently between different speed ranges.

- Synchronizers: These components help synchronize the gear speeds, ensuring a seamless engagement of gears and reducing wear over time.

- Bearings and Bushings: These are vital in reducing friction between moving parts, allowing for efficient rotation and extending the life of the system.

- Input and Output Shafts: The input shaft transfers power from the engine, while the output shaft delivers that power to the vehicle’s drivetrain.

- Shift Forks: These are responsible for moving the gears into the correct positions during operation, ensuring smooth transitions between speeds.

- Countershaft: A

Functionality of the SM420 Parts

This section delves into the purpose and interaction of individual components within a mechanical system designed for gear shifting. Understanding how these elements work together is key to ensuring smooth operation and long-term reliability.

- Gearset: The gearset manages the selection of various speed ratios. Each gear interacts with others to provide different levels of force and movement.

- Synchronizers: These are responsible for matching the speed of different rotating parts, ensuring a smooth transition between different stages of operation.

- Shafts: Shafts are the backbone, transmitting force from one area to another, connecting power sources to the wheels and other output points.

- Bearings: Bearings minimize friction and wear, allowing the shafts and gears to rotate smoothly and efficiently under load.

All these elements work in harmony, providing precise control over the system’s operation, ensuring stability, and enhancing performance under varying conditions.

Common Issues with SM420 Transmissions

Over time, certain mechanical components can experience wear and tear, leading to a variety of operational problems. These challenges can affect the smoothness and reliability of shifting, potentially causing performance drops. Identifying these issues early can help avoid more significant problems down the road.

Shifting Difficulties

One of the most frequent challenges involves difficulty in changing gears. This can occur due to worn linkages or internal wear in critical components. When the mechanism becomes unresponsive or requires more force than usual, it may be a sign of internal wear or misalignment.

Gear Slippage

Another common issue is gear slippage, where the gear disengages unexpectedly during operation. This can be caused by worn-out synchronizers or weakened springs, both of which can affect the precision of the internal setup, leading to unsafe

Maintenance Tips for SM420 Systems

Proper upkeep of mechanical systems is essential for ensuring longevity and smooth operation. By following a few key guidelines, you can avoid common issues and extend the lifespan of the equipment. Regular attention to lubrication, cleanliness, and component wear will help maintain optimal performance and prevent more significant problems from developing.

Regular Inspection

Consistently checking the various components for signs of wear is a critical practice. Identifying minor issues early, such as loose bolts or seals that need replacing, can prevent more extensive damage. Pay special attention to any unusual noises or vibrations, as these could signal the need for adjustment or repair.

Lubrication and Cleaning

Ensuring that moving parts are properly lubricated will reduce friction and wear, contributing to smoother operation. Additionally, keeping the system clean from dirt and debris can prevent contaminants from interfering with the mechanics. Make sure to use the correct type of lubricant

SM420 Transmission Diagram Explained

The internal layout of this mechanical system can seem complex at first glance, but understanding its core elements reveals how efficiently each component works together. By studying the blueprint, we can see how various sections are interconnected to create a seamless operation.

- The primary function of the system is to handle the distribution of motion.

- Each section is designed to manage different forces, ensuring smooth engagement between the parts.

- Key areas include control points that determine shifts and changes in speed.

When examining the structure, it’s important to note how each element is built to endure significant strain, allowing the entire mechanism to perform reliably over time.

- First, the input section transfers energy into the system.

- Next, the central components regulate the flow, adapting to various operational demands.

- Finally, the output ensures that energy is directed towards the necessary functions, completing the cycle.

Comparing SM420 to Other Transmissions

When examining various gear systems, it’s essential to consider factors such as durability, gear ratios, and versatility. Different mechanical systems offer unique advantages depending on their design and intended use. In this section, we will explore how one specific model fares against its counterparts in terms of performance, reliability, and adaptability to different environments.

Durability and Construction

One of the key points to evaluate is the build quality and longevity of these systems. Certain models are renowned for their robust materials and ability to withstand heavy use, while others may be lighter, trading off some strength for better efficiency in specific applications. Understanding these differences can help determine which option is better suited for more demanding tasks.

Performance and Gear Ratios

The gearing setup plays a critical role in overall performance. Some systems are favored for their low-range gearing, providing excellent torque and control, especially in challenging conditions. Others may prioritize smoother shifts and higher-speed capabilities, making them ideal for different types of vehicles and usage scena

Upgrades for SM420 Performance Enhancement

When aiming to enhance the durability and functionality of a gear system, several upgrades are available to significantly boost its performance. These modifications are designed to improve handling under heavy loads, increase operational efficiency, and extend overall service life, making the system more robust for demanding conditions.

Upgrade Benefit Heavy-Duty Bearings Improves load-bearing capacity and reduces wear over time. Enhanced Synchronizers Ensures smoother shifts and reduces gear clash under pressure. Improved Seals Prevents leakage and contamination, increasing the lon Tools Required for SM420 Repair

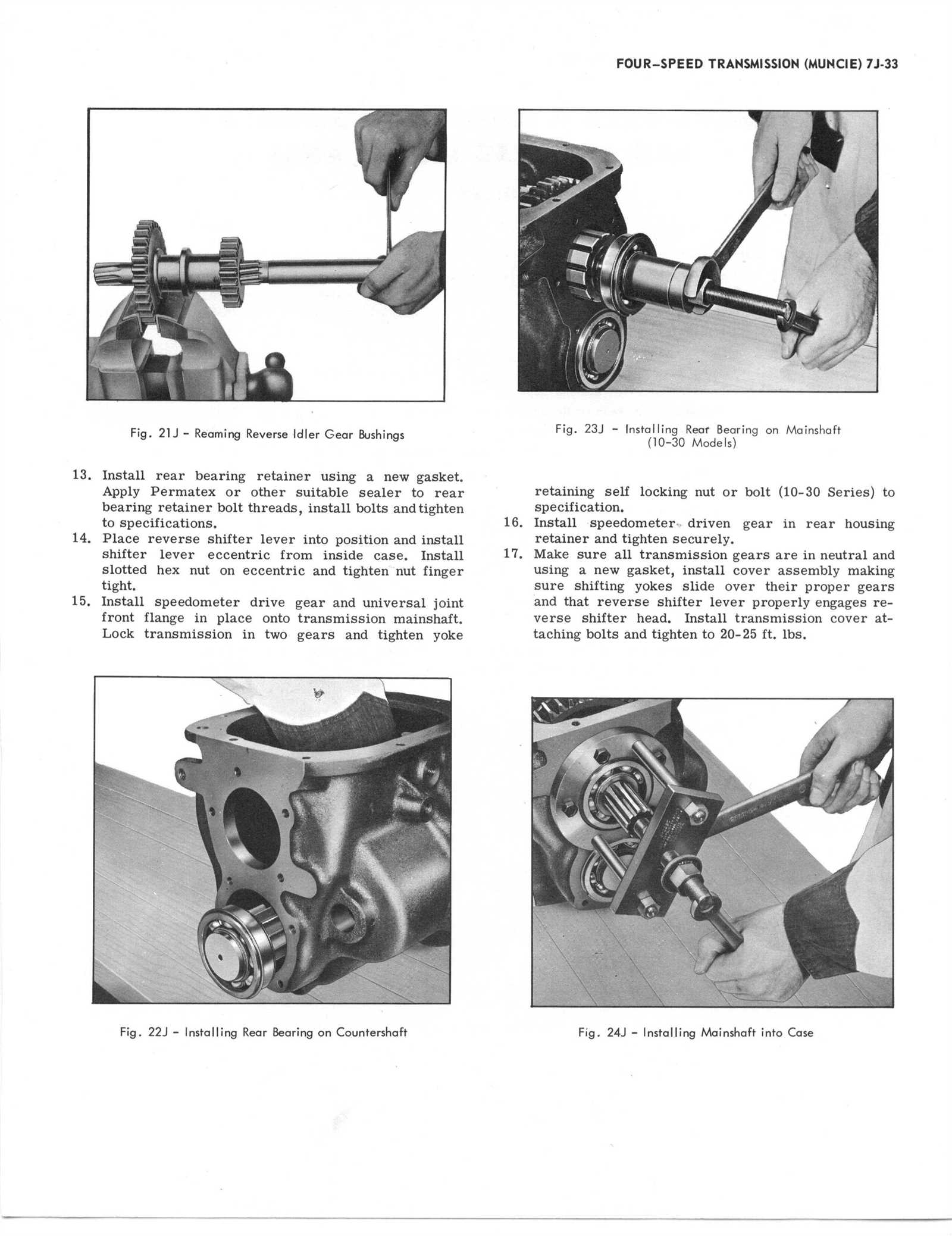

When preparing to perform maintenance on this specific model, it is essential to have the right set of equipment at hand. Proper selection of tools ensures that every step of the process goes smoothly, minimizing the risk of errors and enhancing efficiency.

Basic Hand Tools

- Wrenches of various sizes

- Socket set

- Screwdrivers, both flathead and Phillips

- Pry bars for disassembling tight components

Specialized Equipment

- Gear puller for removing bearings and shafts

- Torque wrench for precise tightening

- Seal drivers for proper placement of seals

- Measuring tools such as calipers for checking dimensions

How to Read a Transmission Diagram

Understanding technical schematics can seem challenging, but with a few guidelines, anyone can interpret them with ease. These illustrations provide a visual breakdown of mechanical systems, showing how different elements fit together and function as a whole. To grasp these drawings, it’s important to recognize key symbols and labels, which indicate the roles and connections between components.

Start with the basics: Begin by identifying the main sections of the layout. Typically, you will find the core elements centrally placed, with other supporting parts arranged around them. This helps form a clear picture of the overall system.

Follow the flow: Once you have located the primary elements, trace the connections between them. Arrows and lines guide you through the process, showing how energy or motion is transferred throughout the assembly.

Study the symbols: Each piece is often represented by a specific symbol or abbreviation. Referring to the legend or key can clarify these representations and make it easier to match them to real-world components.

By focusing on these key points, you can gradually improve your ability to read and interpret technical illustrations, making complex mechanical systems more accessible and understandable.

SM420 in Historical Context

During the mid-20th century, a range of engineering innovations in automotive design led to the creation of durable and highly efficient mechanical systems. These developments played a crucial role in advancing the capabilities of vehicles, particularly in heavy-duty applications. The focus was on creating solutions that could withstand the demands of both commercial and personal transportation in challenging environments.

Impact on Vehicle Design

Mechanical advancements introduced during this era reshaped how vehicles were constructed, with a particular emphasis on enhancing strength, reliability, and adaptability. These designs were adopted by a variety of manufacturers, particularly for off-road vehicles and work trucks, demonstrating their versatility across different platforms. This period marked a significant shift toward more robust and reliable systems that could endure harsh conditions.

Legacy and Influence

The technological breakthroughs from this time set the stage for future innovations in vehicular mechanics. Many of the principles and components developed have continued to influence modern designs, proving their la

Expert Recommendations for SM420 Owners

For enthusiasts and operators of specific vehicle mechanisms, understanding key aspects of maintenance and performance can enhance longevity and efficiency. Knowledge of fundamental practices can help ensure that these systems function optimally under varying conditions.

Regular Maintenance Tips

- Conduct routine checks on fluid levels to ensure proper lubrication and cooling.

- Inspect seals and gaskets for any signs of wear or leakage to prevent damage.

- Keep an eye on connection integrity to avoid unexpected failures.

- Schedule periodic professional evaluations to address any potential issues before they escalate.

Performance Enhancement Suggestions

- Consider upgrading to high-performance fluids designed for enhanced protection and efficiency.

- Evaluate gear ratios to match your driving style and terrain, improving overall responsiveness.

- Install aftermarket components that can provide improved durability and performance metrics.

- Stay informed about the latest advancements in technology that can enhance system capabilities.