Understanding the TH350 Transmission Parts Diagram

In the world of automotive engineering, the intricate machinery that allows vehicles to change speeds and manage power delivery is essential. A closer examination of the essential elements that make up these mechanisms reveals a complex interplay of components, each playing a critical role in performance and reliability. Grasping the layout and functionality of these parts can significantly enhance one’s knowledge of automotive systems.

For enthusiasts and mechanics alike, visualizing the arrangement and interaction of these elements is key to troubleshooting and maintenance. By dissecting the structure of these assemblies, one can uncover the mysteries behind their operation. This exploration not only aids in repairs but also fosters a deeper appreciation for the craftsmanship involved in vehicle design.

As we delve into the specifics, understanding how each component interacts within the assembly will provide valuable insights into both everyday maintenance and high-performance upgrades. Whether you’re a seasoned professional or a curious hobbyist, familiarizing yourself with these details can lead to improved efficiency and longevity of your vehicle.

Understanding the TH350 Transmission

This section explores the intricate mechanisms behind a widely used automotive component that plays a crucial role in vehicle performance. Grasping its functionality can enhance your knowledge of vehicle dynamics and maintenance.

- Design: The assembly features a complex structure designed for efficiency.

- Operation: It operates through a series of gears and hydraulic systems to facilitate smooth power transfer.

- Applications: Commonly found in various classic and modern vehicles, it supports diverse driving needs.

To fully appreciate this component, it’s essential to delve into its key elements and how they interact to achieve optimal performance.

- Hydraulic System: Manages fluid pressure for gear shifts.

- Clutch Mechanism: Engages and disengages gears as needed.

- Gear Sets: Determines speed ratios and overall drive efficiency.

Understanding these aspects will lead to the ultimate grasp of how this crucial assembly contributes to driving experiences.

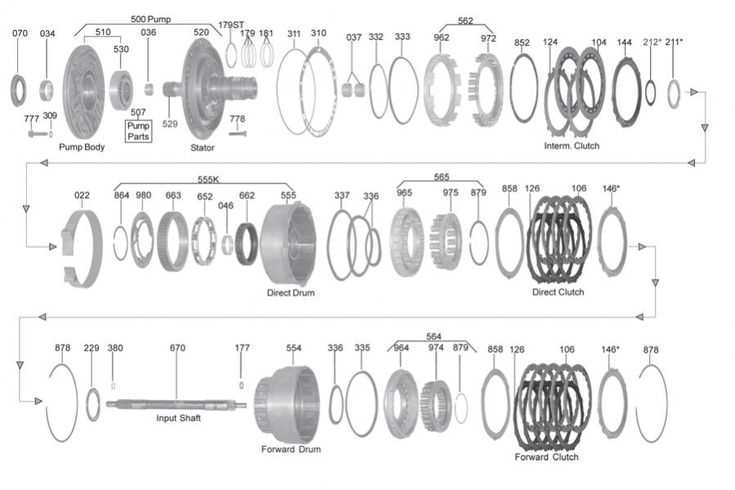

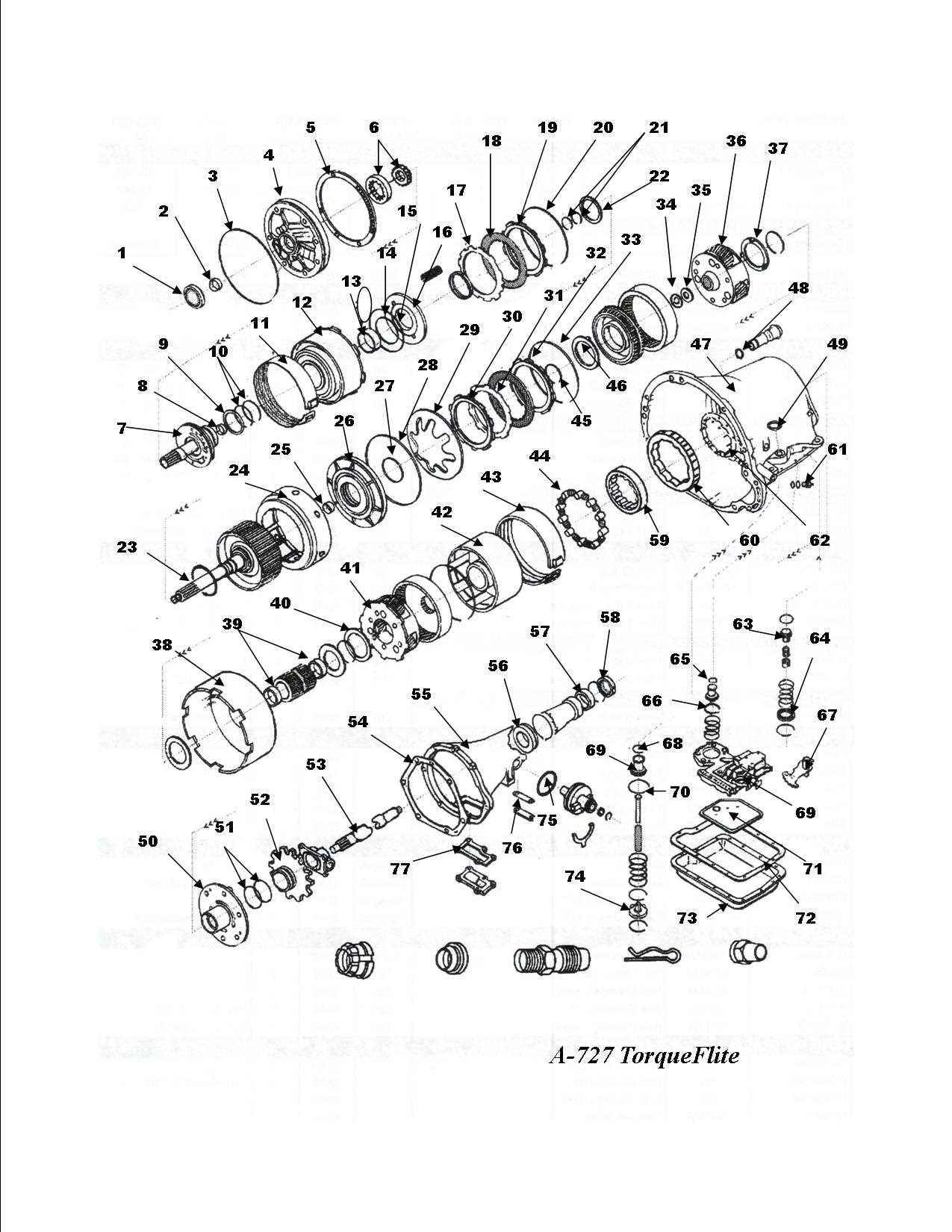

Key Components of TH350 Systems

The efficient operation of an automatic gearbox relies on several crucial elements working in harmony. These components play a vital role in the functionality and performance of the entire assembly, ensuring smooth gear shifts and optimal power transfer.

One of the primary elements is the hydraulic pump, responsible for circulating fluid throughout the system. Coupled with this is the valve body, which directs fluid flow to engage the appropriate gears. Additionally, clutches and bands are essential for holding components in place during operation, allowing for seamless transitions between gears.

Another significant aspect is the governor, which monitors vehicle speed and adjusts shifting patterns accordingly. Lastly, the torque converter enables smooth acceleration by transferring engine power while allowing for slippage during gear changes. Together, these elements create a reliable and efficient system, crucial for any vehicle’s performance.

Importance of Accurate Diagrams

Precise visual representations are essential in any mechanical field, serving as invaluable tools for both learning and troubleshooting. They provide clarity and a structured approach to understanding complex assemblies, ensuring that individuals can efficiently navigate intricate systems.

Facilitating Understanding

Accurate illustrations enhance comprehension by breaking down components into manageable sections. They allow users to easily identify each element’s role and interconnections, which is crucial for effective repairs and maintenance. Without clear visuals, one may struggle to grasp the intricate relationships that exist within a system.

Enhancing Efficiency

Well-crafted visuals can significantly reduce the time spent on diagnostics and repairs. When individuals refer to reliable representations, they can quickly locate issues and implement solutions, minimizing downtime. This efficiency is vital in professional settings where time is money.

In summary, reliable visual aids are not just supplementary; they are fundamental to mastering and maintaining complex mechanical systems. Their role in enhancing understanding and improving efficiency cannot be overstated.

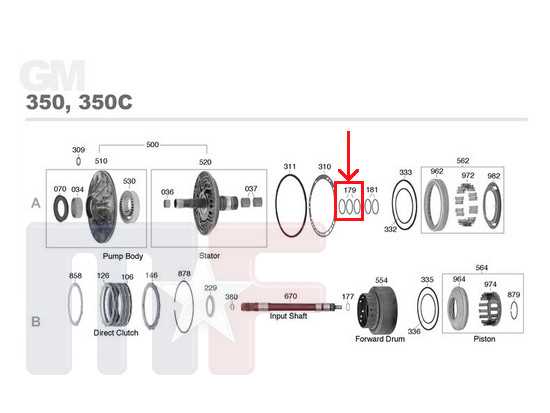

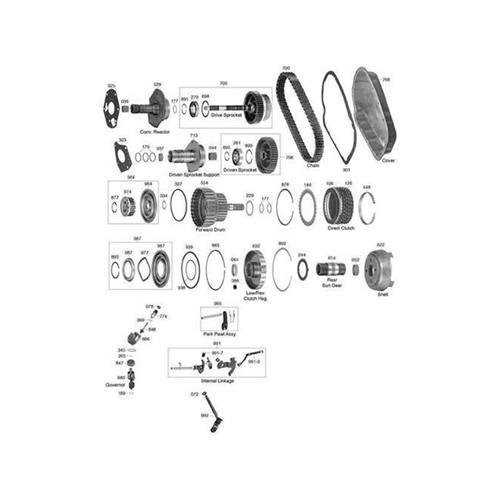

How to Identify TH350 Parts

Understanding the components of an automatic shifting system is essential for effective maintenance and repair. Familiarity with the various elements can enhance your ability to troubleshoot issues and ensure optimal performance. Recognizing the key features of these mechanisms will aid in distinguishing between different elements and their functions.

To start, examining the casing can provide initial clues. Look for any identifying numbers or stamps that might indicate the specific model. Each unit typically has a unique identifier that can be cross-referenced with manufacturer documentation.

Next, focus on the internal components, such as gears and clutches. These elements vary in design and size across different models. Inspecting them closely can help you determine compatibility and condition, which is crucial for effective repairs or upgrades.

Don’t overlook the external fittings and connectors. Various types of hoses, seals, and electrical connections can also signify particular characteristics. Understanding how these elements interact can lead to more informed decisions during any maintenance work.

Lastly, consulting a comprehensive reference guide or service manual can be invaluable. These resources often include detailed descriptions and visual aids that facilitate accurate identification of each item within the assembly.

Common Issues with TH350 Transmissions

Understanding the frequent challenges that arise with this type of gearbox can help vehicle owners maintain optimal performance and extend the lifespan of their machinery. Various factors contribute to these issues, from wear and tear to improper maintenance practices.

Fluid Leaks

One of the most prevalent problems is fluid leakage. This can result from damaged seals or gaskets, leading to inadequate lubrication and potential overheating. Regularly checking fluid levels can prevent significant damage.

Shifting Difficulties

Another common concern involves shifting irregularities. Drivers may experience hard or slipping shifts, often caused by low fluid levels or internal component wear. Addressing these symptoms promptly is essential to avoid further complications.

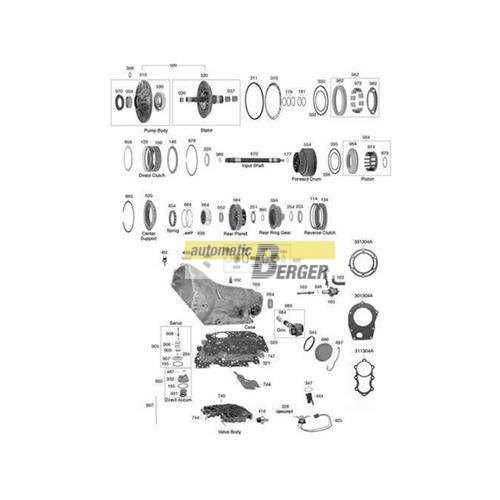

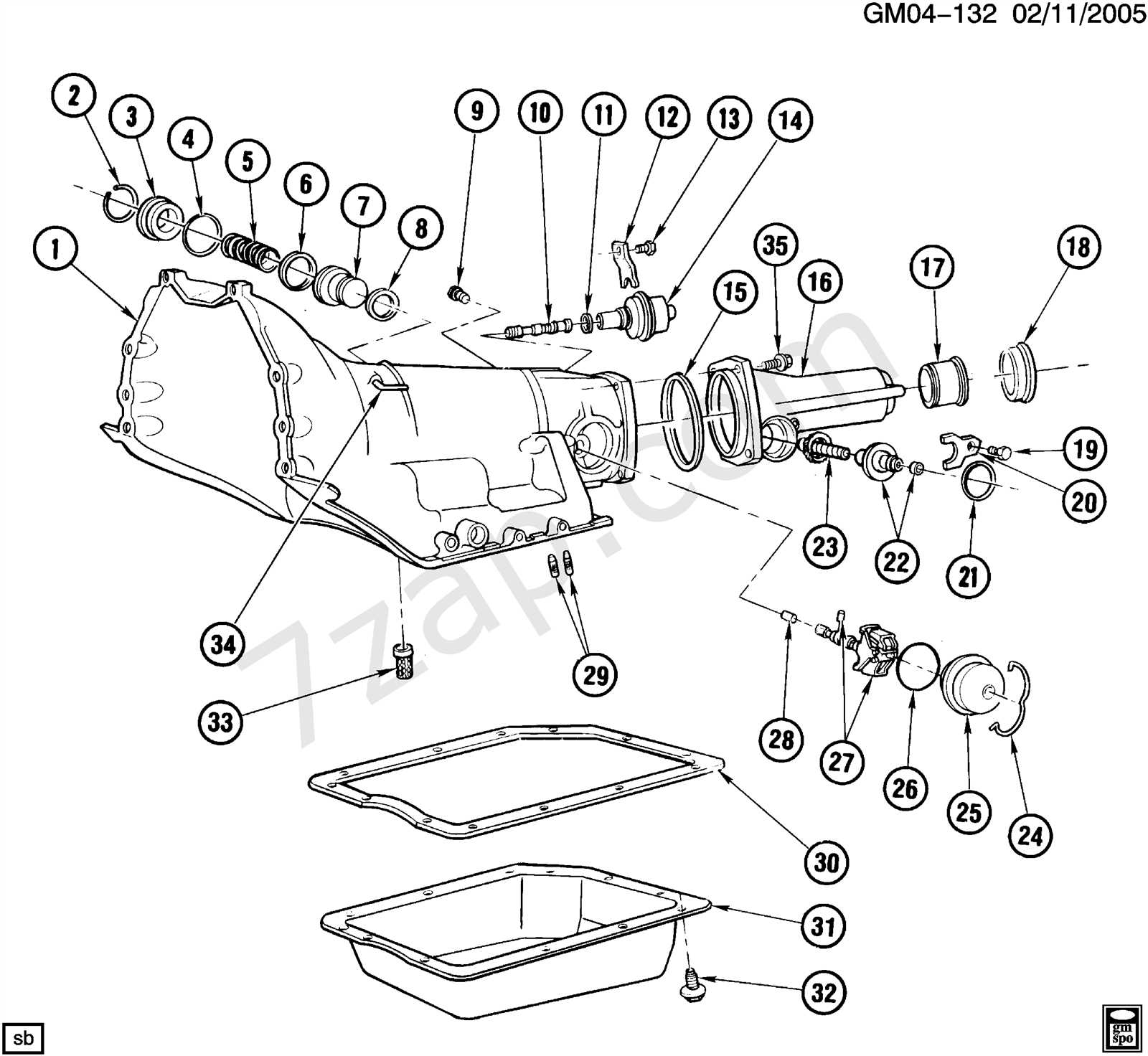

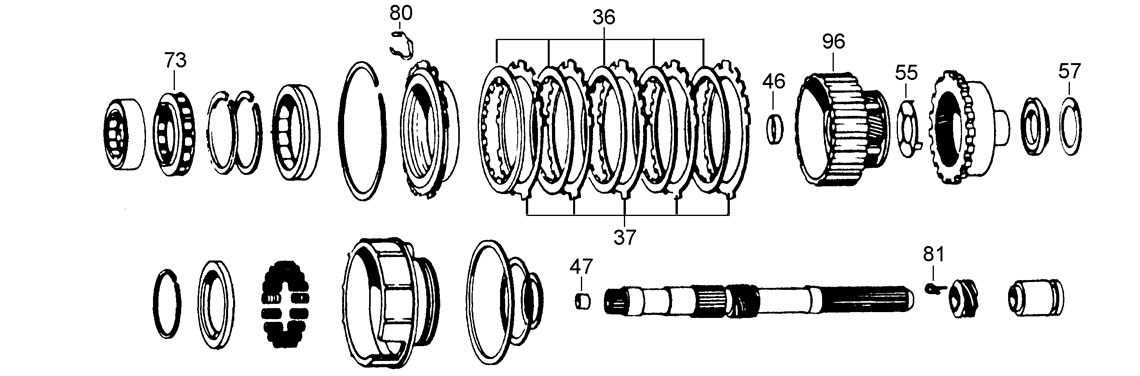

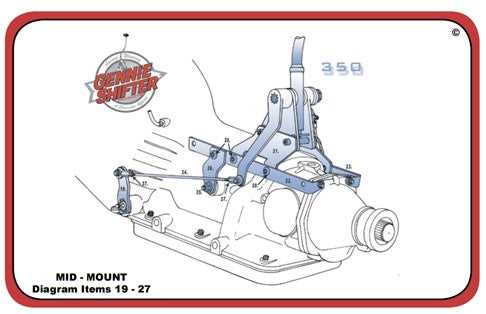

Visual Breakdown of Transmission Assembly

This section offers a comprehensive overview of the intricate components that come together to form a vital mechanical unit in vehicles. Understanding the assembly not only enhances appreciation of its complexity but also aids in identifying the specific elements that contribute to its overall functionality.

Key Components: Each segment plays a crucial role in ensuring smooth operation and performance. From the housing that encloses everything to the gears that manage power transfer, every piece is meticulously designed for optimal efficiency.

Interconnectivity: The interaction between components is essential; understanding how they work together can shed light on potential issues that may arise. A detailed visual representation can serve as a useful tool for both enthusiasts and professionals aiming to delve deeper into mechanics.

Maintenance Tips for Longevity

To ensure the enduring performance of your vehicle’s mechanical components, regular upkeep is essential. Implementing a structured maintenance routine not only enhances reliability but also extends the lifespan of critical elements.

1. Regular Fluid Checks: Frequent inspections of essential fluids can prevent premature wear. Ensure levels are adequate and free from contamination.

2. Clean Components: Keeping surfaces free from debris and dirt can significantly improve functionality. Use appropriate cleaners to avoid damage.

3. Monitor Temperature: Overheating can lead to severe issues. Utilize temperature gauges to detect any anomalies early.

4. Inspect Seals and Gaskets: These components are vital for maintaining proper function. Regular checks can avert leaks and other complications.

5. Schedule Professional Inspections: Engaging a qualified technician for routine evaluations can help identify potential problems before they escalate.

By adhering to these guidelines, you can effectively enhance the durability and overall efficiency of your vehicle’s essential systems.

Replacement Parts Overview

When it comes to maintaining the functionality of automotive systems, understanding the various components that may require attention is essential. This section delves into the essentials needed for effective repairs and enhancements, focusing on ensuring optimal performance and longevity.

Essential Elements play a crucial role in the smooth operation of mechanical assemblies. Each component, whether it’s gears, seals, or other key elements, contributes to the overall efficiency. Recognizing the signs of wear or malfunction is vital for timely intervention.

Quality Choices are paramount when selecting replacements. Opting for reliable brands can significantly influence the performance and durability of your system. It’s advisable to consult with professionals or refer to detailed resources to make informed decisions.

Regular maintenance and timely replacements not only enhance performance but also help in preventing more significant issues down the line. Understanding the various options available empowers vehicle owners to keep their machinery in peak condition.

Upgrades for Enhanced Performance

Improving the efficiency and responsiveness of your vehicle’s drivetrain can significantly enhance your driving experience. By implementing targeted modifications, you can achieve greater power delivery, better acceleration, and improved durability.

Key Enhancements to Consider

- High-Performance Clutch Kits

- Upgraded Torque Converters

- Stronger Input and Output Shafts

- Improved Valve Body Designs

Benefits of Upgrading

- Increased Torque Handling

- Improved Shifting Speed

- Enhanced Heat Dissipation

- Greater Overall Reliability

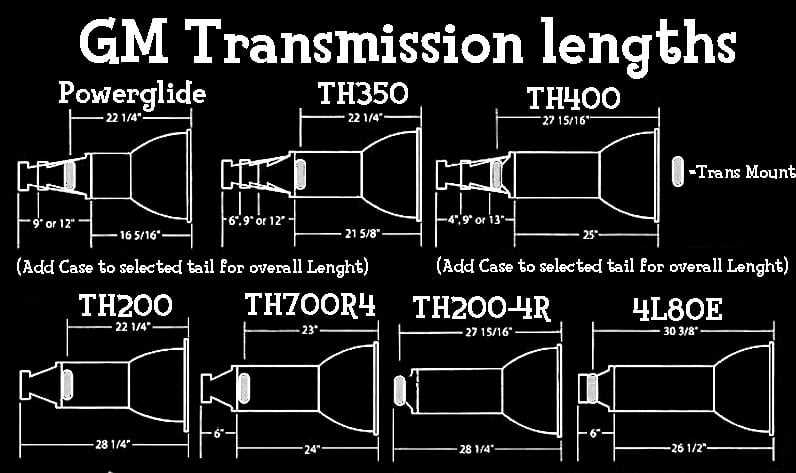

Comparing TH350 with Other Transmissions

This section aims to explore the distinctions and similarities between various automatic gear systems, focusing on performance, efficiency, and design features. Understanding these differences can help enthusiasts and mechanics make informed choices for their vehicles.

When evaluating different automatic gear systems, several key aspects should be considered:

- Gear Ratios: Different systems offer varying gear ratios that impact acceleration and overall performance. For instance, some designs provide a broader range, enhancing driving versatility.

- Durability: The build quality of various systems can greatly affect longevity. Some are known for their resilience under high torque, making them ideal for performance applications.

- Weight: The weight of the assemblies can influence vehicle dynamics. Lighter designs may improve handling and fuel efficiency.

- Ease of Maintenance: Accessibility of components varies, with some systems allowing for simpler repairs and modifications, which is beneficial for enthusiasts looking to customize.

Below are comparisons with a few notable automatic gear systems:

- Turbo 350: Similar in design but offers different gear ratios that can affect performance. Its lighter weight may appeal to those seeking agility.

- 4L60E: A more modern option that provides electronic control, leading to improved fuel efficiency and adaptability in various driving conditions.

- C4: Known for its simplicity and reliability, this older system is often favored in classic car restorations due to its straightforward mechanics.

In conclusion, while there are many options available, the choice often comes down to specific performance needs and personal preferences. Each automatic system presents its unique advantages, making it essential to consider how they align with the intended use of the vehicle.

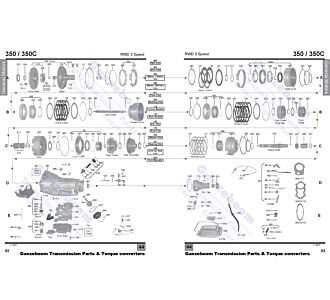

Assembly Process Explained

This section outlines the steps involved in the construction of a key automotive component, focusing on the systematic approach necessary for a successful build. Each phase requires careful attention to detail to ensure optimal functionality and longevity.

The assembly procedure can be divided into several critical stages:

| Stage | Description |

|---|---|

| Preparation | Gather all necessary components and tools, ensuring everything is in good condition. |

| Initial Setup | Align and position components according to manufacturer specifications for proper fit. |

| Fastening | Secure all elements using appropriate fasteners to ensure stability and performance. |

| Testing | Conduct functionality tests to confirm all systems operate smoothly and effectively. |

| Final Inspection | Perform a thorough check to identify any potential issues before the component is put into service. |

By following this structured process, one can ensure the reliability and effectiveness of the assembled unit.

Tools Needed for Repairs

When it comes to performing maintenance on complex mechanical systems, having the right equipment is essential for achieving effective results. Proper tools not only facilitate the repair process but also ensure that the job is done safely and efficiently. Below is a comprehensive list of essential items you’ll need to successfully carry out repairs.

Basic Tools

Start with a solid foundation of basic tools that are crucial for any repair task. Socket sets, wrenches, and screwdrivers are indispensable. These items will help you access and tighten various components easily. Additionally, having a reliable torque wrench is important for ensuring that all fasteners are secured to the manufacturer’s specifications.

Specialized Equipment

For more intricate tasks, specialized equipment is necessary. A fluid transfer pump can be invaluable for handling various fluids during the repair process. A pressure gauge will also aid in diagnosing potential issues. Furthermore, investing in a repair manual specific to your system can provide detailed instructions and specifications, making your repair experience smoother and more informed.

Where to Find Reliable Resources

Accessing trustworthy information is essential for anyone looking to understand complex mechanical systems. Whether you are a professional or a hobbyist, knowing where to source accurate and detailed content can greatly enhance your knowledge and repair capabilities. Numerous platforms offer a wealth of information, including technical manuals, instructional videos, and community forums where enthusiasts share their expertise.

Online retailers often provide access to detailed specifications and guides for various components. Reputable automotive websites and forums can also be invaluable, as they feature discussions and insights from experienced users. Additionally, social media groups dedicated to automotive repair may offer real-time assistance and resources, allowing you to connect with others who share similar interests.

Local libraries and bookstores frequently stock manuals and guides that cover mechanical systems extensively. Participating in workshops or classes hosted by community colleges or automotive schools can provide hands-on experience while also introducing you to reliable literature and resources. Finally, reaching out to local mechanics or enthusiasts can lead to recommendations for trusted materials and resources that cater to your specific needs.