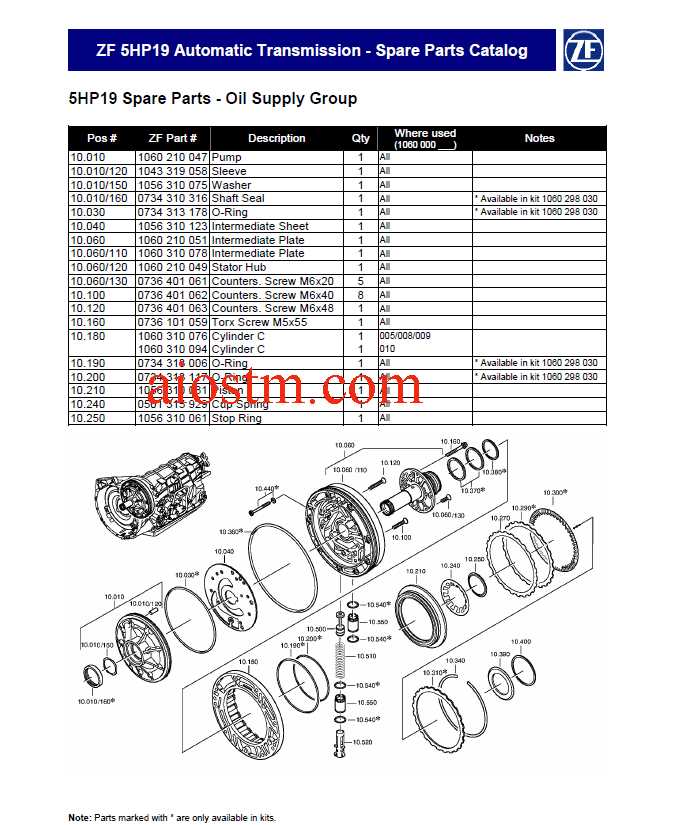

Diagram of ZF 220 Transmission Parts

The complexity of modern gear systems necessitates a detailed examination of their various elements. Each component plays a crucial role in the overall functionality and performance of the machinery. Gaining insights into these individual pieces allows for better maintenance and optimization, ensuring that operations run smoothly and efficiently.

Within the realm of automotive engineering, a comprehensive grasp of how these mechanisms interconnect is vital for both professionals and enthusiasts. By delving into the specifics of each element, one can appreciate the precision involved in their design and the importance of their interaction in facilitating reliable performance. This knowledge also aids in troubleshooting and enhancing the longevity of the entire system.

In this section, we will explore the intricate arrangement and role of various components within ZF gear systems. Understanding the layout and function of these elements empowers users to make informed decisions regarding repairs, upgrades, and general upkeep, thereby enhancing the efficiency and reliability of their machinery.

The assembly process of this specific gearbox involves several crucial steps that ensure its optimal performance and reliability. Each stage must be executed with precision to achieve a seamless integration of various components, ultimately resulting in a fully functional unit. Proper attention to detail and adherence to best practices during assembly are essential for longevity and efficiency.

Preparation Stage

Before commencing assembly, it is vital to gather all necessary components and tools. This stage includes the inspection of individual elements for any signs of wear or damage, which could affect overall functionality. Having a clean and organized workspace is equally important to facilitate a smooth assembly process.

Assembly Steps

The following table outlines the main steps involved in the assembly of the gearbox:

| Step | Description |

|---|---|

| 1 | Begin by aligning the primary housing and securing it in place. |

| 2 | Install the gear sets, ensuring correct orientation and fit. |

| 3 | Attach the auxiliary components, including seals and gaskets, to prevent leaks. |

| 4 | Secure the cover, verifying that all fasteners are tightened to specifications. |

| 5 | Conduct a thorough inspection and perform a function test to ensure proper operation. |

By following these detailed steps, one can ensure the effective assembly of the gearbox, leading to reliable and efficient performance in various applications.

Maintenance Tips for Longevity

Ensuring the durability of your machinery requires consistent upkeep and attention to detail. By implementing a few essential practices, you can enhance the performance and extend the lifespan of your equipment. Here are some effective strategies to consider.

- Regular Inspections: Conduct frequent checks to identify any wear or damage early. Look for signs of leaks or unusual noises that could indicate potential issues.

- Fluid Changes: Keep fluids clean and at appropriate levels. Regularly replacing hydraulic fluids and lubricants helps maintain optimal functionality.

- Proper Lubrication: Ensure all moving components are adequately lubricated. This reduces friction and wear, promoting smoother operation.

- Temperature Monitoring: Keep an eye on operating temperatures. Overheating can cause significant damage, so ensure cooling systems are functioning effectively.

- Component Alignment: Check the alignment of mechanical elements to prevent unnecessary strain. Misalignment can lead to premature failure of parts.

By following these guidelines, you can significantly improve the reliability of your equipment and reduce the likelihood of unexpected breakdowns. Consistent maintenance efforts will yield long-term benefits.

Common Issues and Solutions

Understanding the frequent challenges that may arise with specific mechanical systems is essential for maintaining optimal performance. This section explores typical complications encountered and practical solutions to address them, ensuring smooth operation and longevity.

Frequent Complications

- Fluid leaks that can lead to inadequate lubrication.

- Overheating, often due to insufficient cooling or fluid degradation.

- Unusual noises indicating potential wear or misalignment of components.

- Delayed engagement when shifting gears, suggesting hydraulic or mechanical issues.

Practical Solutions

- Regularly inspect and replace seals and gaskets to prevent fluid loss.

- Monitor fluid levels and temperatures to avoid overheating; change the fluid as recommended.

- Listen for abnormal sounds and investigate immediately to identify worn-out parts.

- Check for proper fluid pressure and consider a professional assessment if shifting delays persist.

Comparison with Other Transmissions

When evaluating different types of gear systems, it’s essential to recognize the unique features and capabilities that set them apart. Each mechanism offers distinct advantages and disadvantages, impacting their performance and suitability for various applications.

One notable system is the automatic type, which excels in providing a smooth driving experience without requiring manual gear shifts. In contrast, manual systems grant drivers greater control over gear selection, enhancing engagement and responsiveness.

- Efficiency: Many modern systems focus on maximizing fuel efficiency, often incorporating advanced technologies such as dual-clutch setups, which facilitate faster gear changes and reduce power loss.

- Durability: The robustness of a particular setup can greatly influence its lifespan. Heavy-duty designs are essential for high-torque applications, while lighter configurations are more suited for everyday use.

- Maintenance: Some systems require regular upkeep to ensure optimal performance. Understanding the maintenance needs is crucial when comparing options.

Ultimately, the choice of a specific setup depends on individual preferences and requirements. Evaluating aspects like driving style, intended use, and desired performance will help determine the most suitable option.

Upgrades and Modifications Available

Enhancements and alterations for your vehicle’s drivetrain can significantly improve performance and efficiency. Various options are available to tailor the system to meet your specific needs, whether you seek increased durability, improved power output, or enhanced handling capabilities.

Performance Enhancements

One of the most popular modifications involves upgrading components to boost overall functionality. High-performance clutches, torque converters, and gear sets can be installed to enhance responsiveness and maximize power transfer. These upgrades often result in improved acceleration and better performance under heavy loads.

Durability Improvements

In addition to performance, durability can be significantly enhanced through the installation of reinforced components. Upgraded seals, bearings, and housings can withstand greater stresses and extend the lifespan of the system. Investing in these modifications ensures that your setup remains reliable even under demanding conditions.

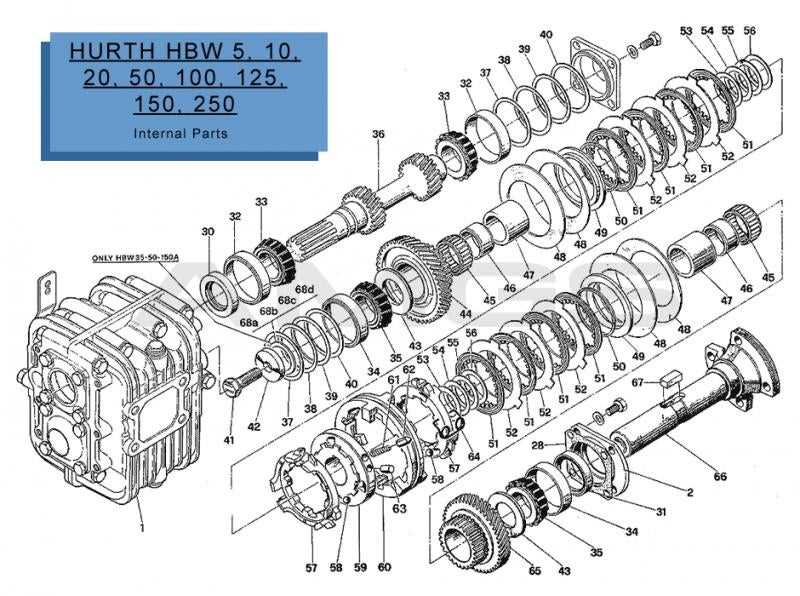

Visual Representation of Parts

This section aims to provide an insightful illustration of the various components involved in the system. Understanding these elements through visual means allows for a clearer comprehension of their functions and interrelationships within the overall mechanism.

Component Overview

Each individual piece plays a crucial role in the efficient operation of the assembly. From gears to seals, these elements must work cohesively to ensure optimal performance. Visual representations facilitate the identification of each part’s location and significance, enhancing the understanding of the entire assembly process.

Importance of Accurate Representation

Accurate illustrations are essential for both troubleshooting and maintenance. They serve as valuable resources for technicians and enthusiasts alike, providing guidance on assembly and disassembly procedures. Furthermore, a well-structured visual aid can assist in identifying wear and tear, enabling timely interventions and prolonging the lifespan of the mechanism.

Resources for Further Learning

For those interested in expanding their knowledge on this subject, a wide range of educational materials are available. By exploring various guides, manuals, and technical books, you can deepen your understanding and gain practical insights. These resources cover essential aspects and are designed to offer in-depth analysis and useful information for enthusiasts and professionals alike.

Recommended Reading Materials

Comprehensive technical literature, including specialized books