Zf Transmission Parts Diagram Explained

Understanding the intricate elements of a ZF system is essential for anyone engaged in automotive engineering or repair. This section will explore the various components that work together to ensure optimal performance and efficiency.

Each component plays a pivotal role, contributing to the overall functionality and reliability of the mechanism. By examining their relationships and functions, one can delve into the ultimate workings of the system.

Furthermore, a comprehensive visual representation can serve as an invaluable tool for mechanics and engineers alike. It enhances the understanding of assembly, maintenance, and troubleshooting procedures.

Zf Transmission Parts Overview

This section provides a comprehensive look into the essential components that work together to ensure seamless operation and efficiency within the gear system. Each element plays a critical role in maintaining performance and durability under various conditions.

Understanding the components is vital for anyone involved in the maintenance or repair of these systems. The key elements include various mechanisms that enable smooth shifting, effective power distribution, and enhanced vehicle control.

Familiarity with these components allows for better troubleshooting and optimization of functionality, ensuring that every aspect operates harmoniously. Regular assessment and timely replacements can significantly enhance overall performance and longevity.

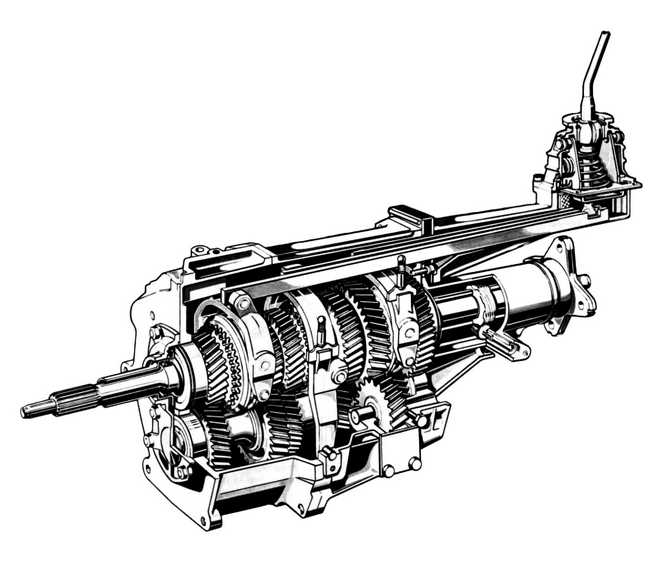

Understanding ZF Transmission Functionality

The intricate workings of ZF systems play a crucial role in enhancing vehicle performance and efficiency. These mechanisms are designed to facilitate the seamless transfer of power, ensuring optimal interaction between the engine and wheels. By employing advanced engineering principles, ZF solutions enable smooth gear shifts and responsive acceleration, significantly improving driving experience.

An in-depth exploration reveals the essential components that contribute to this sophisticated functionality. Each element is meticulously crafted to withstand varying conditions, promoting durability and reliability. The integration of electronic controls further elevates responsiveness, allowing for real-time adjustments based on driving demands.

Ultimately, understanding these systems not only highlights their importance in modern vehicles but also underscores the innovation behind their design. As technology continues to advance, the evolution of these mechanisms promises to enhance performance even further, paving the way for future automotive advancements.

Key Components of ZF Systems

ZF systems are renowned for their engineering excellence and innovative design, which are crucial for the overall performance and efficiency of various applications. Understanding the fundamental elements that constitute these systems can provide valuable insights into their functionality and reliability.

- Hydraulic Components: Essential for the operation of the system, these elements manage fluid flow and pressure, ensuring smooth functionality.

- Electronic Control Units: These units serve as the brain of the system, processing information and coordinating actions for optimal performance.

- Clutch Systems: Vital for engaging and disengaging power transfer, these mechanisms ensure seamless transitions during operation.

- Gear Sets: Fundamental in determining gear ratios, these assemblies play a significant role in adapting power delivery to varying conditions.

- Sensors: Crucial for monitoring system performance, these devices provide real-time data to enhance efficiency and safety.

Each of these components contributes to the overall functionality and reliability of ZF systems, highlighting the intricate interplay between mechanical and electronic elements that defines modern engineering solutions.

Benefits of ZF Transmissions

ZF systems offer numerous advantages that enhance vehicle performance and efficiency. Their advanced engineering ensures smooth operation, improving both driving comfort and fuel economy. These features make them a preferred choice among manufacturers and consumers alike.

| Advantage | Description |

|---|---|

| Efficiency | Optimized gear shifting reduces energy loss, enhancing overall fuel efficiency. |

| Smooth Operation | Seamless gear changes contribute to a more enjoyable driving experience. |

| Durability | Robust design ensures long-lasting performance under various driving conditions. |

| Advanced Technology | Incorporation of innovative features enhances vehicle control and responsiveness. |

Common Issues with ZF Parts

Many users encounter various challenges with components manufactured by ZF. Understanding these problems can aid in effective maintenance and repair, ensuring longevity and optimal performance. Awareness of common pitfalls helps in proactive measures and reduces the likelihood of unexpected failures.

One frequent issue involves wear and tear, often exacerbated by inadequate lubrication or poor installation practices. These factors can lead to premature degradation, affecting the overall efficiency of the system.

Another concern is compatibility, where mismatched elements can cause functionality problems. Ensuring that all components are designed to work harmoniously is crucial for seamless operation.

Additionally, electronic malfunctions are not uncommon, particularly in systems integrating advanced technology. Faulty sensors or wiring can disrupt communication between elements, resulting in performance inconsistencies.

Lastly, environmental factors such as extreme temperatures or contaminants can compromise the integrity of the components. Regular inspections and maintenance are essential to mitigate these risks and maintain optimal functionality.

ZF Transmission Maintenance Tips

Proper upkeep of your vehicle’s essential mechanisms is crucial for optimal performance and longevity. Regular attention to key components ensures smooth operation and reduces the risk of unexpected failures.

Regular Inspection

Conducting routine checks is vital. Pay attention to the following:

- Fluid levels and quality

- Seals and gaskets for signs of wear

- Connections for any leaks or damage

Fluid Changes

Changing the operating fluid at recommended intervals can significantly enhance functionality. Consider these points:

- Use the manufacturer-recommended fluid type.

- Monitor the fluid color and consistency regularly.

- Replace the filter during fluid changes to ensure cleanliness.

Following these guidelines can greatly improve the reliability and efficiency of your vehicle’s systems, helping you avoid costly repairs in the future.

Choosing Quality Replacement Parts

When it comes to maintaining your vehicle’s performance, selecting high-quality components is crucial. The right choices can enhance durability, improve functionality, and ultimately lead to a smoother driving experience. This section will guide you through the essential factors to consider when opting for replacements, ensuring you make informed decisions that benefit your vehicle in the long run.

Understanding Quality Indicators

Not all components are created equal. It’s vital to recognize the markers of quality that distinguish reliable replacements from subpar options. Look for manufacturers with a proven track record, as well as certifications that indicate compliance with industry standards. Additionally, customer reviews and recommendations can provide valuable insights into the durability and performance of specific items.

Prioritizing Compatibility and Performance

Another key aspect is ensuring that replacements are compatible with your vehicle’s specifications. Mismatched components can lead to inefficiencies or even damage. Always consult your owner’s manual or a professional to verify that your selections align with your vehicle’s needs. Investing in compatible options not only maximizes performance but also extends the lifespan of your vehicle.

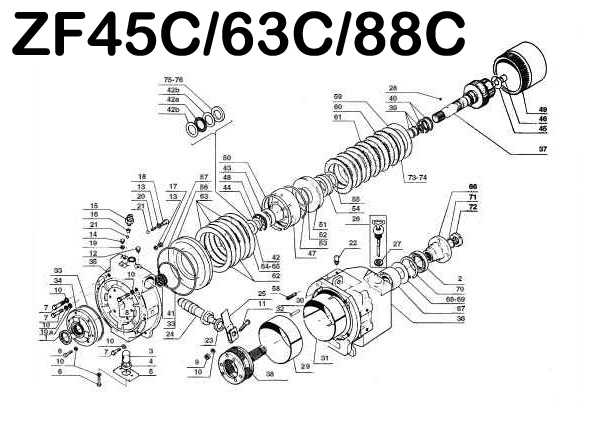

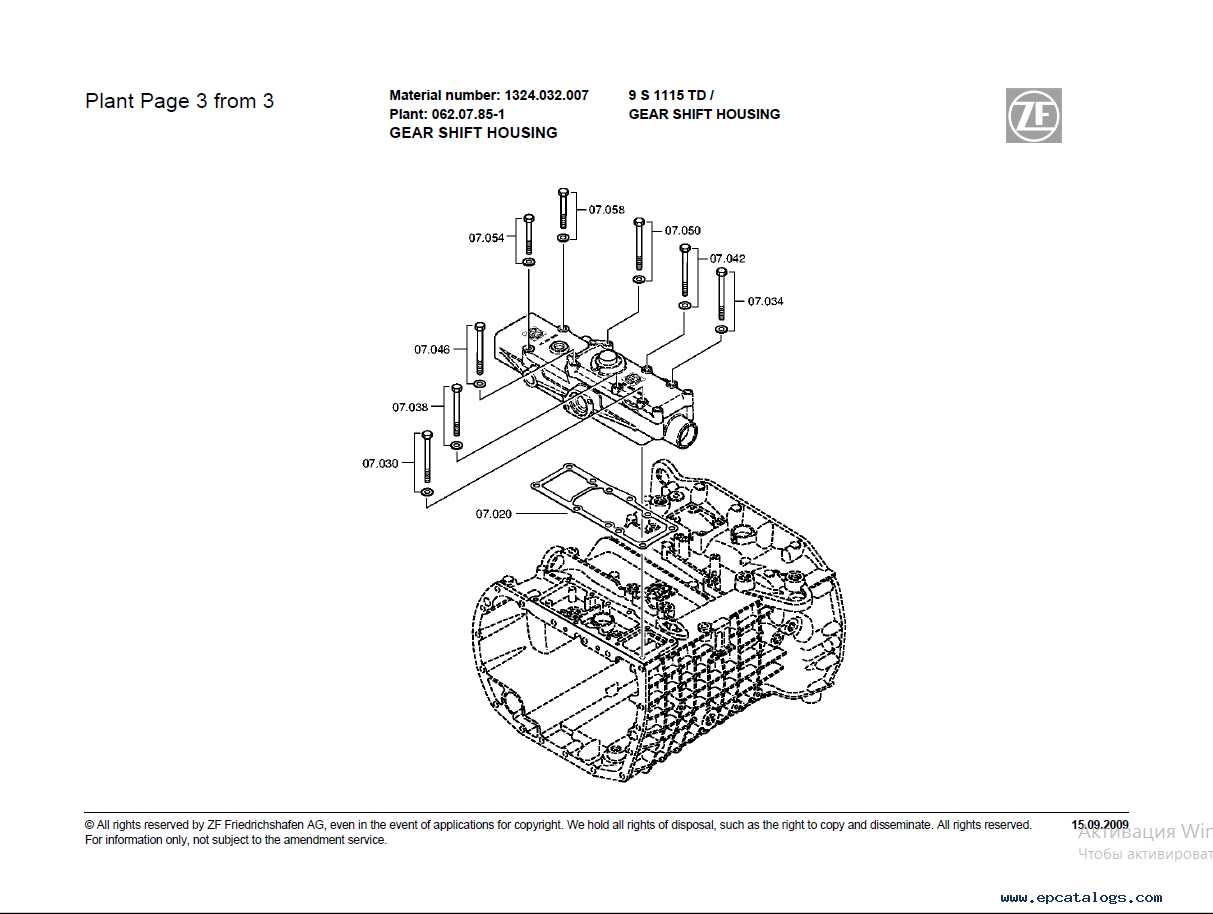

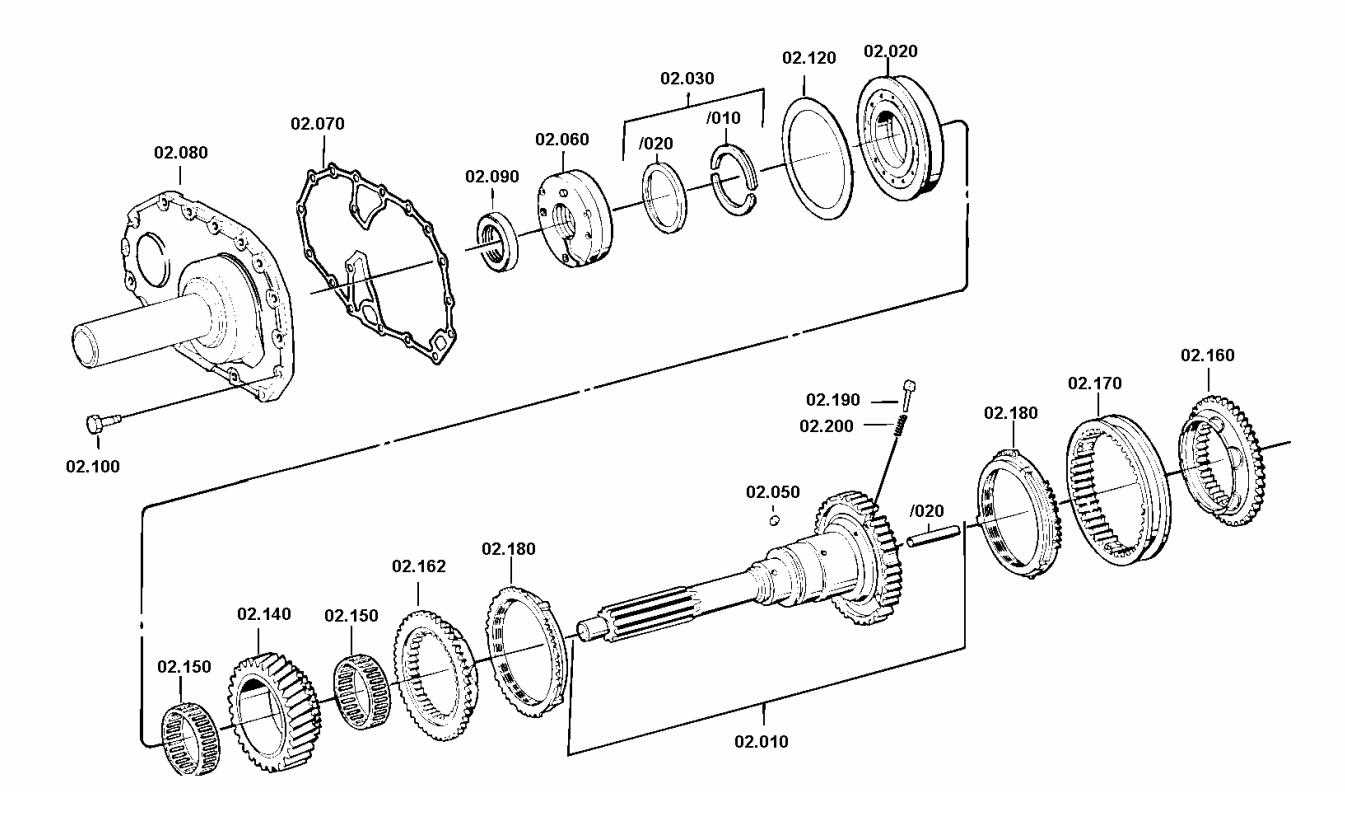

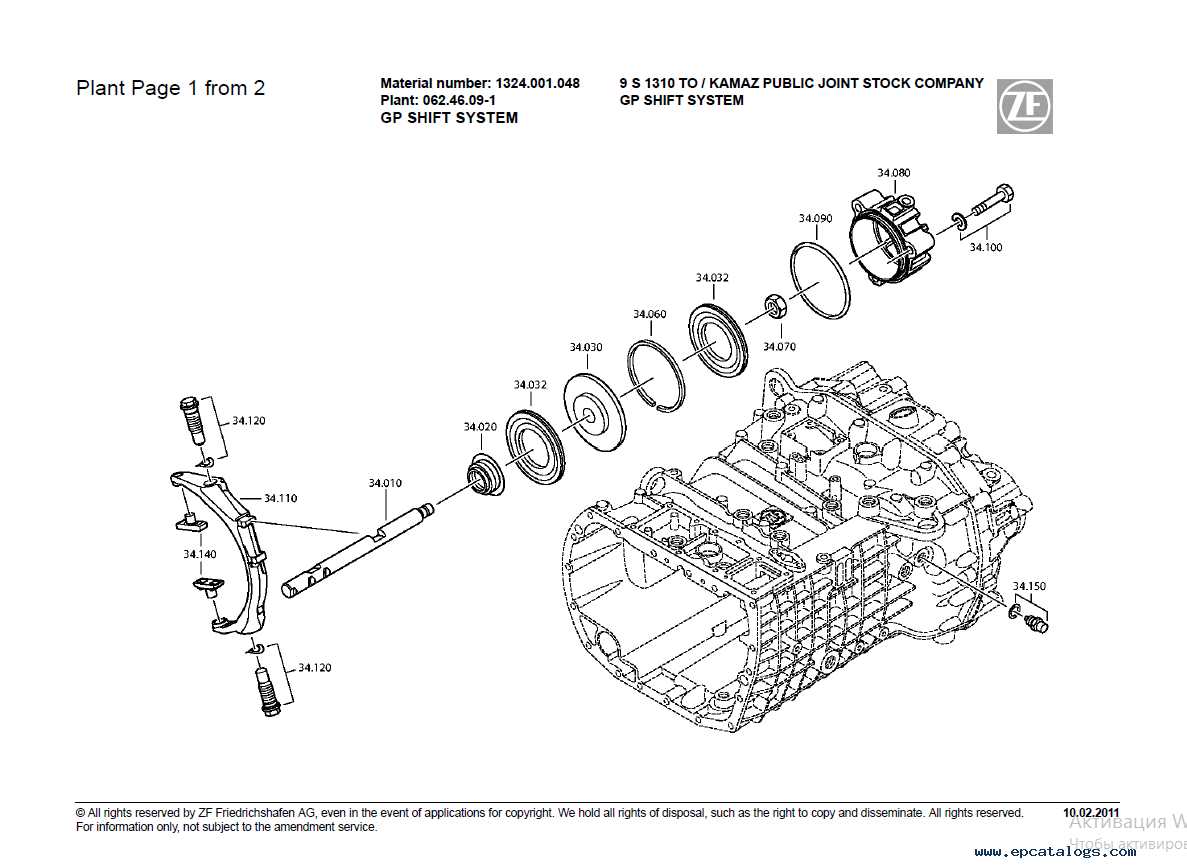

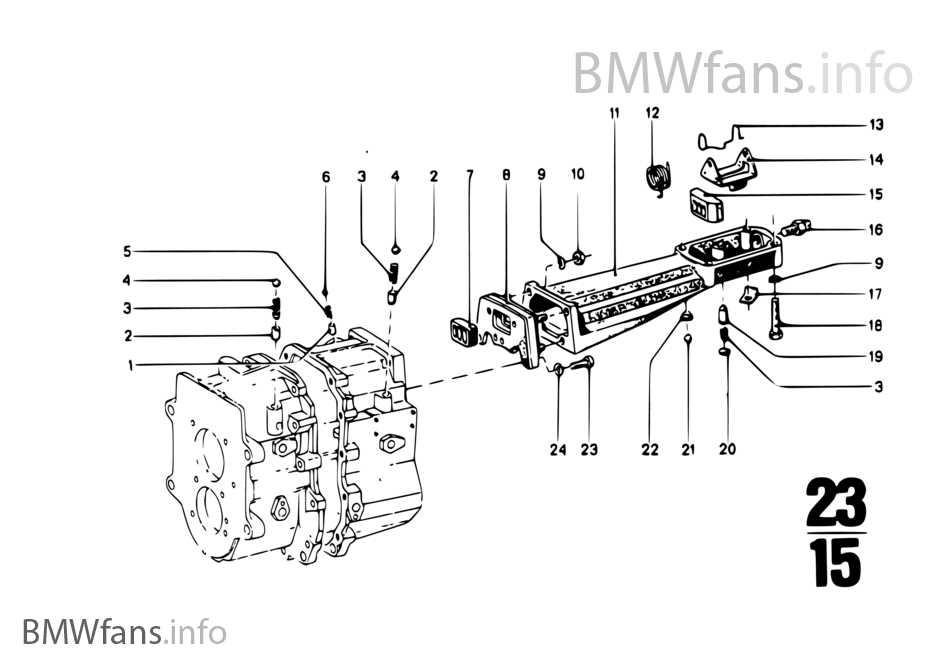

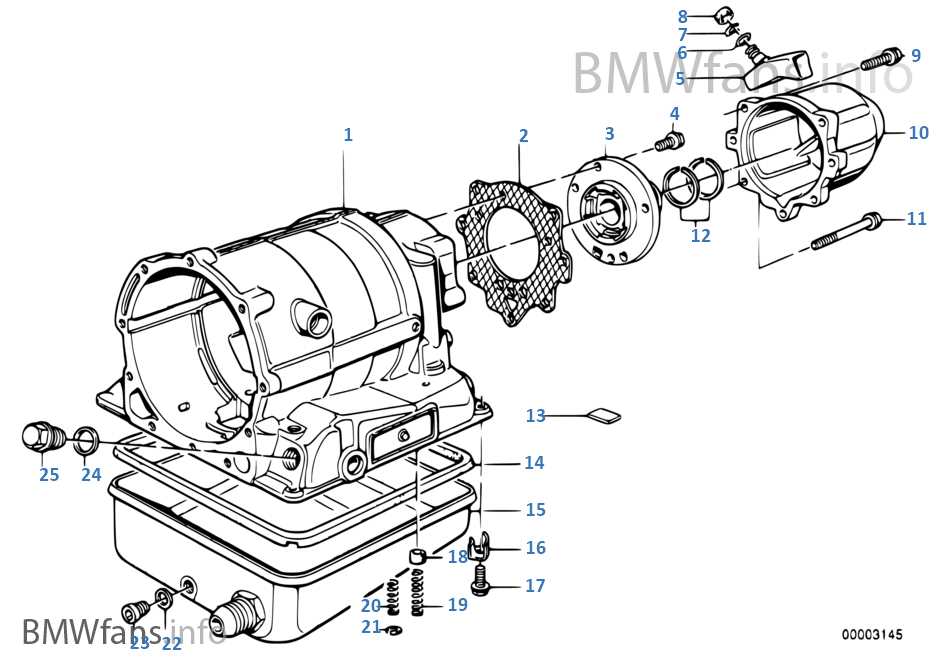

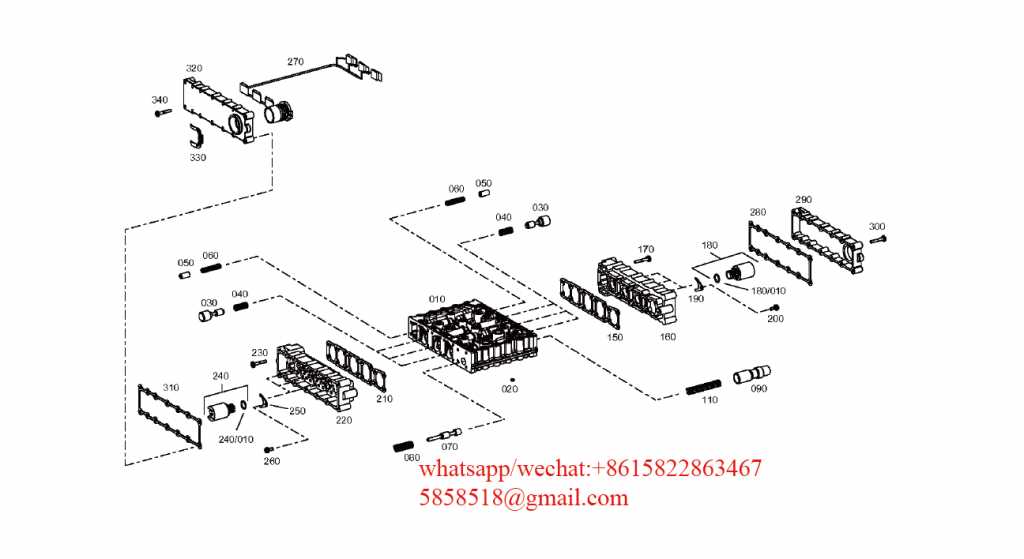

ZF Transmission Diagrams Explained

Understanding the intricacies of complex machinery is crucial for effective maintenance and repair. This section delves into visual representations that illustrate the inner workings of ZF systems, highlighting their functionality and interrelationships. Such illustrations serve as valuable tools for technicians and enthusiasts alike, facilitating a clearer grasp of how components interact.

Key Components Illustrated

- Gears: Essential for changing speeds and torque.

- Clutches: Critical for engaging and disengaging power transfer.

- Valves: Control fluid flow and pressure throughout the mechanism.

- Sensors: Monitor performance and ensure optimal operation.

Benefits of Using Visual Representations

- Enhanced Clarity: Simplifies complex mechanisms for better understanding.

- Efficient Troubleshooting: Helps identify issues quickly by showcasing connections.

- Improved Training: Serves as an educational resource for new technicians.

- Standardization: Provides a common reference for various models and types.

Installation Process for ZF Components

Ensuring proper installation of ZF components is crucial for optimal performance and longevity. This section outlines the necessary steps and considerations to effectively integrate these elements into your system, promoting efficiency and reliability.

Preparation Before Installation

Before beginning the installation, it is important to gather all required tools and components. Follow these preliminary steps:

- Review the installation manual for specific guidelines.

- Gather necessary tools, including wrenches, screwdrivers, and torque wrenches.

- Ensure the workspace is clean and free from debris.

- Check that all components are compatible and in good condition.

Step-by-Step Installation Guide

Follow these steps to ensure a successful installation:

- Disconnect any power sources to prevent accidents.

- Remove the old components carefully, noting their configuration.

- Clean the surfaces where the new components will be installed.

- Position the new components, aligning them according to the manual.

- Secure the components using the recommended fasteners, ensuring proper torque settings.

- Reconnect any necessary wiring or hoses, following safety protocols.

- Test the system under controlled conditions to verify proper operation.

By adhering to these guidelines, you can achieve a successful integration of ZF components, enhancing the overall performance of your system.

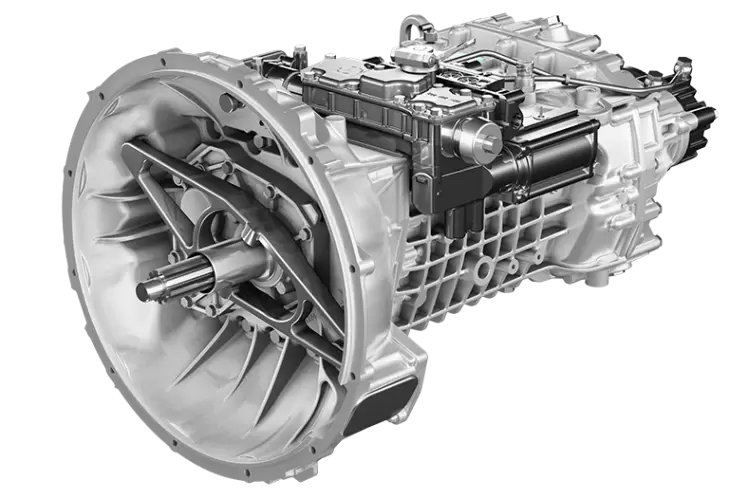

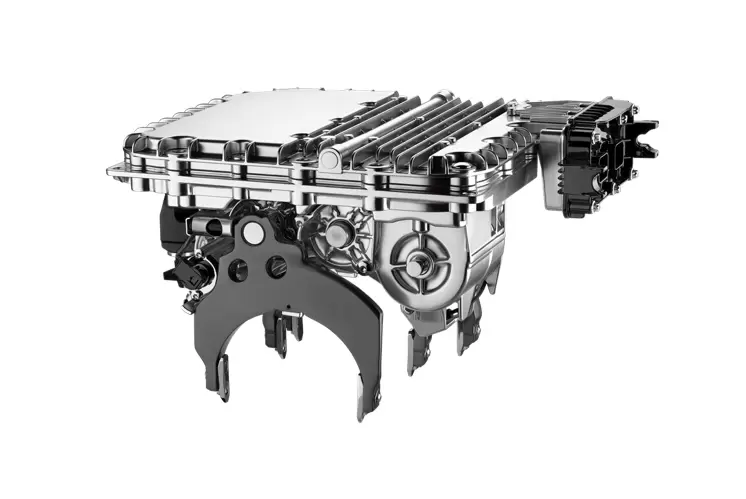

Latest Innovations in ZF Technology

Recent advancements in ZF’s engineering have paved the way for enhanced performance and efficiency in their offerings. The focus has been on integrating cutting-edge materials and smart systems that elevate user experience and operational reliability.

Smart Integration

One of the key innovations is the incorporation of intelligent control systems. These systems adapt to driving conditions in real-time, optimizing performance while reducing energy consumption. This evolution reflects ZF’s commitment to sustainability and advanced user interaction.

Advanced Materials

Moreover, the utilization of lightweight yet durable materials has significantly improved the robustness of ZF’s solutions. This not only contributes to overall efficiency but also enhances safety features, ensuring a superior driving experience.

ZF Transmission Applications in Vehicles

The innovative solutions developed by ZF have found their way into a wide array of vehicles, enhancing performance, efficiency, and driving experience. These advancements are integral to modern automotive engineering, ensuring smooth operation across various driving conditions.

Commercial vehicles benefit significantly from ZF’s technology, as it enables heavy-duty performance while maintaining fuel efficiency. This is crucial for logistics and transportation sectors, where operational costs are a key consideration.

In the realm of passenger cars, ZF’s offerings contribute to an enjoyable and dynamic driving experience. Their systems allow for seamless gear shifts, which improves acceleration and overall handling. This is particularly evident in sporty models where performance is paramount.

SUVs and off-road vehicles also leverage ZF’s expertise, allowing them to navigate challenging terrains with ease. The adaptability of these systems ensures that drivers maintain control and comfort, regardless of the environment.

Furthermore, electric and hybrid vehicles utilize ZF’s cutting-edge solutions to optimize energy management and drive efficiency. This integration supports the growing trend towards sustainable mobility, aligning with the industry’s shift towards greener technologies.

In summary, ZF’s innovations play a pivotal role across various vehicle categories, enhancing functionality and elevating the overall driving experience.

Future Trends in ZF Engineering

The landscape of engineering at ZF is poised for significant transformation as innovative technologies and sustainable practices gain momentum. As the industry evolves, the focus will shift towards enhanced efficiency, integration of advanced automation, and the implementation of cutting-edge materials that promise improved performance and longevity.

One prominent trend is the integration of smart systems that leverage artificial intelligence and machine learning. These technologies are expected to optimize operations and enhance real-time decision-making capabilities, leading to more responsive and adaptable solutions. Furthermore, the push towards electrification in various sectors will encourage the development of eco-friendly designs that minimize environmental impact while maximizing energy efficiency.

Collaboration with technology partners will play a crucial role in fostering innovation. By embracing a more interconnected approach, ZF aims to tap into new markets and enhance its product offerings, ensuring they meet the evolving demands of consumers. This strategic focus on collaboration is likely to drive the development of next-generation solutions that are not only technically advanced but also user-friendly and accessible.

In summary, the future of ZF engineering is set to be characterized by technological integration, sustainability, and strategic partnerships. These trends will not only redefine the company’s operational framework but also position it as a leader in delivering advanced engineering solutions for tomorrow’s challenges.