Understanding the Parts Diagram of Lehr Trimmers

Every gardening enthusiast knows that the efficiency of their equipment relies heavily on the quality and arrangement of its individual elements. By examining the various segments that comprise these tools, one can appreciate how each piece contributes to optimal performance. An organized approach to understanding these components not only enhances functionality but also prolongs the lifespan of the device.

In this exploration, we will delve into the essential features that make up these vital implements. Grasping the interplay between the various elements can lead to more effective maintenance and troubleshooting, ultimately ensuring that your gardening tasks are executed with precision. Whether you are a novice or an experienced user, recognizing the significance of each part is the first step towards achieving your gardening goals.

As we dissect these tools, the focus will be on elucidating the intricate designs and their ultimate purposes. Understanding how these individual pieces fit together can transform your approach to gardening, allowing for a more informed and proactive strategy when it comes to repairs and upgrades.

Understanding Lehr Trimmer Components

Grasping the individual elements of a cutting device is essential for effective operation and maintenance. Each component plays a critical role in the overall functionality, ensuring optimal performance and longevity. This section delves into the key parts that make up these tools, providing insights into their specific functions and interrelations.

Key Elements of the Device

Every cutting apparatus consists of various integral components that contribute to its efficiency. Understanding these elements is crucial for users seeking to optimize their experience and ensure the tool operates smoothly.

| Component | Description |

|---|---|

| Motor | Drives the mechanism, providing the necessary power for cutting operations. |

| Blade | Sharp edge designed for precision cutting; can vary in size and type depending on application. |

| Handle | Ergonomic design that allows for comfortable and controlled operation. |

| Guard | Safety feature that protects the user from accidental contact with the blade. |

Maintenance and Troubleshooting

Regular upkeep of each element is vital for sustained performance. Familiarity with the functions and potential issues of these components enables users to identify problems early and address them efficiently. Proper care not only extends the lifespan of the tool but also enhances safety during use.

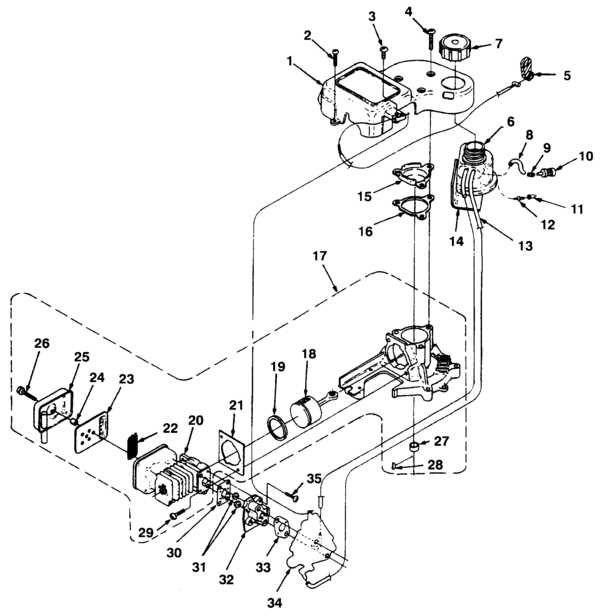

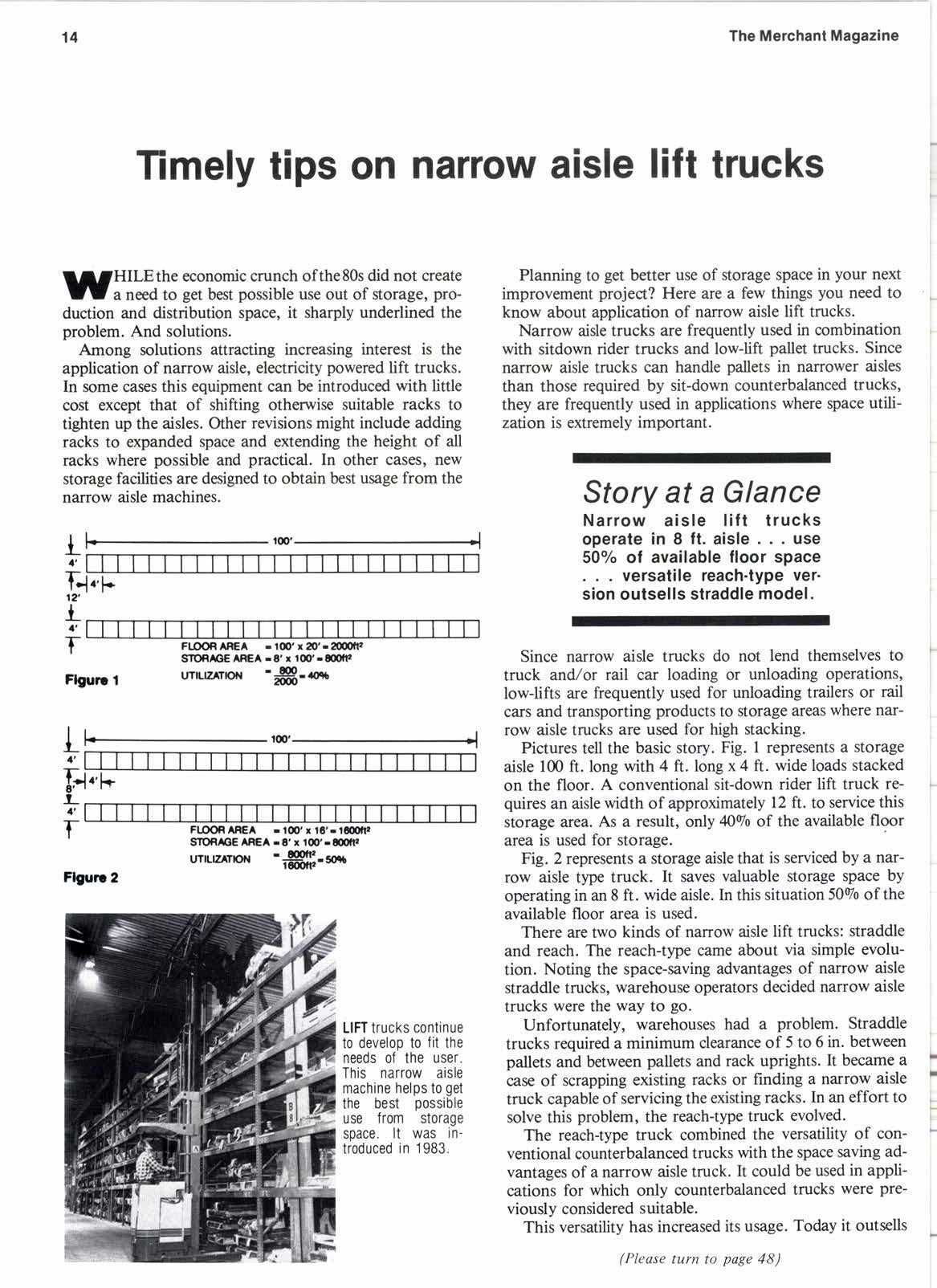

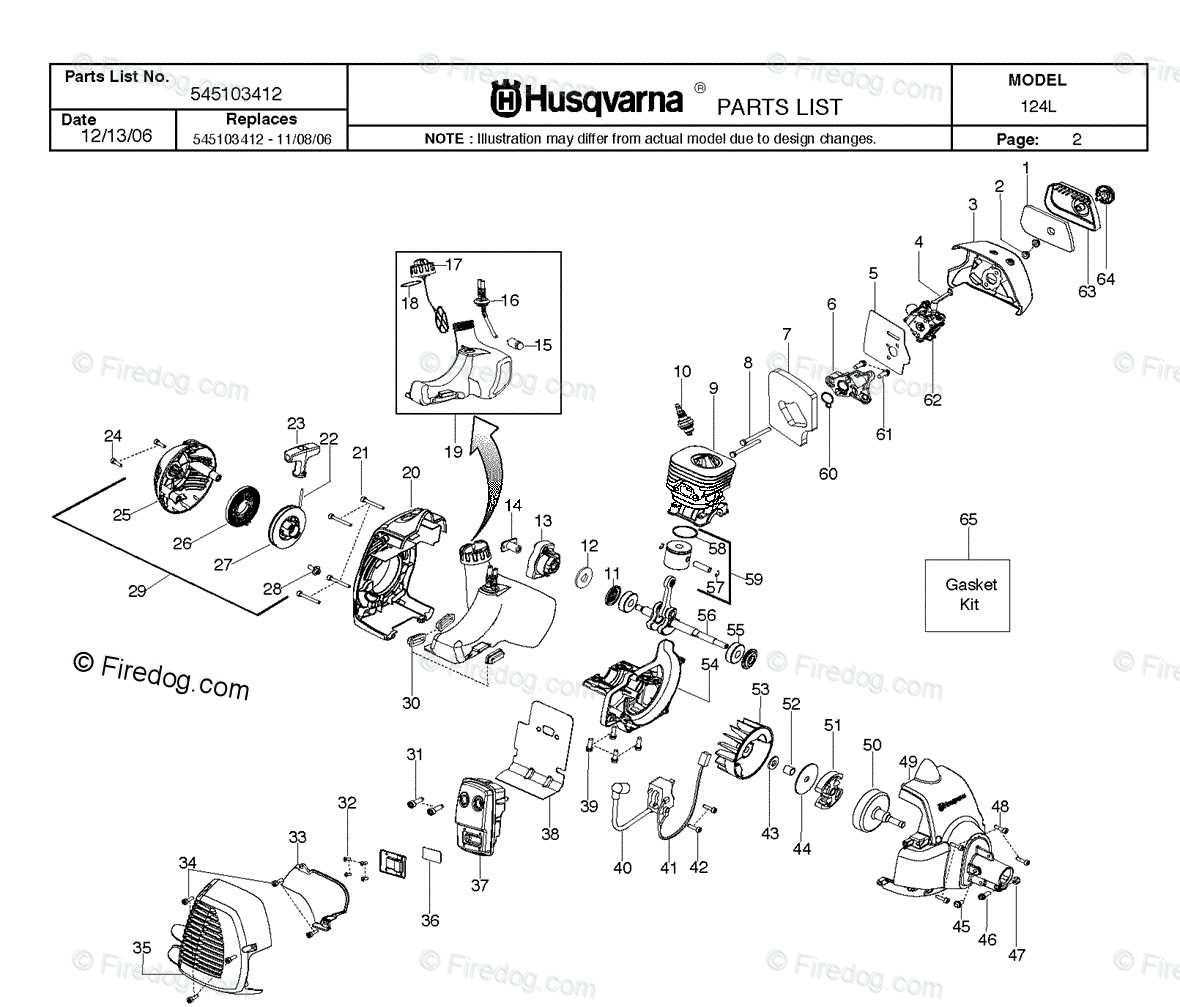

Importance of a Parts Diagram

Understanding the components of a machine is crucial for efficient maintenance and repair. A visual representation of these elements serves as an invaluable tool, enabling users to identify and locate individual sections with ease. This clarity not only enhances the ability to troubleshoot but also streamlines the assembly and disassembly processes.

Facilitating Repairs

A detailed visual guide can significantly reduce downtime during repairs. By offering a clear layout of each component, it allows technicians to quickly pinpoint issues and obtain the necessary replacements. This efficiency is essential for both professional mechanics and DIY enthusiasts alike, ensuring that any interruptions in usage are minimized.

Enhancing Understanding

Furthermore, a well-crafted visual representation fosters a deeper understanding of how each element interacts within the larger system. Users can grasp the relationship between different parts, leading to better decision-making when it comes to upgrades or modifications. This knowledge empowers individuals to maintain their equipment effectively, prolonging its lifespan.

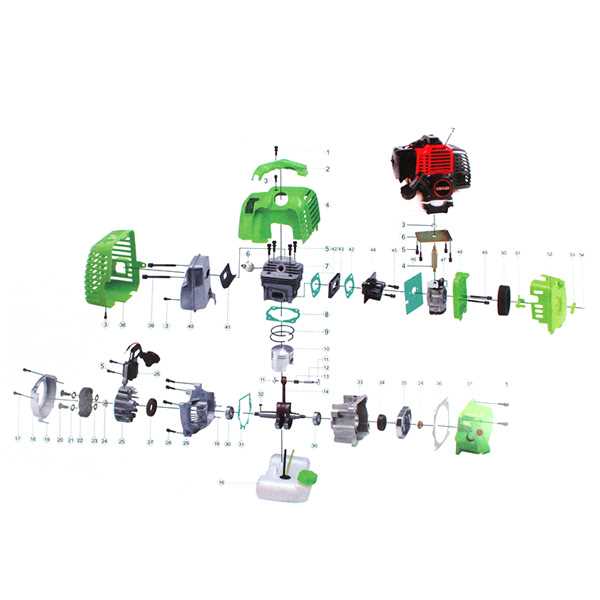

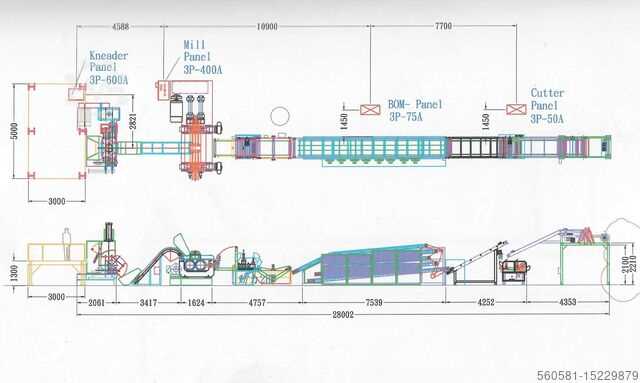

Main Parts of Lehr Trimmers

This section explores the essential components that contribute to the functionality and efficiency of the cutting tool. Each element plays a vital role in ensuring optimal performance and ease of use.

Power Source: The driving force behind the tool, this element can be either electric or gas-powered, providing the necessary energy for operation.

Cutter Head: The area where the cutting action occurs, it houses the blades or line that performs the trimming tasks.

Handle: Designed for comfort and control, this component allows the user to maneuver the equipment easily.

Safety Guard: An essential feature that protects the user from debris and ensures safe operation during use.

Throttle Control: This mechanism regulates the power output, giving the operator control over the tool’s speed and performance.

Support Frame: Provides structural integrity, ensuring that all components are securely attached and aligned for optimal functioning.

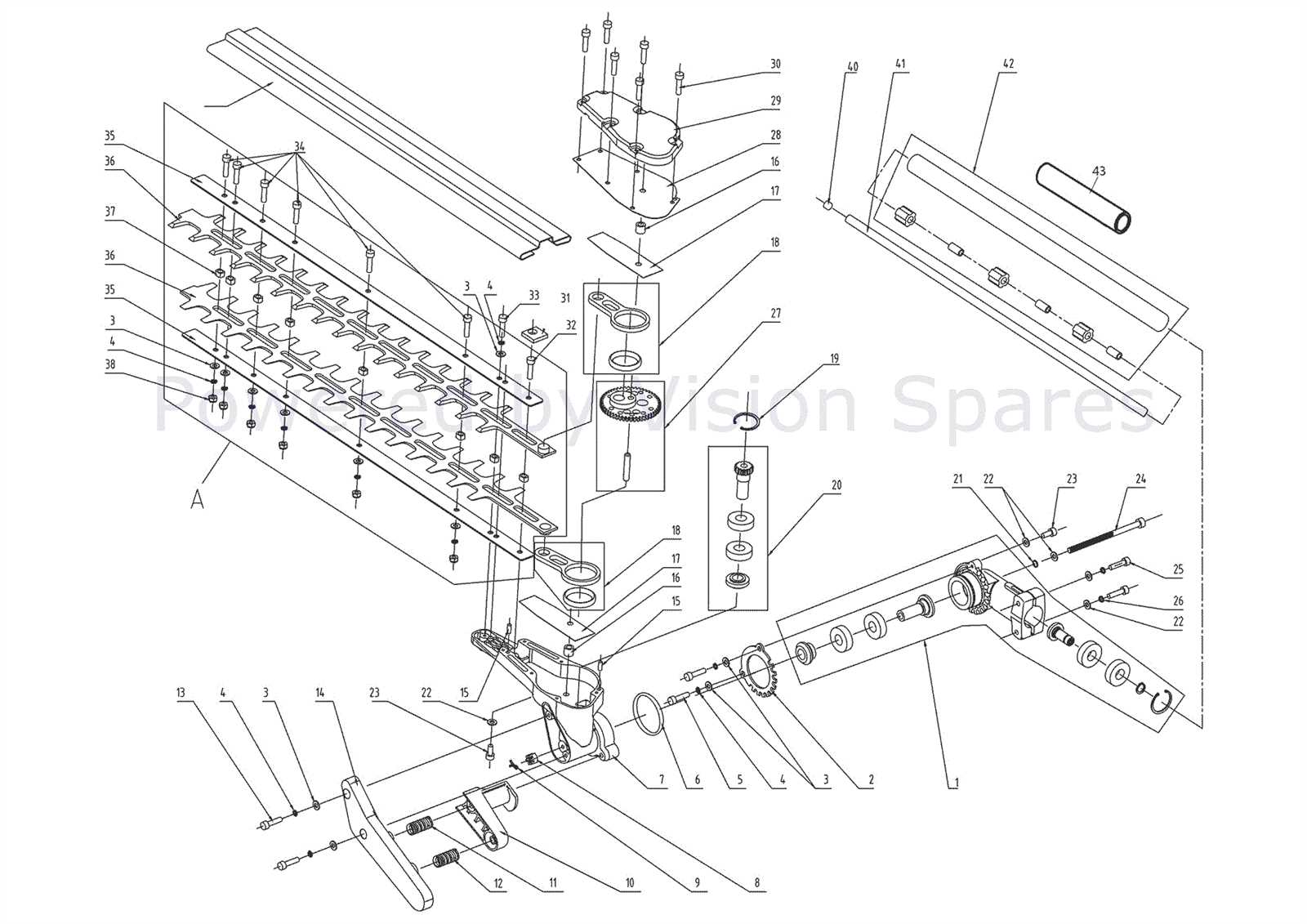

How to Read the Diagram

Understanding the layout of components can greatly enhance your ability to troubleshoot and maintain equipment. Familiarizing yourself with the schematic is essential for efficient assembly and repair.

Here are some key steps to effectively interpret the illustration:

- Identify Symbols: Learn the meaning of various symbols used to represent different elements.

- Follow the Flow: Observe how connections are represented, tracing the flow of energy or function.

- Group Components: Note clusters of parts that work together, recognizing how they interact.

- Refer to Legends: Use any provided legends or keys to clarify any unclear symbols or abbreviations.

By systematically approaching the layout, you can delve deeper into its intricacies and ultimately improve your comprehension of the machinery.

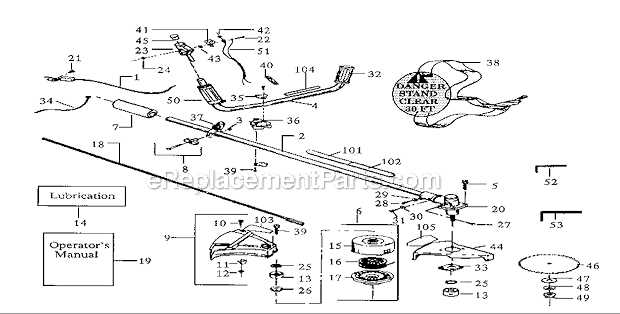

Common Issues with Trimmer Parts

Many users encounter various challenges with their cutting tools that can hinder performance and efficiency. Understanding these frequent problems is essential for effective maintenance and repair.

Wear and Tear

Durability is a key factor, as components often degrade over time due to regular use. This can lead to reduced functionality, causing the device to perform below expectations.

Improper Assembly

Incorrect installation of components can lead to operational issues. Ensuring all parts are fitted correctly is crucial for the tool’s overall performance and longevity.

Maintenance Tips for Longevity

To ensure the lasting performance of your equipment, regular upkeep is essential. By following a few key practices, you can enhance its efficiency and extend its operational life. Consistent attention to maintenance can prevent wear and tear, ultimately saving time and resources.

1. Regular Cleaning: Keep the machinery clean from debris and dirt. A buildup can cause overheating and mechanical issues.

2. Lubrication: Apply appropriate lubricants to moving parts to reduce friction and prevent rust. This simple step can significantly increase durability.

3. Inspection: Frequently check for any signs of wear or damage. Early detection of issues allows for timely repairs, preventing larger problems.

4. Storage: When not in use, store the equipment in a dry place to protect it from moisture and environmental damage. Proper storage practices can make a substantial difference.

5. Follow Manufacturer Guidelines: Always adhere to the recommendations provided by the manufacturer regarding maintenance schedules and techniques. This ensures optimal functionality.

By integrating these practices into your routine, you can delve deeper into the nuances of care and achieve the ultimate longevity of your equipment.

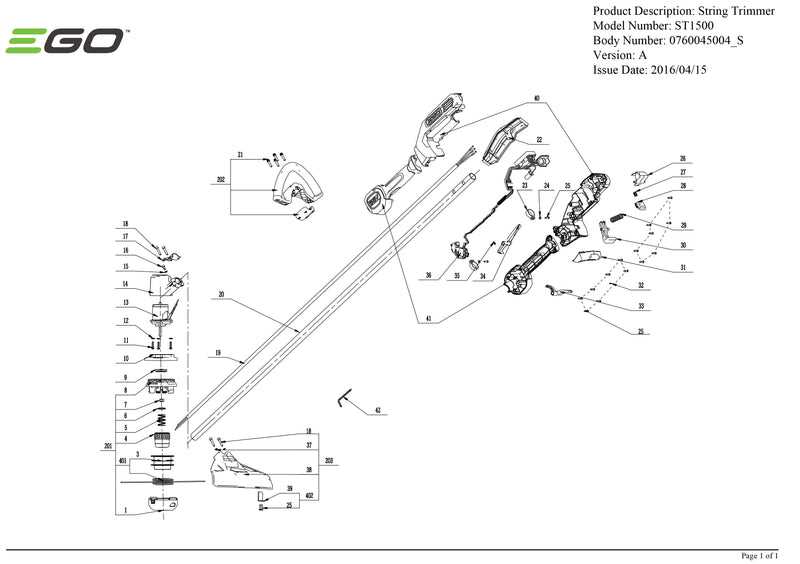

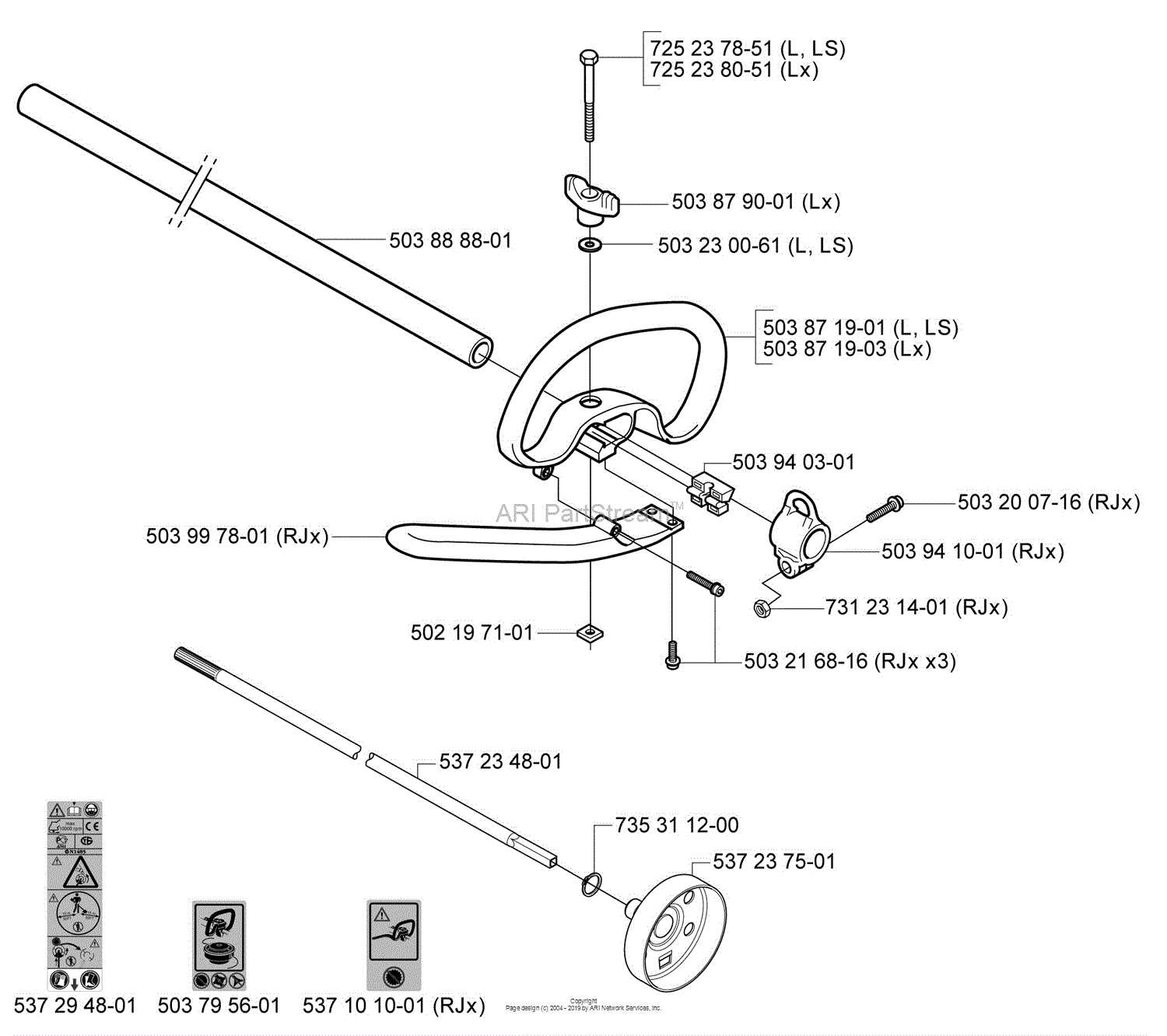

Identifying Replacement Parts Easily

Finding the right components for your equipment can often feel overwhelming, especially when various options are available. However, with a systematic approach, you can simplify the process and ensure that you select the correct items needed for maintenance or repairs.

Here are some effective strategies to help you identify the necessary components:

- Consult the Manual: Always start by referring to the user guide that came with your device. It typically contains valuable information on specifications and compatible replacements.

- Online Resources: Utilize manufacturer websites or specialized forums where you can find detailed descriptions and images of the components.

- Visual Inspection: Take a close look at the current items on your equipment. Note any markings, serial numbers, or unique characteristics that can assist in matching replacements.

In addition, consider these tips:

- Gather Information: Write down all relevant details such as model number, year of manufacture, and any specific features that may affect compatibility.

- Cross-Reference: If you have access to multiple resources, compare the information to ensure accuracy and avoid mistakes.

- Ask for Help: Don’t hesitate to reach out to customer service or knowledgeable friends. They can often provide insights that save time and effort.

By following these steps, you can confidently navigate the process of identifying and obtaining the components you need, ensuring your equipment remains in top condition.

Comparing Lehr Models and Diagrams

When examining various models and their corresponding illustrations, it becomes essential to understand the nuances that differentiate them. Each variant offers unique characteristics that cater to specific needs, making it crucial for users to grasp these distinctions for optimal performance.

Visual representations play a significant role in identifying the components and functionalities of each model. By analyzing these visuals, one can delve into the intricate details, facilitating better decision-making and maintenance strategies.

Furthermore, understanding the similarities and differences across these designs allows users to pinpoint the ultimate choice for their requirements. This knowledge not only enhances usability but also extends the longevity of the equipment.

Tools Required for Repairs

When undertaking maintenance tasks, having the right equipment is essential for achieving efficient results. A variety of instruments will enhance your ability to diagnose issues and implement effective solutions.

Essential Tools: A set of screwdrivers, wrenches, and pliers will form the foundation of your toolkit. These items allow for easy access to components and facilitate adjustments.

Specialized Equipment: Depending on the complexity of the repair, you may require additional tools such as a multimeter for electrical diagnostics or a torque wrench for precision. These specialized instruments ensure accuracy and reliability.

Safety Gear: Don’t overlook the importance of personal protection. Safety goggles and gloves should be part of your standard gear to safeguard against potential hazards.

With the right tools in hand, you can delve into your project confidently, ensuring a smoother and more successful repair experience.

Safety Precautions While Working

Ensuring a safe environment during any maintenance or operational task is crucial for preventing accidents and injuries. Adhering to proper guidelines can significantly reduce risks associated with equipment usage and handling.

Personal Protective Equipment

Wearing appropriate gear is essential. This includes safety goggles, gloves, and ear protection to shield yourself from debris, noise, and potential hazards. Always inspect your equipment before use to ensure it is in good condition.

Work Area Awareness

Maintain a clean and organized workspace. Be mindful of your surroundings, keeping the area free of clutter and distractions. Additionally, ensure proper lighting to enhance visibility, which can help you avoid accidents.

Where to Purchase Spare Parts

Finding the right components for your gardening equipment is crucial for maintaining optimal performance. Whether you’re looking for specific items or complete sets, knowing where to shop can make a significant difference.

| Source | Advantages |

|---|---|

| Online Retailers | Wide selection and convenient home delivery. |

| Local Hardware Stores | Immediate availability and personal assistance. |

| Manufacturer’s Website | Genuine quality and reliable compatibility. |

| Specialty Shops | Expert advice and specialized inventory. |

Consider these options carefully to ensure you acquire the correct items efficiently.

Upgrading Your Trimmer Efficiently

Enhancing your outdoor maintenance tool can significantly boost its performance and longevity. By focusing on key components and features, you can achieve optimal results in your gardening tasks. This guide aims to help you explore efficient upgrades that ensure your device runs smoothly and effectively.

Identifying Key Components

To begin, assess the current condition of your equipment. Look for areas that require improvement, such as the cutting mechanism, motor efficiency, or fuel system. Prioritizing these elements can lead to the ultimate enhancement of functionality.

Choosing Quality Replacements

Investing in high-quality replacements is crucial for achieving the best results. Look for reliable brands that offer durable and efficient options. Researching user reviews and recommendations can help you make informed decisions and delve deeper into the advantages of each component.

FAQs About Lehr Trimmer Parts

This section aims to address common inquiries regarding components associated with grass cutting tools. Understanding the essential elements and their functionalities can greatly enhance the user experience and maintenance efficiency. Below are some frequently asked questions that can provide clarity and assist users in their endeavors.

What are the most common components found in these tools?

The typical assembly includes a cutting head, motor, fuel tank, and various attachments. Each of these elements plays a crucial role in the overall performance, ensuring effective operation and ease of use.

How can I identify when a component needs replacement?

Indicators of wear may include reduced cutting efficiency, unusual noises, or visible damage. Regular inspections and maintenance checks can help users determine the condition of the components, allowing for timely replacements and optimal functionality.