Understanding the Trimmer Parts Diagram for Efficient Maintenance

In the realm of maintaining a pristine outdoor space, having a comprehensive understanding of the machinery involved is essential. Properly functioning equipment enhances efficiency and ensures a well-groomed landscape. Familiarity with each element of these devices enables users to optimize their performance and extend their lifespan.

The intricate design of these tools includes various essential elements that work in harmony to achieve desired results. From the engine to the cutting mechanism, each component plays a vital role. By examining these individual parts, one can gain insights into how they contribute to the overall functionality and reliability of the equipment.

Moreover, recognizing the arrangement and interaction of these elements aids in troubleshooting common issues. Users can identify problems more effectively, allowing for timely maintenance and repairs. Understanding these connections not only empowers users but also enhances their confidence in managing outdoor tasks efficiently.

Understanding Trimmer Parts Functionality

Grasping the inner workings of garden maintenance tools is essential for effective usage and maintenance. Each component plays a critical role in ensuring optimal performance and longevity of the equipment. By exploring the individual functionalities, users can enhance their understanding and efficiency during operation.

The cutting mechanism, often the most recognizable feature, is designed to handle various types of vegetation with precision. Its sharp edges enable clean cuts, promoting healthier growth in the surrounding plants. Meanwhile, the motor is the powerhouse, converting energy into motion, allowing for seamless operation across different terrains.

Additionally, the handle and shaft contribute significantly to user comfort and control, making it easier to navigate tight spaces. Accessories, such as guards and spools, serve as vital safety features, ensuring that users can operate their tools without risk of injury. Understanding these elements can lead to more informed choices and improved care.

Essential Components of a Trimmer

Understanding the fundamental elements of a cutting tool is crucial for both maintenance and optimal performance. Each component plays a significant role in ensuring efficiency and effectiveness in various tasks. Familiarity with these elements can greatly enhance user experience and prolong the lifespan of the device.

Key Elements

- Engine: The power source driving the mechanism.

- Cutting Head: The area where the blades or line are located for cutting.

- Handle: Provides grip and control during operation.

- Guard: Safety feature protecting the user from debris.

- Shaft: Connects the engine to the cutting head, enabling movement.

Additional Accessories

- Replacement Blades: For maintaining cutting efficiency.

- Harness: Aids in balancing the tool during prolonged use.

- Fuel Tank: Stores the necessary fuel for engine operation.

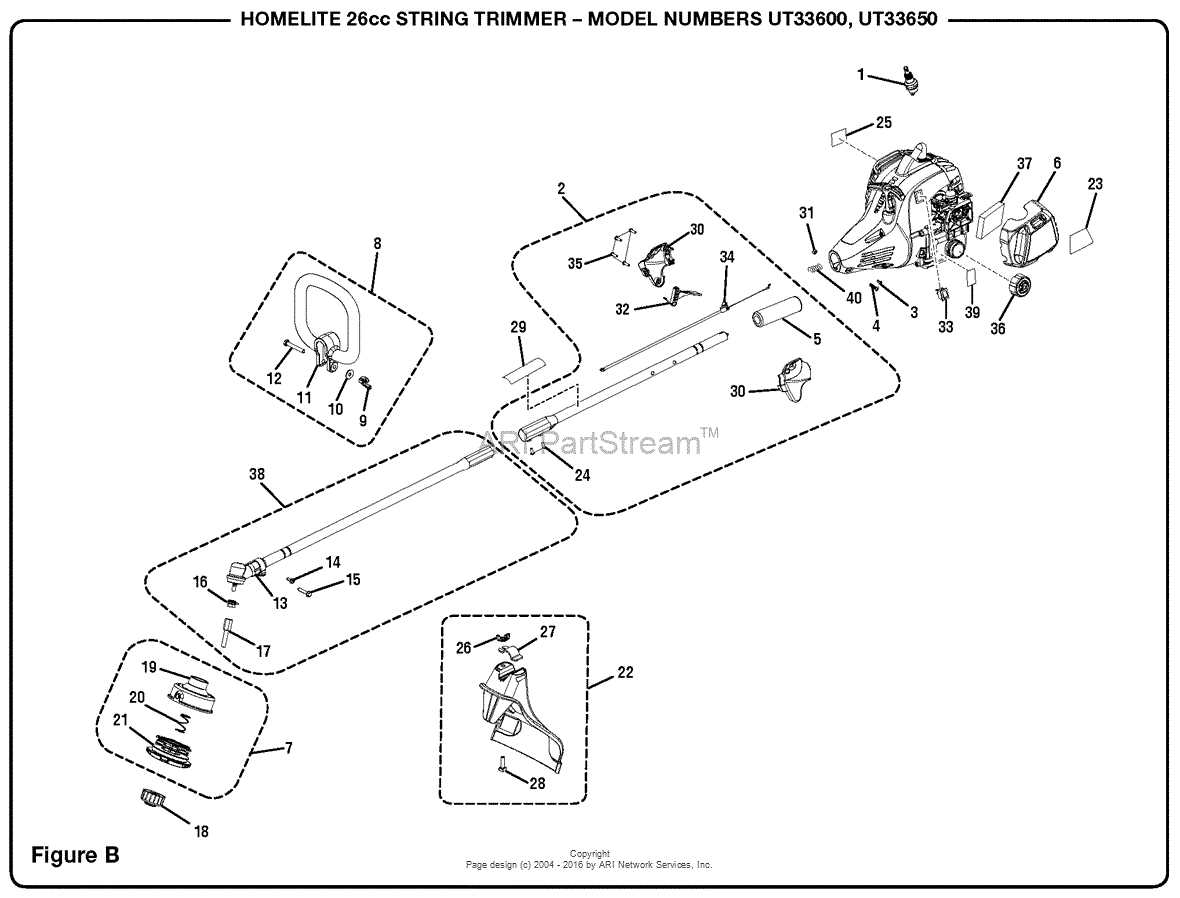

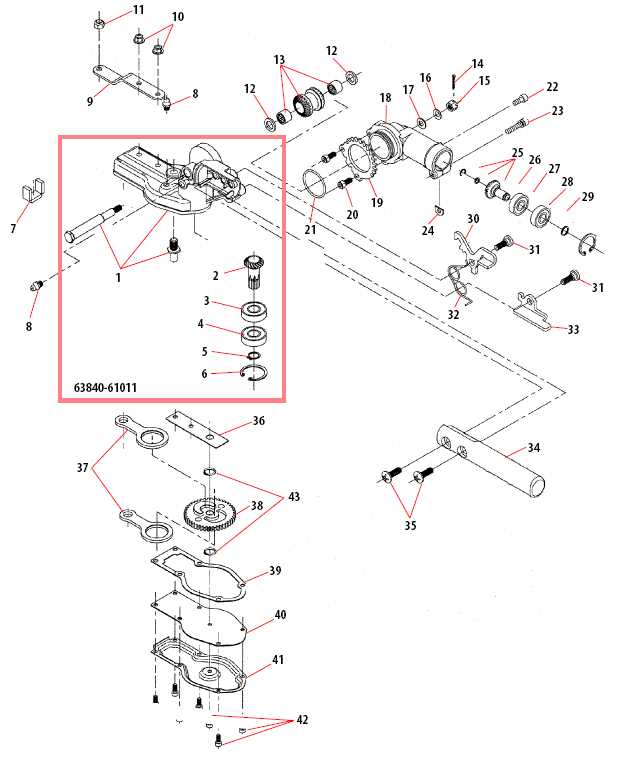

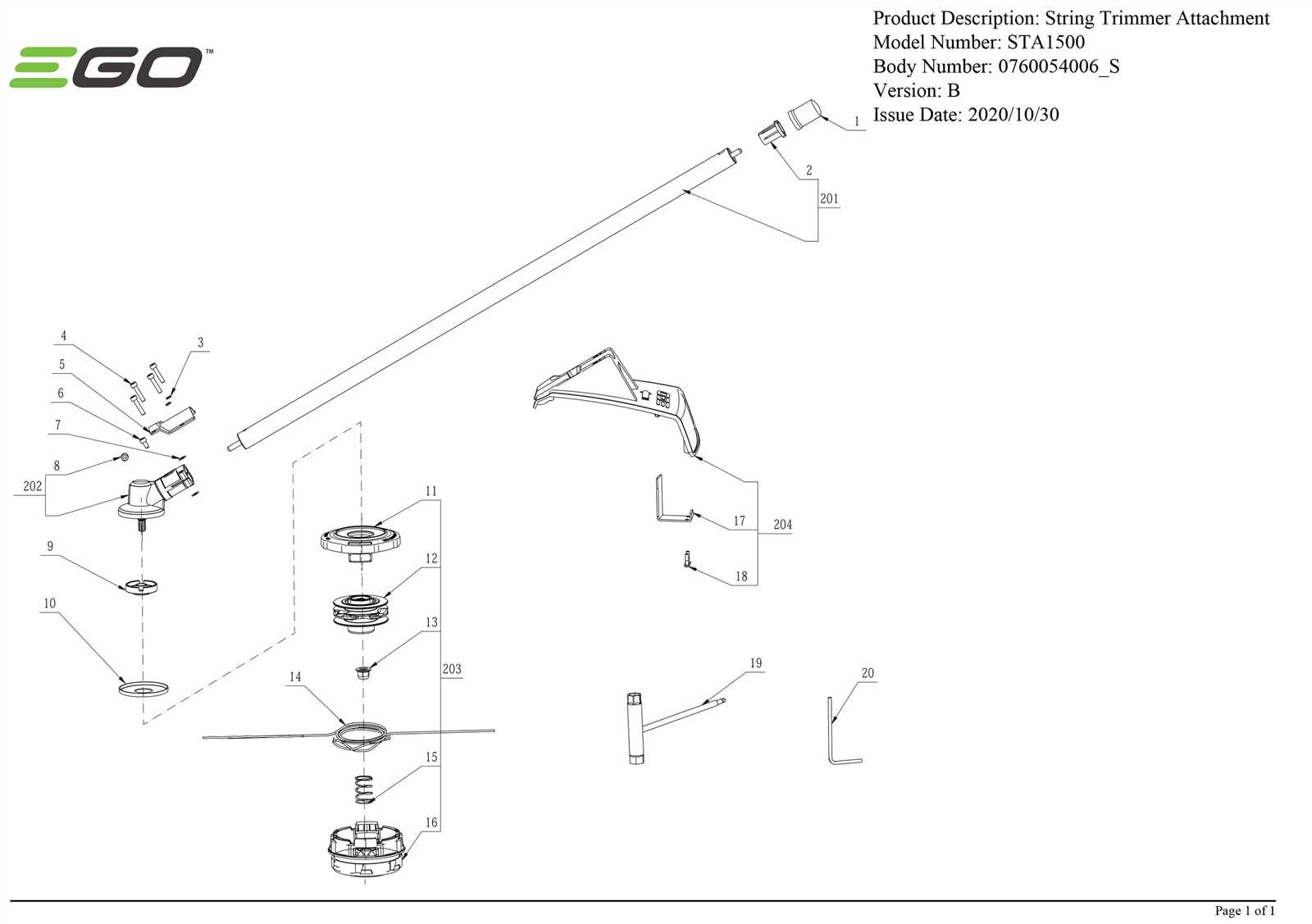

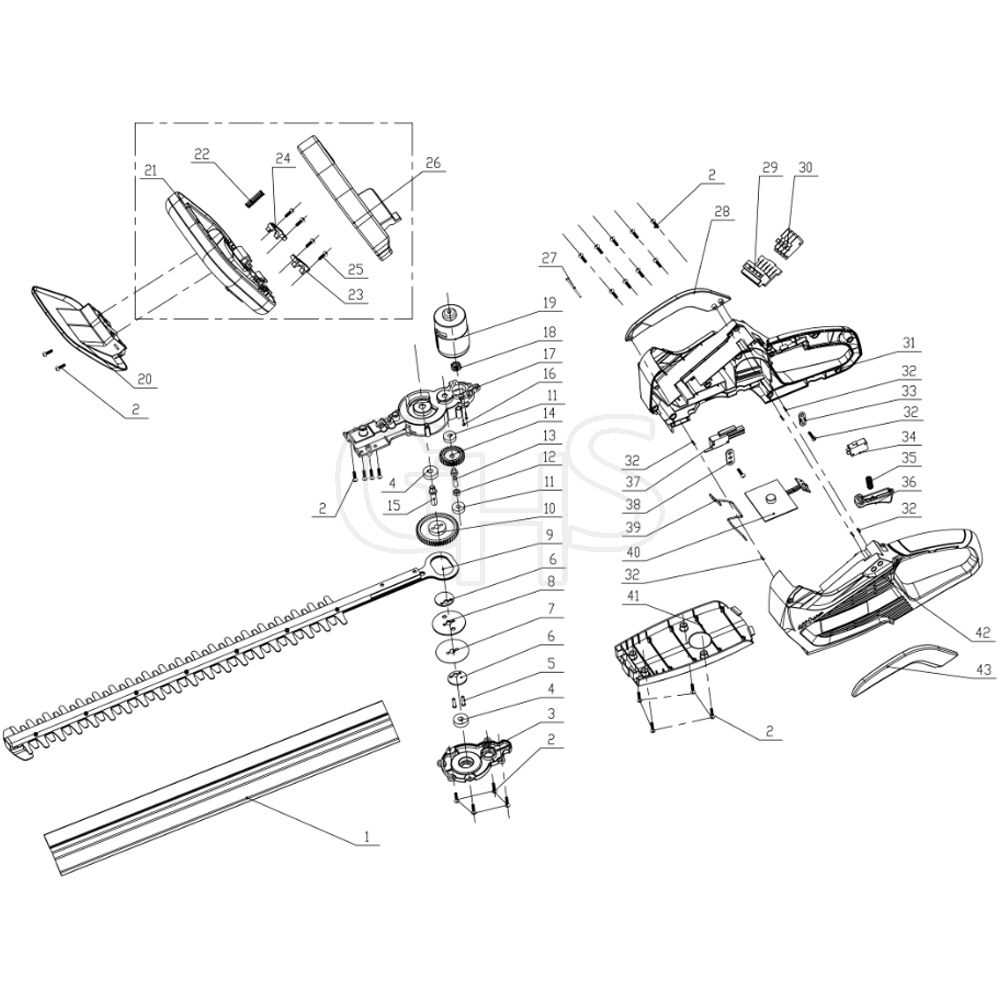

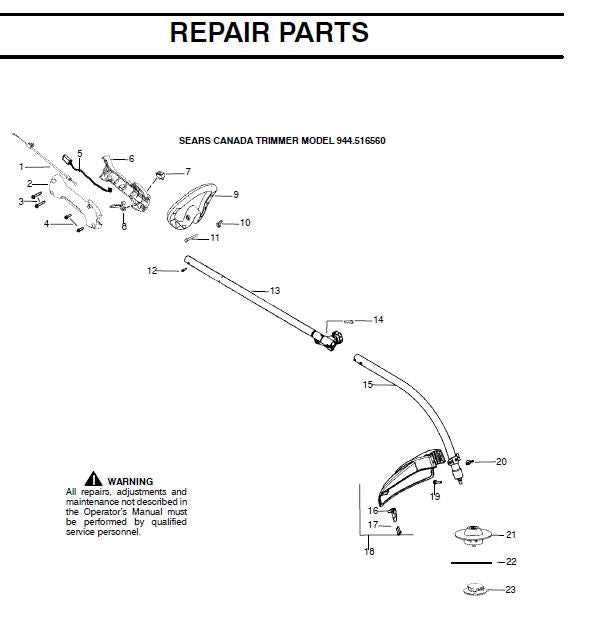

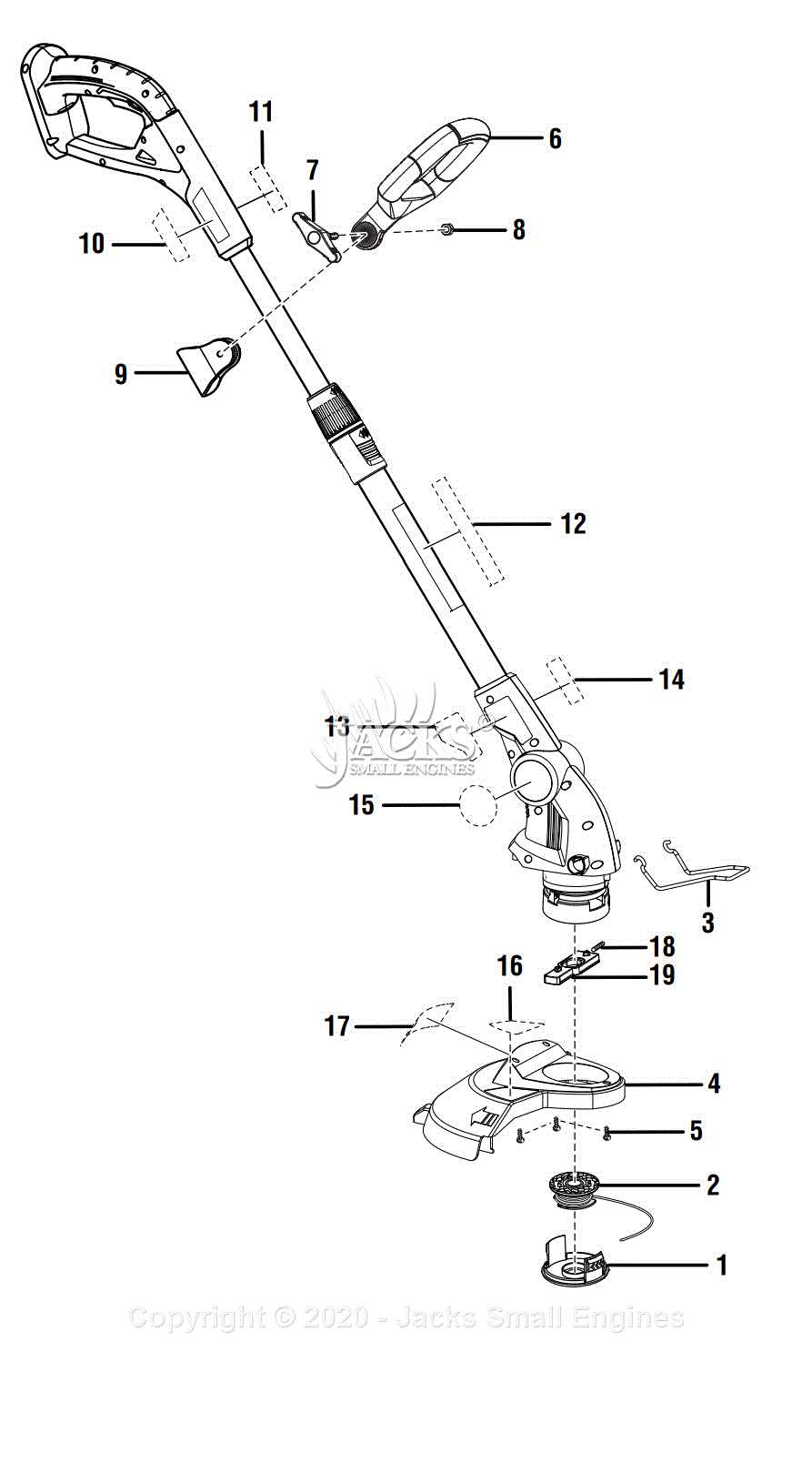

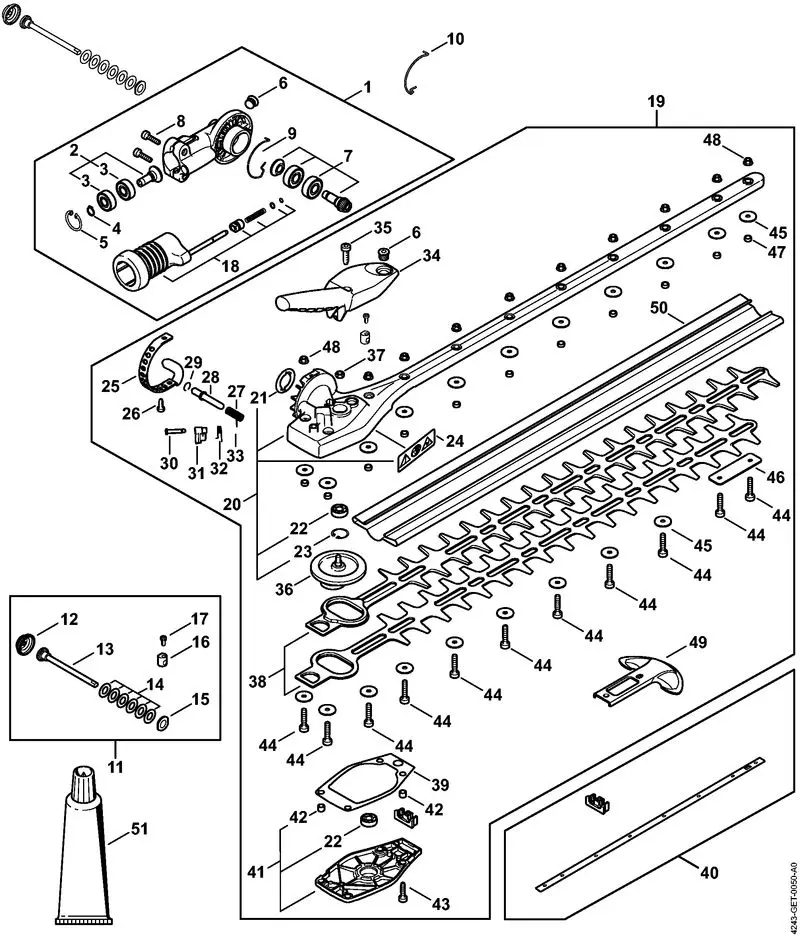

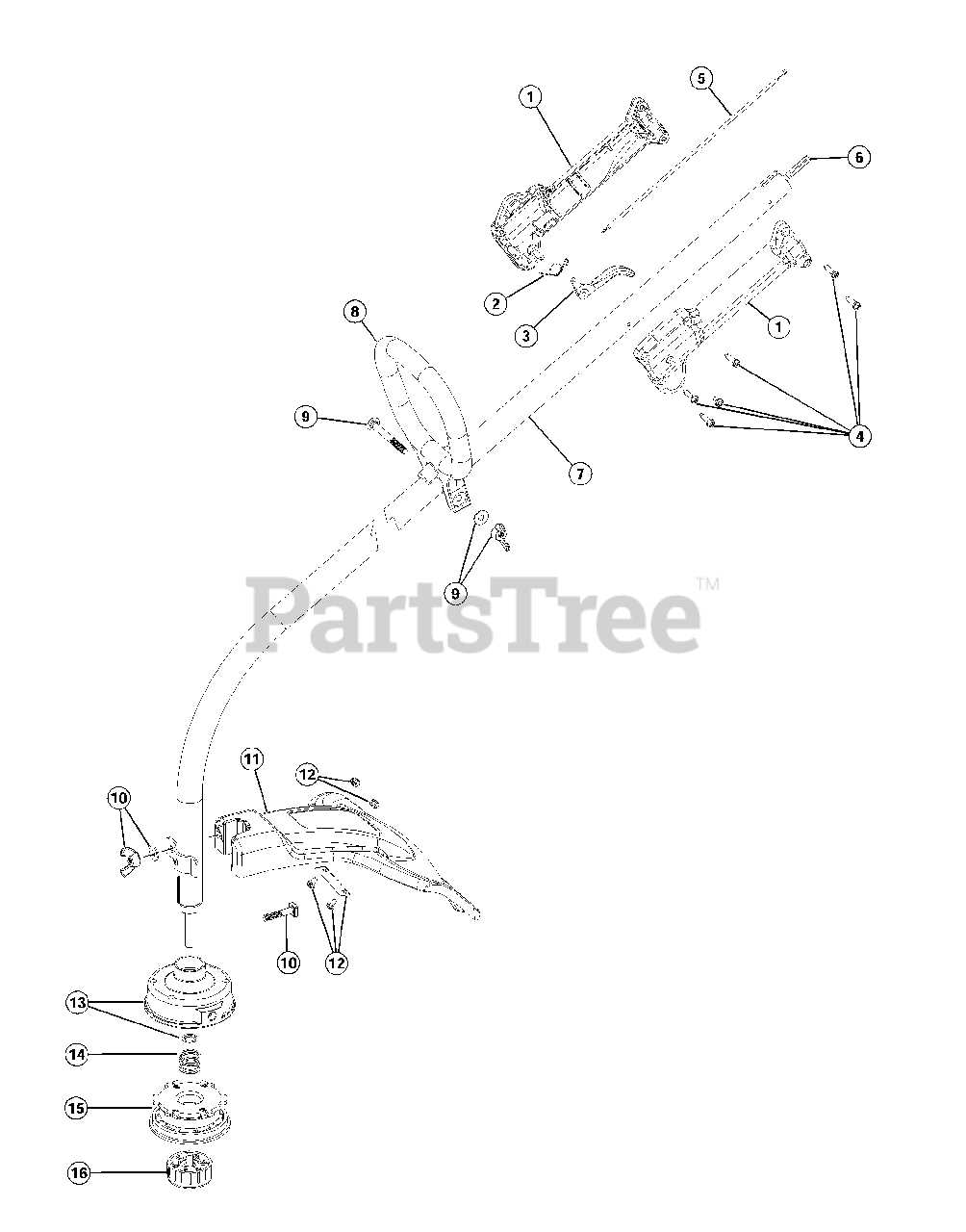

How to Read a Parts Diagram

Understanding a schematic representation can significantly enhance your ability to maintain and repair equipment. These visual guides serve as blueprints, illustrating the various components and their interconnections. By familiarizing yourself with these images, you can efficiently identify each element’s function and position.

Firstly, focus on the labels accompanying each item. These notations provide crucial information regarding the specific roles and specifications of each component. Pay attention to numbers and letters that correspond to a list, as they often clarify part names and quantities.

Next, observe the layout carefully. The arrangement typically reflects how the elements are assembled in the actual device. Recognizing groupings and sequences will aid in understanding the overall design and operation.

Finally, consult the accompanying documentation or manuals for additional context. These resources often contain valuable insights into assembly and maintenance procedures, ensuring you grasp the complete picture. By mastering this skill, you’ll be better equipped to tackle repairs and enhance your equipment’s performance.

Common Trimmer Parts and Their Roles

Understanding the various components of a cutting device is essential for effective operation and maintenance. Each element serves a specific purpose, contributing to the overall efficiency and functionality of the tool. Here, we explore the key components and their respective roles in ensuring optimal performance.

Key Components

- Cutting Head: This is the primary component responsible for trimming. It houses the line or blade, facilitating precise cutting.

- Line Feed Mechanism: This mechanism ensures a steady supply of cutting line, allowing for uninterrupted work.

- Handle: The handle provides control and stability, enabling the user to maneuver the device effectively.

- Power Source: Whether electric or gas, the power source drives the device, determining its cutting capacity.

- Guard: The guard protects the user from debris and reduces the risk of accidents during operation.

Supporting Elements

- Shaft: Connects the power source to the cutting head, transmitting energy for operation.

- Spool: Holds the cutting line, allowing for easy replacement and adjustments.

- Throttle Control: Enables the user to adjust the speed and power according to the task at hand.

- Anti-Vibration System: Reduces fatigue by minimizing vibrations during extended use.

Familiarity with these essential components not only aids in proper usage but also enhances the longevity and effectiveness of the tool.

Identifying Wear and Tear in Parts

Recognizing the signs of degradation is crucial for maintaining the efficiency and longevity of equipment. Over time, components can experience various forms of damage due to regular use, environmental factors, and material fatigue. Understanding how to identify these issues can help prevent further complications and costly repairs.

Visual Inspection is often the first step in assessing condition. Look for any obvious signs such as cracks, fraying, or discoloration. Surface irregularities can indicate excessive wear that may compromise functionality.

Additionally, performance evaluation plays a vital role in detecting issues. If a device exhibits unusual sounds, vibrations, or decreased efficiency, it may suggest that certain elements are deteriorating. Regular monitoring of how equipment operates can reveal trends that signal impending failure.

Material Assessment involves checking the integrity of different components. Utilizing tools to measure wear can provide a clearer picture of their current state. For instance, calipers and gauges can help determine if a part is still within acceptable tolerances.

Lastly, maintaining a log of usage can assist in predicting when certain elements may need attention. Keeping track of hours of operation and environmental conditions will help identify patterns of wear, allowing for proactive maintenance before problems arise.

Benefits of Knowing Trimmer Components

Understanding the individual elements of a gardening tool enhances the overall user experience and effectiveness. Familiarity with these components not only aids in maintenance but also empowers users to troubleshoot issues more efficiently. This knowledge ultimately leads to improved performance and longevity of the equipment.

Improved Maintenance and Repairs

When users are well-versed in the various components, they can perform routine maintenance with ease. Recognizing wear and tear allows for timely replacements, which can prevent further damage. Additionally, knowing how each part functions facilitates easier repairs, reducing reliance on professional services.

Enhanced Efficiency and Performance

Awareness of how each segment contributes to the overall functionality enables users to optimize their practices. Understanding the specific roles of different elements can lead to more effective usage, maximizing results in the garden. Users can make informed decisions about upgrades or modifications based on their knowledge of these components.

Repair vs. Replace: Making Decisions

When faced with a malfunctioning tool, users often grapple with whether to fix the existing unit or invest in a new one. This decision can significantly impact both finances and productivity.

To navigate this dilemma effectively, consider the following factors:

- Cost:

- Assess the expense of repairs versus the price of a new model.

- Factor in potential long-term savings.

- Time:

- Determine how quickly repairs can be completed.

- Consider how downtime affects your projects.

- Performance:

- Evaluate whether repairs will restore functionality to an optimal level.

- Consider advancements in technology that a new purchase may offer.

- Usage:

- Think about how frequently the tool is used.

- If it’s essential for daily tasks, replacement might be prudent.

Ultimately, making the right choice hinges on a careful assessment of these factors to ensure you achieve the best outcome for your needs.

Maintenance Tips for Trimmer Parts

Regular upkeep of your equipment is crucial for ensuring its longevity and optimal performance. By focusing on specific components and their care, you can prevent breakdowns and enhance efficiency. Here are some essential tips to keep in mind.

Routine Checks

- Inspect components for wear and tear regularly.

- Clean debris from all areas after each use.

- Ensure fasteners are tight and secure to avoid vibrations.

Lubrication and Replacement

- Apply lubricant to moving parts to minimize friction.

- Replace worn-out elements promptly to maintain functionality.

- Use manufacturer-recommended fluids and oils for best results.

Upgrading Trimmer Parts for Performance

Enhancing the components of your gardening tool can significantly improve its efficiency and effectiveness. By focusing on key elements that influence power and usability, you can achieve superior results in your outdoor tasks. This approach not only prolongs the life of the equipment but also optimizes its operation, allowing for a smoother experience.

| Component | Benefit |

|---|---|

| Engine | Increased power and reduced vibration. |

| Cutting System | Improved precision and speed. |

| Handle | Enhanced comfort and control. |

| Fuel System | Better efficiency and fewer emissions. |

Investing in these upgrades can yield the ultimate performance boost, making your tool more capable of tackling demanding tasks with ease.

Safety Precautions When Handling Parts

When working with mechanical components, ensuring safety is paramount. Proper precautions can prevent injuries and damage, creating a secure environment for maintenance and repairs. Understanding the potential hazards associated with these tasks is essential for anyone involved in such activities.

Always wear appropriate personal protective equipment (PPE). This includes gloves, safety goggles, and sturdy footwear. These items serve as a barrier against sharp edges and flying debris, significantly reducing the risk of accidents.

Be aware of your surroundings. Ensure that your workspace is clean and organized to avoid tripping hazards. Keep all tools and equipment in their designated places, which will help you maintain focus and efficiency.

Use tools correctly. Familiarize yourself with the operation of each tool before use. Improper handling can lead to serious injuries or damage to components. Always follow the manufacturer’s instructions and guidelines.

Disconnect power sources before beginning any maintenance. This prevents accidental startups that could lead to severe injuries. Make it a habit to double-check that all energy sources are deactivated.

Handle components with care. Some parts may have sharp edges or delicate mechanisms. Use appropriate techniques to lift and move them, ensuring you do not exert excessive force that could result in breakage.

In case of any uncertainty, seek assistance. If you are unsure about a procedure or safety measure, consult with a knowledgeable colleague or reference material. It’s better to ask for help than to risk an injury.

By adhering to these guidelines, you can create a safer working environment and minimize risks while managing mechanical elements.

Where to Find Replacement Parts

Finding suitable components for your gardening equipment can significantly extend its lifespan and maintain optimal performance. Whether you are looking for original items or compatible alternatives, various sources can help you acquire what you need.

- Official Manufacturer Websites: Start by visiting the official sites of the equipment manufacturers. They often provide a comprehensive catalog of components tailored specifically for their products.

- Local Hardware Stores: Many local stores stock essential components or can order them for you. Building relationships with staff can also yield valuable advice.

- Online Retailers: Websites like Amazon and eBay offer a vast selection of components. Be sure to check customer reviews to ensure quality.

- Specialized Repair Shops: Some shops focus on repairing and refurbishing equipment. They might have spare items or can direct you to reliable sources.

By exploring these options, you can find the necessary items to keep your equipment running smoothly and efficiently.

Trimmer Parts Diagram Examples Explained

Understanding the components of gardening tools is essential for effective maintenance and repair. This section delves into various visual representations that break down the key elements of these devices, providing clarity on their functions and interrelations. Each illustration serves as a guide, making it easier to identify and troubleshoot issues.

Common Components Overview

Among the most frequently encountered elements are the motor, cutting head, and protective casing. The motor is the powerhouse, converting electrical energy into mechanical motion. The cutting head, equipped with various blades or strings, is responsible for achieving a clean cut. Lastly, the protective casing ensures safety while housing the internal mechanisms.

Understanding Functionality Through Visuals

Illustrations not only enhance comprehension but also facilitate quicker assembly or disassembly. For instance, an exploded view can clarify how each component fits together, allowing users to see how wear and tear may affect performance. Maintenance tips can be derived from these representations, guiding users on how to replace or repair worn parts effectively. Visual aids play a crucial role in simplifying complex processes.