Understanding the Troy-Bilt Chipper Parts Diagram for Easy Maintenance

Every piece of equipment requires a thorough understanding of its inner workings to ensure optimal performance and longevity. Knowing how various elements interact can significantly enhance maintenance and troubleshooting efforts. This section aims to provide clarity on the essential components of your device, allowing users to easily navigate through potential issues.

Visual aids play a crucial role in comprehending the layout and function of different sections. By exploring detailed illustrations, operators can gain insights into the assembly and identify specific components swiftly. This knowledge not only aids in repairs but also empowers users to make informed decisions regarding upgrades and replacements.

Delving into the intricacies of your machine’s configuration equips you with the ultimate understanding necessary for effective care. Familiarity with each segment enables better handling and extends the lifespan of the equipment, ensuring you get the most out of your investment.

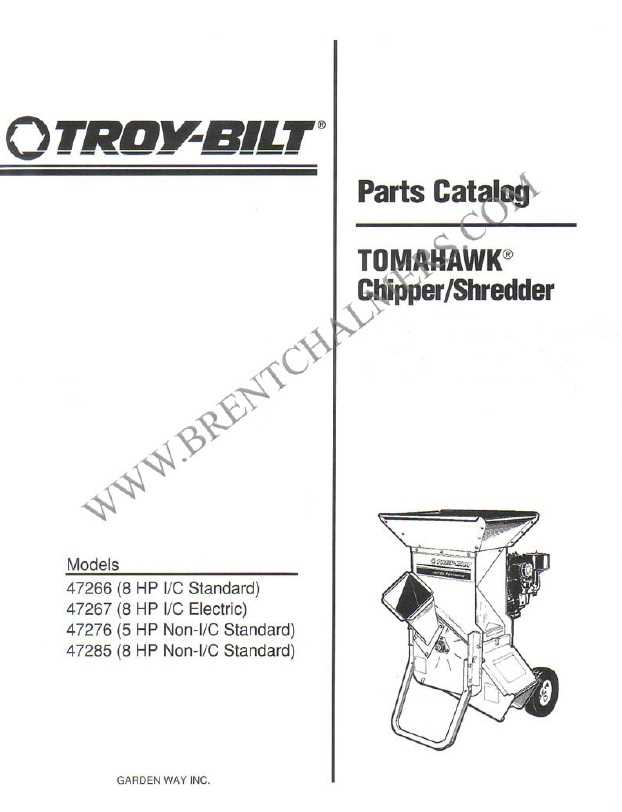

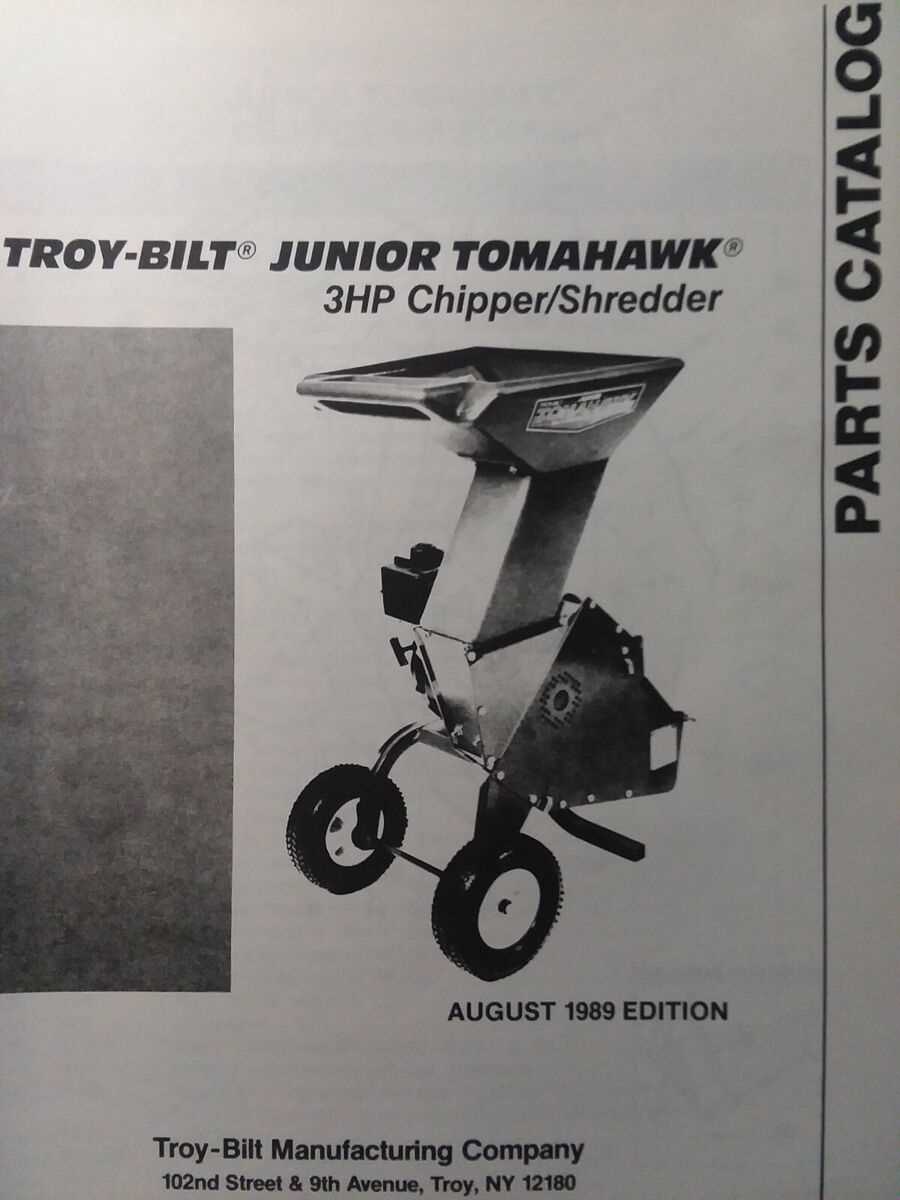

Troy-Bilt Chipper Overview

This section provides a comprehensive look at a specific type of outdoor machinery designed for reducing yard waste. These devices play a crucial role in maintaining landscapes by efficiently converting branches and debris into manageable pieces. Their robust design ensures durability and ease of use, making them a valuable addition to any gardening toolkit.

Key Features

The machinery boasts several features that enhance its performance. Powerful engines provide ample force for tackling tough materials, while user-friendly controls allow for seamless operation. Additionally, the compact design facilitates easy storage and transport, making it ideal for homeowners and professionals alike.

Maintenance Tips

Proper care is essential to prolong the lifespan of this equipment. Regularly checking blades and filters can significantly improve efficiency. It’s also advisable to clean the machine after each use to prevent buildup and ensure optimal performance during subsequent tasks.

Common Issues with Chipper Parts

Many users encounter various challenges with their equipment, often stemming from wear and tear or improper maintenance. Understanding these frequent problems can significantly enhance performance and longevity. Identifying symptoms early can lead to effective solutions, ensuring smooth operation and reducing downtime.

1. Dull Blades: One of the most prevalent issues is the dulling of cutting edges. When blades lose their sharpness, efficiency drops, resulting in poor cutting performance. Regular sharpening is essential to maintain optimal functionality.

2. Blockages: Another common concern is clogging, which occurs when debris accumulates in the feed chute. This can cause the machine to stall or operate inefficiently. Regular cleaning and maintenance can help mitigate this problem.

3. Vibration: Excessive shaking during operation often indicates loose components or imbalanced parts. This can lead to further damage if not addressed promptly. Regular inspections can help identify and correct any issues.

4. Engine Problems: Mechanical issues can arise in the power unit, including difficulties in starting or stalling during use. Regular checks on fuel levels, spark plugs, and air filters can prevent these problems from escalating.

5. Wear on Belts and Cables: Components such as belts and cables can fray or break over time due to continuous use. Monitoring their condition and replacing worn parts promptly can prevent unexpected failures.

By being aware of these common issues and implementing proactive maintenance, users can ensure their equipment operates efficiently and reliably for years to come.

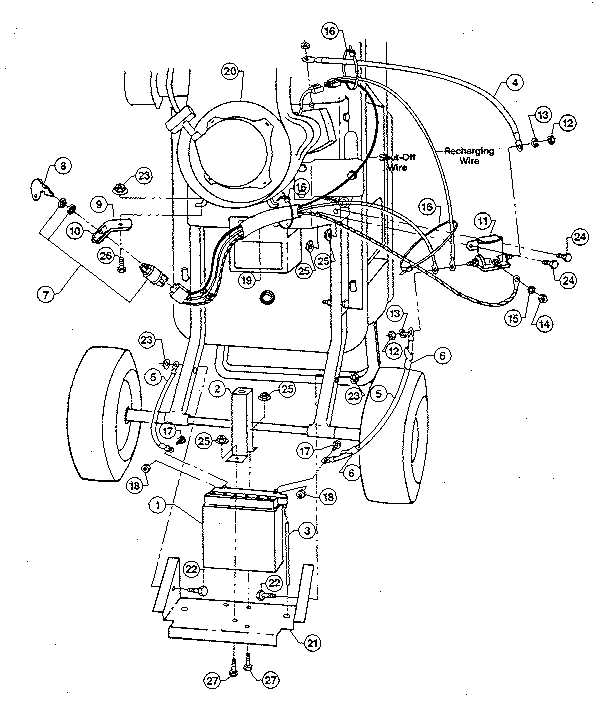

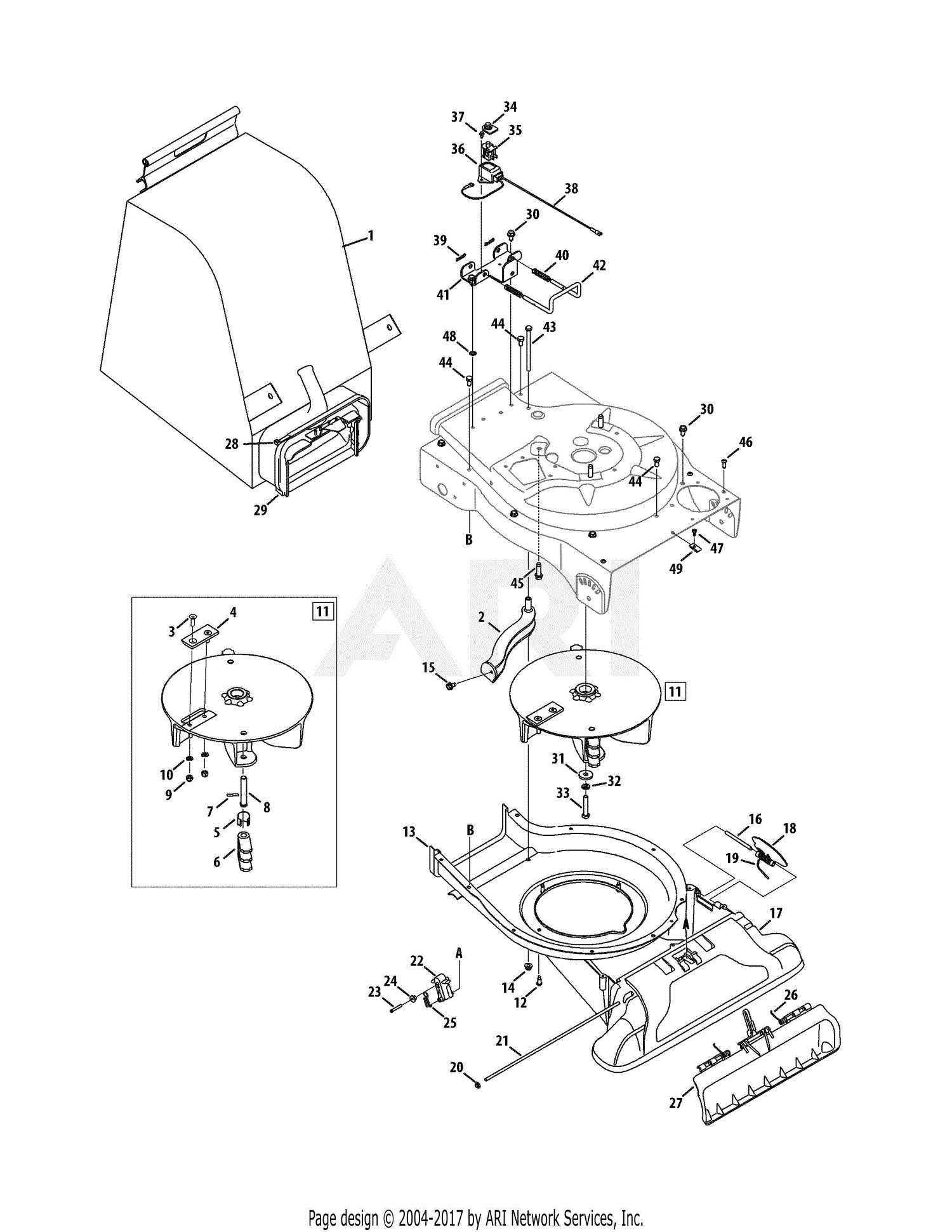

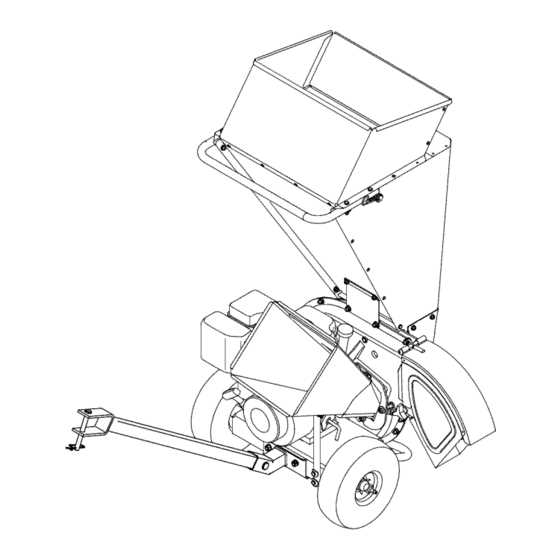

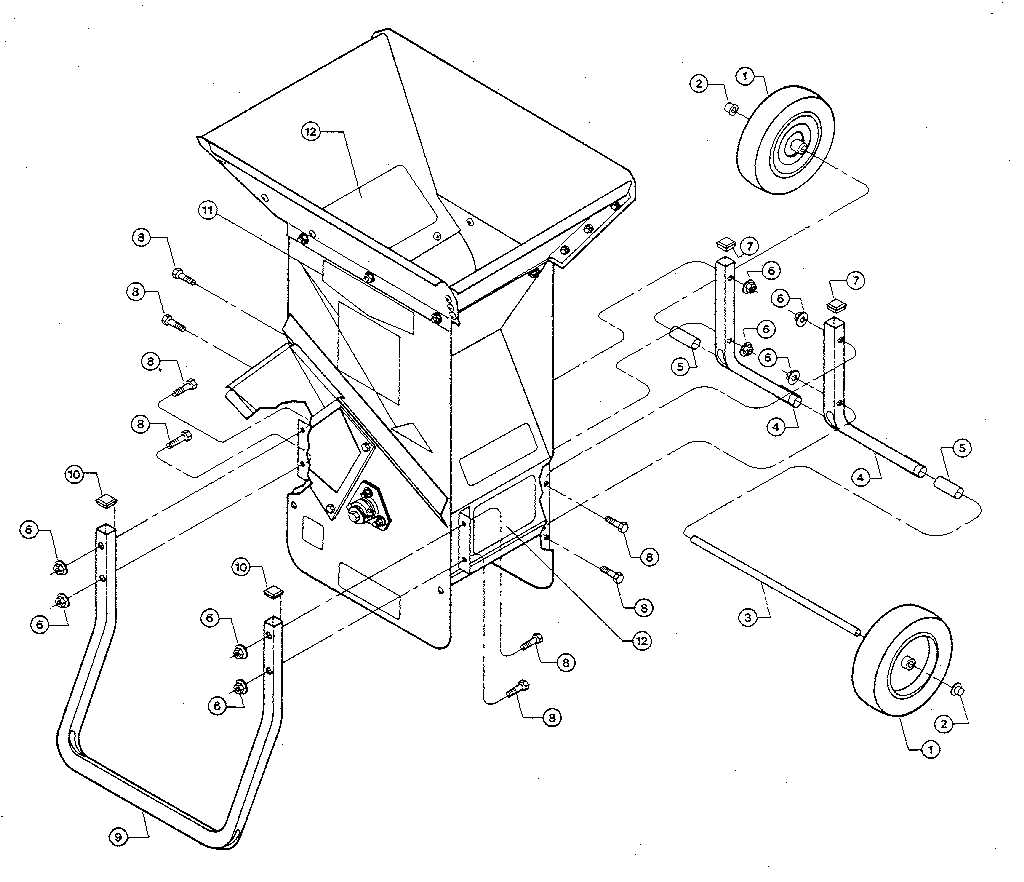

Understanding the Parts Diagram

Gaining insight into a machine’s internal components is essential for effective maintenance and troubleshooting. A visual representation of these elements not only facilitates a clearer understanding of how they interact but also aids in identifying potential issues. Familiarity with these illustrations can empower users to take better care of their equipment and streamline repair processes.

Typically, such representations include labeled sections that denote each component’s function and position within the overall structure. This organization helps users quickly locate specific parts and understand their relationships with other elements. Knowing where to find these components can save time and reduce frustration during maintenance tasks.

| Component Name | Description | Function |

|---|---|---|

| Blade | Sharp metal piece for cutting | To shred material efficiently |

| Hopper | Opening for feeding material | To guide material into the mechanism |

| Engine | Power source for operation | To drive the cutting mechanism |

| Chassis | Framework of the device | To support and stabilize components |

Understanding these elements fosters confidence in handling maintenance tasks. With the aid of these visual aids, users can effectively navigate repairs and ensure optimal performance over time.

Essential Tools for Maintenance

Proper upkeep of outdoor equipment is crucial for ensuring longevity and optimal performance. Having the right implements at hand can significantly simplify the maintenance process, allowing for efficient repairs and adjustments. Understanding which tools are necessary can help any user navigate routine checks and extensive refurbishments with ease.

1. Wrenches and Sockets: A comprehensive set of wrenches and socket tools is fundamental. These instruments facilitate the tightening and loosening of various fasteners, ensuring that components remain securely in place.

2. Screwdrivers: A variety of screwdrivers, including flathead and Phillips types, are essential for accessing and securing screws on different assemblies. They come in handy for both routine maintenance and deeper inspections.

3. Pliers: Versatile pliers can assist in gripping, twisting, and cutting wire or other materials. They are invaluable for making quick adjustments and repairs.

4. Oil and Lubricants: Keeping moving parts well-lubricated is vital for smooth operation. Quality oils and lubricants help reduce friction and prevent wear, ultimately extending the lifespan of your machinery.

5. Cleaning Supplies: Regular cleaning is crucial to prevent buildup and rust. Brushes, cloths, and suitable cleaning agents help maintain the equipment in top condition.

6. Safety Gear: Never overlook personal safety. Gloves, goggles, and ear protection are necessary to ensure safety during maintenance tasks, minimizing the risk of injury.

Equipping yourself with these essential tools will not only make maintenance tasks more manageable but also enhance the overall reliability of your equipment. Regular attention and the right implements can lead to a more enjoyable and efficient experience in outdoor activities.

How to Replace Worn Parts

Over time, equipment components can wear down, affecting performance and safety. Recognizing when to substitute these elements is crucial for maintaining optimal functionality. This guide provides essential steps to ensure a seamless replacement process.

1. Identify the Affected Components: Start by inspecting your machine thoroughly. Look for signs of wear, such as cracks, breaks, or excessive rust. Take note of any parts that seem less effective.

2. Gather Necessary Tools: Before proceeding, collect all required tools for the replacement task. Commonly needed items may include wrenches, screwdrivers, and safety gloves to protect yourself during the process.

3. Remove the Old Components: Carefully detach the worn elements from the machine. Use the appropriate tools to avoid damaging surrounding areas. Ensure that you follow safety protocols, such as disconnecting power sources.

4. Install New Components: Position the new items in place, ensuring a secure fit. Refer to any manuals or guides to verify correct installation procedures. Proper alignment is key to avoiding future issues.

5. Test the Equipment: After replacing the worn elements, conduct a test run to check functionality. Monitor for any unusual sounds or behaviors. If everything operates smoothly, you’ve successfully completed the replacement!

Regular maintenance and timely replacements can significantly extend the lifespan of your equipment, ensuring it operates at its best.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is paramount. By adhering to specific guidelines, one can significantly reduce the risk of injury or accidents. This section outlines essential precautions to take during repair activities.

- Always disconnect power sources before beginning any work.

- Wear appropriate personal protective equipment, including gloves and goggles.

- Ensure your workspace is clean and free of obstructions.

- Read and understand the manufacturer’s manual prior to repairs.

By following these safety measures, you can create a secure environment that promotes effective and safe repair practices.

Where to Buy Replacement Parts

Finding the right components for your outdoor equipment is essential for maintaining its performance. There are several avenues to explore when looking for high-quality replacements, ensuring you can continue your tasks without interruption.

Online Retailers

Many websites specialize in offering a wide range of components for various machinery. Websites like Amazon and eBay provide user-friendly interfaces where you can easily search for specific items and compare prices. Additionally, you can read customer reviews to make informed decisions.

Local Dealers

Visiting local dealerships can be beneficial as well. They often stock essential items and provide personalized service, allowing you to ask questions and receive expert advice. Supporting local businesses also helps strengthen your community.

Benefits of Using Genuine Parts

Utilizing authentic components for your equipment ensures optimal performance and longevity. These original pieces are designed specifically to fit your machinery, providing a seamless integration that enhances functionality and reliability. By choosing genuine alternatives, you can protect your investment and maintain the efficiency of your tools.

Here are some key advantages of opting for original components:

| Benefit | Description |

|---|---|

| Enhanced Durability | Authentic items are manufactured to high standards, ensuring they withstand the demands of regular use. |

| Optimal Performance | Original components are engineered to work together, resulting in better overall performance of your machinery. |

| Safety Assurance | Using certified components reduces the risk of malfunctions, promoting a safer working environment. |

| Warranty Protection | Many manufacturers offer warranties on their equipment when genuine components are used, providing peace of mind. |

| Improved Resale Value | Maintaining your equipment with original items can enhance its resale value, attracting potential buyers. |

Comparing Different Chipper Models

When evaluating various models for yard maintenance, it’s essential to understand their unique features and capabilities. Each variant offers distinct advantages that cater to different landscaping needs, making the choice crucial for efficiency and effectiveness.

Key Features to Consider

- Power source: gas, electric, or battery-operated

- Cutting capacity: maximum branch diameter

- Weight and portability: ease of transport

- Noise level: impact on the environment and user comfort

- Safety features: shields and automatic shut-offs

Popular Options on the Market

- Model A: Known for its robust engine and high throughput.

- Model B: Compact and lightweight, ideal for small yards.

- Model C: Electric option with low noise and zero emissions.

- Model D: Versatile with multiple functions for different tasks.

Tips for Optimal Performance

Achieving peak efficiency with your outdoor machinery requires attention to detail and regular maintenance. Understanding the key components and their functionality is essential for seamless operation. By implementing a few straightforward practices, you can enhance longevity and reliability.

Regularly inspecting and cleaning the equipment will prevent clogs and reduce wear. Ensure that all connections are secure, and replace worn-out items promptly to maintain smooth performance. Lubricating moving parts as recommended in the manual contributes significantly to operational efficiency.

Using the right materials is crucial; always follow guidelines for size and type to avoid unnecessary strain. Additionally, storing the equipment in a dry place will help protect it from environmental damage, ensuring it remains in top shape for future use.