Troy-Bilt Pony Tiller Parts Diagram Guide

When it comes to maintaining a flourishing garden, having a clear grasp of the machinery involved is essential. Familiarity with the various components can significantly enhance the efficiency of your gardening tasks. This guide aims to provide a comprehensive overview of the essential elements that make up a popular gardening machine.

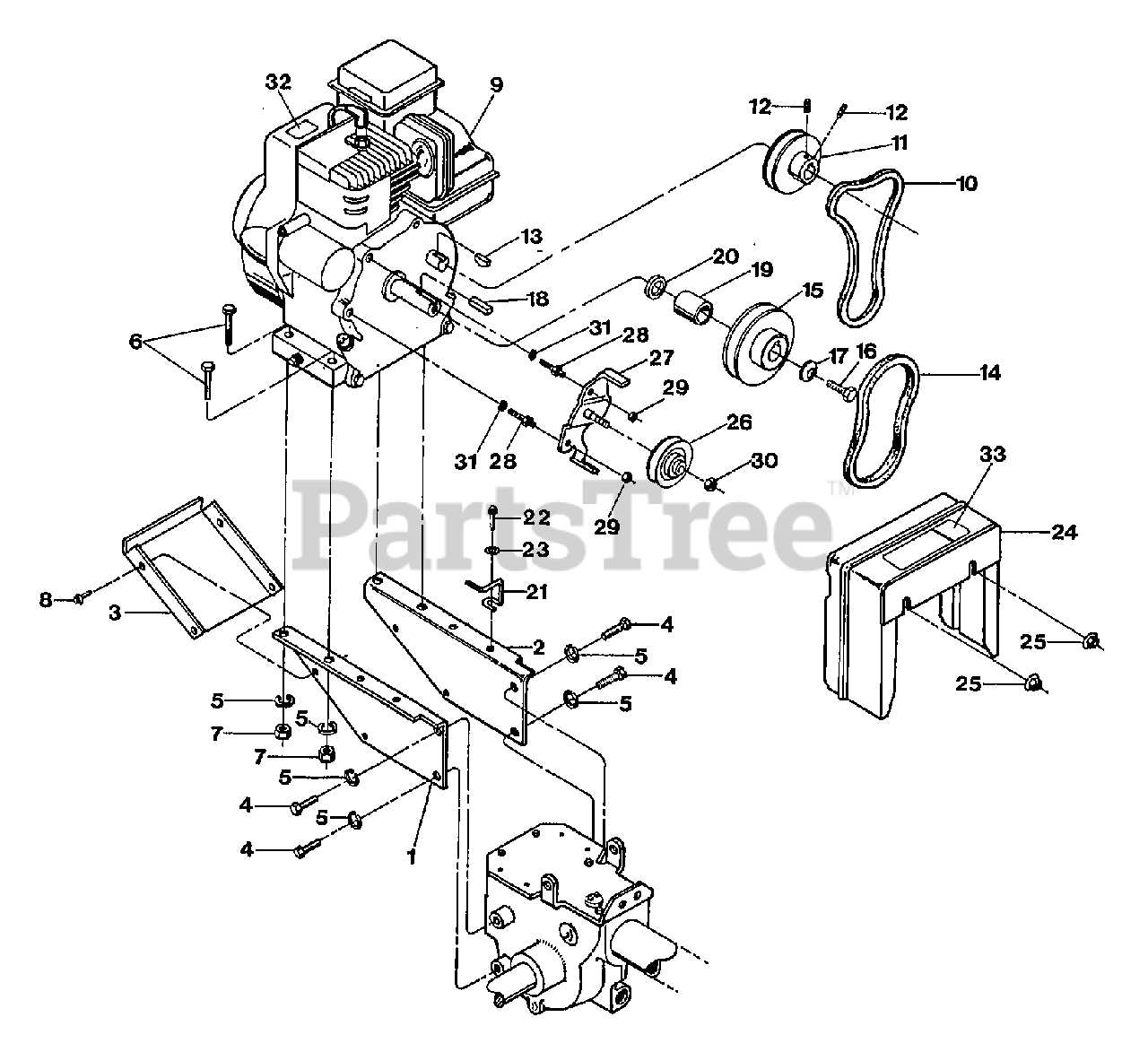

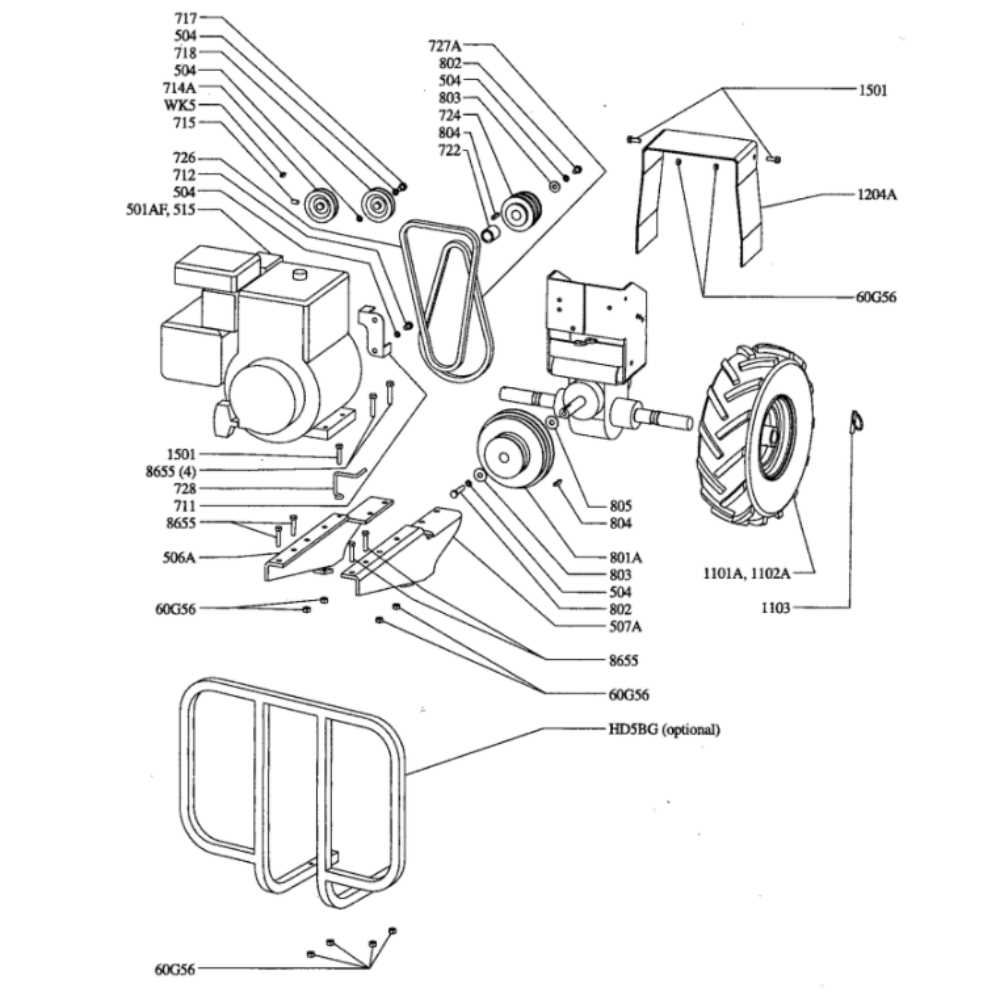

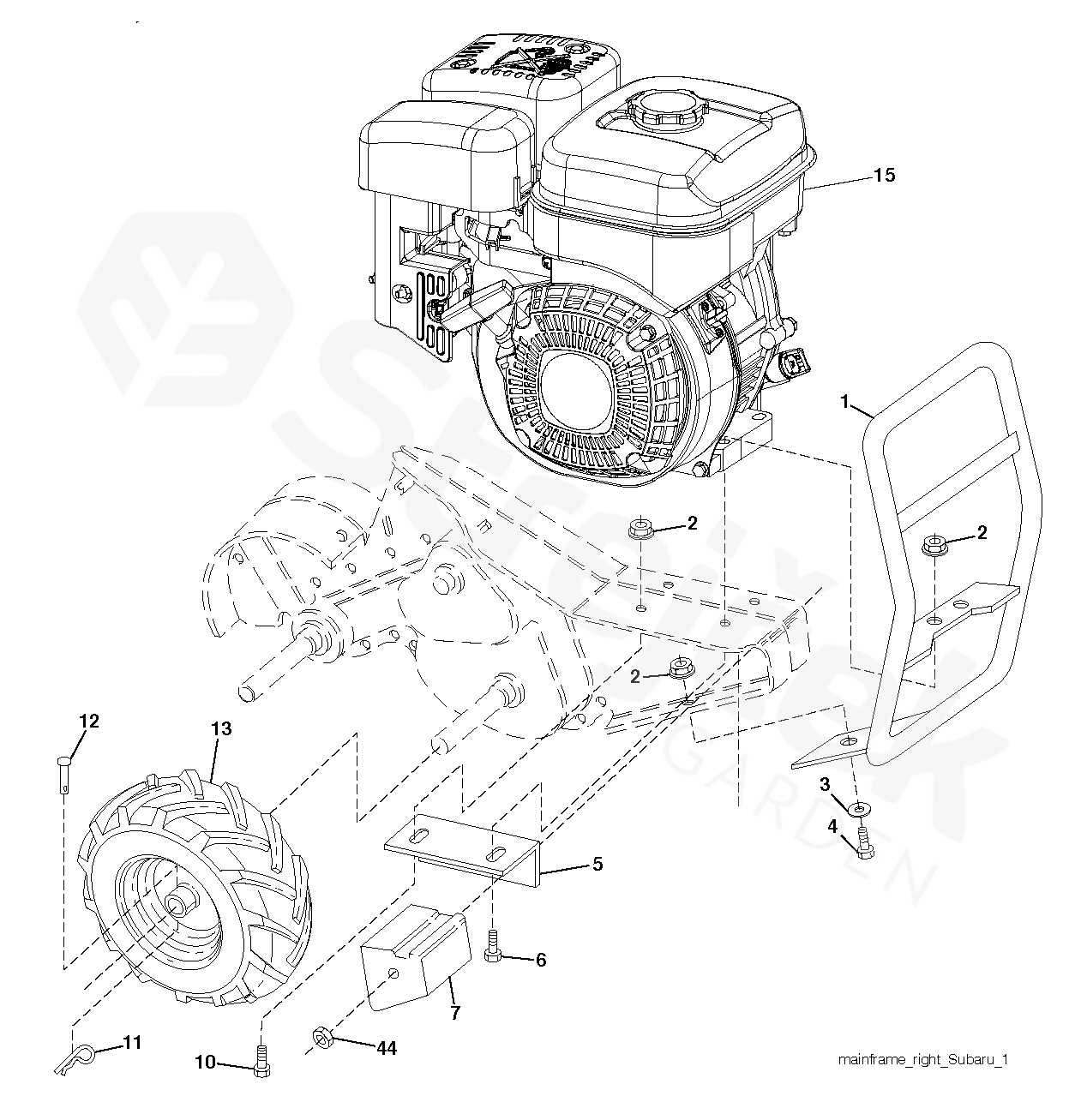

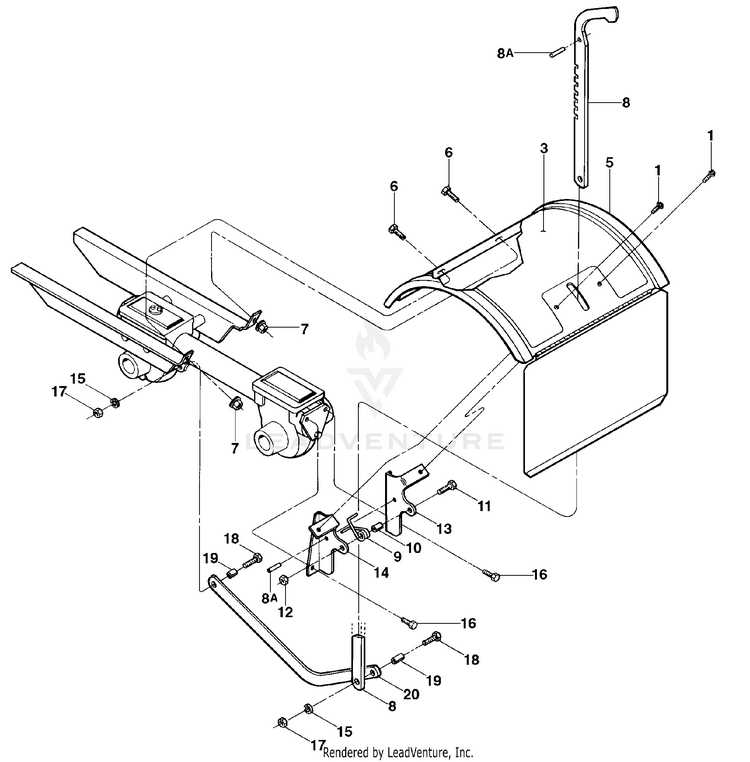

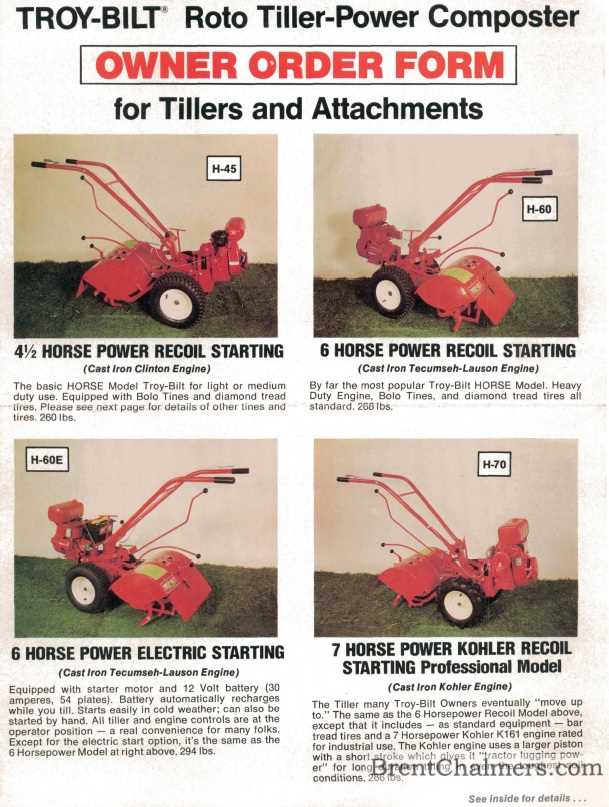

Visual aids play a crucial role in simplifying the understanding of complex machinery. By exploring a detailed schematic, users can better appreciate how each individual piece contributes to the overall functionality of the device. This knowledge not only aids in troubleshooting but also in ensuring the equipment runs smoothly.

Whether you’re a seasoned gardener or a newcomer to the world of cultivation, having access to detailed information about the internal structure of your gardening tools is invaluable. Armed with this knowledge, you can make informed decisions regarding maintenance and repairs, ultimately enhancing your gardening experience.

Understanding Troy-Bilt Pony Tiller Parts

Exploring the components of gardening machinery is essential for efficient maintenance and optimal performance. Familiarizing yourself with each element enhances your ability to troubleshoot and repair when necessary. Below is a breakdown of key components and their functions.

Key Components

- Engine: The powerhouse that drives the entire mechanism.

- Transmission: Manages power distribution for different speeds and torque.

- Blades: Crucial for soil aeration and preparation.

- Frame: The structural foundation supporting all other elements.

- Wheels: Facilitate movement and maneuverability across various terrains.

Maintenance Tips

- Regularly check the engine oil level and quality.

- Inspect the blades for wear and sharpness.

- Ensure all connections are tight and secure.

- Clean the frame to prevent rust and corrosion.

- Test the transmission for smooth operation.

Overview of Tiller Components

Understanding the essential elements of soil cultivation machinery is crucial for effective gardening and landscaping. Each component plays a specific role in ensuring optimal performance and ease of use, contributing to the overall efficiency of the equipment.

Key components typically include:

- Engine: Powers the entire unit, providing the necessary force for operation.

- Transmission: Transmits power from the engine to the working parts, enabling speed adjustments.

- Tines: Rotating blades that break up and aerate the soil, facilitating better planting conditions.

- Frame: The structure that houses all components, ensuring stability and durability during use.

- Handlebars: Provide control and maneuverability, allowing the user to guide the machine effectively.

- Wheels: Assist in movement, providing transportability across various terrains.

Familiarity with these components helps users maintain their equipment and troubleshoot any issues that may arise, ultimately enhancing the gardening experience.

Common Issues with Tiller Parts

Maintaining garden equipment often reveals various challenges that can hinder performance and efficiency. These complications can arise from wear and tear, improper maintenance, or environmental factors, impacting the overall functionality of the machine.

1. Worn Blades: Over time, the cutting elements can become dull or damaged, reducing their ability to effectively break up soil. Regular inspections and timely replacements are crucial for optimal performance.

2. Fuel System Problems: Clogs or leaks in the fuel system can lead to poor engine performance or starting issues. Ensuring clean fuel and inspecting hoses regularly can prevent these disruptions.

3. Drive Belt Wear: The drive mechanism may experience slippage or breakage due to age or excessive strain. Regular checks and timely replacements can extend the life of this component.

4. Engine Troubles: Common symptoms like difficulty starting or unusual noises may indicate underlying engine problems. Routine maintenance, including oil changes and filter replacements, is essential for engine health.

5. Loose Fasteners: Vibrations during operation can cause nuts and bolts to loosen, leading to potential safety hazards. Regularly tightening these components can prevent accidents and enhance stability.

Addressing these common challenges through proactive maintenance can significantly improve the longevity and effectiveness of garden equipment.

How to Identify Replacement Parts

When maintaining or repairing outdoor equipment, recognizing the necessary components can significantly enhance the process. Knowing how to locate and identify the right pieces ensures optimal functionality and longevity of your machine.

Understanding Component Numbers

Most machinery includes a unique identifier for each component, typically found in the user manual or on the machine itself. These identifiers facilitate the search for replacements, allowing you to source exactly what you need without confusion.

Using Visual References

Visual aids, such as charts and images, can be invaluable. They provide a clear representation of each component, making it easier to match the physical parts with their corresponding numbers. Below is a table outlining common identifiers and their respective descriptions.

| Identifier | Description |

|---|---|

| Part Number | Unique code assigned to a specific component. |

| Model Number | Identifier for the entire machine, useful for finding compatible components. |

| Serial Number | Unique code for tracking and warranty purposes, often found on the machine. |

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life and optimal performance of your gardening equipment. By following a few straightforward practices, you can minimize wear and tear, enhance efficiency, and save on future repairs. Regular maintenance not only prolongs the life of your machine but also contributes to a more enjoyable gardening experience.

Routine Cleaning

Cleaning your equipment after each use is crucial. Remove dirt, debris, and any residue that may accumulate during operation. Pay special attention to the blades and any moving parts. Using a soft brush or cloth can help maintain cleanliness without causing damage. Regular cleaning prevents rust and ensures that your equipment functions smoothly.

Regular Inspections

Frequent checks on your machinery can identify potential issues before they escalate. Inspect belts, cables, and other components for signs of wear. Tightening loose parts and replacing damaged elements promptly can prevent breakdowns and improve overall performance. Keeping an eye on oil levels and fluid quality is also vital for maintaining engine health.

Where to Find Diagrams Online

Locating detailed visual references for machinery components is essential for effective repairs and maintenance. The internet offers a wealth of resources where users can find these helpful illustrations. From manufacturer websites to dedicated forums, there are various platforms that provide access to essential schematics and technical drawings.

Manufacturer Websites

Many manufacturers host comprehensive online resources that include user manuals and technical illustrations. These sites often provide downloadable PDFs that feature clear images and part numbers, making it easy to identify what you need.

Online Marketplaces and Forums

In addition to official sites, online marketplaces and community forums can be valuable resources. Users often share links or upload files, making it easier to find specific illustrations that may not be readily available elsewhere.

| Resource Type | Examples |

|---|---|

| Manufacturer Websites | Official brand sites |

| Online Marketplaces | eBay, Amazon |

| Community Forums | Reddit, specialized repair forums |

Step-by-Step Repair Guide

Maintaining and fixing your garden equipment is essential for optimal performance. This guide will walk you through a systematic approach to identifying issues, sourcing necessary components, and executing repairs efficiently. With the right steps, you can extend the lifespan of your machinery and ensure it operates smoothly.

Identifying Common Issues

Begin by observing any irregularities during operation. Listen for unusual sounds, check for leaks, and monitor performance. Make a list of symptoms that could indicate underlying problems. This preliminary assessment will help you narrow down potential areas that require attention.

Gathering Tools and Components

Once you’ve identified the issues, compile a list of tools you’ll need for the repair process. Commonly required tools include wrenches, screwdrivers, and pliers. Next, refer to the equipment’s manual to determine the specific components that may need replacement. Ensure you have all necessary items ready before starting the repair to minimize downtime.

Essential Tools for Repairs

Maintaining and fixing outdoor equipment requires a selection of key instruments to ensure efficiency and accuracy. Proper tools not only streamline the repair process but also enhance safety and effectiveness. Below are the fundamental implements you should consider having on hand for any maintenance task.

- Wrenches: A variety of sizes is essential for loosening and tightening bolts and nuts.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for different types of screws.

- Pliers: Useful for gripping, twisting, and cutting wires or small components.

- Socket Set: Ideal for dealing with various fasteners, providing more torque and leverage.

- Hammer: Useful for driving in nails or adjusting components without damaging them.

In addition to these basic tools, consider the following specialized equipment for more intricate repairs:

- Multimeter: For diagnosing electrical issues and checking voltage levels.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

- Cleaning Tools: Brushes and solvents to keep parts free from dirt and debris.

- Safety Gear: Gloves and goggles to protect yourself during repairs.

Having these essential tools readily available will significantly improve your ability to conduct repairs effectively, ensuring your equipment runs smoothly and lasts longer.

Comparing OEM and Aftermarket Parts

When it comes to maintaining and repairing garden equipment, the choice between original components and those produced by third-party manufacturers can significantly impact performance and longevity. Each option has its own set of advantages and disadvantages that should be considered before making a decision.

Original equipment manufacturer (OEM) components are designed and produced by the same company that made the original machine. These parts are often viewed as reliable and high-quality. On the other hand, aftermarket alternatives can offer cost savings and a wider selection, but their quality may vary.

- Quality: OEM parts are typically held to strict quality standards, while aftermarket options can vary widely in their manufacturing processes.

- Cost: Aftermarket components often come at a lower price, making them attractive for budget-conscious consumers.

- Availability: Aftermarket suppliers may offer a broader range of options, which can be beneficial if original components are hard to find.

- Warranty: OEM components usually come with a warranty that guarantees their performance, while many aftermarket parts may not offer the same level of protection.

Ultimately, the decision between OEM and aftermarket options depends on individual needs, budget constraints, and the importance of reliability in specific applications. Carefully weighing these factors can lead to a more informed and satisfactory choice.

Assembly Instructions for Beginners

Building your gardening machine can be an exciting venture, especially for those new to this process. Understanding how to put together various components is crucial for ensuring optimal performance. This guide will simplify the assembly process and provide you with the confidence to tackle the task.

Before you start, make sure you have all the necessary components laid out. Familiarizing yourself with each piece will make it easier to understand how they fit together. It’s essential to read through the instruction manual thoroughly, as it contains vital information on the order of assembly and specific tools required.

Step-by-step assembly typically involves first securing the frame, followed by attaching the motor and other key elements. Use the correct fasteners to avoid issues later. Ensure that all connections are tight and that moving parts have the appropriate range of motion.

As you progress, double-check each connection against the manual. If something doesn’t seem right, don’t hesitate to revisit the earlier steps. Patience is key; taking your time will lead to a more successful assembly.

Once fully assembled, perform a thorough inspection to ensure everything is in place and functioning correctly. Following these instructions will not only enhance your understanding but also help you enjoy the gardening experience to the fullest.

Frequently Asked Questions on Repairs

This section addresses common inquiries regarding maintenance and troubleshooting of garden equipment. Understanding these aspects can help users efficiently resolve issues and prolong the lifespan of their machinery.

Here are some frequently asked questions:

- What should I do if my equipment won’t start?

- Check the fuel level and ensure it is fresh.

- Inspect the spark plug for damage or dirt.

- Look for any loose or disconnected wires.

- How often should I perform maintenance?

- Regularly inspect all moving parts for wear.

- Change the oil according to the manufacturer’s recommendations.

- Sharpen the blades at least once a season.

- What are the signs that I need to replace a part?

- Unusual noises during operation.

- Reduced performance or efficiency.

- Visible cracks or excessive wear on components.

- Can I perform repairs myself?

- Many users can handle basic repairs with the right tools and guidance.

- For complex issues, consider consulting a professional.

- Always refer to the user manual for specific instructions.

By addressing these common concerns, users can better manage their repair processes and ensure their equipment operates smoothly.