Troy-Bilt TH 1002 Parts Diagram Guide

When it comes to maintaining your outdoor machinery, a clear understanding of its various elements is essential. Each section and piece plays a vital role in ensuring smooth operation and longevity. Familiarity with these components not only aids in effective repairs but also enhances overall performance.

Visual aids can be incredibly helpful in grasping the intricate relationships between different parts. They provide a comprehensive overview, making it easier to identify and troubleshoot any issues that may arise. Knowing how each segment interacts allows for more efficient maintenance and improved functionality.

Whether you’re a seasoned professional or a weekend warrior, having access to detailed representations of your equipment can significantly simplify the upkeep process. It empowers users to approach repairs with confidence, ensuring that every task is handled with precision and care.

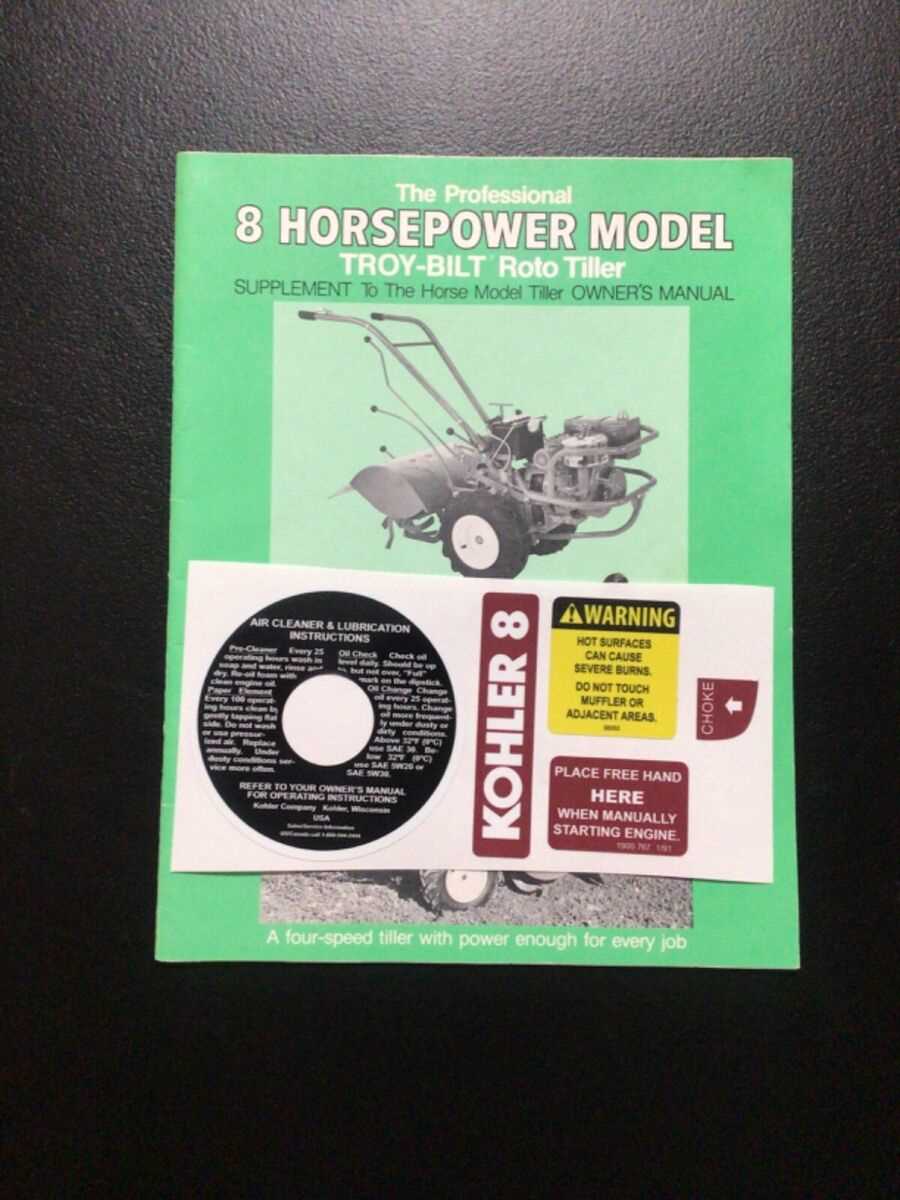

Troy-Bilt TH 1002 Overview

This section provides a comprehensive look at a popular gardening tool designed for efficiency and ease of use. Ideal for homeowners and landscaping professionals alike, it combines power and functionality to tackle various outdoor tasks. Understanding its features and specifications can enhance the user experience and maintenance practices.

Key Features

The equipment boasts a robust engine, enabling it to handle a range of terrains and vegetation types. Its ergonomic design ensures comfort during prolonged use, while various attachments allow for versatile applications. Additionally, maintenance and repair are streamlined, making it accessible for users to keep the machine in top condition.

Usage and Maintenance

Importance of Parts Diagrams

Visual representations of components play a crucial role in maintenance and repair tasks. These illustrations serve as essential tools for understanding the assembly and functionality of various machinery. By offering clear insights into individual elements, they facilitate efficient troubleshooting and replacement processes.

Key benefits of utilizing these visual aids include:

- Enhanced clarity: Users can easily identify and locate specific elements.

- Improved organization: Systematic layouts help in understanding the overall structure.

- Time-saving: Quick reference reduces the time spent on repairs or replacements.

Moreover, these visual guides contribute to:

- Accurate repairs: Minimizing errors by providing precise locations for components.

- Increased safety: Ensuring proper handling and assembly to prevent accidents.

- Better knowledge retention: Aiding users in memorizing and understanding machinery.

In summary, effective visual representations are indispensable for anyone involved in maintenance and repair, leading to a smoother and more efficient workflow.

Key Components of TH 1002

The efficiency and functionality of this outdoor equipment heavily rely on its essential elements. Understanding these critical components can enhance maintenance practices and improve overall performance.

Engine: At the heart of the machine, the engine provides the necessary power to drive various operations. Its reliability directly influences the performance and durability of the unit.

Transmission: This mechanism is responsible for transferring power from the engine to the wheels, ensuring smooth movement. A well-maintained transmission can significantly affect the responsiveness of the equipment.

Cutting Deck: The cutting deck plays a crucial role in determining the quality of the job. Its design impacts the precision of cutting and the overall efficiency of lawn care tasks.

Controls: User-friendly controls allow for intuitive operation, making it easier to navigate different functions. Properly functioning controls ensure safety and enhance the user experience.

Wheels: Quality wheels contribute to mobility and stability on various terrains. Their durability affects the overall maneuverability of the equipment.

Familiarity with these key elements is essential for anyone looking to maximize the performance and longevity of their outdoor machine.

Where to Find Replacement Parts

When it comes to maintaining your outdoor equipment, sourcing the right components is essential for ensuring optimal performance. Whether you are repairing a lawn care tool or a garden machine, knowing where to look can save time and effort. There are various options available, ranging from online retailers to local supply stores, each providing different advantages.

Online Retailers

The internet offers a plethora of websites dedicated to outdoor equipment. Many of these platforms specialize in providing various components, allowing for easy comparison of prices and availability. Look for reputable online shops that focus on gardening and lawn maintenance tools, as they often carry a wide range of options, including OEM and aftermarket selections.

Local Stores and Authorized Dealers

Your neighborhood hardware store or authorized dealer can be invaluable resources. These establishments often have knowledgeable staff who can assist in identifying the correct items you need. Additionally, visiting a local store allows you to physically inspect the components before purchasing, ensuring they meet your specific requirements.

Understanding the Parts List

When it comes to maintaining and repairing outdoor equipment, having a clear overview of the components involved is essential. This section aims to elucidate the significance of a detailed inventory that outlines each element, its function, and how it interacts within the overall system. An organized list serves as a roadmap for users to identify and source the necessary items for upkeep or replacement.

Familiarity with each component is crucial for anyone engaged in repairs or enhancements. By understanding the role that each piece plays, one can more effectively troubleshoot issues and determine which elements may require attention. This knowledge not only facilitates efficient repairs but also enhances the longevity and performance of the equipment.

Moreover, having access to an accurate inventory can significantly streamline the maintenance process. Users can quickly refer to the list to locate specific components, ensuring that they have the correct replacements on hand. This proactive approach minimizes downtime and helps maintain optimal operation.

How to Read the Diagram

Understanding the layout of components is crucial for effective maintenance and repair. A well-structured illustration can guide users through the various elements of a machine, allowing for easier identification and replacement. Mastering this skill enhances overall efficiency and minimizes frustration during service tasks.

First, familiarize yourself with the overall structure presented in the illustration. Look for labels and numbers that correspond to specific components. Each element is typically marked for easy reference, helping you navigate through complex assemblies.

Next, pay attention to the legend or key included, if available. This section provides essential information regarding symbols and color coding used throughout the representation. Understanding these details will enable you to interpret the visual information accurately.

As you analyze the illustration, take note of the relationships between different components. Observe how they connect or interact with each other, which can reveal insights into assembly procedures or troubleshooting methods. Recognizing these connections is vital for effective repairs.

Finally, keep the illustration handy while working on your equipment. Referring back to it can provide clarity during the process, ensuring that you are aligning your actions with the correct components. This approach not only streamlines repairs but also builds your confidence in handling machinery.

Common Issues with the TH 1002

Understanding the frequent challenges faced by users of this particular model can greatly enhance maintenance and operational efficiency. Many of these problems stem from regular wear and tear, improper use, or lack of timely upkeep. Identifying these issues early can prevent more significant damage and costly repairs.

Typical Problems Encountered

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Engine Won’t Start | No response when the starter is engaged. | Check fuel levels, inspect the battery, and examine the ignition system. |

| Loss of Power | Engine stutters or struggles under load. | Clean or replace the air filter, check the fuel system for blockages. |

| Excessive Vibrations | Unusual shaking during operation. | Tighten loose components and inspect for damaged parts. |

| Overheating | Engine temperature rises above normal. | Ensure proper coolant levels and check for obstructions in cooling fins. |

Preventive Measures

Regular maintenance is essential to mitigate these common issues. Routine inspections, timely oil changes, and proper storage practices can extend the life of the equipment and enhance its performance. Users should familiarize themselves with the operational manual and adhere to recommended schedules for upkeep.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular care and attention. Proper maintenance not only enhances performance but also extends the lifespan of your machinery. By following a few essential practices, you can prevent common issues and ensure that your tools remain in optimal condition for years to come.

Start by routinely checking fluid levels, including oil and fuel, as well as replacing them when necessary. Clean air filters regularly to maintain airflow and engine performance. Inspect belts and cables for wear and tear, replacing them as needed to prevent breakdowns. Keeping the exterior clean helps to avoid rust and corrosion, which can significantly impact functionality.

Sharpen blades and other cutting tools periodically to ensure efficient operation. Store equipment in a dry, sheltered area to protect it from the elements. Following the manufacturer’s recommended service schedule will also help catch any potential issues early, allowing for timely repairs.

Finally, familiarize yourself with the operational guidelines to avoid misuse. By implementing these simple maintenance tips, you can enjoy reliable performance and prolong the life of your equipment.

Identifying Parts by Model Number

Understanding the components of your equipment is crucial for effective maintenance and repair. By using the model number, you can easily pinpoint specific elements needed for replacement or enhancement. This systematic approach not only streamlines the identification process but also ensures compatibility and efficiency in servicing your machinery.

Why Model Numbers Matter

Model identifiers serve as a key reference for locating the appropriate components. Each designation is unique and corresponds to a specific configuration, allowing you to access precise information regarding dimensions, compatibility, and specifications. This specificity reduces the likelihood of errors and increases the likelihood of successful repairs.

How to Use Model Numbers Effectively

When searching for replacements, start by noting down the model number found on your equipment. Use this number in conjunction with reputable online resources or parts suppliers. Many platforms offer detailed inventories categorized by model, making it easier to find exactly what you need. Additionally, always double-check the part specifications to ensure you are selecting the correct items for your device. Proper identification leads to enhanced performance and longevity of your machinery.

Comparing with Other Troy-Bilt Models

When evaluating various garden tillers, it’s essential to consider how specific models stack up against one another. Each machine brings unique features and capabilities that cater to different gardening needs. By analyzing these distinctions, users can make informed choices that best suit their landscaping requirements.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Engine Power | 5 HP | 6 HP | 5.5 HP |

| Working Width | 18 inches | 16 inches | 20 inches |

| Weight | 120 lbs | 130 lbs | 115 lbs |

| Fuel Capacity | 1.5 gallons | 2 gallons | 1.8 gallons |

| Warranty | 2 years | 3 years | 2 years |

By examining the differences in specifications and features across various models, potential buyers can better understand which unit aligns with their gardening goals. Whether it’s about power, efficiency, or user-friendliness, these comparisons highlight the strengths and weaknesses inherent in each option.

DIY Repairs and Modifications

Embarking on a journey of self-repair and enhancement can be both rewarding and economical. With a little knowledge and the right tools, you can tackle common issues and make personalized modifications to your outdoor equipment. This guide offers insights into how you can effectively manage repairs and creatively adjust your machinery to better suit your needs.

Common Issues and Solutions

Understanding the frequent challenges faced by outdoor tools is crucial for effective maintenance. Below is a table highlighting some typical problems and their corresponding solutions:

| Issue | Suggested Fix |

|---|---|

| Engine won’t start | Check the fuel level and spark plug condition. |

| Unusual noise during operation | Inspect for loose components and tighten as necessary. |

| Reduced power output | Clean or replace the air filter and ensure proper fuel mixture. |

| Vibration issues | Examine the blades for damage and balance them appropriately. |

Enhancements and Custom Modifications

Beyond repairs, you may want to personalize your equipment for improved performance. Simple modifications can make a significant difference. Consider upgrading components such as the air filter for better airflow or adding ergonomic handles for enhanced comfort during use. Always ensure that any modifications comply with safety standards to maintain the integrity of your machinery.

Resources for Further Assistance

When tackling repairs or maintenance on your machinery, having access to reliable resources is essential. Whether you’re looking for specific components or seeking troubleshooting guidance, various platforms offer invaluable support. This section will outline some of the best places to find the information you need.

Online Forums and Communities

Engaging with fellow enthusiasts can provide quick answers and insights. Online forums often feature sections dedicated to troubleshooting and part identification, where users share their experiences and solutions.

Official Manufacturer Support

Most manufacturers provide detailed support through their official websites. Here, you can often find manuals, replacement part information, and contact details for customer service representatives.

| Resource Type | Description | Link |

|---|---|---|

| Online Forums | Community-driven platforms for sharing tips and troubleshooting. | Visit Forum |

| Manufacturer Website | Official support with manuals and customer service contacts. | Visit Website |

| Video Tutorials | Step-by-step guides available on video-sharing platforms. | Watch Videos |

| Local Repair Shops | Professional help for hands-on assistance and advice. | Find Repair Shop |