Tundra Parts Diagram Overview

Understanding the intricate layout of various elements in a vehicle can greatly enhance the efficiency of maintenance and repairs. By studying the arrangement of different components, one can gain insights into how the entire system functions together, enabling better decision-making when it comes to troubleshooting or replacements.

A well-detailed schematic can serve as a visual guide, highlighting the connections between each element. This helps users easily identify specific elements within the larger system, improving accuracy and reducing the time spent on complex tasks.

Whether you are a seasoned mechanic or a DIY enthusiast, having access to these visual references can simplify the process of identifying issues or learning about the internal structure of a vehicle.

Tundra Parts Diagram Overview

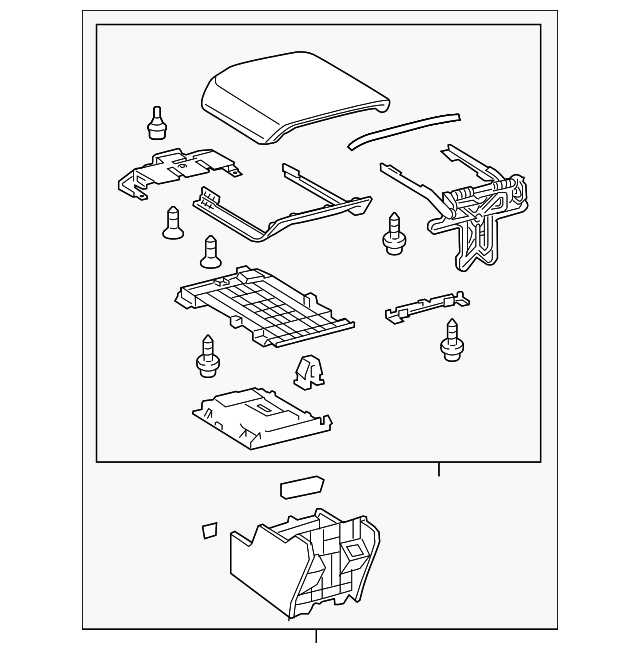

This section offers a comprehensive look at the structure and individual elements that compose a robust mechanical system. By examining the layout, one can easily identify key components and their relationships, ensuring a clearer understanding of the overall setup.

Main Components

- Engine block and its attachments

- Transmission and drivetrain elements

- Suspension and support structures

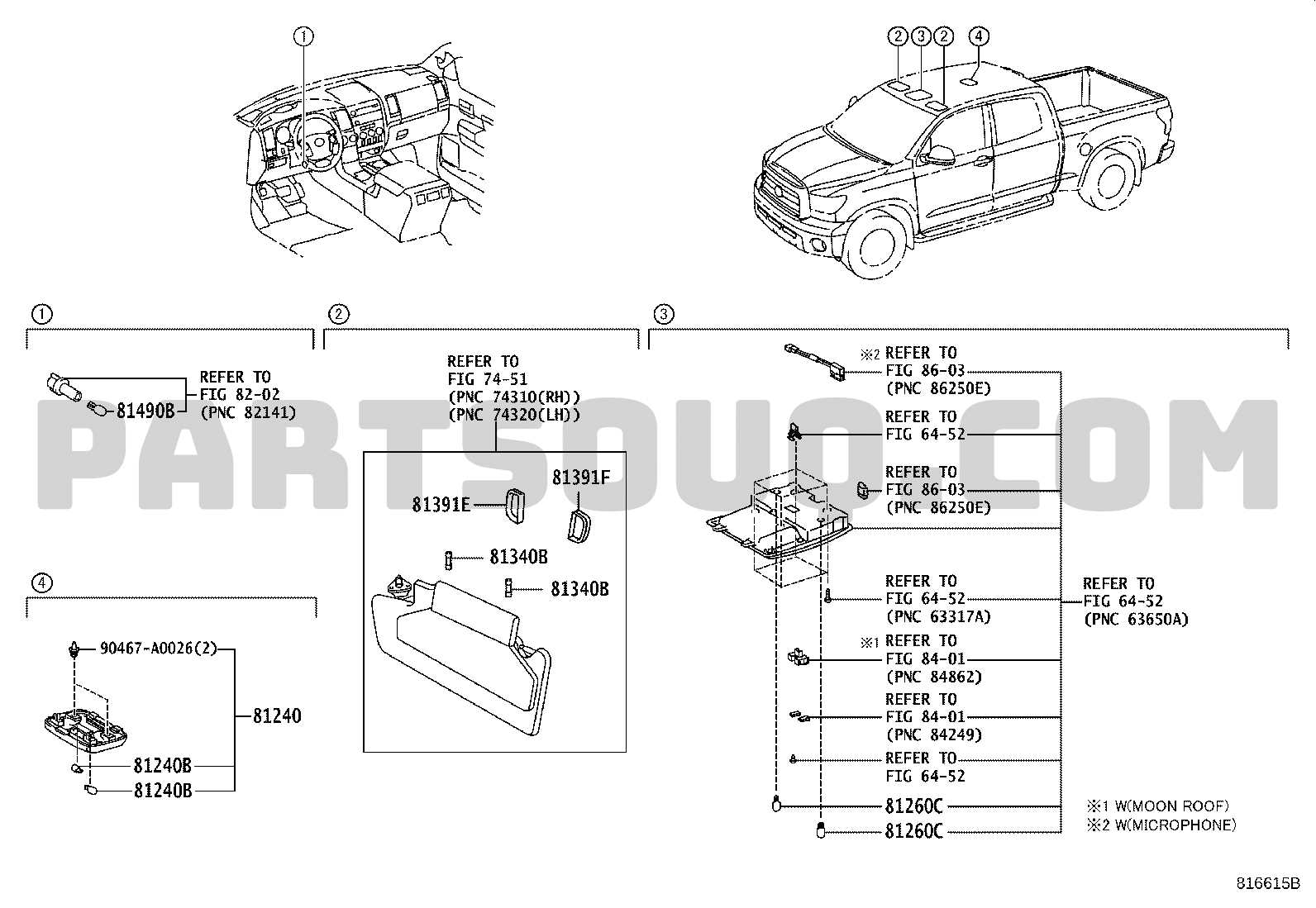

- Electrical wiring and control units

Key Connections

- Powertrain linked with the drivetrain assembly

- Suspension interacting with the chassis for stability

- Control units integrating with the electronic framework

Each part plays a crucial role in ensuring smooth operation, and understanding the layout is essential for maintenance and troubleshooting.

Understanding the Tundra Structure

When examining the overall framework of this environment, it’s essential to grasp the various interconnected elements that contribute to its function. Each component plays a crucial role in maintaining balance and ensuring smooth operation, with the relationships between different systems being the key to its stability. By understanding how these elements work together, one can better appreciate the complexity and resilience of the overall structure.

Key Sections of the System

- Main framework supporting essential operations

- Critical units responsible for movement and control

- Subsections dedicated to environmental adaptation and durability

Interactions Between Core Components

- Primary sections connect through a network of smaller units.

- Each unit works in tandem, ensuring the seamless integration of different processes.

- Adaptive systems respond to external changes, enhancing overall stability.

Key Components of Tundra Vehicles

Understanding the essential elements of this type of vehicle is crucial for ensuring its proper operation and longevity. These elements form the core of the vehicle’s structure and functionality, allowing for smooth performance across various conditions.

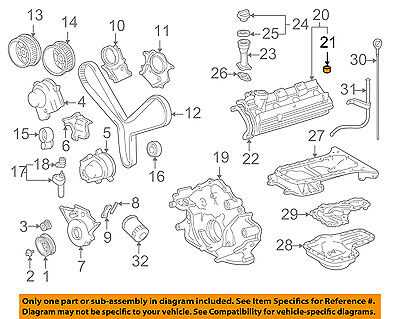

Engine System

The engine is the heart of any vehicle, responsible for converting fuel into the energy needed to propel the vehicle forward. Key aspects of the engine system include:

- Fuel injection system for efficient fuel delivery

- Cooling mechanism to prevent overheating

- Exhaust system for emissions control

Transmission and Drive Components

The transmission plays a vital role in transferring power from the engine to the wheels. It ensures the vehicle can adjust speeds and manage different terrains. Main components involved include:

- Gearbox for regulating speed and torque

- Drive shafts connecting the engine to the wheels

- Differential system managing wheel rotation balance

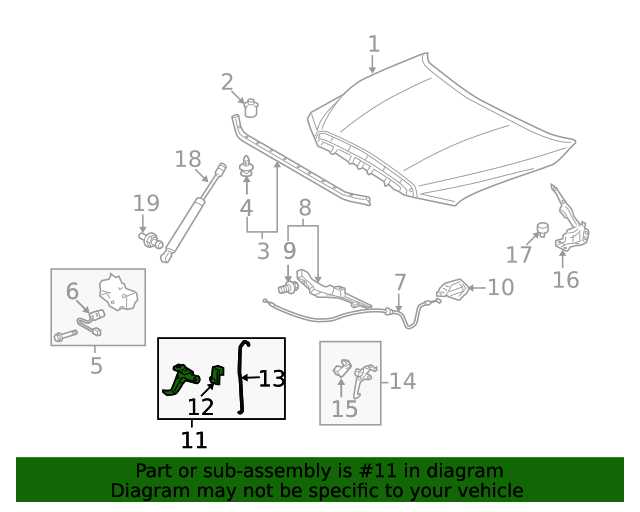

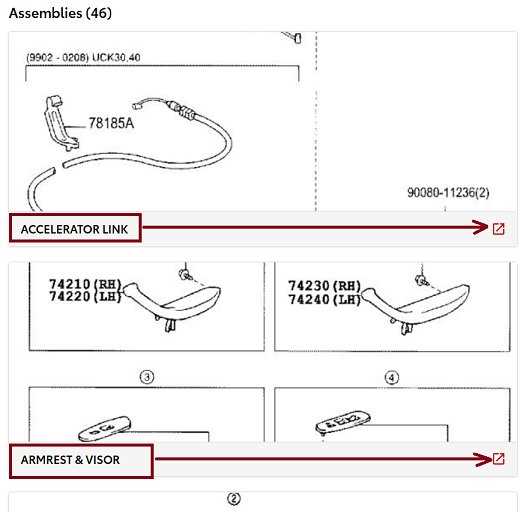

How to Read Parts Diagrams

Understanding component illustrations is essential for effectively assembling or repairing complex machinery. These visual guides represent different elements, showing their arrangement and relationships. By analyzing such schematics, you can better grasp how individual sections connect to form the whole, making the task of maintenance or assembly smoother.

First, identify key sections. Schematics often highlight groups of related items. Focus on these clusters to recognize how smaller elements interact within larger systems. This method makes it easier to visualize connections.

Next, follow numbering and labeling conventions. These labels help you match components to their respective explanations or instructions, ensuring accurate assembly. Taking time to learn the reference numbers or labels makes the process more efficient.

Finally, consider the sequence. Diagrams typically suggest an order of operations or assembly steps. Observing the flow of elements from one point to another will help you assemble items in the correct sequence, reducing errors and saving time.

Common Tundra Issues Identified

Various mechanical challenges can arise over time, often affecting the performance and reliability of vehicles. These issues are typically tied to key components that experience wear and tear or malfunction due to regular use. Identifying these problems early can help prevent more serious damage and ensure the smooth operation of the system.

Engine performance is one of the most frequent concerns, with factors such as mis

Importance of Regular Maintenance

Consistent care and upkeep are essential for ensuring the longevity and optimal performance of any equipment. By adhering to routine checks and necessary adjustments, potential issues can be identified early, preventing more significant problems down the road. This proactive approach helps avoid unnecessary expenses and prolongs the lifespan of various systems.

Preventing Major Failures

Regular maintenance plays a crucial role in detecting minor wear or malfunctions that could lead to significant breakdowns. Early identification of issues allows for timely intervention, minimizing the risk of severe damage. This not only enhances reliability but also reduces downtime and repair costs.

Ensuring Efficiency

Ongoing maintenance ensures that components function at their peak efficiency, allowing systems to operate smoothly. Neglecting routine care can result in decreased performance, which can affect overall productivity. Therefore, maintaining optimal working conditions is key to maximizing efficiency and minimizing energy consumption.

Comparing Tundra Models and Diagrams

When exploring various models of a specific vehicle series, understanding how their structural and functional designs differ is crucial. Each variation can present unique features and configurations that affect performance, maintenance, and customization options. By comparing these models, it’s possible to discern subtle changes in design that may not be immediately apparent without a closer look at their detailed layouts.

The evolution of these models often reflects advancements in technology, materials, and consumer needs. Identifying the differences between the layouts of earlier and newer versions helps in grasping how improvements have been implemented to enhance reliability, comfort, and functionality.

Tips for Identifying Parts Quickly

Recognizing components efficiently can save time and ensure smooth repairs or maintenance. To achieve this, it’s crucial to familiarize yourself with the structure and layout of the system. By developing a clear understanding of the key elements, you can easily pinpoint what you need without hesitation.

| Tip | Explanation |

|---|---|

| Visual Consistency | Identify common patterns in the design to quickly recognize related items. Similar shapes, sizes, or placements can often indicate connected elements. |

| Organized Reference | Use a well-structured reference that organizes components into groups. This makes locating specific items faster and reduces confusion. |

| Component Labels | Ensure each part is clearly labeled or marked with distinguishing features, such as numbers or colors, for quicker identification. |