Comprehensive Guide to Volvo D13 Parts Diagram

Understanding the intricate layouts of engine components is essential for effective maintenance and repair. These visual representations serve as invaluable resources for technicians, allowing for a comprehensive grasp of how each part integrates within the larger system. By examining these layouts, one can gain insights into the functionality and relationship between various elements.

In this section, we will delve into the various elements that contribute to optimal engine performance. From critical systems to auxiliary components, each section reveals the ultimate assembly required for seamless operation. Familiarity with these illustrations empowers professionals to diagnose issues more efficiently and execute repairs with precision.

Moreover, recognizing the interconnectedness of components aids in preventing future malfunctions. Armed with detailed knowledge of how each piece fits together, technicians can ensure longevity and reliability in their machinery. This exploration not only enhances understanding but also elevates the overall standard of service provided to clients.

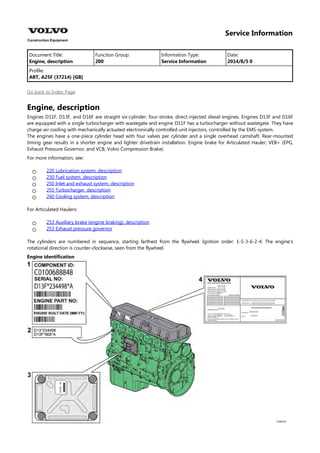

Understanding the Volvo D13 Engine

This section aims to provide a comprehensive overview of a prominent heavy-duty power unit known for its robust performance and efficiency. This engine model is widely utilized in various commercial applications, delivering reliability and high torque output, essential for demanding operational environments.

Key Features

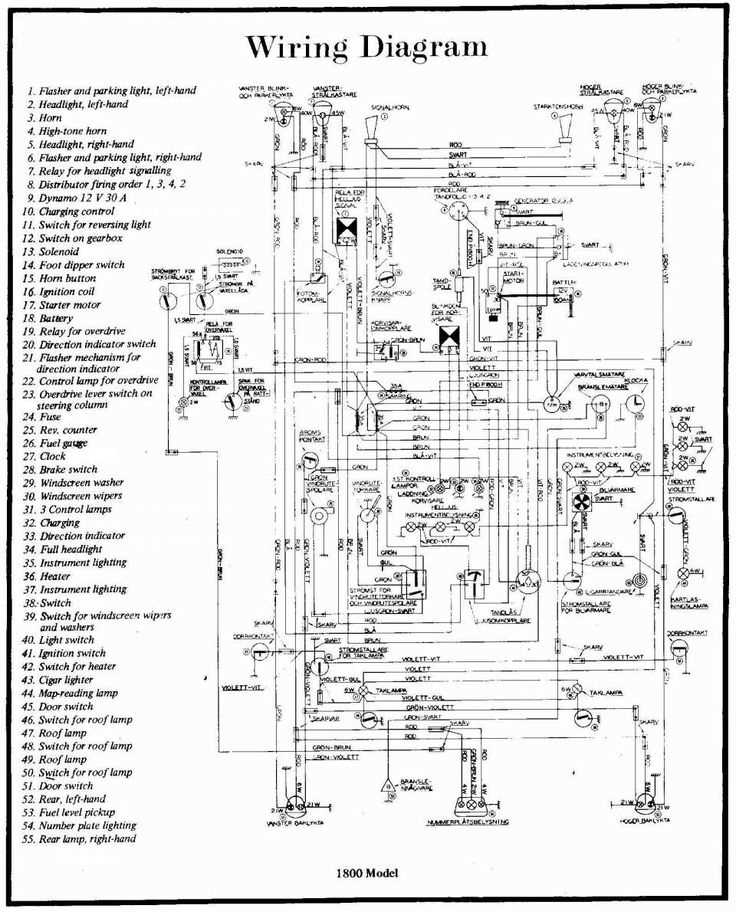

The highlighted power unit is designed with several remarkable characteristics that enhance its performance and longevity. Key elements include advanced fuel injection systems, a durable construction that withstands high stress, and sophisticated electronic control systems that optimize fuel efficiency and reduce emissions.

Maintenance Considerations

| Component | Description | Function |

|---|---|---|

| Fuel Pump | Delivers fuel from the tank | Ensures proper fuel supply for combustion |

| Turbocharger | Increases engine air intake | Enhances power output and efficiency |

| Exhaust System | Directs exhaust gases away | Reduces emissions and noise |

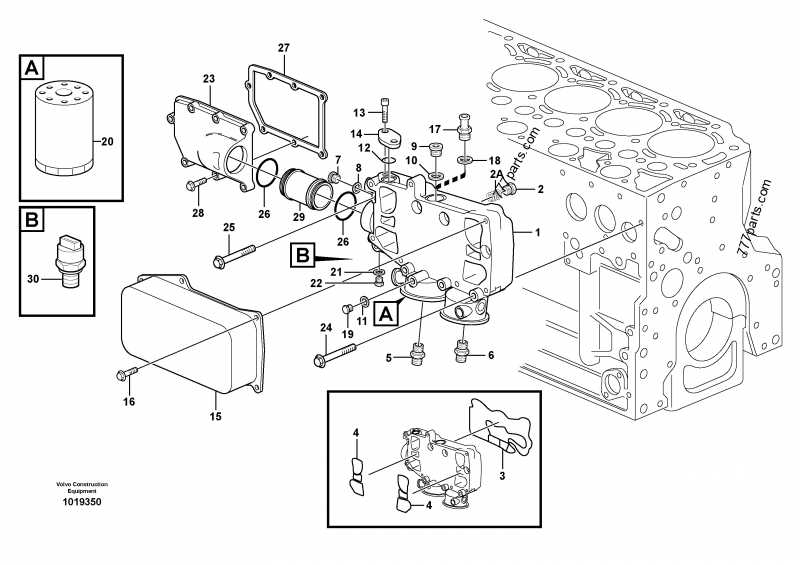

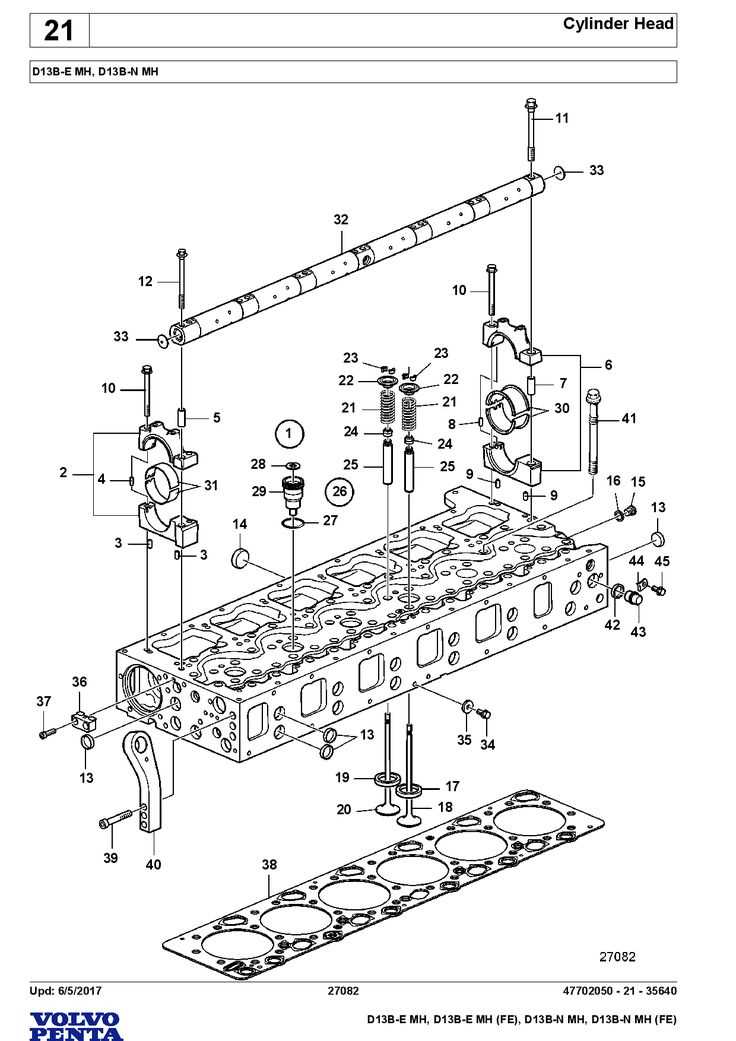

Key Components of the D13 Engine

This section explores the essential elements that contribute to the performance and efficiency of this powerful engine. Each component plays a vital role in ensuring optimal operation and longevity.

Essential Elements

- Cylinder Block

- Crankshaft

- Pistons

- Turbocharger

- Fuel Injection System

Supporting Systems

- Cooling System

- Lubrication System

- Exhaust System

- Air Intake System

Importance of Accurate Parts Diagrams

Having precise representations of components is crucial in any mechanical field. These illustrations serve as essential tools for technicians, enabling them to identify and understand the various elements that make up complex machinery. Accurate visual references reduce the likelihood of errors during maintenance and repair, ensuring that each part is correctly handled and fitted. This reliability contributes significantly to the overall performance and longevity of the equipment.

Enhanced Efficiency in Repairs

When technicians have access to detailed schematics, they can work more efficiently. These visuals provide clear guidance on the assembly and disassembly of parts, minimizing time spent on troubleshooting. Consequently, the overall downtime of the machinery is reduced, allowing for quicker turnaround in service and enhancing productivity.

Cost Savings Through Precision

Inaccurate representations can lead to costly mistakes, such as ordering the wrong components or misaligning elements during installation. By relying on well-constructed visuals, businesses can avoid unnecessary expenses and ensure that repairs are executed correctly the first time. This approach not only saves money but also helps maintain a good relationship with clients by providing reliable service.

| Benefits | Description |

|---|---|

| Reduced Errors | Minimizes the chances of incorrect installations or replacements. |

| Faster Turnaround | Enhances the speed of repairs through clear guidance. |

| Cost Efficiency | Decreases expenses by preventing mistakes and ensuring correct orders. |

Common Issues with D13 Parts

When dealing with complex machinery, certain components can often present challenges that impact performance and reliability. Understanding these frequent concerns can help in maintaining optimal operation and extending the lifespan of the system.

| Component | Common Issue | Possible Solution |

|---|---|---|

| Fuel Injectors | Clogging | Regular cleaning and inspection |

| Turbocharger | Oil leaks | Seal replacement |

| Cylinder Head | Overheating | Check coolant levels and flow |

| Exhaust System | Blockages | Thorough cleaning |

How to Read Parts Diagrams

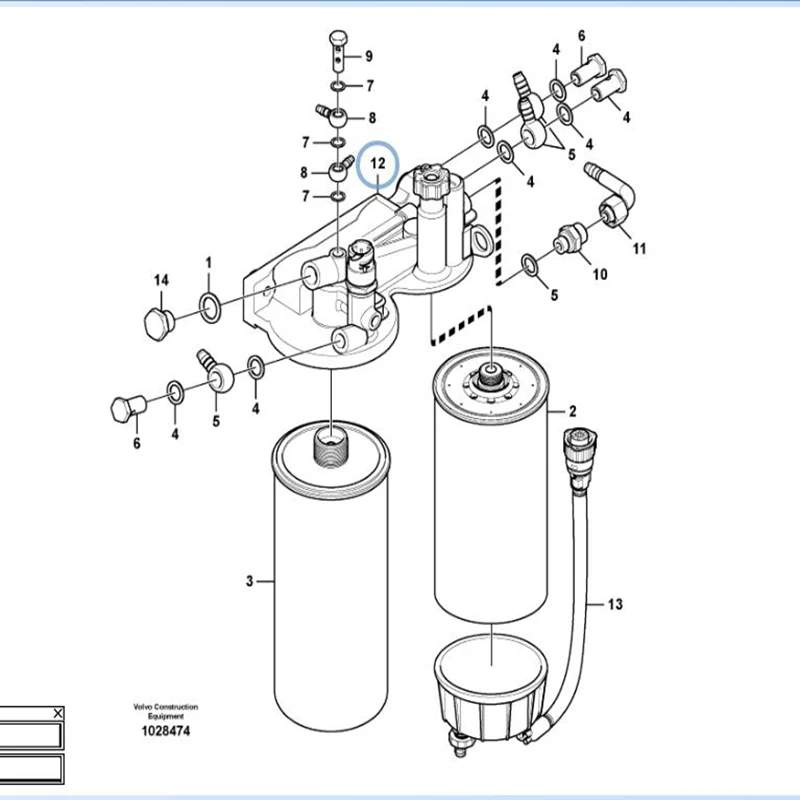

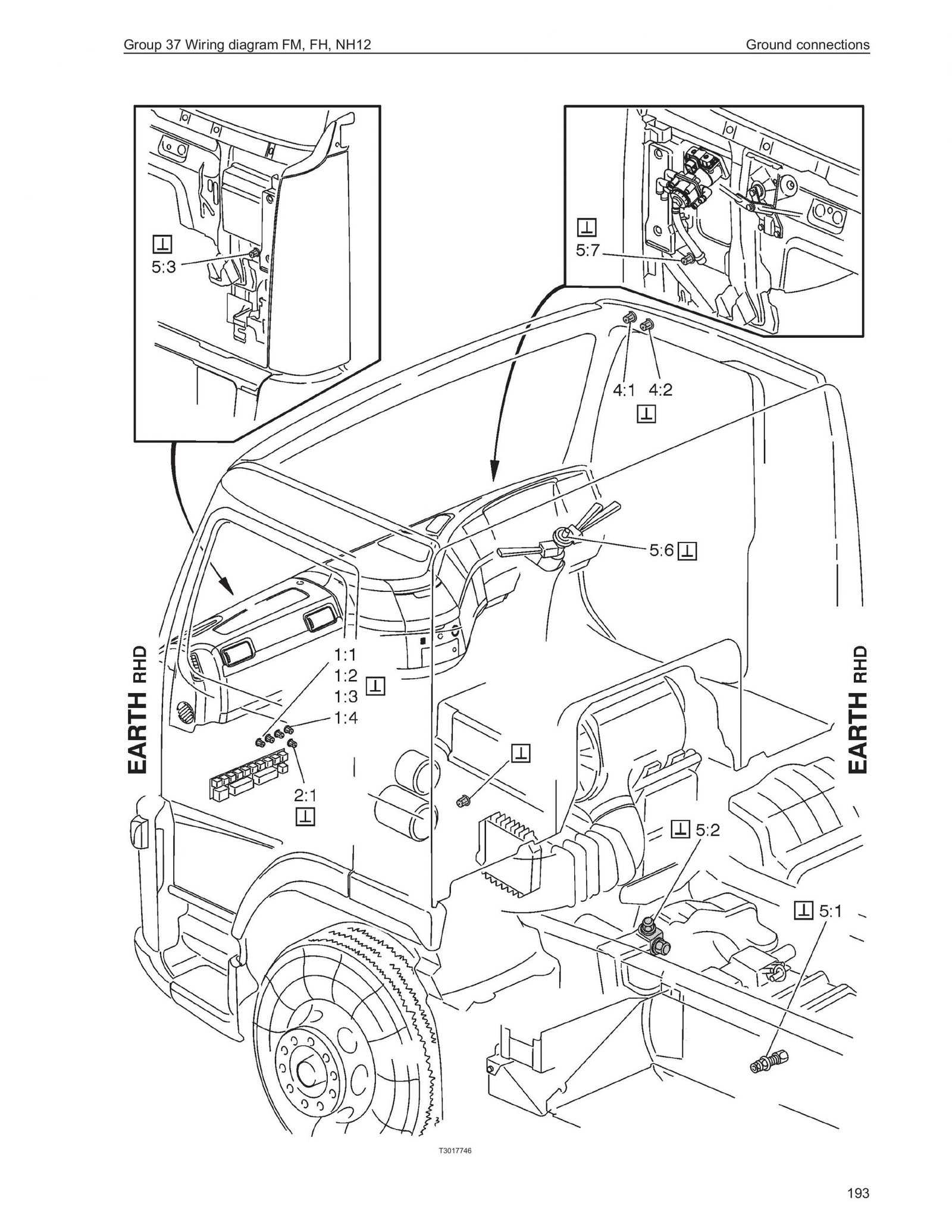

Understanding technical illustrations is essential for effective maintenance and repairs. These visual representations provide crucial information about components and their relationships within a system. Knowing how to interpret these images can significantly enhance your ability to troubleshoot and perform necessary tasks.

Key Elements of Technical Illustrations

- Labels: Each component typically has a label or part number for easy identification.

- Connections: Arrows or lines may indicate how various elements are linked or interact.

- Views: Different perspectives may be shown, such as top, side, or exploded views, to give a comprehensive understanding.

Steps to Interpret the Illustration

- Start by identifying the overall layout of the components.

- Locate the labels and cross-reference them with a list or key, if available.

- Pay attention to the connections and flow indicated, as this can help in understanding functionality.

- Refer to accompanying manuals for additional details or specifications related to the components.

By mastering these techniques, you can confidently navigate technical illustrations, making repairs and maintenance tasks more efficient.

Finding Genuine Volvo Parts

When it comes to maintaining the performance and longevity of your vehicle, sourcing authentic components is essential. These high-quality elements ensure that your machine operates smoothly, enhancing safety and reliability. This section will guide you on how to effectively locate and purchase original items for your automotive needs.

Why Authentic Components Matter

Opting for genuine components offers numerous advantages:

- Quality Assurance: Original items are manufactured to meet specific standards.

- Compatibility: They fit perfectly, reducing the risk of issues during installation.

- Warranty Protection: Using authorized components often helps maintain the vehicle’s warranty.

Where to Find Authentic Items

Here are some reliable sources to consider:

- Authorized Dealers: They provide certified components and often have knowledgeable staff.

- Official Websites: Many manufacturers offer direct sales through their online platforms.

- Specialty Retailers: Look for shops that focus on your vehicle’s make and model for a curated selection.

By focusing on these sources, you can ensure that you acquire the right components to keep your vehicle in top condition.

Maintenance Tips for D13 Engines

Regular upkeep of heavy-duty engines is crucial for ensuring optimal performance and longevity. Proper care not only enhances efficiency but also helps prevent costly repairs down the line. Below are some essential tips for maintaining these powerful machines.

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Oil Change | Every 10,000 miles or as needed | Prevents engine wear and improves lubrication |

| Coolant Check | Every month | Prevents overheating and protects components |

| Filter Replacement | Every 20,000 miles | Ensures clean fuel and air intake |

| Inspection of Belts and Hoses | Every 5,000 miles | Prevents breakdowns and ensures system integrity |

| Battery Check | Every month | Ensures reliable starts and electrical performance |

By adhering to these maintenance guidelines, operators can significantly enhance the reliability and efficiency of their engines, ultimately leading to better performance on the road.

Upgrading Your Volvo D13 System

Enhancing your heavy-duty engine system can significantly improve performance and efficiency. Whether you’re seeking better fuel economy, increased power output, or enhanced durability, modern advancements provide numerous options to elevate your engine’s capabilities. Careful selection of components and systems will ensure optimal functionality and longevity.

To begin, consider investing in advanced turbochargers and intercoolers. These components can boost airflow, leading to improved combustion efficiency and overall performance. Additionally, upgrading the fuel injection system can optimize fuel delivery, resulting in better responsiveness and reduced emissions.

Furthermore, integrating a high-performance exhaust system can enhance airflow, promoting better engine breathing and potentially increasing horsepower. Don’t overlook the importance of electronic control modules, as modern software upgrades can optimize engine parameters for improved performance metrics.

Finally, regular maintenance and the use of quality lubricants are essential in supporting your enhancements. This proactive approach will help maintain the integrity of your system while maximizing the benefits of any upgrades.

Tools Needed for D13 Repairs

When it comes to conducting maintenance and repairs on complex machinery, having the right instruments is essential. Proper tools not only ensure efficiency but also contribute to the longevity of the equipment.

- Wrenches: Various sizes for different fasteners.

- Screwdrivers: Both flat and Phillips for different screws.

- Socket set: Essential for reaching tight spaces.

- Torque wrench: For applying precise tension on bolts.

- Pliers: Useful for gripping and twisting.

- Multimeter: For electrical diagnostics.

- Oil filter wrench: Specifically designed for removing filters.

Additionally, consider having a reliable workbench and appropriate safety gear to ensure a safe working environment.

Where to Source D13 Parts

Finding the right components for heavy-duty engines can be a challenging task, but understanding where to look can streamline the process significantly. Numerous avenues are available for sourcing quality materials, each offering distinct advantages depending on your specific needs and budget.

Authorized Dealers

One of the most reliable sources for obtaining engine components is through authorized dealers. These establishments typically stock a comprehensive range of original equipment manufacturer (OEM) items, ensuring compatibility and durability. Moreover, purchasing through authorized channels often comes with added benefits, such as warranties and expert advice from knowledgeable staff.

Online Marketplaces

The internet provides a vast landscape of options for procuring necessary engine materials. Online marketplaces and specialized websites can connect buyers with a multitude of suppliers. It’s essential to verify the credibility of sellers and check reviews to ensure you receive high-quality items. Additionally, many online platforms offer competitive pricing, making it easier to find budget-friendly solutions.