Volvo Penta 2003 Parts Diagram Overview

The intricate assembly of a marine engine is vital for its optimal performance and longevity. Familiarity with the various elements that comprise this system can greatly enhance maintenance efforts and troubleshooting procedures. This section delves into the essential components, offering a clear visual representation to aid in identification and understanding.

Whether you are a seasoned technician or a recreational enthusiast, recognizing each segment’s role is crucial for effective operation. Knowledge of these components not only facilitates smoother repairs but also contributes to the overall efficiency of the vessel. Here, you will find a comprehensive overview that highlights the significance of each part, ensuring you are well-equipped for any task at hand.

By mastering the layout and function of these key segments, you can ensure that your marine engine remains in peak condition. This resource serves as a guide, providing valuable insights to empower users in their maintenance journeys. Navigate through the details to discover how each piece interconnects to form a reliable and high-performing marine engine.

Understanding the essential elements of a marine power unit is crucial for maintenance and performance optimization. Each component plays a vital role in ensuring the engine operates smoothly and efficiently, contributing to the overall functionality of the vessel.

Essential Elements

- Block: The core structure that houses various engine components and withstands internal pressures.

- Cylinder Head: Encloses the cylinders and contains the valves and spark plugs, playing a critical role in the combustion process.

- Pistons: Move up and down within the cylinders, converting fuel energy into mechanical power.

- Crankshaft: Transforms the linear motion of the pistons into rotational motion, driving the propulsion system.

- Camshaft: Regulates the opening and closing of the valves, ensuring the engine breathes properly.

Additional Components

- Fuel Injectors: Deliver fuel directly into the combustion chamber for efficient burning.

- Cooling System: Maintains optimal operating temperatures, preventing overheating.

- Lubrication System: Ensures all moving parts are properly lubricated to reduce friction and wear.

- Exhaust System: Safely directs exhaust gases away from the engine, improving efficiency and performance.

Common Issues with Components

Understanding the typical challenges associated with mechanical elements can enhance maintenance and repair strategies. This section highlights prevalent complications faced by users, ensuring informed decisions during troubleshooting.

Frequent Complications

- Wear and Tear: Continuous usage can lead to degradation, affecting performance and reliability.

- Corrosion: Exposure to moisture and elements can result in rust, weakening structural integrity.

- Misalignment: Improper installation or operational stresses may cause components to misalign, leading to inefficient function.

- Fluid Leaks: Seals and gaskets can deteriorate over time, resulting in leaks that compromise efficiency.

Maintenance Tips

- Regularly inspect components for signs of damage or wear.

- Keep surfaces clean and dry to prevent corrosion.

- Follow manufacturer guidelines for installation and alignment.

- Replace seals and gaskets at scheduled intervals to avoid leaks.

Identifying Replacement Parts

When maintaining or repairing a mechanical system, it’s crucial to determine the appropriate components that need to be replaced. Ensuring compatibility and selecting the correct replacements helps extend the system’s lifespan and prevents further issues. Proper identification also minimizes downtime, allowing the system to continue operating smoothly.

Key elements to focus on include checking the model specifications, understanding the configuration of the equipment, and recognizing any signs of wear or damage. Each component plays a specific role, so it is important to accurately match them with the original ones to ensure optimal performance.

Using resources such as technical manuals and detailed sketches will make it easier to find suitable substitutes. Cross-referencing these with part numbers or identifying markings can assist in narrowing down the exact items needed for the task.

Maintenance Tips for Longevity

Ensuring the extended functionality of your marine engine requires attention to regular upkeep and careful monitoring of its components. Proactive care prevents potential issues, improving the lifespan of the machinery and maintaining optimal performance.

Regular Inspection: Conduct frequent check-ups to identify wear or damage early. Replace aging elements as necessary to avoid more significant problems down the line.

Proper Lubrication: Maintaining appropriate lubrication levels is critical for reducing friction and ensuring smooth operation. Always use recommended oils and follow manufacturer guidelines.

Cleaning and Protection: Consistently clean and protect key areas from corrosive environments. Removing debris and salt buildup can significantly extend the life of the engine.

Keep the fuel system clear and ensure filters are replaced at regular intervals. Clean fuel flow helps to avoid power loss and maintain efficiency.

Timely Component Replacement: Don’t delay the replacement of worn parts. Replacing essential components before they fail helps to prevent major repairs and downtime.

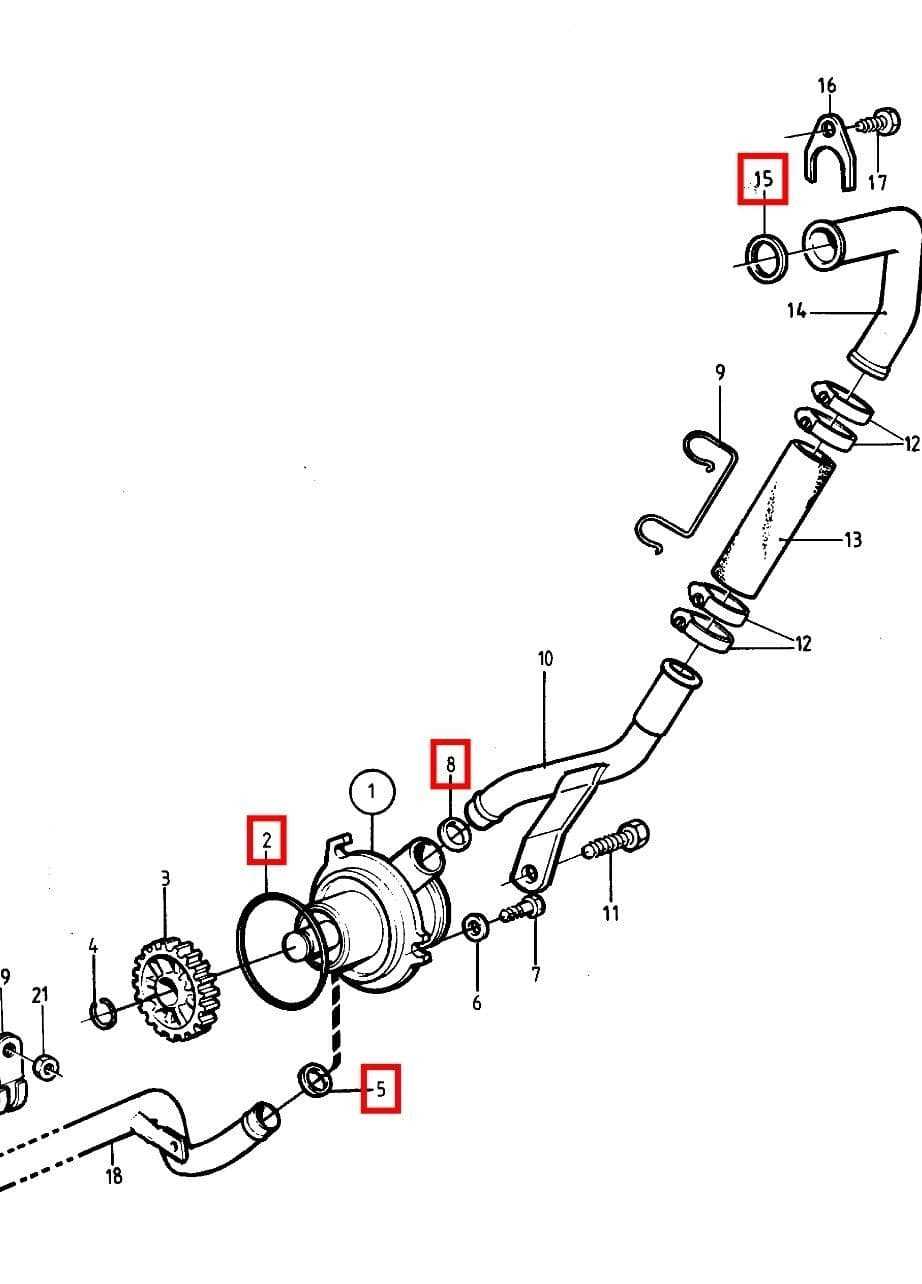

Parts Diagram Overview

This section provides an in-depth look at the visual representation of various components that make up the system. It helps in identifying key elements and their placement, giving a comprehensive understanding of how different units interconnect and work together. The schematic simplifies the maintenance process, making it easier to track down specific areas for repair or replacement.

Component Breakdown

The illustration highlights critical mechanical sections, showing detailed connections between individual segments. Each element is clearly labeled, allowing for easy identification during repairs or upgrades. This breakdown is essential for both experienced technicians and newcomers.

Structure and Assembly

Understanding the structure and assembly is crucial when dealing with replacements or troubleshooting. The table below outlines various sections along with their corresponding identifiers, streamlining the process of locating specific components for maintenance tasks.

| Section | Identifier | Description | |||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Main Unit | A1 | Primary assembly with core mechanical functions. | |||||||||||||||||||||||||||||||

| Cooling System | B3 | Ensures optimal operating temperature, preventing overheating. | |||||||||||||||||||||||||||||||

| Transmission | C7 | Transfers power between systems, ensuring smooth operation. |

| Component | Description | Availability | |||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cooling System Components | Essential for regulating engine temperature and preventing overheating. | In stock | |||||||||||||||||||||||||||||||

| Fuel Delivery Systems | Ensures smooth and efficient fuel flow, crucial for engine performance. | Backordered | |||||||||||||||||||||||||||||||

| Transmission Parts | Key elements for maintaining seamless shifting and power transfer. |

| Component Type | Compatible Models | Special Notes | |||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fuel Injector | Model A, Model B, Model C | Ensure matching fuel pressure ratings | |||||||||||||||||||||||

| Water Pump | Model D, Model E |

| Tool | Purpose | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Torque Wrench | Ensures accurate tightening of bolts to the specified torque, preventing over-tightening or loosening. | ||||||||||||

| Hex Key Set | Useful for driving screws with hexagonal heads, often found in various assemblies. | ||||||||||||

| Screwdrivers | Commonly used for assembling and securing smaller fasteners, both flathead and Phillips types. | ||||||||||||

| Pliers | Used for gripping, bending, or cutting wires and securing clips or small components. | ||||||||||||

| Rubber Mallet | Ideal for gently adjusting parts into place without damaging delicate surfaces. |

| Factor | Impact on Cost |

|---|---|

| Quality of the Component | High-quality items tend to be more expensive but offer better longevity and performance. |

| Supplier | Different vendors may offer varying prices for the same item, making it essential to compare options. |

| Shipping Costs | Distance and shipping method can significantly add to the overall expense, especially for larger or heavier components. |

| Installation Services | Hiring professionals for installation can increase the total cost but ensures correct fitting and functionality. |

| Availability | Items that are rare or in high demand may command a premium price due to limited stock. |

Where to Find Service Manuals

When maintaining or repairing complex machinery, having access to detailed guides is essential for both professionals and hobbyists. These manuals provide step-by-step instructions, technical specifications, and essential diagrams, which can greatly simplify the troubleshooting and repair process.

Online Resources

There are numerous platforms where service manuals can be found. Many websites specialize in offering digital copies of technical guides. These platforms typically allow users to search for specific models or engines and download manuals in various formats. Some may require registration, while others offer free access to a wide range of documents.

- Specialized online libraries

- Manufacturer’s official website

- Forums and communities dedicated to maintenance

Printed Manuals

For those who prefer physical copies, printed manuals are often available through various retailers. These can be found in specialized stores or ordered online. Having a hard copy can be convenient in environments where digital access may not be readily available.

- Search technical bookstores

- Check online marketplaces for used manuals

- Visit local repair shops that may have extra copies

Upgrades for Enhanced Performance

Optimizing engine performance can significantly extend the lifespan and efficiency of your vessel. By integrating modern improvements and fine-tuning key components, you can achieve smoother operation, increased power output, and better fuel economy. Below are some recommended enhancements that cater to various aspects of a marine engine.

- Fuel Injection Systems: Upgrading to advanced fuel injectors can improve fuel delivery, resulting in more efficient combustion and reduced fuel consumption.

- Turbocharging: Adding or upgrading a turbocharger boosts engine power by increasing air intake, leading to better overall engine performance, especially at higher speeds.

- Cooling System Improvements: Enhanced cooling components, such as modern heat exchangers or high-flow water pumps, can help maintain optimal engine temperatures, preventing overheating during extended use.

- Electronic Engine Management: Installing updated electronic control units (ECUs) allows for more precise control over various engine functions, enhancing reliability and efficiency.

- Exhaust System Upgrades: Replacing or improving exhaust components can reduce backpressure and improve exhaust flow, which contributes to overall engine efficiency and power.

These upgrades offer a well-rounded approach to enhancing