Comprehensive Guide to Volvo Penta 4.3 GL Parts Diagram

When it comes to the intricate world of marine engines, grasping the layout of their components is essential for effective maintenance and repairs. A clear understanding of how each element interacts within the system can significantly enhance performance and longevity.

In this section, we will explore a specific power unit that is widely utilized in boating. By delving into its internal structure, we aim to provide an ultimate resource for enthusiasts and professionals alike. This comprehensive overview will facilitate easier troubleshooting and efficient part identification.

As we navigate through the essential components, we will highlight key features and functions, ensuring that readers are equipped with the knowledge necessary for optimal engine care. Whether you are a seasoned mechanic or a novice boat owner, this guide will serve as a valuable reference point.

Understanding Volvo Penta 4.3 GL Engine

This section explores the intricacies of a specific marine power unit, emphasizing its components and functionality. An in-depth comprehension of this engine type is crucial for optimal performance and maintenance in various aquatic applications.

Key Features

This power unit is characterized by a robust design, delivering reliable output and efficiency. Its construction allows for easy integration into various watercraft, making it a popular choice among enthusiasts.

Component Overview

| Component | Description |

|---|---|

| Cylinder Block | The core structure housing the cylinders, providing strength and durability. |

| Intake Manifold | Distributes air and fuel mixture to the cylinders for combustion. |

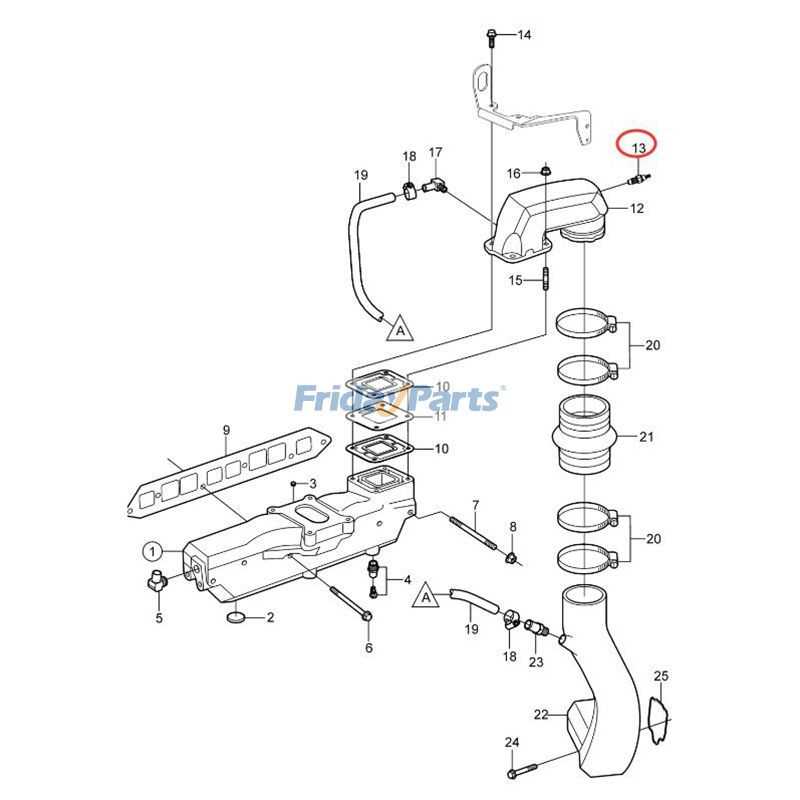

| Exhaust System | Channels exhaust gases away from the engine, ensuring efficiency and safety. |

| Cooling System | Maintains optimal operating temperature through effective heat exchange. |

Key Components of the Engine

Understanding the essential elements of a marine engine is crucial for maintaining optimal performance and longevity. Each component plays a vital role in the overall functionality, ensuring that the system operates efficiently under various conditions.

Block: The core structure that houses the cylinders and provides the framework for the entire assembly. It withstands the immense pressures generated during combustion.

Cylinder Head: This component seals the top of the cylinders, facilitating the combustion process. It also contains important elements like the valves and spark plugs, which are essential for engine operation.

Crankshaft: Serving as the heart of the engine, this rotating shaft converts the linear motion of the pistons into rotational energy, powering the propulsion system.

Pistons: Moving within the cylinders, these components are critical for compressing the fuel-air mixture and transferring energy to the crankshaft. Their movement directly affects the engine’s efficiency and power output.

Oil Pump: This component circulates lubricant throughout the engine, reducing friction and ensuring smooth operation. Proper oil flow is essential for preventing overheating and wear.

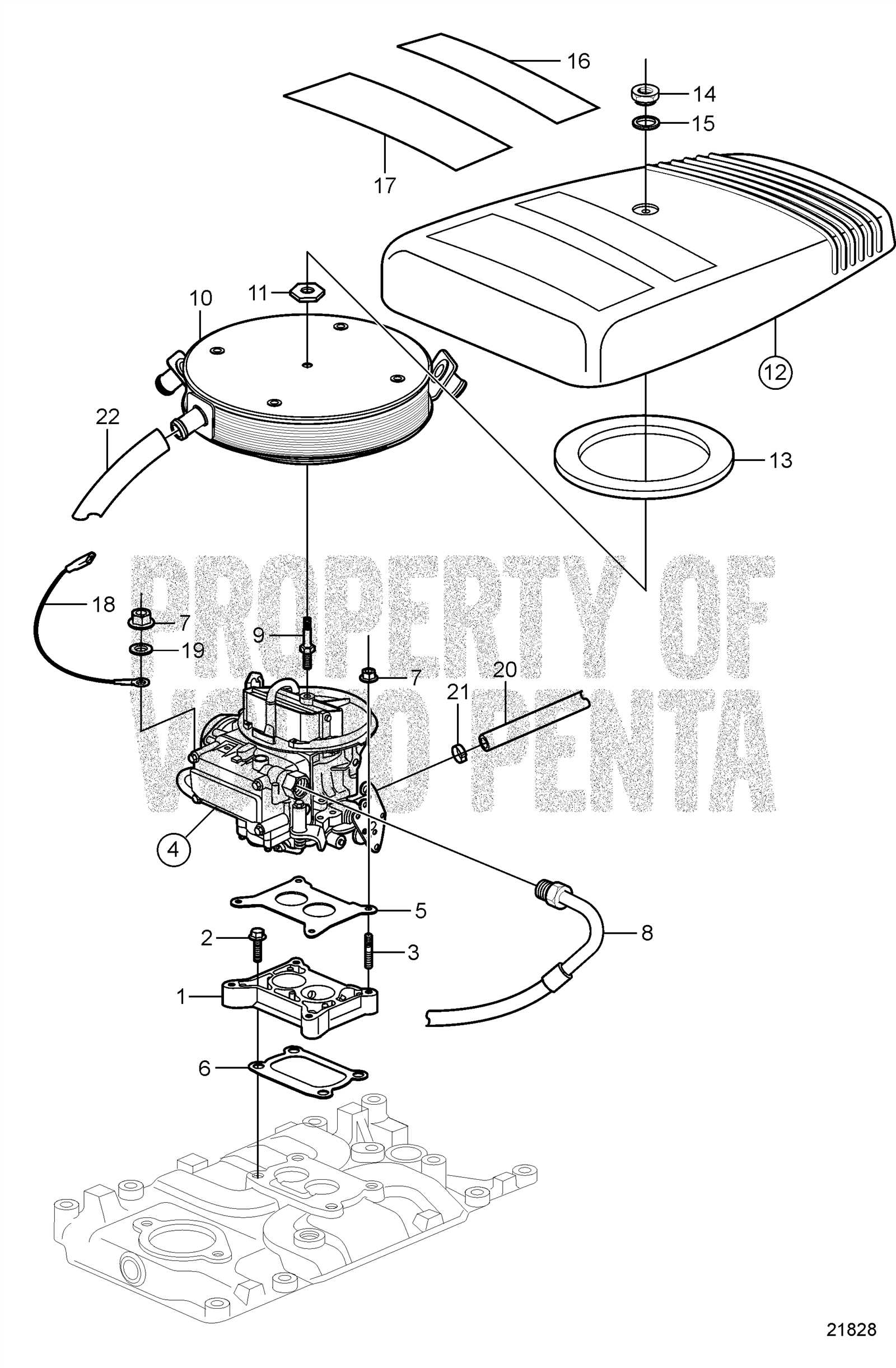

Fuel System: Comprising injectors and filters, this system is responsible for delivering the right amount of fuel to the combustion chamber, optimizing performance and fuel efficiency.

Cooling System: Essential for regulating engine temperature, this system prevents overheating by circulating coolant through various engine components.

Each of these vital elements must work in harmony to ensure reliable operation and peak performance. Regular maintenance and inspection of these components can significantly enhance the longevity and efficiency of the engine.

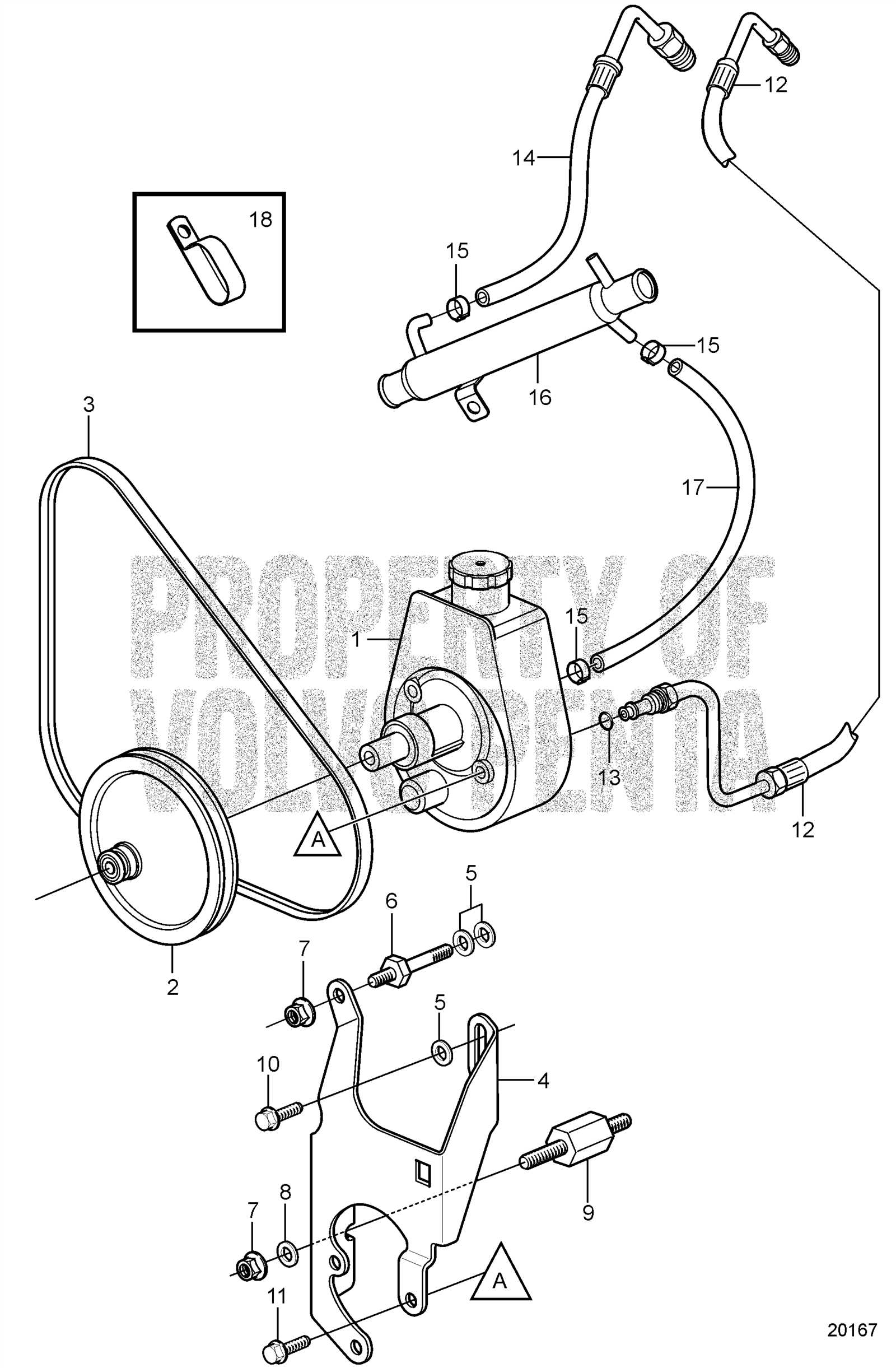

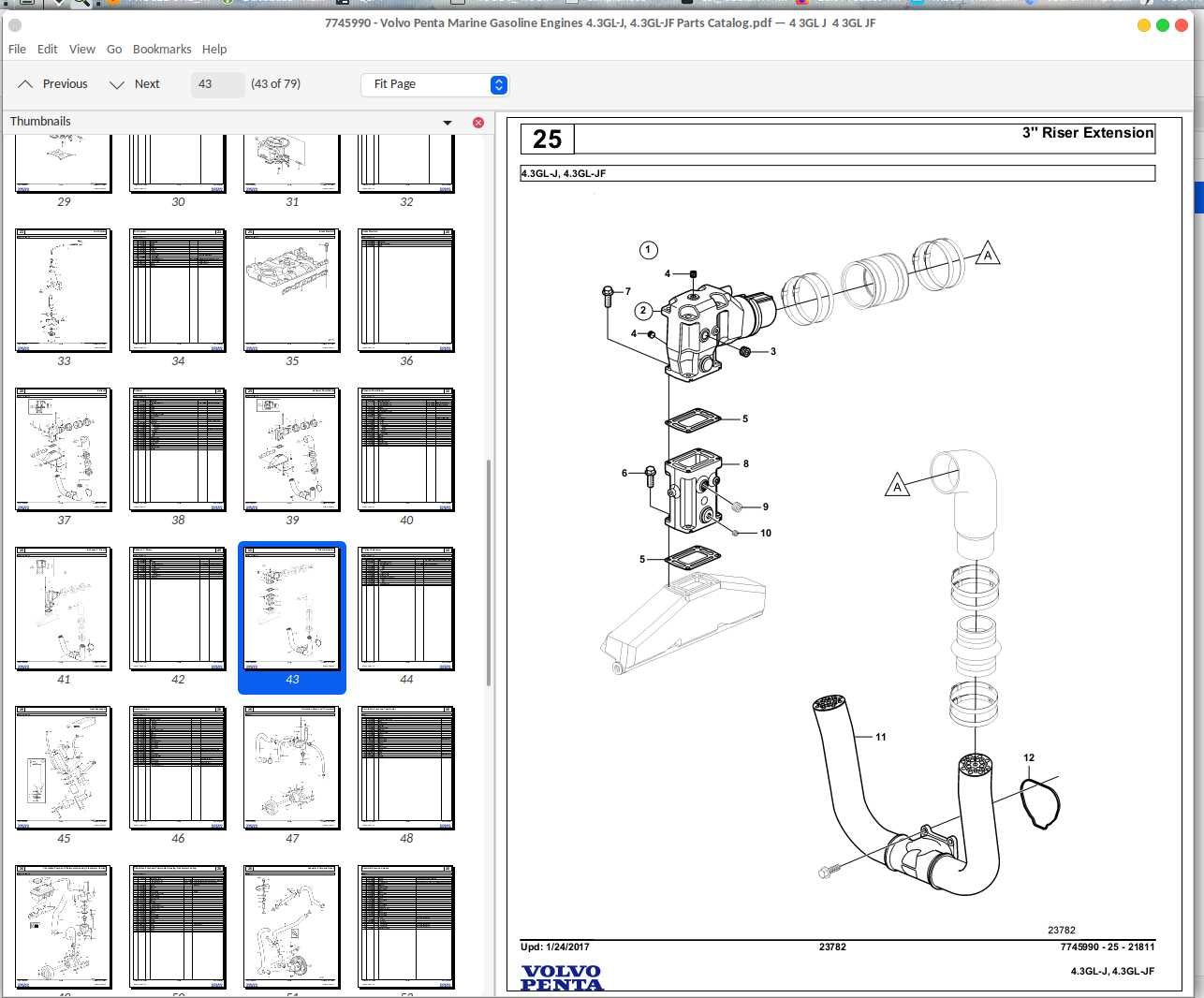

Importance of Parts Diagrams

Understanding the layout and function of components is crucial for effective maintenance and repair. Visual representations of each element not only enhance comprehension but also streamline the troubleshooting process.

Key benefits of utilizing such illustrations include:

- Enhanced Clarity: Visual aids simplify complex systems, making it easier to identify and locate specific components.

- Efficient Repairs: Quick access to information allows for faster identification of issues, reducing downtime.

- Accurate Ordering: When replacements are necessary, having a clear view of what is needed ensures correct procurement.

- Improved Training: New technicians can learn more effectively by studying visual guides alongside hands-on experience.

- Prevention of Errors: Clear illustrations help avoid mistakes during assembly or disassembly, leading to safer and more effective work.

In summary, having clear visual representations of components significantly contributes to more effective maintenance, repair, and training processes, ultimately promoting better performance and longevity of the machinery.

Common Issues with 4.3 GL

Understanding the frequent problems that arise with this engine can help owners maintain optimal performance and extend its lifespan. Regular checks and timely interventions can mitigate many common challenges faced by users.

| Issue | Description | Solution |

|---|---|---|

| Overheating | Caused by blocked cooling passages or malfunctioning thermostat. | Inspect cooling system; replace thermostat if necessary. |

| Fuel Leakage | Leaks can occur due to worn fuel lines or faulty injectors. | Regularly check and replace any damaged components. |

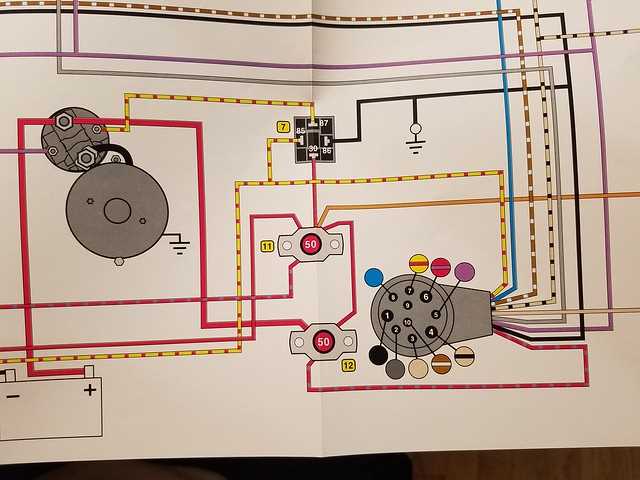

| Starting Issues | May stem from weak battery or faulty ignition system. | Test battery voltage and inspect ignition components. |

| Oil Consumption | Excessive use can indicate worn piston rings or valve seals. | Monitor oil levels and perform engine diagnostics. |

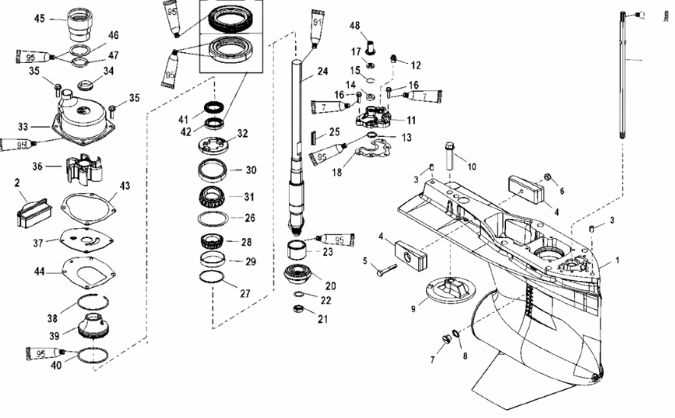

Identifying Replacement Parts

When maintaining marine engines, recognizing the necessary components is crucial for ensuring optimal performance. Each part plays a specific role, and understanding these roles can significantly enhance repair and maintenance efforts.

Common Components Overview

Familiarity with the essential elements of your engine allows for more efficient troubleshooting and replacement. Below is a summary of typical components you might encounter:

| Component | Description |

|---|---|

| Cylinder Head | Seals the top of the cylinders, essential for compression. |

| Fuel Pump | Delivers fuel from the tank to the engine. |

| Water Pump | Circulates coolant to prevent overheating. |

| Ignition Coil | Generates the spark needed for combustion. |

Tips for Identification

When seeking replacements, always refer to the specifications provided in your engine’s manual. Additionally, utilizing online resources and community forums can provide valuable insights into compatible replacements.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your marine engine involves a combination of regular upkeep and preventive measures. By following essential maintenance practices, you can enhance performance and reduce the risk of costly repairs. This section outlines key strategies to maintain your engine in optimal condition.

Regular Inspections

Frequent assessments of various components can prevent minor issues from escalating into significant problems. Focus on the following areas during your inspections:

| Component | Recommended Frequency | Notes |

|---|---|---|

| Oil Levels | Every 50 hours | Check for clarity and consistency. |

| Cooling System | Every 100 hours | Inspect for leaks and proper coolant levels. |

| Fuel System | Before each use | Look for contaminants and ensure proper filtration. |

Fluid Changes

Changing fluids at regular intervals is crucial for maintaining engine health. Ensure you adhere to the following guidelines:

- Engine oil should be replaced every 100 hours or annually, whichever comes first.

- Transmission fluid should be checked every 200 hours and replaced as needed.

- Fuel filters should be changed regularly to ensure clean fuel supply.

By following these maintenance tips, you can significantly extend the life of your marine engine, ensuring reliable performance for years to come.

Where to Find Diagrams

Locating comprehensive schematics for marine engines can greatly enhance maintenance and repair efforts. Various resources provide access to these detailed illustrations, making it easier for enthusiasts and professionals alike to understand the assembly and components involved.

One of the most reliable sources is the official manufacturer’s website, where users can often find downloadable materials and manuals. Additionally, specialized marine forums and online communities frequently share diagrams and insights, fostering a collaborative environment. Local dealerships or service centers may also offer printed resources or guidance on where to access them.

Furthermore, online marketplaces and auction sites sometimes have manuals available for purchase, catering to those seeking specific schematics. Lastly, digital libraries and archives dedicated to marine engineering can serve as excellent repositories for high-quality illustrations and technical information.

Aftermarket vs. OEM Parts

When maintaining or upgrading your marine engine, the choice between alternative and original equipment manufacturer components can significantly impact performance and longevity. Understanding the differences between these options helps in making informed decisions, ensuring that your vessel operates at its best.

Quality and Performance

Original components are designed specifically for your engine, adhering to strict manufacturer standards. They often guarantee compatibility and reliability. In contrast, alternative components can vary widely in quality, with some offering similar performance at a lower cost, while others may not meet the same rigorous benchmarks.

Cost Considerations

While original components typically come with a higher price tag, they may offer long-term savings through durability and reduced maintenance needs. Alternative components, on the other hand, can be more budget-friendly upfront but may lead to increased costs over time if they fail or require more frequent replacements.

| Criteria | OEM Components | Aftermarket Components |

|---|---|---|

| Quality | High, consistent | Varies widely |

| Compatibility | Perfect fit | May vary |

| Cost | Higher upfront | Generally lower |

| Warranty | Often included | Varies by manufacturer |

| Longevity | Typically longer | Can be shorter |

Tools Required for Repairs

When undertaking maintenance tasks, having the right equipment is crucial for efficiency and safety. This section outlines essential instruments that facilitate smooth repairs and ensure optimal performance of your machinery.

Essential Tools

To effectively address repairs, you will need a variety of tools designed for specific tasks. A combination of hand tools, power tools, and specialized instruments will enhance your repair process.

| Tool | Purpose |

|---|---|

| Socket Wrench Set | For loosening and tightening fasteners. |

| Screwdriver Set | To remove and secure screws. |

| Pliers | For gripping and bending materials. |

| Torque Wrench | To apply a specific torque to fasteners. |

| Multimeter | For measuring electrical values. |

Safety Gear

In addition to tools, safety equipment is vital to protect yourself during repairs. Wearing appropriate gear helps prevent injuries and ensures a safer work environment.

Installing New Components

When upgrading or replacing elements within a marine engine, a systematic approach is essential for achieving optimal performance. Proper installation not only enhances functionality but also extends the lifespan of the equipment. This section outlines the critical steps and considerations to ensure a smooth installation process.

Preparation and Planning

Before embarking on the installation journey, it is vital to gather all necessary tools and components. Create a checklist to verify that nothing is overlooked. Review the manufacturer’s guidelines for specific instructions and safety precautions. Taking the time to plan can prevent complications during the process.

Step-by-Step Installation

Begin by ensuring the engine is cool and the power source is disconnected. Carefully remove the old components, noting their arrangement for reference. Install the new parts methodically, following the sequence outlined in the documentation. Secure each component appropriately, checking for tightness without over-torquing. Finally, reconnect the power supply and conduct thorough tests to confirm that everything operates correctly.

Safety Precautions During Repairs

Ensuring safety during maintenance and repair work is crucial to prevent accidents and injuries. Proper precautions not only protect the individual performing the task but also safeguard the equipment and surrounding environment. A thorough understanding of safety measures can significantly reduce risks associated with mechanical work.

Personal Protective Equipment (PPE)

Wearing appropriate personal protective equipment is fundamental. This includes safety goggles to protect the eyes from debris, gloves to shield the hands from sharp edges and chemicals, and steel-toed boots to safeguard the feet. Ear protection is also recommended in noisy environments to prevent hearing damage.

Workspace Organization

A well-organized workspace minimizes hazards. Keep tools and materials in designated areas, ensuring pathways are clear. Proper ventilation is essential when working with hazardous substances, reducing the risk of inhalation. Additionally, be mindful of electrical safety; ensure tools are in good condition and that you are aware of potential electrical hazards.

Cost Considerations for Repairs

When planning maintenance or restoration for marine engines, understanding the financial implications is crucial. Various factors contribute to the overall expense, and being informed can aid in budgeting effectively.

- Parts Pricing: The cost of components can vary significantly based on quality and sourcing. Original equipment may be more expensive but could offer better durability.

- Labor Costs: Hiring a professional for repairs may incur additional charges. Rates can differ based on location and technician experience.

- Frequency of Repairs: Regular maintenance can reduce the likelihood of costly major repairs in the future, making it a smart investment.

- Diagnostic Services: Initial assessments can add to costs but are essential for accurate identification of issues, potentially saving money in the long run.

Evaluating these factors allows for a comprehensive view of potential expenditures, ultimately leading to more informed decisions regarding maintenance strategies.

Customer Reviews and Experiences

This section explores the insights and feedback from users who have engaged with their marine engines. By sharing their stories and opinions, customers provide valuable perspectives on performance, reliability, and overall satisfaction. Their experiences can guide potential buyers in making informed decisions.

Many users highlight the durability and efficiency of these engines, noting their impressive power output and fuel economy. Regular maintenance and accessibility of components are frequently praised, making upkeep straightforward for owners. A common theme among reviews is the responsiveness of customer support, ensuring that any issues are promptly addressed.

However, some experiences reveal challenges, such as sourcing specific components or navigating the initial setup. Users recommend consulting manuals and online resources to enhance understanding and streamline the installation process. Overall, the collective feedback reflects a commitment to quality and user satisfaction, fostering a loyal community of enthusiasts.