Comprehensive Guide to Volvo Penta Marine Parts Diagram

In the realm of seafaring machinery, having a clear representation of the intricate assemblies is essential for both maintenance and enhancement. This visual documentation serves as a pivotal tool for enthusiasts and professionals alike, enabling them to navigate through the complexities of various systems aboard vessels. By examining these layouts, users can gain insights into the operational synergy between different elements.

When it comes to the functionality of aquatic engines, every detail matters. The arrangement of these crucial components influences not only performance but also longevity. With a thorough understanding of how each piece interconnects, individuals can make informed decisions regarding repairs, replacements, and upgrades. This knowledge empowers them to optimize their experiences on the water.

Moreover, a well-structured representation can significantly simplify troubleshooting processes. By visualizing the relationships between elements, users can quickly identify potential issues, saving both time and resources. This proactive approach fosters a deeper appreciation for the engineering marvels that power our maritime adventures.

Understanding Volvo Penta Marine Parts

Familiarizing oneself with the components that ensure smooth operation on the water is crucial for any boating enthusiast. These essential elements work in harmony to provide reliability and performance. A comprehensive understanding of these various segments allows for better maintenance, troubleshooting, and enhancement of overall functionality.

Each unit is designed to fulfill a specific role, contributing to the vessel’s efficiency and safety. From the engine assembly to the propulsion systems, recognizing the interplay between these components can significantly impact your boating experience. It is important to be aware of the different classifications and functions, as this knowledge aids in making informed decisions regarding repairs and upgrades.

Moreover, accessing detailed illustrations or schematics of these components can greatly assist in visualizing their arrangement and interaction. This insight is invaluable for both seasoned mariners and novices alike, facilitating a deeper appreciation of the technology that powers their journeys.

In summary, understanding the intricacies of these essential elements not only enhances operational skills but also fosters a sense of confidence while navigating the waters. Armed with this knowledge, you can ensure that your vessel remains in optimal condition for countless adventures ahead.

Key Components of Volvo Penta Engines

The intricate design of marine power units consists of several essential elements that work harmoniously to deliver optimal performance and reliability. Understanding these vital components is crucial for maintenance and effective operation, ensuring longevity and efficiency on the water.

At the heart of the system lies the engine block, where combustion occurs, generating the necessary power. This component is surrounded by critical systems, including the cooling mechanism, which regulates temperature and prevents overheating. Additionally, the fuel delivery system ensures a steady supply of fuel to maintain efficient operation.

Another significant aspect is the exhaust system, which directs waste gases away from the engine, allowing for smoother performance. Complementing these are various sensors and control units that monitor and adjust engine parameters, enhancing responsiveness and safety during operation.

Lastly, the transmission system plays a pivotal role in converting engine power into propulsion, ensuring that the vessel moves efficiently through water. Together, these components form a cohesive unit, driving the vessel’s performance and ensuring a seamless experience for users.

How to Read Marine Parts Diagrams

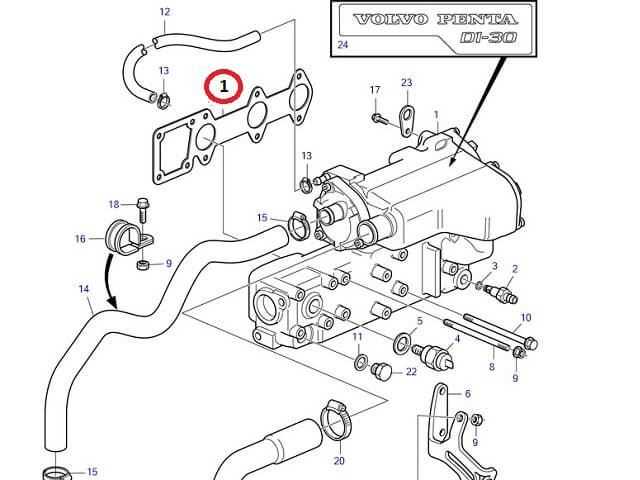

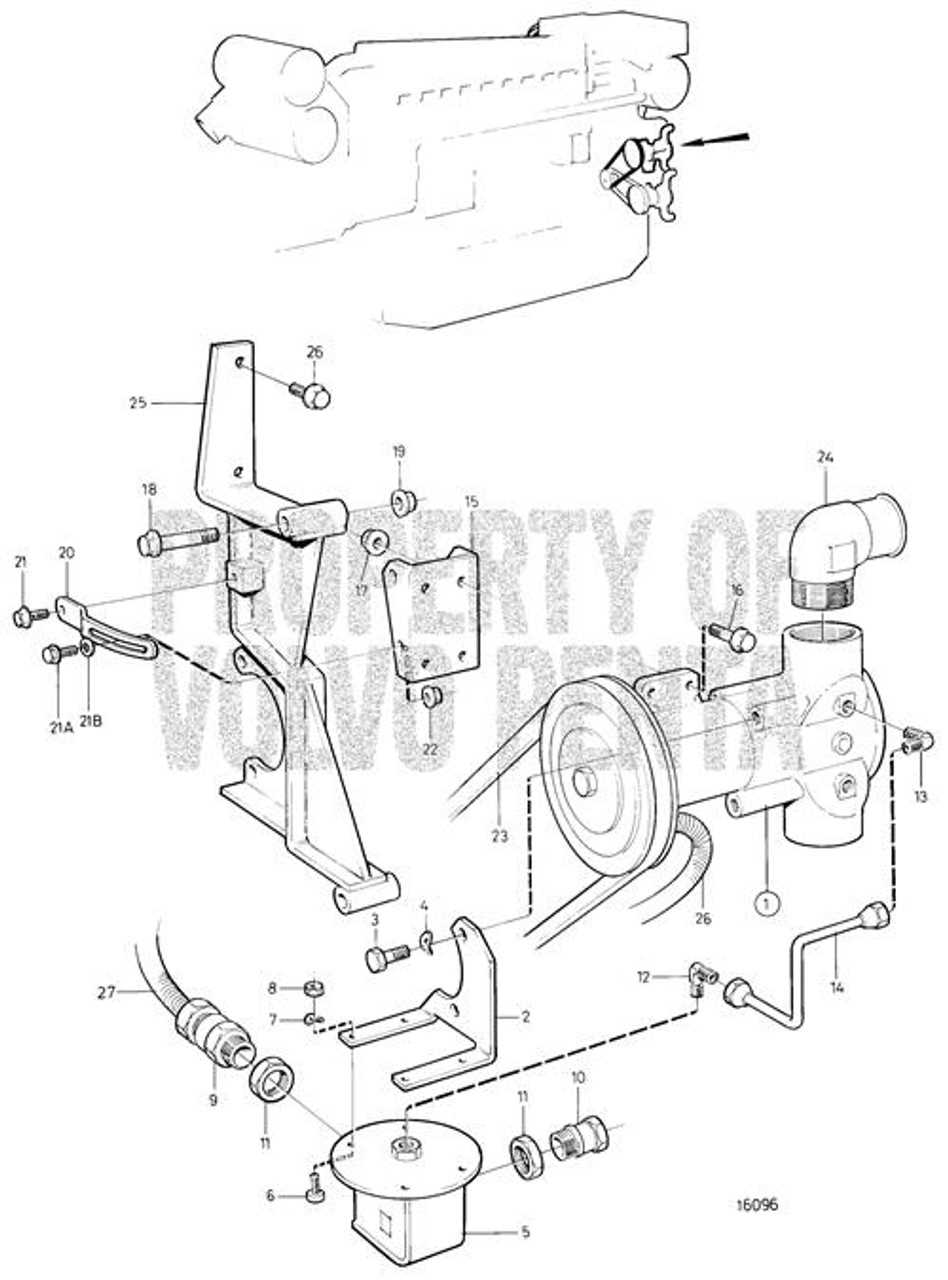

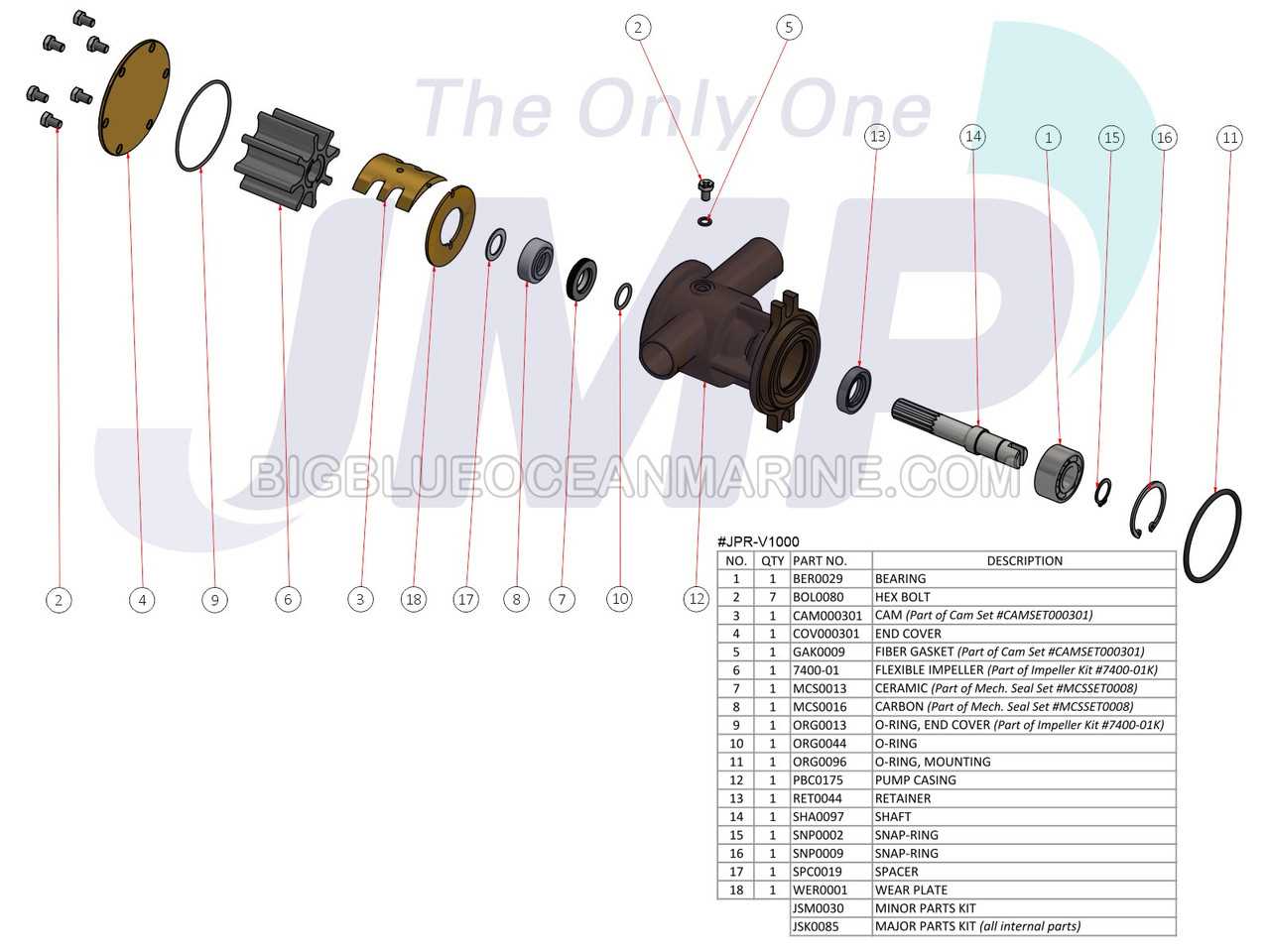

Understanding technical illustrations for watercraft components is essential for efficient maintenance and repair. These visual representations provide a detailed overview of various elements, helping users identify and locate each item within the system. Familiarity with these graphics can significantly enhance one’s ability to navigate complex assemblies.

When approaching these visuals, start by examining the legend or key, which typically explains the symbols used throughout the illustration. Each symbol corresponds to a specific component, making it easier to understand the layout. Pay attention to any notes or annotations, as they often provide critical information about installation or maintenance procedures.

Next, break down the illustration into sections. Focus on one area at a time to avoid feeling overwhelmed. Trace connections between elements to grasp how they interact with one another, which is crucial for troubleshooting or upgrading systems. It’s beneficial to cross-reference the visual with a list of components to ensure all necessary items are accounted for.

Finally, practice is key. Regularly engaging with these illustrations will improve your ability to interpret them quickly and accurately. Over time, you’ll become more adept at recognizing various components and their functions, ultimately leading to more effective repairs and enhancements.

Common Issues with Marine Parts

Understanding the frequent challenges faced with components in aquatic vehicles is crucial for maintaining optimal performance. Various factors can lead to malfunctions, ranging from wear and tear to environmental influences. Identifying these issues early can prevent more significant complications and ensure smooth operation.

Wear and Corrosion

One of the most prevalent concerns is wear and corrosion. Components exposed to saltwater environments are particularly susceptible to deterioration. Regular inspections can help detect signs of damage, allowing for timely replacements or repairs. Utilizing protective coatings and high-quality materials can significantly extend the lifespan of critical elements.

Overheating and Cooling Failures

Another issue often encountered is overheating. Inadequate cooling systems can lead to excessive temperatures, potentially causing serious damage to internal mechanisms. Regular maintenance, including checking coolant levels and ensuring proper airflow, is essential to avoid overheating and maintain efficient operation.

Maintenance Tips for Volvo Penta Systems

Proper upkeep of your engine and propulsion systems is crucial for ensuring longevity and optimal performance. Regular attention to key components not only enhances reliability but also minimizes the risk of unexpected breakdowns during usage. Here are some essential practices to consider for effective maintenance.

Routine Inspections

Performing regular inspections of your equipment can help identify potential issues before they escalate. Check for signs of wear or damage, focusing on vital areas such as hoses, belts, and electrical connections. Make it a habit to inspect fluid levels and look for leaks, as maintaining appropriate levels is essential for smooth operation.

Scheduled Maintenance Tasks

Adhering to a consistent maintenance schedule is fundamental. Change lubricants and filters as recommended by the manufacturer, and ensure cooling systems are functioning properly. Additionally, pay attention to the condition of the propeller and hull, as these elements significantly impact performance. Keeping everything in peak condition will not only enhance efficiency but also improve safety on the water.

Replacement Parts: What You Need to Know

When it comes to maintaining your vessel, understanding the essentials of substitute components is crucial. Whether you are performing routine maintenance or addressing unexpected failures, knowing what to look for and how to choose the right replacements can significantly impact your vessel’s performance and longevity.

Here are some key considerations to keep in mind:

- Quality Matters: Always opt for high-quality replacements to ensure durability and compatibility.

- Compatibility: Verify that the component is suitable for your specific model to avoid any fitting issues.

- Manufacturer Recommendations: Consult the manufacturer’s guidelines for approved replacements to maintain warranty coverage.

- Installation: Consider whether you will handle the installation yourself or need professional assistance. Some parts may require specialized knowledge.

- Cost vs. Value: Balance the cost of the replacement with its long-term value. Sometimes a higher initial investment can save money down the line.

By focusing on these aspects, you can make informed decisions that enhance the reliability and efficiency of your vessel.

Benefits of Using Genuine Parts

Choosing authentic components for your vessel’s maintenance is crucial for ensuring optimal performance and longevity. These original items are specifically designed to fit perfectly and function seamlessly, offering a level of reliability that aftermarket alternatives often cannot match.

Quality Assurance

One of the primary advantages of opting for original components is the assurance of quality. These items are produced to meet strict standards, ensuring:

- Enhanced durability

- Consistent performance

- Fewer breakdowns and repairs

Warranty and Support

Utilizing genuine components often comes with additional benefits, such as warranty coverage and customer support. This can include:

- Comprehensive warranty terms

- Access to professional advice and assistance

- Peace of mind knowing that the manufacturer stands behind their product

In summary, investing in authentic components is not just a choice; it is a commitment to quality, reliability, and long-term value for your maritime endeavors.

Where to Find Parts Diagrams Online

Locating detailed illustrations and schematics for components can be essential for maintenance and repairs. Fortunately, a variety of online resources are available to assist in this search. Below are several avenues to explore when seeking these valuable references.

- Official Manufacturer Websites: Many companies provide comprehensive resources directly on their sites, including user manuals and technical drawings.

- Dedicated Online Forums: Communities focused on specific brands or types of equipment often share diagrams and insights that can aid in your search.

- Online Retailers: Some e-commerce platforms specialize in equipment and may offer access to schematics alongside their product listings.

- Technical Documentation Repositories: Websites that aggregate technical documents can be a treasure trove of information, including schematic representations.

- YouTube Tutorials: Video guides often include visual breakdowns of components, and the description sections may link to further resources.

By utilizing these resources, users can efficiently find the illustrations needed to assist with repairs and ensure optimal performance of their equipment.

DIY Repairs: Step-by-Step Guide

Engaging in self-repairs can be a rewarding experience, allowing you to save time and money while enhancing your skills. This guide will walk you through essential steps to troubleshoot and fix common issues effectively. Whether you’re dealing with mechanical failures or electrical malfunctions, following a systematic approach can lead to successful outcomes.

Essential Tools and Materials

Before starting any repair task, it’s crucial to gather the right tools and materials. Below is a list of commonly needed items:

| Tool/Material | Purpose |

|---|---|

| Screwdriver Set | To remove and secure screws |

| Wrench Set | For loosening and tightening nuts and bolts |

| Multimeter | To test electrical components |

| Sealant | To prevent leaks |

| Replacement Parts | For any worn or damaged components |

Step-by-Step Process

Follow these steps to ensure a smooth repair process:

1. Identify the Issue: Start by observing the problem closely. Listen for unusual sounds or look for visible signs of wear.

2. Consult Documentation: Refer to manuals or online resources for specific troubleshooting techniques related to your situation.

3. Disassemble Components: Carefully take apart the necessary parts, ensuring you keep track of screws and small pieces.

4. Replace or Repair: Depending on the damage, either replace the faulty components or make necessary adjustments.

5. Reassemble and Test: Put everything back together, and run a test to ensure that the problem has been resolved.

By following this guide, you can tackle various repairs with confidence, ensuring your equipment operates smoothly for years to come.

Understanding Engine Performance Metrics

Analyzing the performance indicators of a power unit is essential for optimizing its efficiency and longevity. These metrics provide insights into how effectively the engine converts fuel into mechanical energy, ensuring that it operates within its designed parameters. Understanding these values allows operators to make informed decisions about maintenance and adjustments.

Key Performance Indicators

Among the primary metrics to consider are horsepower, torque, and fuel efficiency. Horsepower reflects the engine’s ability to perform work, while torque indicates the rotational force produced. Both metrics are crucial for assessing the overall power output and suitability for specific applications. Fuel efficiency, often measured in miles per gallon or liters per hour, determines how well the engine utilizes fuel, impacting operational costs and environmental considerations.

Monitoring and Adjustments

Regular monitoring of these indicators enables timely adjustments to enhance performance. For instance, if fuel efficiency declines, it may signal issues such as improper tuning or mechanical wear. By addressing these concerns promptly, operators can maintain optimal functionality and reduce the risk of costly repairs. Continuous evaluation of performance metrics is vital for achieving peak operation and ensuring the reliability of the engine over time.

Choosing the Right Parts Supplier

Selecting an appropriate supplier for your components is crucial for ensuring the reliability and performance of your equipment. The right provider not only offers quality items but also delivers exceptional service, helping you maintain your systems efficiently. In this section, we will explore key factors to consider when evaluating potential vendors for your needs.

| Criteria | Importance | Considerations |

|---|---|---|

| Quality Assurance | High | Look for suppliers with certifications and a reputation for reliability. |

| Product Availability | Medium | Ensure the supplier has a wide inventory to meet your specific requirements. |

| Customer Service | High | Responsive support is essential for addressing any issues promptly. |

| Pricing | Medium | Compare prices but avoid compromising on quality for cost savings. |

| Delivery Options | Medium | Check for reliable shipping methods and lead times that fit your schedule. |

| Warranty and Returns | High | Understand the warranty terms and return policy for peace of mind. |

By carefully assessing these factors, you can identify a supplier that aligns with your operational goals and ensures the longevity of your systems.