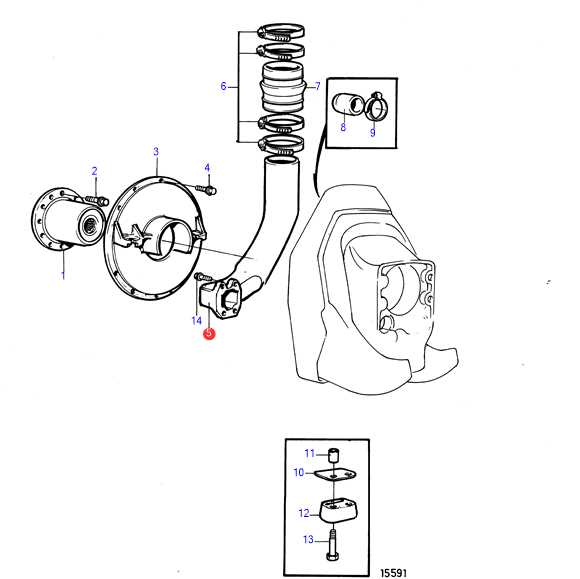

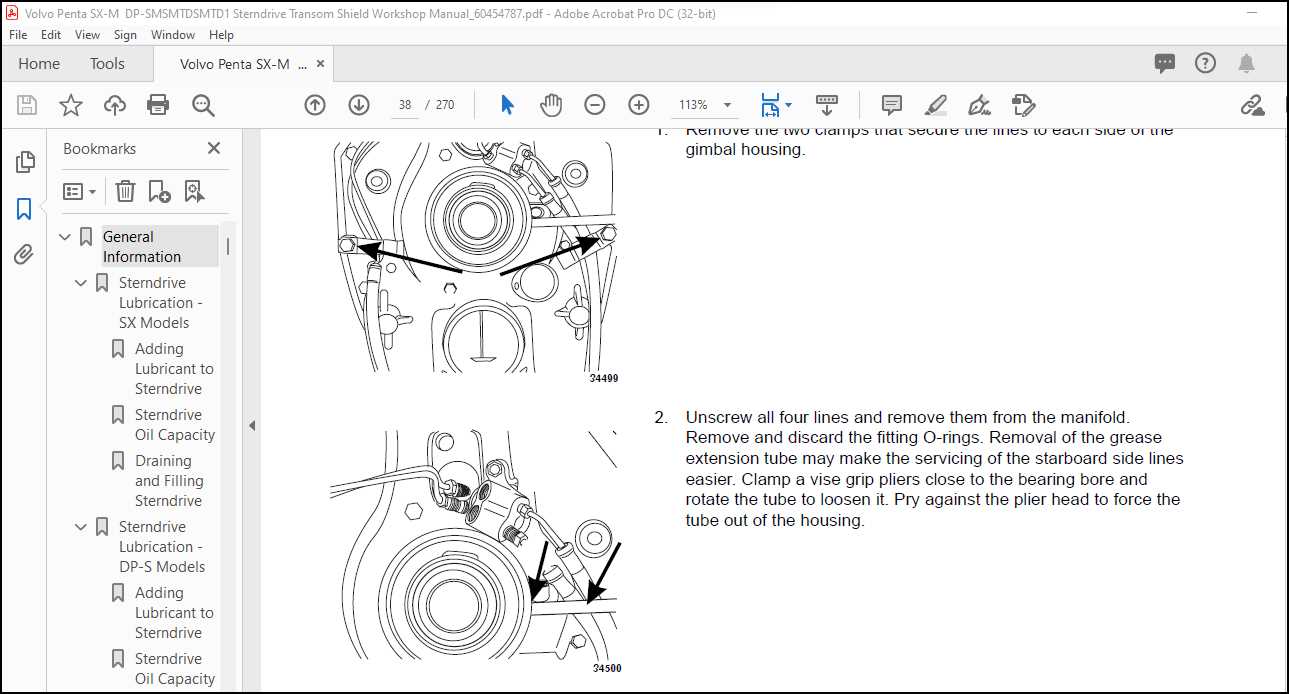

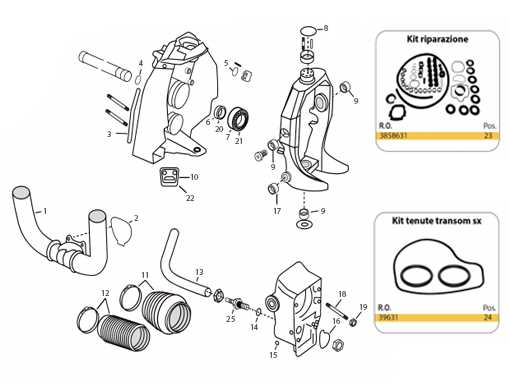

| Water Pump and Cooling Mechanism

The efficiency of a marine engine heavily relies on its cooling system, particularly the water pump, which plays a critical role in maintaining optimal temperatures. This component circulates coolant through the engine, ensuring that heat generated during operation is effectively dissipated. A well-functioning cooling mechanism is essential for preventing overheating and ensuring the longevity of the engine.

Functionality of the Water Pump

The water pump is designed to draw in water from the surrounding environment and propel it through the engine’s cooling circuit. Its operation is crucial for:

- Maintaining appropriate temperature levels

- Enhancing engine performance

- Preventing potential damage due to overheating

Components of the Cooling System

A typical cooling system consists of several key elements that work together with the water pump:

- Thermostat: Regulates coolant flow based on temperature.

- Heat Exchanger: Transfers heat from the engine to the cooling medium.

- Hoses and Fittings: Facilitate the movement of coolant throughout the system.

- Coolant Reservoir: Stores the coolant for the system, allowing for expansion and contraction.

Understanding the function and components of the cooling mechanism is vital for maintaining engine health and preventing malfunctions.

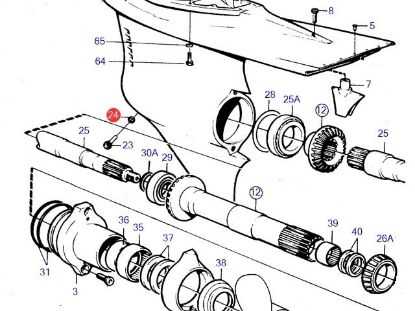

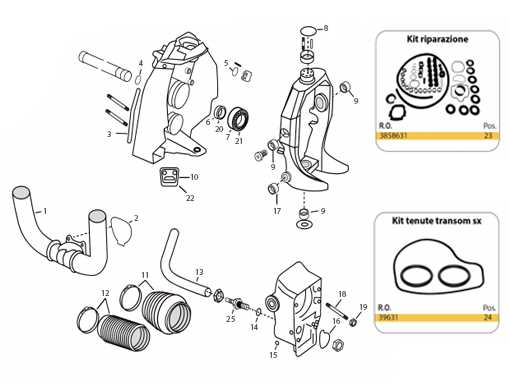

Drive Bellows and Their Importance

Drive bellows serve as essential components in marine propulsion systems, playing a crucial role in ensuring optimal functionality and performance. These flexible enclosures are designed to protect vital internal mechanisms from water intrusion and external contaminants.

The importance of drive bellows can be highlighted through several key aspects:

- Protection: Bellows create a barrier against water and debris, safeguarding internal parts from potential damage.

- Flexibility: Their design allows for necessary movement during operation, accommodating changes in angle and alignment.

- Maintenance: Regular inspection of bellows can prevent more significant issues, ensuring the longevity of the entire system.

- Performance: Well-functioning bellows contribute to smoother operation, enhancing overall efficiency and reliability.

In summary, maintaining the integrity of drive bellows is vital for the longevity and effectiveness of marine propulsion systems. Proper care and timely replacement can significantly impact overall performance and safety.

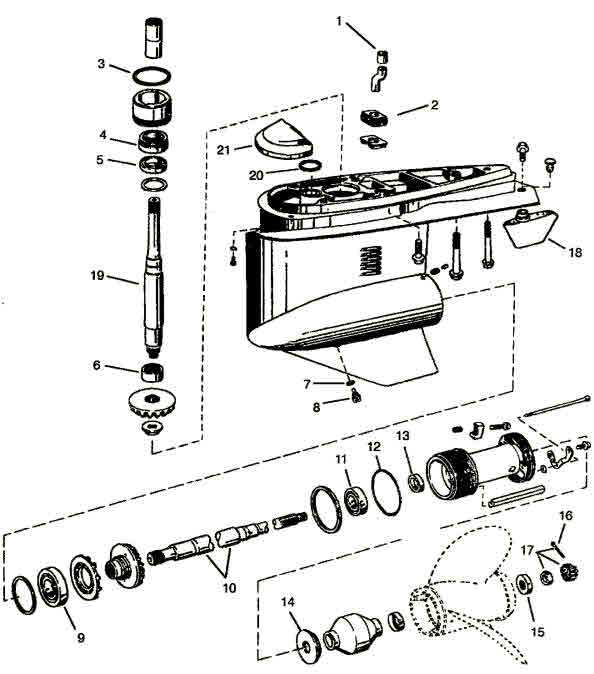

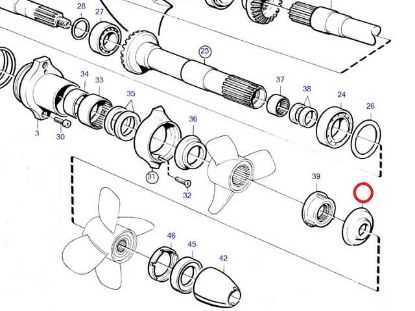

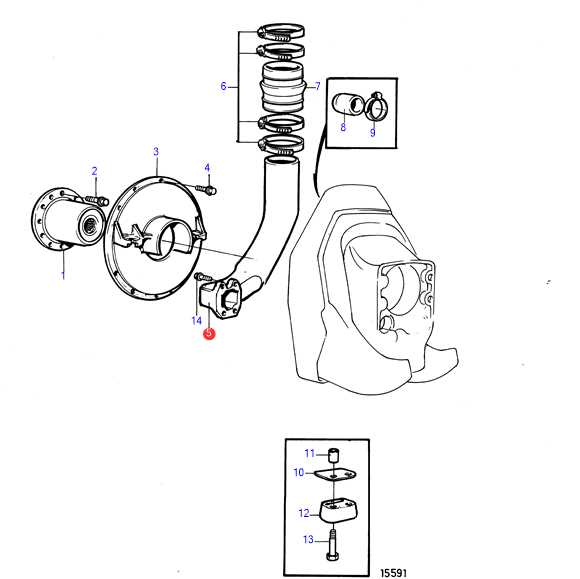

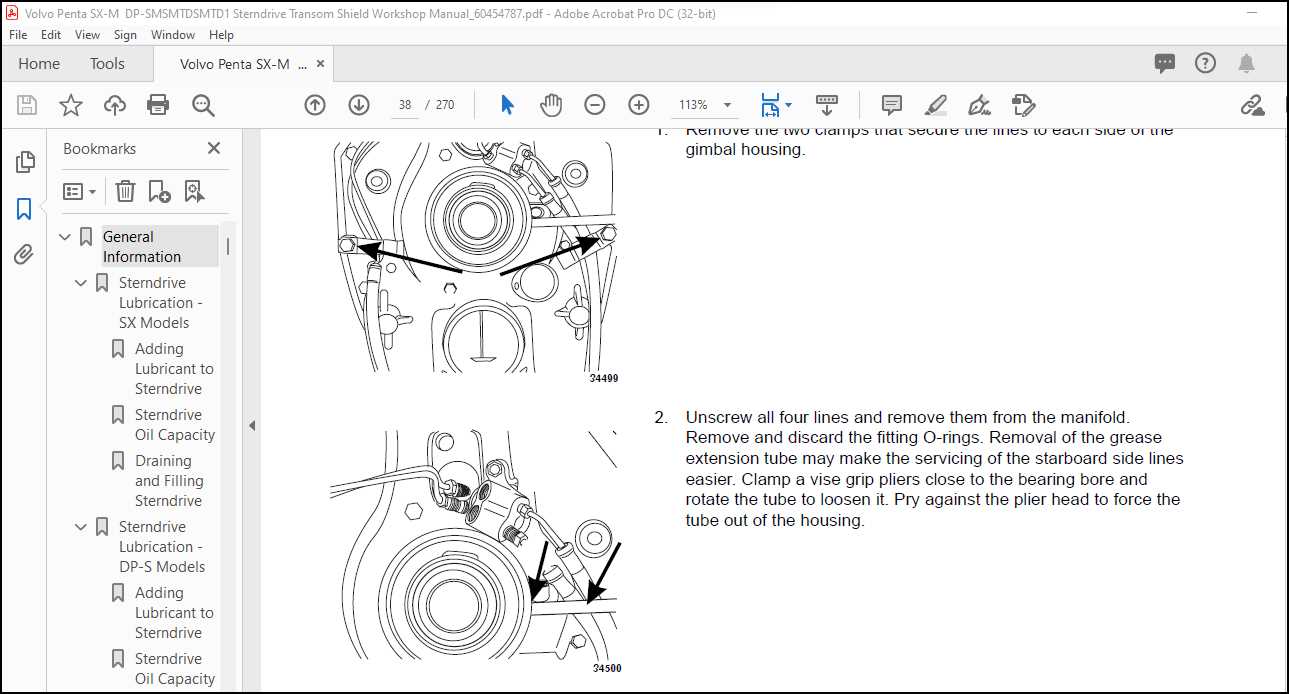

Lubrication and Oil Flow Diagram

The efficiency of marine propulsion systems relies heavily on effective lubrication mechanisms. Understanding the flow of lubricants is crucial for maintaining optimal performance and extending the lifespan of various components. Proper oil circulation ensures that moving parts receive adequate protection against wear and tear, thereby enhancing reliability.

Within this framework, the lubrication system typically incorporates several key elements that facilitate the distribution of oil. Oil pumps play a vital role in drawing lubricant from a reservoir and directing it to necessary areas. Filters are equally important, as they remove contaminants from the oil, ensuring that only clean fluid circulates throughout the system. Additionally, pressure relief valves help maintain appropriate pressure levels, preventing potential damage from excessive pressure buildup.

Moreover, the flow of lubricant is designed to reach critical components, such as bearings and gears, where friction is most prevalent. This targeted approach minimizes the risk of overheating and prolongs the operational life of these parts. In summary, a well-structured lubrication system not only safeguards mechanical integrity but also optimizes the overall functionality of the propulsion mechanism.

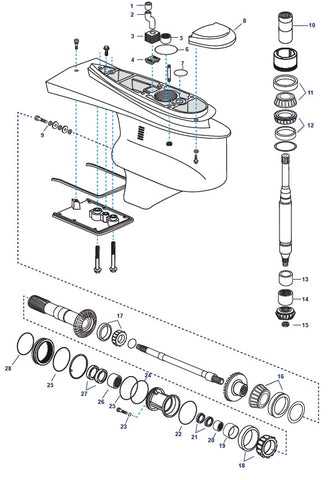

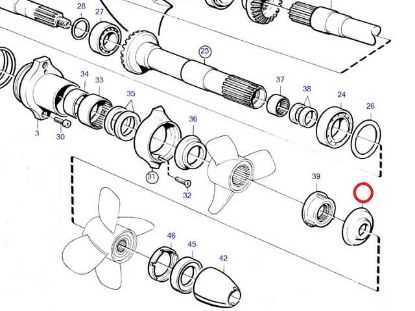

Internal Seals and Gaskets Overview

Internal seals and gaskets play a crucial role in ensuring the optimal performance of marine propulsion systems. These components are designed to prevent the leakage of fluids and maintain the integrity of various systems within the assembly. Their effective functioning is vital for safeguarding the machinery from potential damage caused by environmental factors and operational pressures.

Functionality and Importance

The primary function of internal seals is to create a barrier that prevents the escape of lubricants and other essential fluids. This is essential for maintaining proper lubrication and reducing wear on moving parts. Gaskets, on the other hand, are employed to fill the gaps between mating surfaces, ensuring a tight seal that protects against contaminants and pressure loss. Both components contribute significantly to the overall reliability and efficiency of the mechanical system.

Types of Seals and Gaskets

There are various types of seals and gaskets used in marine applications, each designed for specific functions and materials. Understanding these variations helps in selecting the right components for maintenance and repair. Below is a table summarizing some common types and their applications:

| Type |

Material |

Application |

| O-Ring |

Nitrile Rubber |

Rotary shafts and static seals |

| Flat Gasket |

Fiberglass |

Flange connections |

| Backup Ring |

Polyurethane |

Support for O-rings under pressure |

| Sealant Gasket |

Silicone |

Engine components and various assemblies |

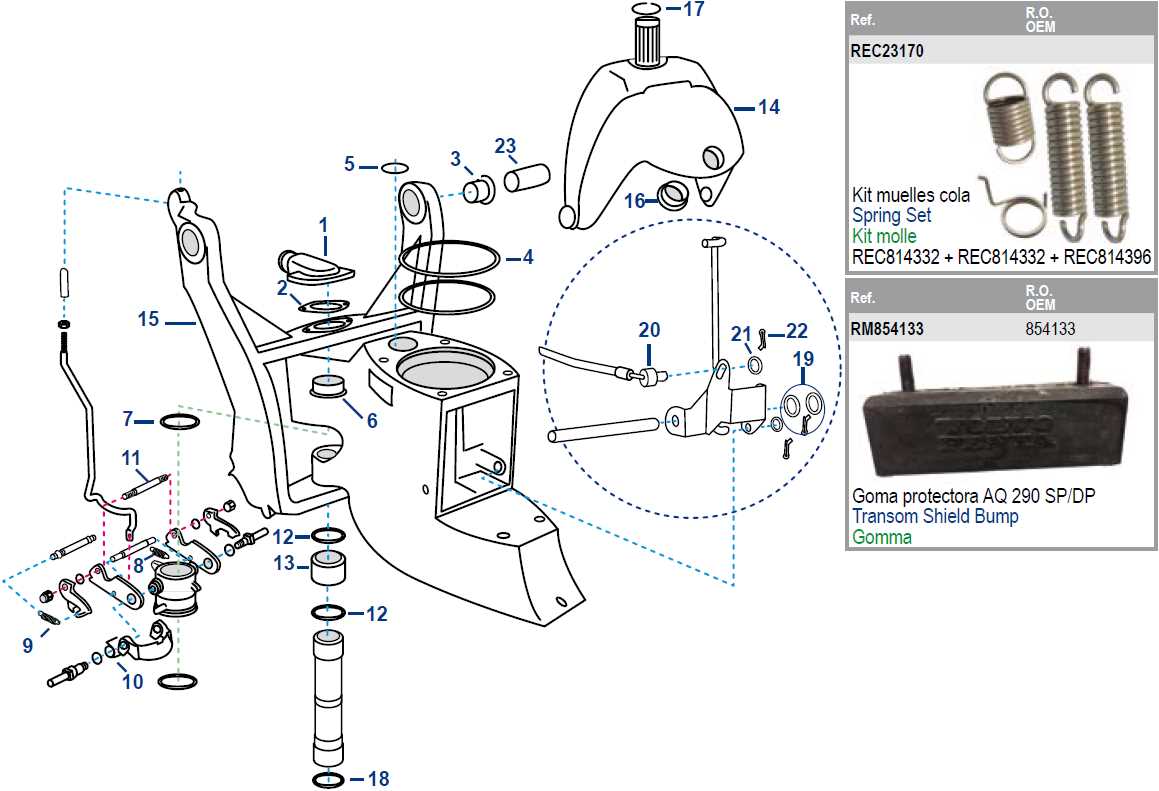

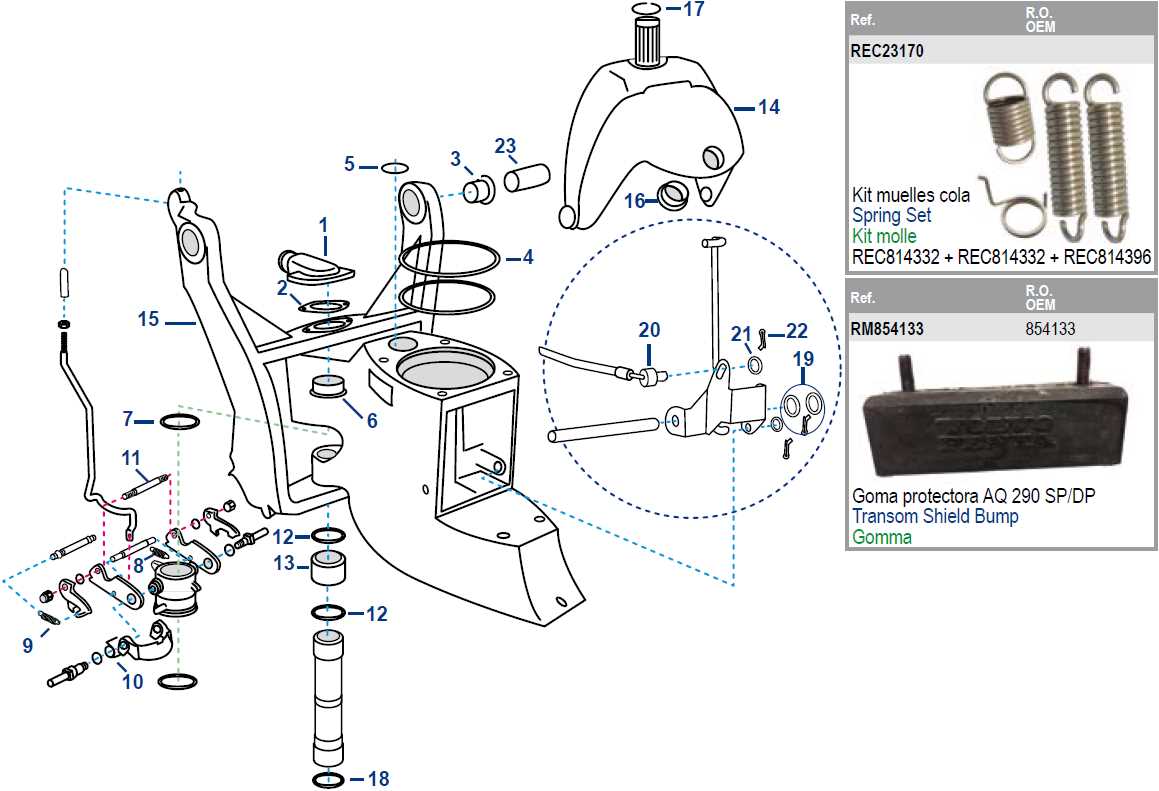

Trim and Tilt Mechanism Explained

The trim and tilt system is an essential component in enhancing the performance and handling of marine vessels. This mechanism allows for the adjustment of the propulsion unit’s angle relative to the water surface, enabling better control during navigation. By modifying the tilt angle, users can optimize speed, fuel efficiency, and stability, which ultimately contributes to a more enjoyable boating experience.

Functionality and Benefits

This mechanism operates through hydraulic systems that facilitate the movement of the propulsion unit. By utilizing controls located within the cockpit, operators can easily raise or lower the unit, adapting to varying water conditions and vessel loads. Such adjustments help to prevent cavitation, reduce drag, and improve overall maneuverability, making it a vital feature for both recreational and professional marine activities.

Maintenance Considerations

Regular inspection and maintenance of the trim and tilt system are crucial for ensuring optimal performance. Common issues can arise from hydraulic fluid leaks, worn seals, or electrical malfunctions. By keeping the system well-maintained, vessel owners can prevent costly repairs and ensure consistent operational efficiency, contributing to the longevity of their marine equipment.

Maintenance Tips for Long-Term Performance

Ensuring optimal functionality and durability of your marine propulsion system requires diligent care and routine upkeep. By following a structured maintenance regimen, you can enhance performance, prevent issues, and extend the lifespan of crucial components.

Here are some essential practices to keep in mind:

- Regular Inspection: Conduct frequent visual checks for signs of wear, corrosion, or damage. Pay special attention to seals, connections, and any exposed areas.

- Fluid Replacement: Regularly change lubricants and hydraulic fluids as per manufacturer recommendations. This helps maintain proper functioning and reduces friction.

- Cleanliness: Keep all components clean and free of debris. Use appropriate cleaning agents and techniques to avoid damaging sensitive parts.

- Electrical Systems: Inspect wiring and connections for corrosion or damage. Ensure all electrical systems are functioning correctly to avoid potential failures.

- Winterization: Prepare the system for off-season storage by following proper winterization steps. This includes draining fluids, adding antifreeze, and protecting against environmental factors.

By adhering to these maintenance tips, you will not only improve the reliability of your marine system but also enjoy smoother and more efficient operation for years to come.

|