Comprehensive Guide to Volvo SX Outdrive Parts Diagram

The intricate world of marine propulsion systems encompasses a variety of essential elements that ensure optimal performance and reliability on the water. A thorough comprehension of these components is crucial for both enthusiasts and professionals alike, facilitating effective maintenance and repairs.

In this section, we will explore the detailed arrangement of critical mechanisms that play a pivotal role in driving vessels. By examining these assemblies, individuals can gain insight into their functionality and interconnections, paving the way for improved operation and troubleshooting.

Whether you are seeking to enhance your knowledge for personal projects or professional undertakings, a closer look at these vital components will ultimately empower you to make informed decisions and maintain the longevity of your marine equipment. Join us as we delve into this fascinating topic and uncover the intricacies of marine drive systems.

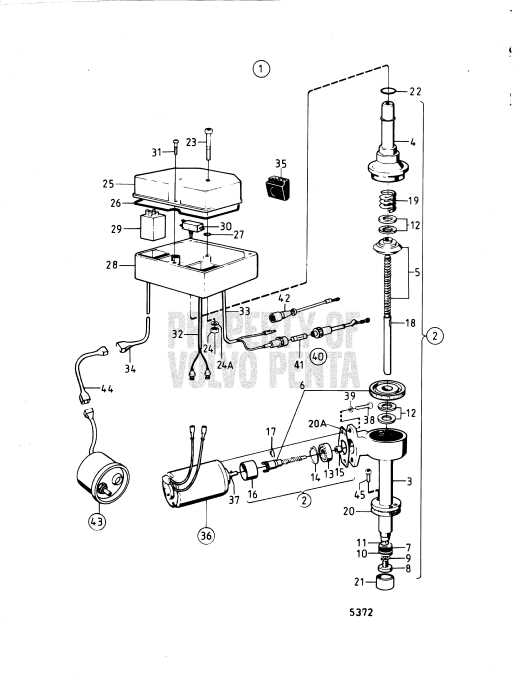

Understanding Volvo SX Outdrive Components

This section explores the essential elements that contribute to the functionality of marine propulsion systems. A comprehensive grasp of these components is crucial for maintenance and performance optimization.

- Drive Unit: Central to the mechanism, responsible for transferring power from the engine.

- Propeller: Converts rotational energy into thrust, critical for movement.

- Gimbal Housing: Supports the drive unit while allowing for tilt and steering.

- Trim Tab: Adjusts the angle of the unit to enhance performance and stability.

- Oil Seal: Prevents leakage and protects internal components from water intrusion.

Understanding these elements allows for better troubleshooting and effective maintenance strategies, ultimately leading to improved operational efficiency.

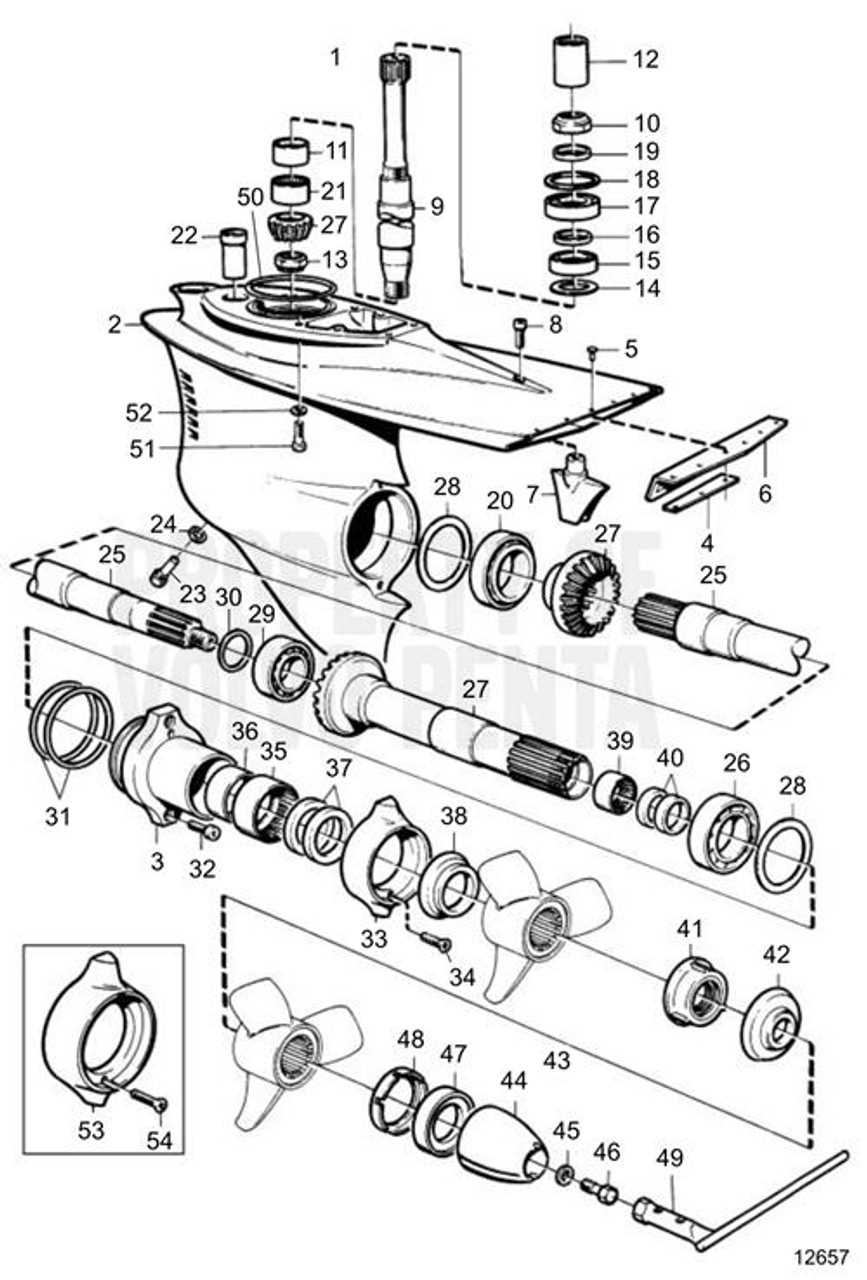

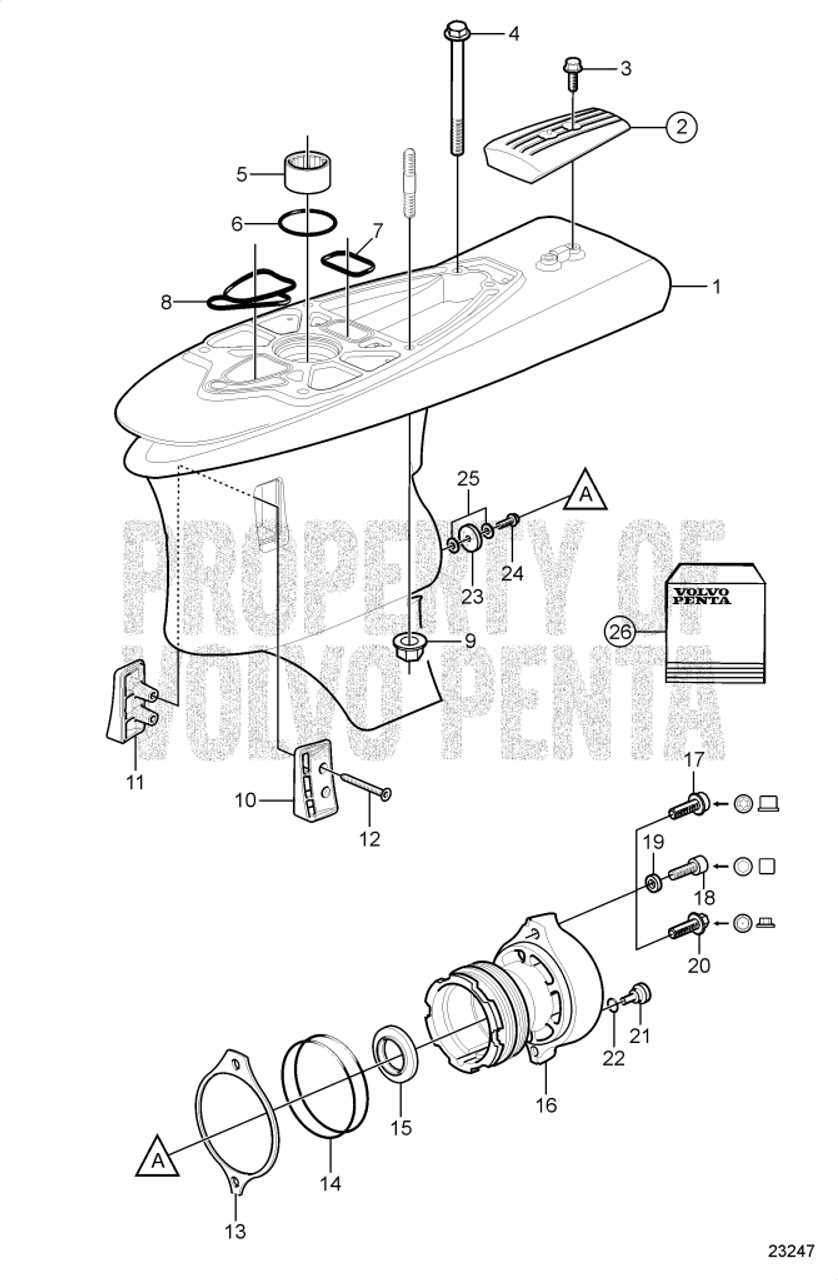

Essential Parts of the Outdrive

Understanding the fundamental components of marine propulsion systems is crucial for optimal performance and maintenance. Each element plays a significant role in ensuring the vessel operates smoothly and efficiently in various water conditions.

- Gearcase: This housing protects the internal mechanisms and contains the gears necessary for transferring power from the engine to the propeller.

- Propeller: The vital component that converts rotational energy into thrust, allowing the boat to move through the water.

- Drive Shaft: This rod transmits power from the engine to the gearcase, facilitating the movement of the propeller.

- Trim Tab: An adjustable fin that helps stabilize the vessel and improve handling by controlling the angle of the propeller in the water.

- Transom Plate: The structure that mounts the assembly to the boat, providing support and alignment for the entire propulsion system.

Regular inspection and maintenance of these key components can prevent breakdowns and enhance the lifespan of the entire assembly, ensuring safe and reliable navigation.

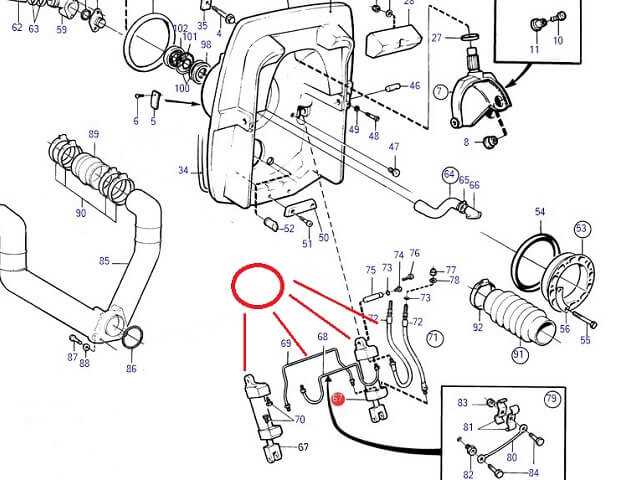

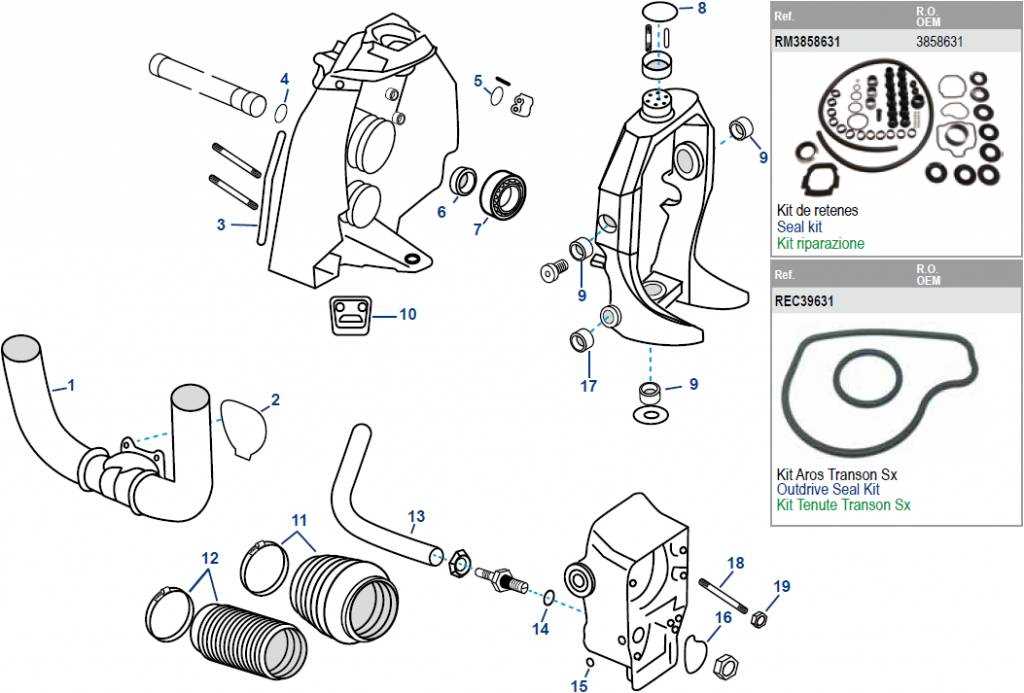

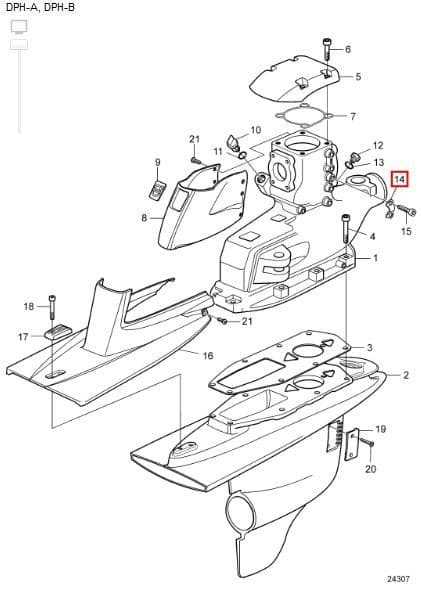

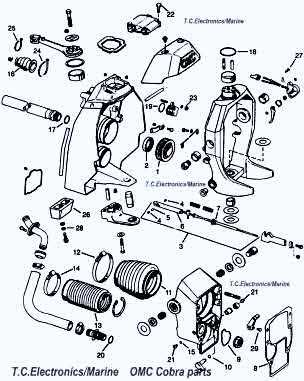

Diagram Overview for Easy Reference

This section serves as a comprehensive guide, simplifying the understanding of the assembly components involved in marine propulsion systems. It offers a structured representation that enhances clarity and accessibility, enabling users to identify essential elements quickly.

Component Identification

Each section is designed to facilitate the identification of critical components, promoting efficiency in maintenance and repair tasks.

| Component Name | Description |

|---|---|

| Drive Shaft | Transmits power from the engine to the propeller. |

| Gear Assembly | Facilitates speed and torque adjustment. |

| Seal | Prevents water ingress and maintains lubrication. |

| Trim Tab | Improves steering and stability in water. |

Utilizing the Overview

By consulting this structured overview, users can effectively navigate through the various components, ensuring accurate assessments and informed decisions in their marine operations.

Functionality of Each Component Explained

This section delves into the essential roles played by various elements within the system, highlighting their significance in overall performance and reliability.

- Gear Assembly: Responsible for transmitting power efficiently, ensuring smooth operation.

- Propeller: Converts rotational energy into thrust, enabling movement through water.

- Shaft: Acts as a connector between the engine and the propeller, facilitating power transfer.

- Seal: Prevents water ingress, protecting internal components from damage.

- Trim Tab: Enhances stability and control, allowing for better handling at various speeds.

Understanding each component’s function is crucial for maintaining optimal performance and longevity.

Common Issues with Outdrive Parts

When operating marine propulsion systems, certain challenges frequently arise that can affect performance and reliability. Understanding these issues is crucial for maintaining optimal functionality and ensuring safe navigation.

Wear and Tear: Over time, components may experience degradation due to exposure to harsh marine environments. Regular inspections can help identify signs of wear early.

Corrosion: Saltwater can lead to significant deterioration of metal components. Employing protective coatings can mitigate this risk.

Sealing Failures: Gaskets and seals can become compromised, resulting in leaks that affect overall system efficiency. Replacing worn seals promptly is essential.

Misalignment: Proper alignment is critical for smooth operation. Misalignment can cause excessive vibration, leading to further damage if not addressed quickly.

Clogged Filters: Debris accumulation in filters can restrict flow and reduce performance. Regular maintenance ensures filters are clean and functioning effectively.

How to Identify Worn Parts

Recognizing signs of deterioration in mechanical components is crucial for maintaining optimal performance and safety. By understanding the indicators of wear, you can prevent further damage and ensure longevity.

- Visual Inspection: Look for cracks, discoloration, or unusual wear patterns.

- Surface Feel: Check for roughness or pitting that may indicate wear.

- Measurement: Use calipers or gauges to compare dimensions against specifications.

- Functionality Test: Observe any changes in performance during operation.

Regularly assessing these factors will help in making informed decisions about replacements or repairs, ultimately enhancing reliability and efficiency.

Maintenance Tips for Longevity

Ensuring the durability and performance of your marine equipment requires a proactive approach to upkeep. Regular attention to maintenance can significantly extend the lifespan of your machinery, preventing costly repairs and downtime.

Routine Inspections

Frequent assessments of components are essential. Look for signs of wear, corrosion, or leaks. Addressing minor issues before they escalate can save both time and money.

Lubrication and Cleaning

Keeping moving parts well-lubricated reduces friction and wear. Regular cleaning helps prevent the buildup of debris that can hinder functionality.

| Maintenance Task | Frequency |

|---|---|

| Visual Inspection | Monthly |

| Lubrication | Every 3 Months |

| Thorough Cleaning | Biannually |

| Fluid Replacement | Annually |

Replacing Components Safely

When it comes to maintaining mechanical systems, ensuring the secure replacement of various elements is crucial for both performance and safety. This process requires a systematic approach to avoid potential hazards and guarantee that all components function harmoniously together. Adopting proper techniques and adhering to safety protocols can greatly enhance the reliability of the equipment.

Preparation and Safety Measures

Before beginning any replacement task, it is essential to prepare adequately. Start by gathering all necessary tools and materials, ensuring that they are in good condition. Personal protective equipment, such as gloves and goggles, should be worn to minimize the risk of injury. Additionally, consult relevant manuals to understand the specific requirements and procedures for the task at hand.

Installation Techniques

When installing new components, take care to follow manufacturer instructions closely. Alignment is critical; ensure that all parts fit correctly without forcing them into place. Torque specifications should be adhered to during fastening, as this prevents damage and promotes optimal functionality. After installation, perform a thorough inspection to confirm that everything is secure and functioning properly before operating the system.

Upgrades for Improved Performance

Enhancing the efficiency and capability of your marine propulsion system can significantly elevate your boating experience. By focusing on key components, you can achieve better handling, speed, and fuel efficiency.

Key Areas for Improvement

- Propeller Optimization

- Transmission Enhancements

- Hydraulic System Upgrades

- Cooling System Improvements

Recommended Upgrades

- Install a high-performance propeller for increased thrust.

- Upgrade the gear ratio for enhanced acceleration.

- Incorporate a more efficient hydraulic system for better control.

- Enhance the cooling system to prevent overheating during extended use.

Resources for Parts Acquisition

Finding reliable sources for obtaining essential components is crucial for maintaining and repairing marine equipment. Whether you are seeking new items, used options, or hard-to-find elements, a variety of avenues exist to assist in your quest. Utilizing both online and local resources can streamline the process, ensuring you have access to the necessary tools for effective maintenance.

Online Marketplaces

Web platforms provide a vast selection of components, often at competitive prices. Websites specializing in marine supplies frequently feature detailed listings and customer reviews, helping you make informed decisions. Additionally, auction sites can offer unique opportunities to discover rare or discontinued items, often at lower costs.

Local Dealers and Salvage Yards

Visiting local distributors and salvage facilities can yield valuable finds, as these venues may stock both new and second-hand options. Establishing relationships with local suppliers can also lead to insights about upcoming shipments or exclusive deals. Engaging with community forums can further enhance your search by connecting you with fellow enthusiasts who might share leads on where to find specific components.

DIY Repairs vs. Professional Help

When it comes to maintaining and fixing marine equipment, enthusiasts often find themselves at a crossroads: tackle the challenges themselves or seek expert assistance. Both options have their merits, and understanding the benefits and drawbacks can significantly impact the outcome of repairs.

Benefits of DIY Repairs

Engaging in self-repairs can lead to substantial cost savings and a sense of accomplishment. Additionally, taking the time to learn about the machinery allows for a deeper understanding and connection with the equipment. However, this approach requires a commitment to research and the acquisition of necessary skills.

When to Seek Professional Assistance

On the other hand, enlisting the help of a specialist ensures that repairs are conducted with expertise and efficiency. Professionals often possess the tools and knowledge to address complex issues that may be beyond the scope of a DIY enthusiast. Ultimately, knowing when to ask for help can save time and prevent costly mistakes.

Understanding Service Manuals and Diagrams

Service manuals and visual aids are essential tools for anyone involved in maintenance and repair tasks. They provide comprehensive insights into the assembly, disassembly, and troubleshooting of complex machinery. By using these resources, technicians can ensure they follow the correct procedures, enhancing both efficiency and safety.

Service manuals typically include detailed descriptions, specifications, and step-by-step instructions, allowing users to tackle repairs with confidence. Visual aids, on the other hand, complement these texts by illustrating components and their relationships, making it easier to identify parts and their functions.

Utilizing these resources not only streamlines the repair process but also extends the lifespan of equipment. Understanding how to navigate these manuals is crucial for achieving optimal results in any maintenance endeavor.