Understanding the Bradley Eyewash Parts Diagram

In environments where safety is paramount, understanding the key elements of emergency flushing systems is crucial. These mechanisms play a vital role in ensuring immediate response to potential hazardous exposures, providing a lifeline for individuals in distress. A clear comprehension of their construction and functionality is essential for effective maintenance and operation.

Within this section, we will explore the intricate assembly of these crucial safety devices. By dissecting their various components, users can gain insights into how each element contributes to the overall efficacy of the system. Familiarity with these features not only enhances safety preparedness but also aids in troubleshooting and repairs.

Furthermore, grasping the configuration of these systems empowers users to implement best practices for upkeep. With the right knowledge, personnel can ensure that these vital safety measures remain operational and ready to provide assistance when it matters most. A thorough understanding of the system’s layout can ultimately enhance workplace safety protocols.

Understanding Bradley Eyewash Components

This section explores the essential elements of emergency flushing systems designed to provide immediate relief during hazardous incidents. Understanding the individual components and their functions is crucial for maintaining safety in environments where exposure to harmful substances may occur.

Key Components: At the heart of these systems are the flushing outlets, which deliver a steady stream of water to cleanse affected areas. The activation mechanism allows for quick engagement, ensuring that assistance is available without delay. Additionally, the water supply connections play a vital role in maintaining adequate pressure and flow.

Maintenance Importance: Regular inspection and maintenance of these components ensure optimal performance. Any malfunctions can compromise the effectiveness of the system, making it imperative to keep each part in top condition.

Importance of Eyewash Stations

The presence of emergency flushing systems in workplaces is crucial for ensuring the safety and well-being of employees. These installations provide immediate assistance in cases of chemical exposure or other hazardous incidents, effectively minimizing the risk of long-term damage. Their strategic placement and proper maintenance can significantly influence the outcome of an emergency situation.

| Key Benefits | Description |

|---|---|

| Rapid Response | Ensures quick access to cleansing solutions in emergencies, reducing potential harm. |

| Compliance | Helps organizations meet safety regulations and standards, avoiding legal issues. |

| Employee Confidence | Promotes a culture of safety, reassuring staff about workplace hazards. |

| Training Opportunities | Facilitates training on emergency protocols, enhancing preparedness. |

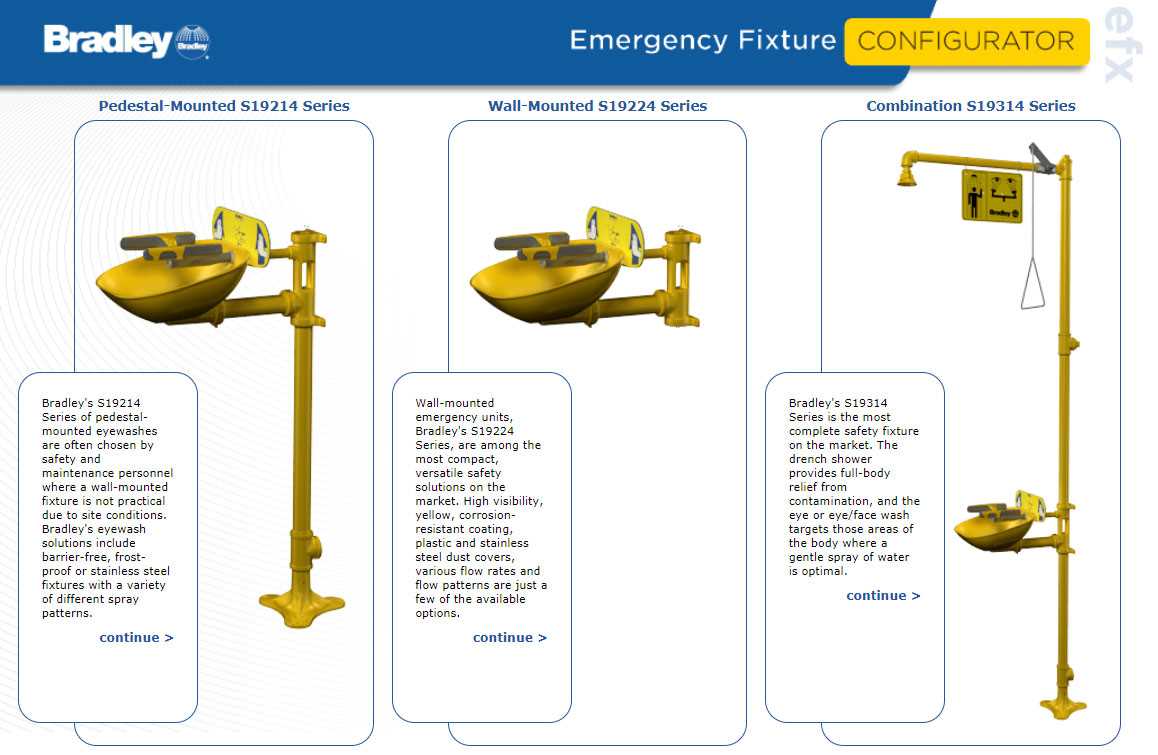

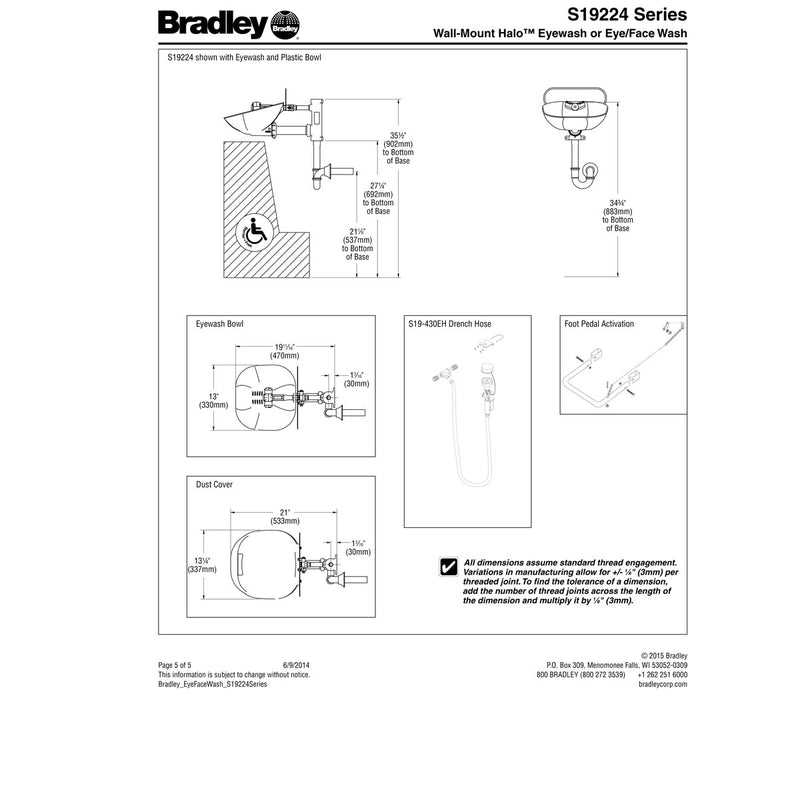

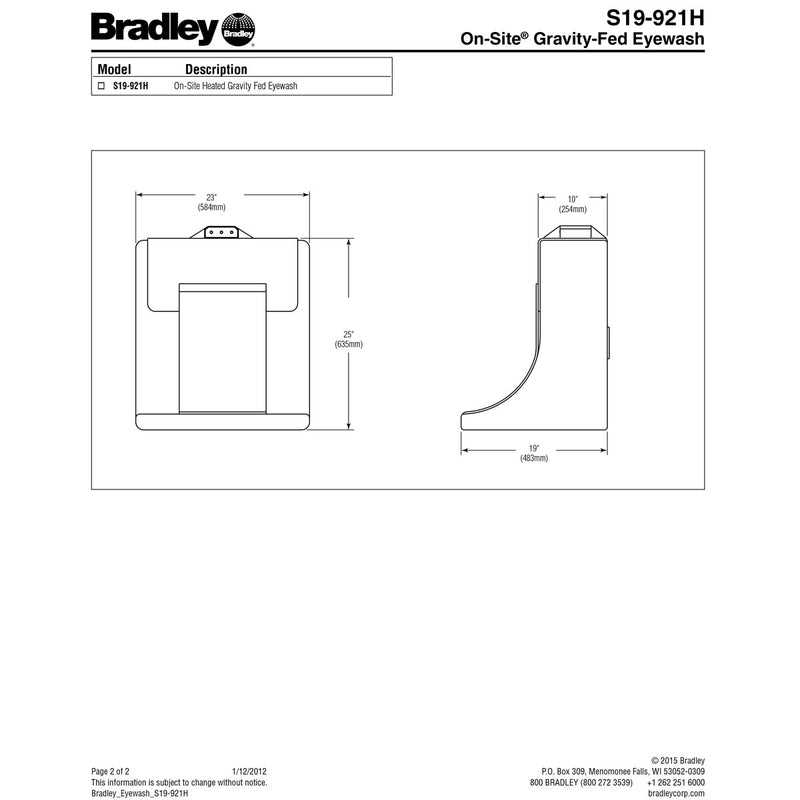

Common Bradley Eyewash Models

This section explores various popular models designed for eye safety and decontamination. These units are essential for providing immediate assistance in emergencies, ensuring that users can quickly address harmful exposures. Each model offers unique features catering to different needs and environments.

| Model Name | Type | Features |

|---|---|---|

| Classic 2000 | Stationary | Dual spray heads, adjustable height, wall-mounted. |

| Portable 100 | Portable | Compact design, easy transport, self-contained. |

| Emergency 300 | Floor-mounted | Quick activation, high flow rate, ANSI compliant. |

| Deluxe 400 | Wall-mounted | Heated water option, stainless steel construction, ergonomic design. |

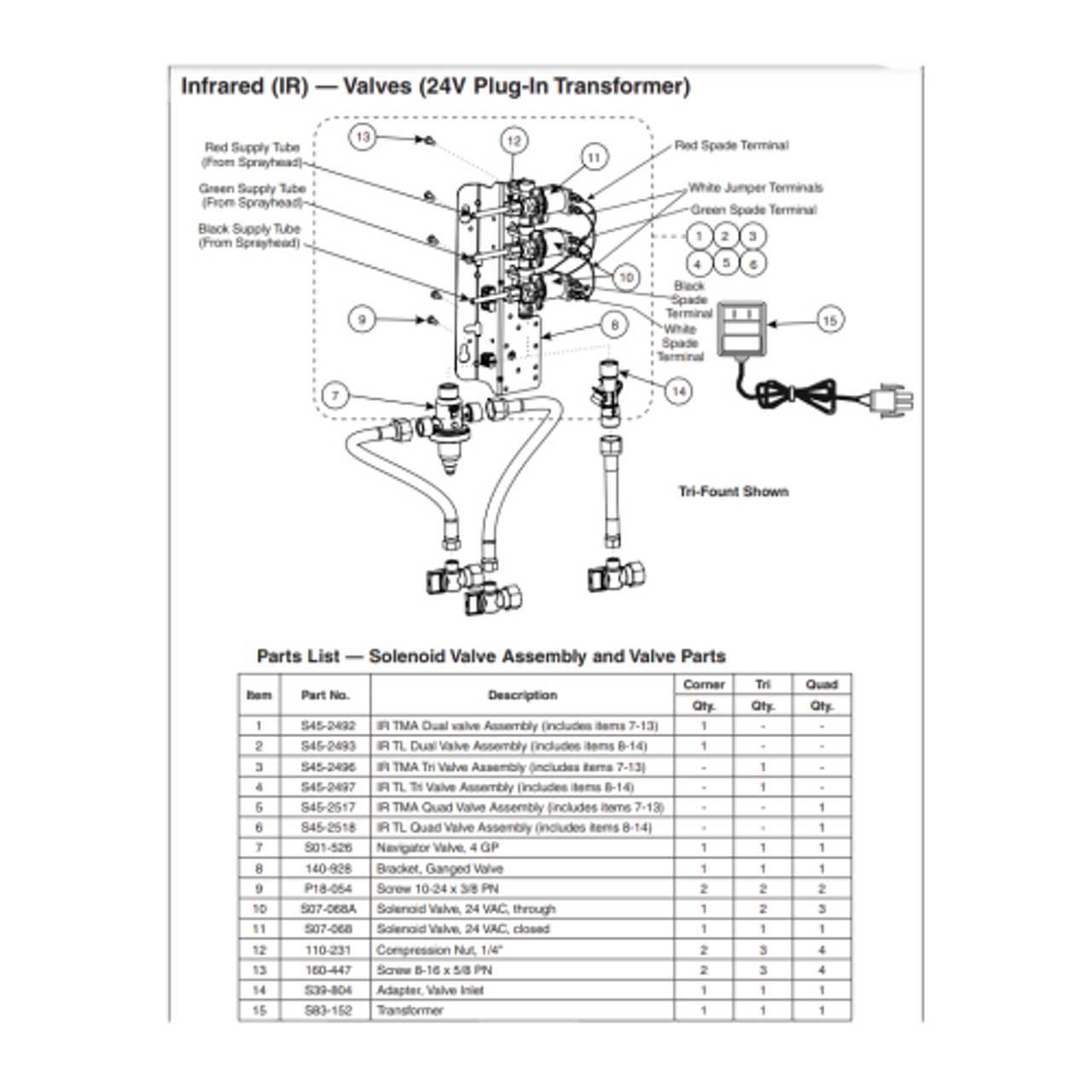

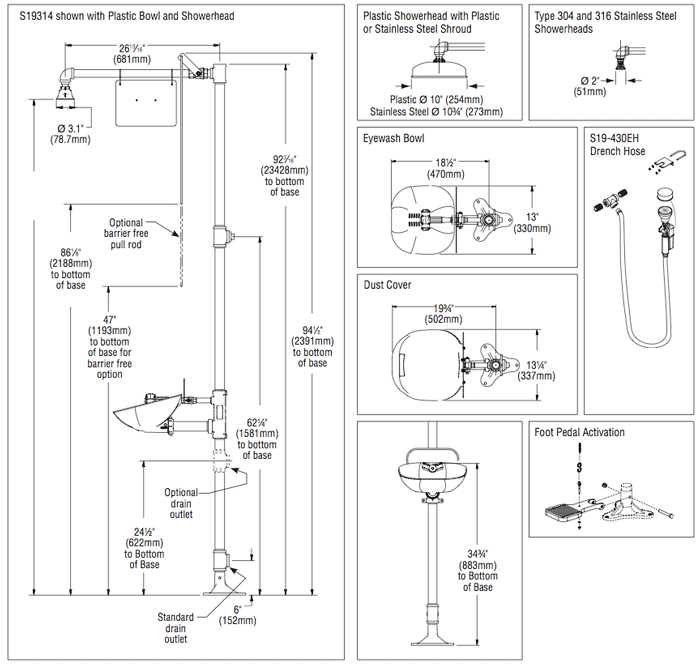

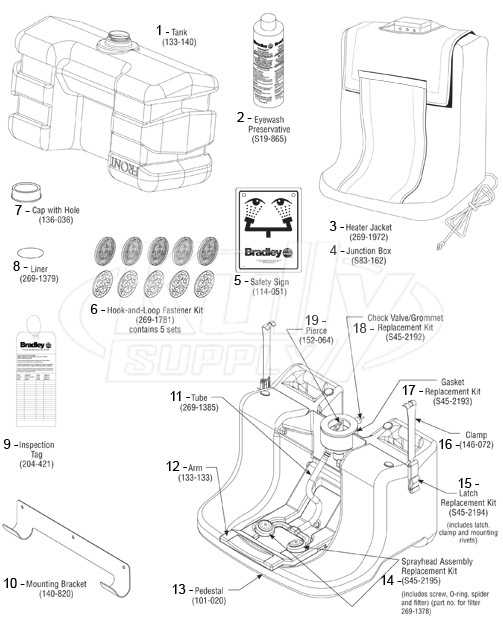

Parts Breakdown of Eyewash Systems

Understanding the components of emergency flushing equipment is essential for ensuring functionality and compliance with safety standards. Each element plays a critical role in providing immediate assistance in case of exposure to harmful substances, and knowing how these pieces work together can help in maintenance and troubleshooting.

Key Components

Essential elements include the water supply system, activation mechanism, and drainage setup. The water supply must be reliable, delivering a consistent flow at appropriate pressure. The activation mechanism is designed for ease of use, allowing quick response in emergency situations. Proper drainage ensures that any contaminants do not linger, maintaining a safe environment.

Maintenance Considerations

Regular inspections are crucial for each component to prevent malfunctions. Checking for leaks, ensuring the activation mechanism operates smoothly, and confirming adequate water pressure can make a significant difference in performance during critical moments. Familiarity with each part can aid in efficient troubleshooting and ensure compliance with health and safety regulations.

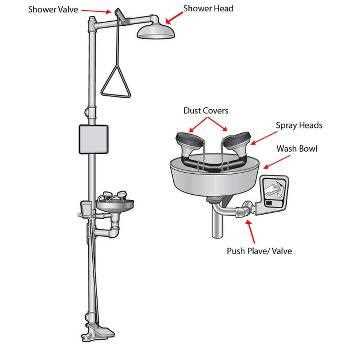

How to Read Eyewash Diagrams

Understanding technical illustrations related to emergency flushing stations is crucial for effective maintenance and operation. These visual guides offer essential information about components and their arrangements, ensuring proper functionality in critical situations.

When interpreting these illustrations, consider the following steps:

- Identify Symbols: Familiarize yourself with common icons representing various elements, such as valves and nozzles.

- Follow Connections: Trace lines to see how components are interconnected, which aids in troubleshooting.

- Check Annotations: Read any notes or labels that provide additional context or specifications.

By mastering these techniques, you can ensure that you are well-equipped to manage these safety devices effectively.

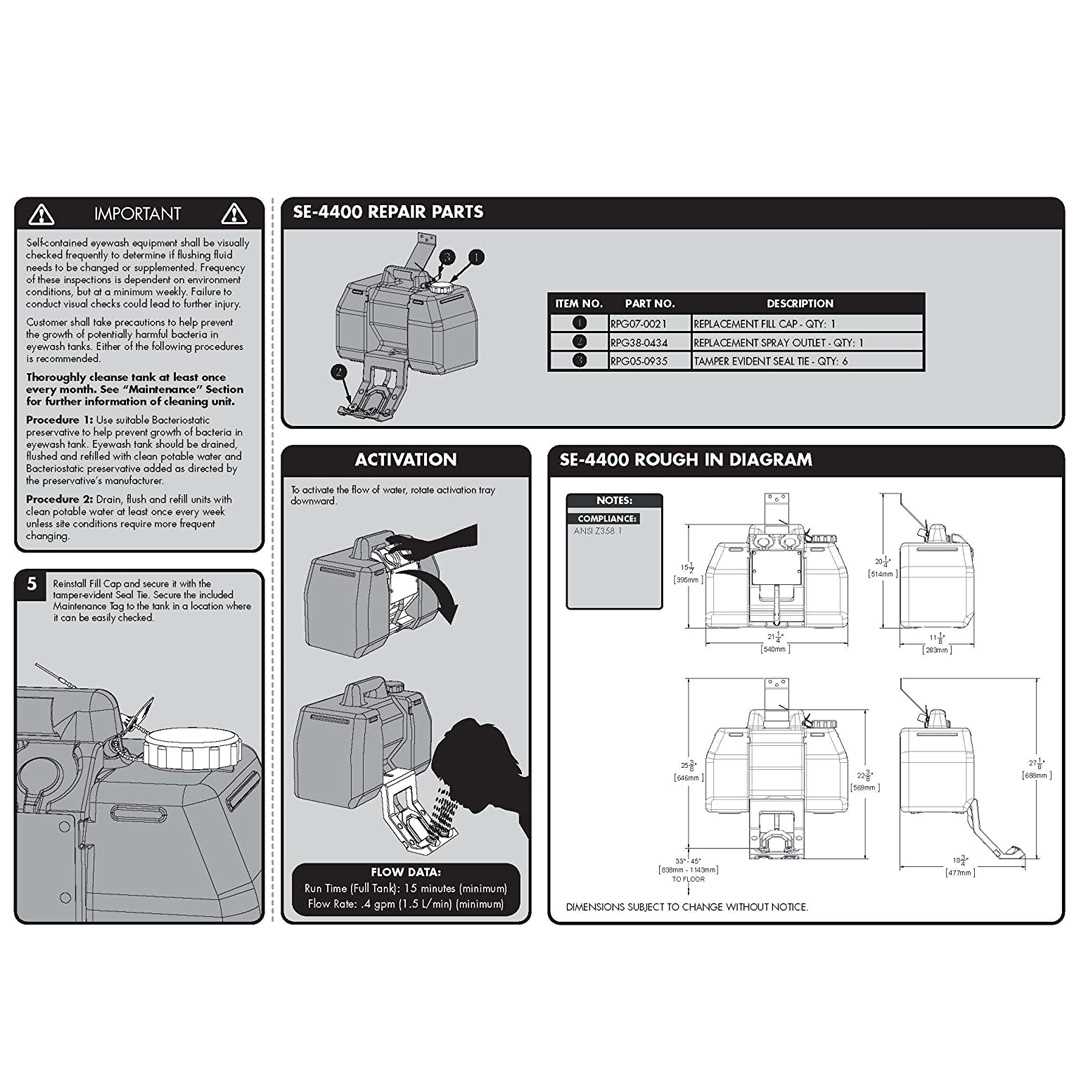

Maintenance Tips for Eyewash Units

Regular upkeep of safety equipment is essential to ensure optimal performance in emergencies. This section outlines effective strategies to maintain your equipment, ensuring it functions correctly when needed most.

Routine Inspections

Conduct frequent checks to identify any issues before they escalate. Look for signs of wear, corrosion, or blockages. Ensure that the flushing fluid is clean and the nozzles are free of debris.

Cleaning Procedures

Establish a cleaning schedule to maintain hygiene. Use approved cleaning agents to disinfect all surfaces and ensure that all components are functioning properly. This helps prevent contamination and ensures user safety.

| Task | Frequency |

|---|---|

| Inspect for corrosion | Monthly |

| Check fluid levels | Weekly |

| Clean nozzles | Every 3 months |

Identifying Replacement Parts

Understanding the components of safety equipment is crucial for ensuring optimal functionality. Recognizing which elements may need replacement allows for timely maintenance and enhances overall safety. Familiarity with various pieces can help in identifying the specific items required for efficient repairs.

Common Components to Examine

When evaluating the essential elements, focus on seals, nozzles, and valves. These components are often subject to wear and tear due to regular use. Regular inspection will help in determining the condition and functionality of each part, ensuring that any necessary replacements are made swiftly.

Resourceful Identification Techniques

Utilizing manufacturer manuals, online resources, and part catalogs can significantly aid in the identification process. These tools provide valuable insights into specifications and compatibility, ensuring that the correct components are selected for replacement. Accurate identification not only streamlines maintenance but also prolongs the lifespan of the equipment.

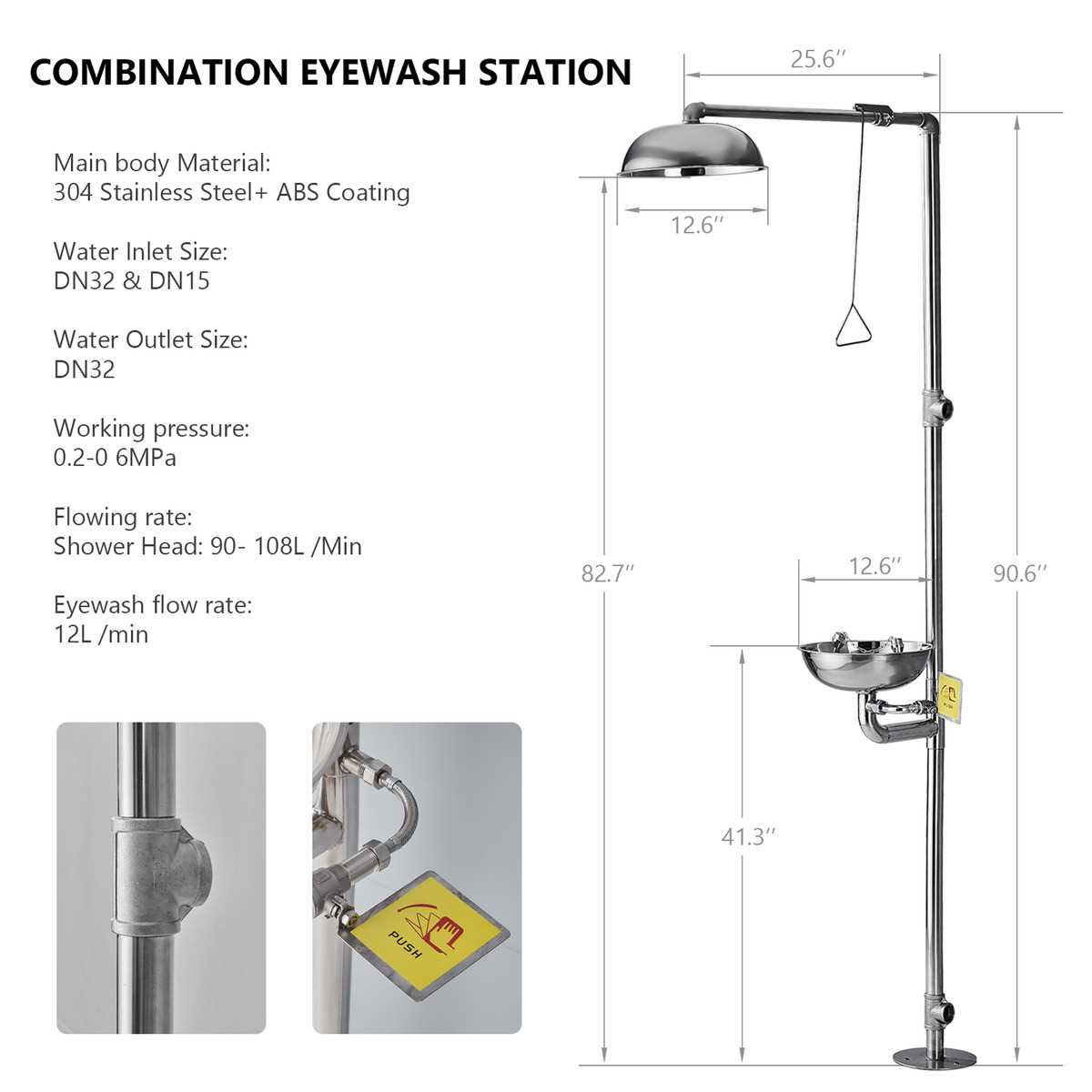

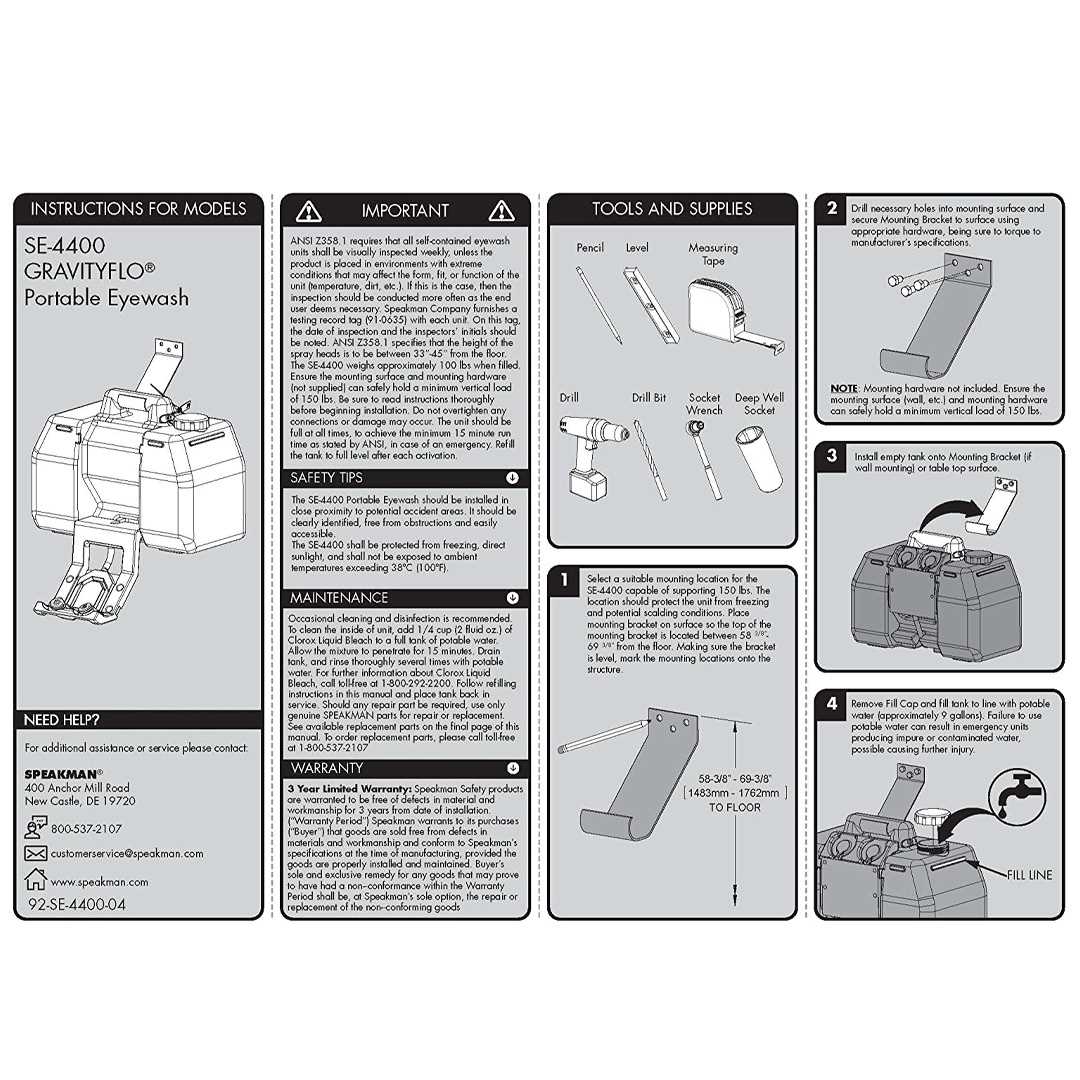

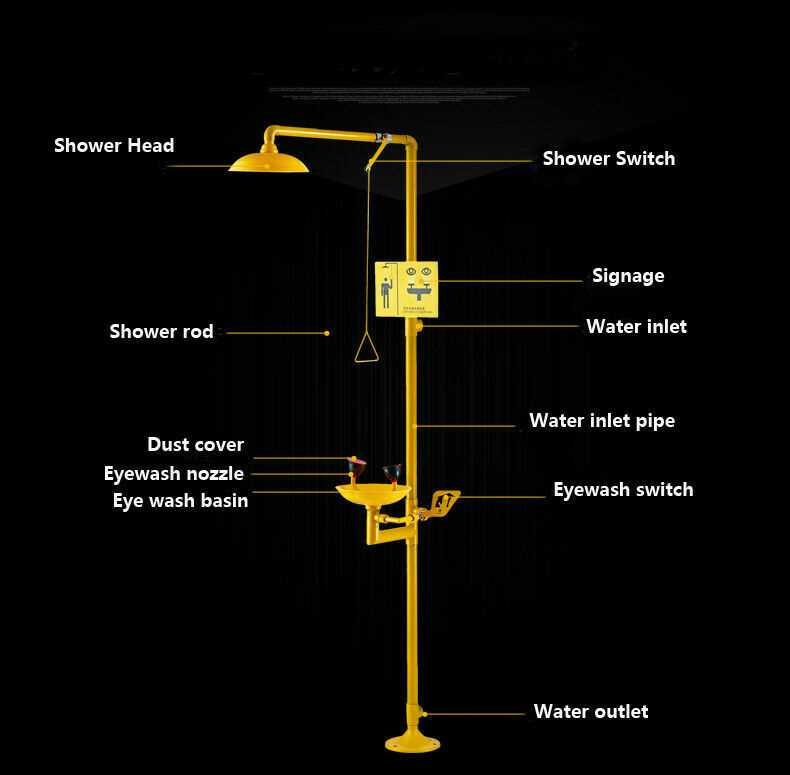

Installation Guidelines for Eyewash Stations

Proper setup of emergency flushing units is crucial for ensuring quick access to decontamination in case of hazardous exposure. Following precise installation procedures guarantees functionality and compliance with safety regulations. The following guidelines provide a comprehensive overview for effective installation.

Preparation Steps

- Assess the environment to determine the optimal location, ensuring the unit is easily accessible within a 10-second reach.

- Check local regulations and standards to confirm compliance with safety requirements.

- Gather all necessary tools and materials for installation, including plumbing supplies and mounting hardware.

Installation Process

- Secure the unit to a wall or surface using appropriate anchors, ensuring it is stable and can withstand frequent use.

- Connect the water supply, ensuring that the flow meets the minimum requirements for effective decontamination.

- Test the flushing mechanism to verify proper operation, adjusting water pressure as needed for optimal performance.

- Clearly mark the location with visible signage to enhance awareness and accessibility in emergencies.

Following these steps will help ensure that the emergency flushing station is effectively installed and ready for immediate use when needed.

Safety Standards for Eyewash Equipment

Ensuring the safety of individuals in hazardous environments is paramount. The equipment designed for flushing contaminants from the eyes must meet specific regulations to guarantee its effectiveness and reliability. Compliance with established safety standards not only protects users but also promotes a culture of preparedness and response in workplaces.

Regulatory Compliance

Various organizations have established guidelines that dictate the minimum requirements for emergency washing stations. These regulations focus on aspects such as the flow rate, duration of water delivery, and accessibility. Adhering to these protocols ensures that the equipment functions properly during emergencies and provides immediate relief from harmful substances.

Maintenance and Training

Regular maintenance is essential to ensure the operational readiness of flushing units. Routine inspections should include checking for blockages, testing water flow, and verifying temperature control. Additionally, training personnel on the proper usage and maintenance of these systems enhances overall safety and preparedness. Understanding how to respond quickly and effectively can significantly reduce the risk of long-term damage caused by exposure to irritants.

In summary, meeting safety standards and ensuring regular maintenance of emergency flushing systems is crucial for protecting individuals in hazardous work environments. A commitment to safety fosters a proactive approach to workplace health and well-being.

Repairing Common Eyewash Issues

Addressing frequent malfunctions in emergency flushing stations is crucial for ensuring safety. Over time, components may wear out or become clogged, hindering their functionality. This section explores common problems and offers guidance for effective solutions.

One typical issue is insufficient flow. This can result from blockages in the nozzles or piping. Regular cleaning and maintenance can help prevent this, ensuring a steady stream when needed. Check for debris and clean the filters regularly.

Another common concern is inconsistent water temperature. If the unit supplies water that is too hot or too cold, it may cause discomfort or be ineffective. Installing a mixing valve can help regulate the temperature, providing a more comfortable experience for users.

Leaks and drips are also prevalent problems. Inspecting seals and connections for wear can mitigate this issue. Replacing worn gaskets or tightening fittings can often resolve leaks promptly.

Lastly, make sure the unit is easily accessible and properly marked. Obstructions can delay response time in emergencies. Regular inspections ensure that the station remains unobstructed and in compliance with safety regulations.

Upgrading Your Eyewash Setup

Enhancing your emergency response system is crucial for ensuring safety in any environment. By evaluating and improving the existing setup, you can provide more effective and efficient care during critical moments. This process not only boosts safety but also meets regulatory standards and enhances overall preparedness.

Choosing Advanced Equipment

Selecting modern, high-quality equipment can significantly improve functionality. Look for features such as adjustable flow rates, ergonomic designs, and quick activation mechanisms. Investing in advanced technology ensures that your system is reliable and accessible when needed most.

Regular Maintenance and Training

Implementing a routine maintenance schedule is vital to keep your setup in optimal condition. Additionally, providing training for personnel on how to use the equipment correctly can make a significant difference in emergency situations. Regular drills can help familiarize everyone with the process, ultimately enhancing response times.