Understanding the Components of a Cat Pressure Washer Pump

In the world of cleaning technology, efficient machinery plays a crucial role in achieving optimal results. Whether for residential or industrial use, these devices rely on a variety of intricate elements that work together seamlessly. A clear understanding of these components is essential for both maintenance and troubleshooting.

Each element within this specialized equipment has its own function, contributing to the overall effectiveness of the cleaning process. Recognizing how these individual pieces interact can significantly enhance the user experience and prolong the lifespan of the equipment. Familiarity with the arrangement and function of these components empowers users to perform informed repairs and adjustments.

As we delve deeper into the specifics of these essential units, we will explore the intricacies involved. This will provide a comprehensive overview that not only aids in better comprehension but also facilitates more efficient handling of the equipment. Gaining insight into the operational dynamics will ultimately lead to more effective usage and maintenance strategies.

Understanding Cat Pressure Washer Pumps

This section delves into the intricacies of high-performance cleaning units designed for various applications. These mechanisms are crucial for delivering effective water flow and pressure, ensuring thorough cleaning in both residential and industrial settings. By comprehending their components and functionality, users can optimize their cleaning experience and enhance the lifespan of their equipment.

Key Components

- Motor: Provides the necessary energy to drive the unit.

- Intake: Facilitates the entry of water into the system.

- Outlet: Directs the flow of water to the nozzle.

- Valves: Control the flow and pressure within the unit.

- Piston: Creates the force needed to propel water.

Operating Principles

- The motor engages, initiating the intake process.

- Water enters the unit through the intake valve.

- The piston moves, compressing the water and increasing its pressure.

- Pressurized water is expelled through the outlet valve.

- The user directs the flow using a nozzle for optimal cleaning.

Key Components of Pressure Washer Pumps

The functionality of high-efficiency cleaning machines relies on several crucial elements that work together seamlessly. Understanding these components helps users appreciate their importance in delivering optimal performance.

Motor: This is the powerhouse of the device, converting electrical energy into mechanical energy. A reliable motor ensures consistent operation and longevity.

Compressor: Responsible for generating the required force to propel the liquid, this element is vital for achieving effective cleaning results. Different designs can influence the flow and pressure levels.

Valves: These control the flow of the liquid within the system. They regulate the intake and discharge, ensuring that the machine operates efficiently without leaks or blockages.

Sealants: These components are essential for preventing leaks. They maintain pressure within the system, safeguarding against performance loss and potential damage.

Cylinders: The heart of the mechanism, cylinders house the moving components that create the required pressure. Their construction and material can significantly impact durability and efficiency.

Hoses: These flexible conduits transport the liquid from the source to the nozzle. Their quality affects not only the flow rate but also the ease of maneuvering during use.

Understanding these fundamental elements enables users to maintain their equipment effectively and troubleshoot any issues that may arise.

How to Identify Pump Parts

Understanding the components of a fluid delivery system is crucial for effective maintenance and troubleshooting. Recognizing each element’s role can significantly enhance your ability to perform repairs and optimize performance.

Here are some key steps to help you identify the various components:

- Familiarize Yourself with Terminology: Start by learning the specific names and functions of each element in the system.

- Consult the Manual: Manufacturer manuals often contain diagrams and descriptions that clarify each component’s purpose.

- Visual Inspection: Examine the system closely. Look for labels or engravings that might indicate part numbers or functions.

To further aid your identification process, consider the following tips:

- Look for Wear Indicators: Signs of wear can help you determine which parts may need replacement.

- Understand the Flow Path: Knowing how fluid moves through the system can help you trace components more easily.

- Take Photos: Documenting the layout before disassembly can assist you during reassembly.

By applying these strategies, you’ll enhance your understanding of the system’s inner workings, leading to more effective maintenance and troubleshooting.

Functionality of Each Pump Component

Understanding the various elements that contribute to the overall operation of a fluid delivery system is essential for effective maintenance and troubleshooting. Each component plays a specific role, ensuring the efficient transfer of liquid while maintaining optimal performance. This section will delve into the functionality of each vital component, highlighting their contributions to the entire mechanism.

Key Components and Their Functions

- Motor: The driving force that powers the entire assembly, converting electrical energy into mechanical energy.

- Intake Valve: Regulates the entry of fluid, ensuring a consistent supply while preventing backflow.

- Discharge Valve: Controls the exit of fluid, allowing for the pressurized delivery to the desired location.

- Cylinder: Houses the working fluid, facilitating compression and expansion necessary for fluid movement.

- Piston: Moves within the cylinder, generating the necessary pressure to propel the fluid through the system.

- Seals and Gaskets: Ensure leak-proof operation by providing barriers between various components, maintaining efficiency.

Supportive Elements

- Connecting Rod: Links the motor to the piston, translating rotational motion into linear movement.

- Crankshaft: Converts the motor’s rotational energy into a reciprocating motion for the piston.

- Filter: Removes impurities from the fluid, safeguarding internal components from damage.

- Pressure Switch: Monitors pressure levels, ensuring the system operates within safe parameters and activating safety measures if necessary.

Each of these components works in harmony to create a reliable and efficient system. Understanding their functionalities not only aids in troubleshooting but also enhances overall maintenance practices.

Common Issues with Pressure Washer Pumps

When dealing with high-performance cleaning devices, several challenges may arise that can affect their efficiency and effectiveness. Understanding these typical complications can aid in both prevention and resolution, ensuring optimal functionality over time.

Frequent Complications

Among the most common challenges faced by users are leaks, inconsistent water flow, and unusual noises. These issues often stem from wear and tear, improper maintenance, or component malfunctions.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Leaks | Worn seals or damaged fittings | Replace seals or tighten connections |

| Inconsistent Flow | Clogged inlet or worn components | Clear blockages and inspect parts |

| Unusual Noises | Loose parts or low fluid levels | Tighten components and refill fluids |

Maintenance Tips

Regular upkeep is essential for longevity and performance. This includes routine inspections, timely replacements of worn parts, and ensuring proper fluid levels to prevent complications from arising.

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your cleaning equipment requires regular attention and care. Implementing a few key practices can significantly enhance its performance and extend its lifespan. By following these guidelines, you can maintain peak functionality and avoid costly repairs.

1. Regular Inspection: Frequently check the device for any signs of wear or damage. Look for cracks, leaks, or loose connections, as these can hinder operation. Addressing issues promptly can prevent more serious problems down the line.

2. Clean Filters: Clogged filters can reduce efficiency and strain the machine. Make it a habit to clean or replace filters as recommended by the manufacturer to ensure optimal airflow and operation.

3. Lubrication: Proper lubrication of moving components is essential for smooth functioning. Use the recommended lubricants and apply them according to the service schedule to minimize friction and wear.

4. Seasonal Maintenance: Depending on usage and environmental conditions, seasonal check-ups can be beneficial. Prepare the equipment for storage in colder months and ensure it’s clean and dry to prevent corrosion.

5. Use Quality Accessories: Utilizing high-quality attachments and accessories can enhance performance and protect the equipment. Choose compatible products that meet the specifications provided by the manufacturer.

6. Follow Operating Guidelines: Adhering to the manufacturer’s operational guidelines is crucial. Avoid overloading the machine and use it within the recommended parameters to maintain efficiency.

By incorporating these maintenance practices, you can ensure your cleaning device operates at its best, providing reliable performance whenever needed.

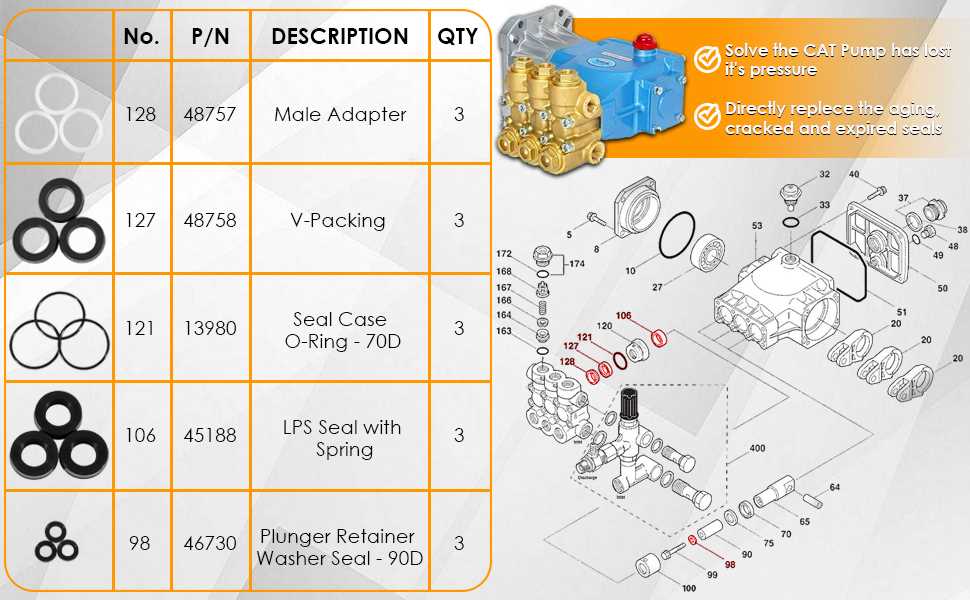

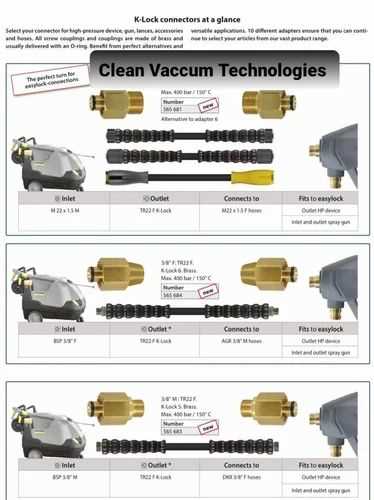

Replacement Parts: What You Need to Know

Maintaining equipment is essential for optimal performance, and knowing how to find the right components can make a significant difference. This section focuses on the critical aspects of acquiring new elements to ensure your machinery operates smoothly and efficiently.

When considering replacements, keep the following points in mind:

- Compatibility: Always verify that the new component matches your existing system. Check model numbers and specifications.

- Quality: Opt for high-quality replacements from reputable suppliers to avoid premature failures and ensure longevity.

- Warranty: Look for parts that come with a warranty, providing peace of mind and protection against defects.

- Installation: Be prepared to follow the manufacturer’s guidelines for installation. Improper fitting can lead to inefficiency or damage.

- Maintenance: Regularly check and maintain new components to prolong their life and ensure consistent performance.

By understanding these factors, you can make informed decisions that enhance the reliability and functionality of your equipment.

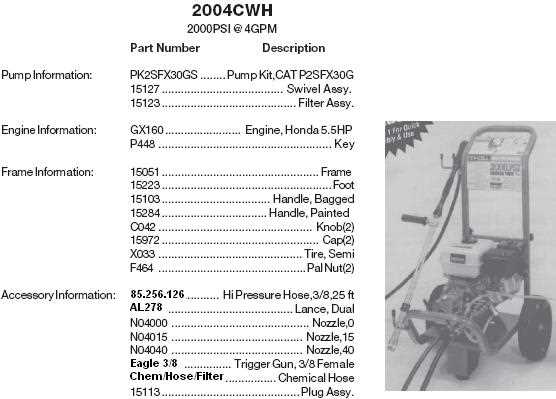

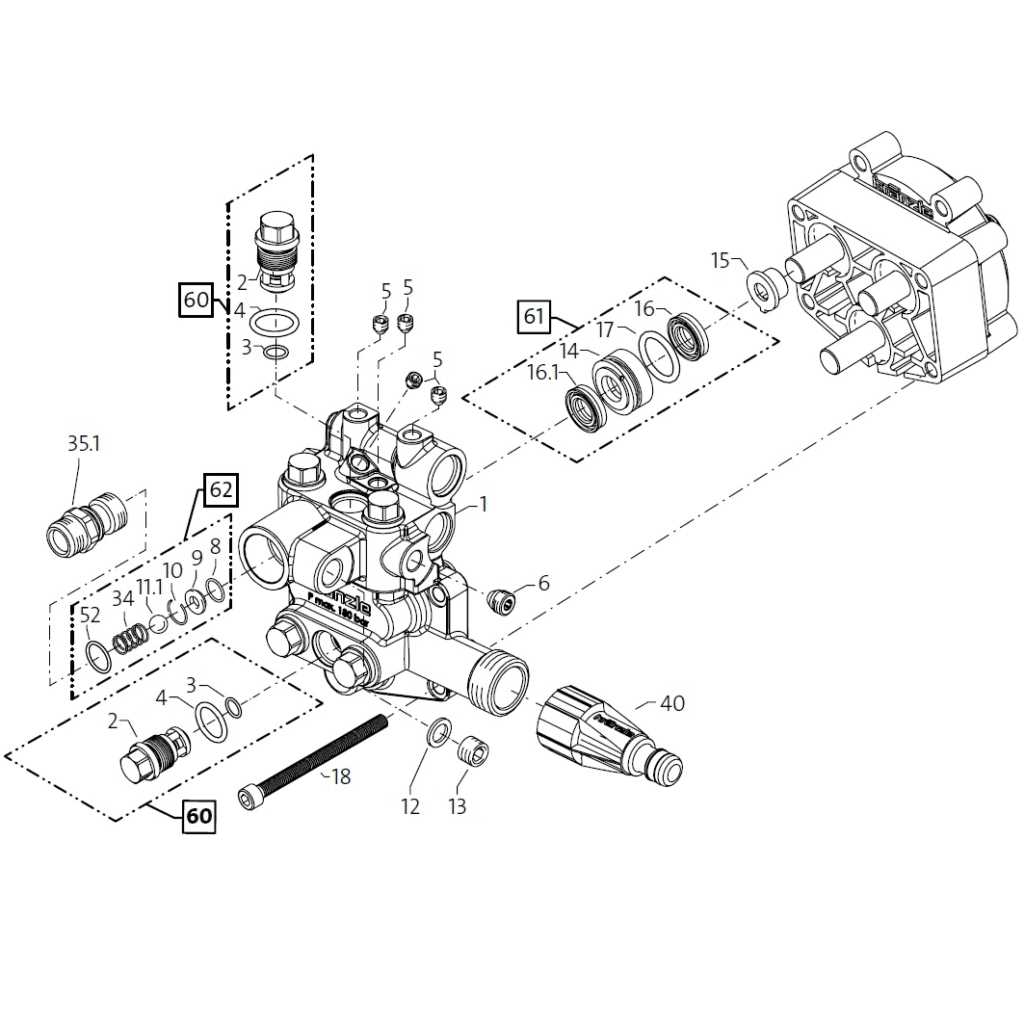

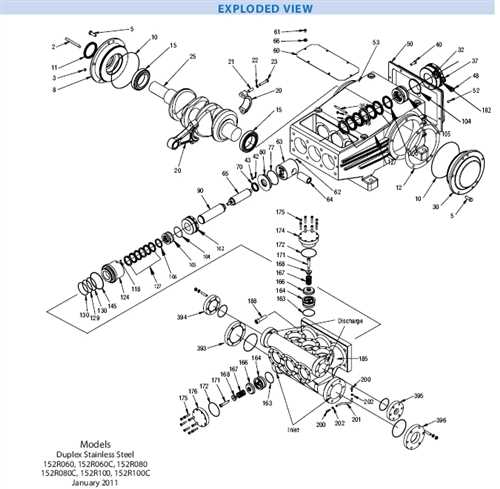

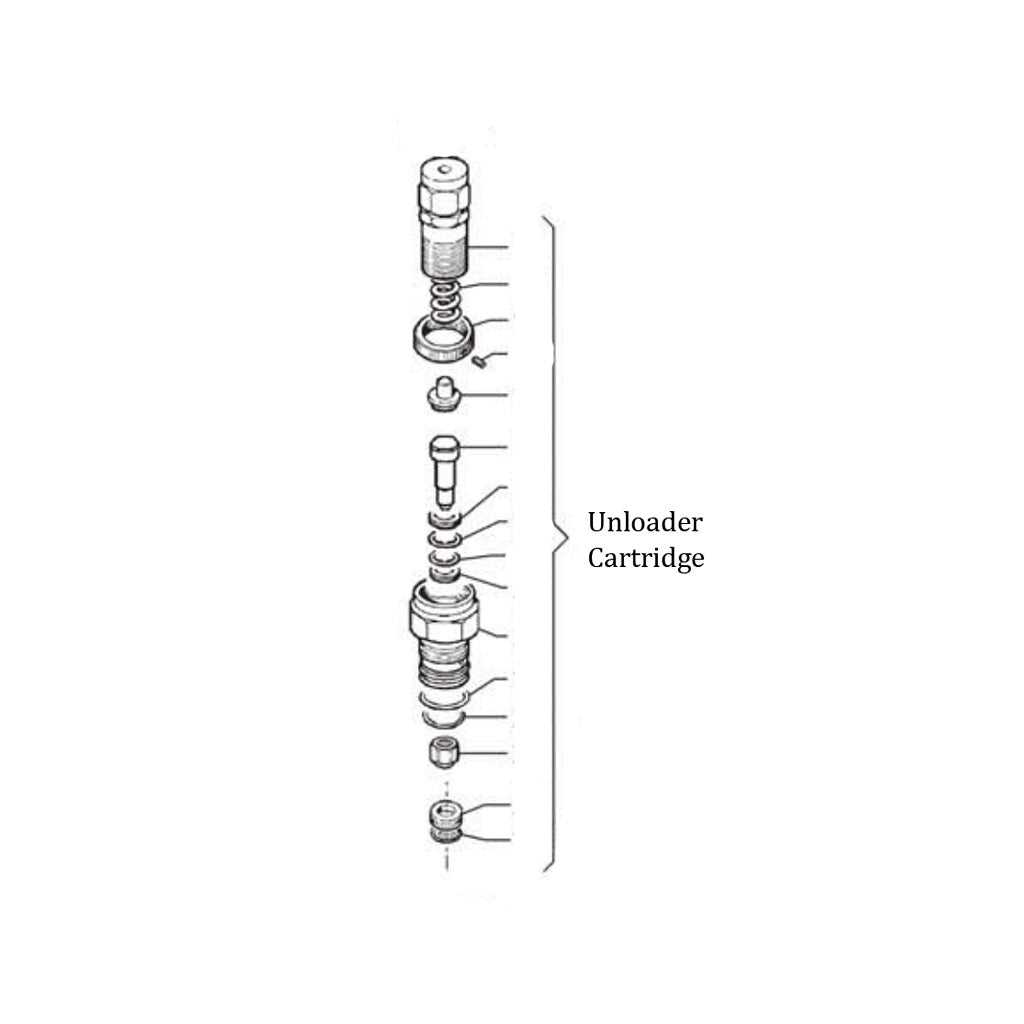

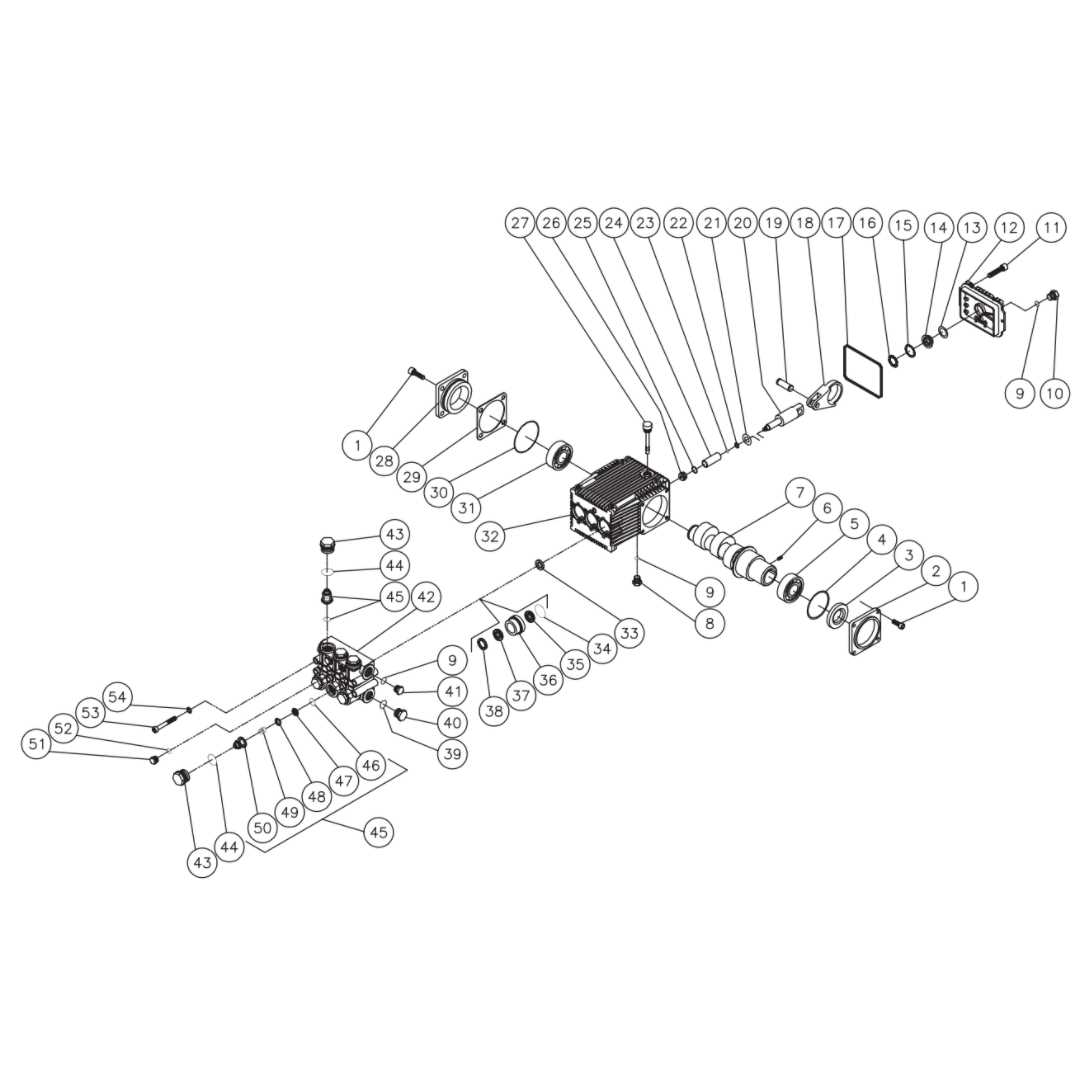

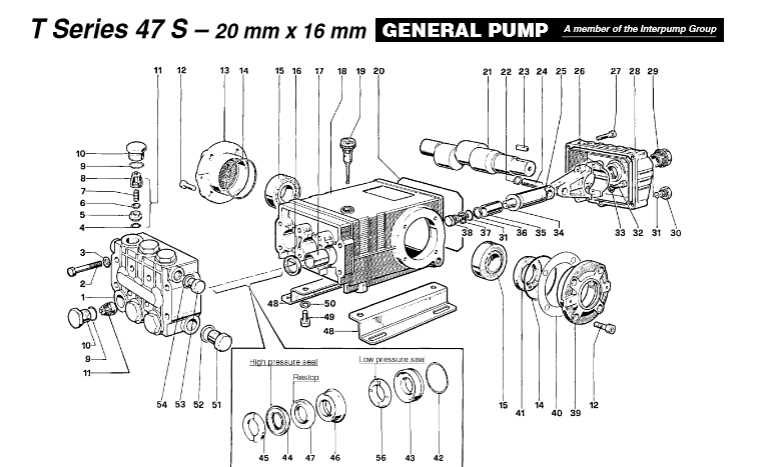

Reading a Pump Parts Diagram

Understanding a schematic representation of mechanical components is essential for effective maintenance and repair. Such illustrations provide a visual guide that simplifies the identification of individual elements and their functions within a system. Familiarity with these visuals can significantly enhance troubleshooting efforts and overall efficiency.

To effectively interpret these illustrations, consider the following key aspects:

- Labels and Symbols: Each component is typically marked with specific identifiers. Familiarize yourself with common symbols to streamline the identification process.

- Component Relationships: Observe how different parts interact with one another. This can help in understanding the flow and operation of the entire system.

- Numbering System: Many schematics use a numbering system to indicate a sequence or hierarchy. Pay attention to these numbers to grasp the assembly order.

- Material Specifications: Some illustrations include details about the materials used for each component, which can be critical for replacements or repairs.

By mastering these elements, you can enhance your comprehension of mechanical schematics, leading to more effective diagnostics and repair strategies.

Tools Required for Pump Repair

Effective maintenance and troubleshooting of cleaning equipment necessitate a well-equipped toolkit. Having the right instruments on hand can significantly streamline the repair process, ensuring that each task is performed efficiently and accurately.

Below is a list of essential tools that will aid in the repair and upkeep of your machinery:

- Screwdrivers: A set of various sizes, including both flathead and Phillips, for removing and tightening screws.

- Wrenches: Adjustable and socket wrenches to loosen or tighten nuts and bolts.

- Pliers: Needle-nose and standard pliers for gripping and manipulating small components.

- Torque wrench: To ensure that all fasteners are tightened to the manufacturer’s specifications.

- Multimeter: For checking electrical components and ensuring proper functionality.

- Sealant: To prevent leaks and ensure a tight seal during reassembly.

- Cleaning brushes: For removing dirt and debris from internal components.

- Safety gear: Goggles and gloves to protect against debris and chemicals.

By having these tools readily available, you can tackle repairs with confidence and maintain the longevity of your equipment.

Safety Precautions During Maintenance

Ensuring a safe environment while conducting upkeep tasks is crucial for both the user and the equipment. Proper precautions help prevent accidents and damage, allowing for effective maintenance. Familiarity with safety protocols can significantly enhance the overall experience and extend the lifespan of the equipment.

Always disconnect the power source before starting any maintenance work. This step is vital to avoid accidental activation that could lead to injuries. Additionally, use appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear, to safeguard against potential hazards. Ensure that the workspace is clean and free of obstructions to minimize risks during the upkeep process.

Furthermore, it’s essential to refer to the manufacturer’s guidelines for specific safety recommendations related to the maintenance of the equipment. Regularly inspect tools and equipment for any wear or damage to prevent malfunctions. By adhering to these safety measures, individuals can conduct maintenance effectively and confidently.

Upgrading Your Pressure Washer Pump

Enhancing the efficiency of your cleaning device can significantly improve its performance and longevity. By investing in better components, you can achieve superior results, reduce downtime, and enjoy a more effective cleaning experience. This section explores the advantages of upgrading essential components for optimal operation.

Benefits of Upgrading

One of the primary advantages of enhancing your equipment lies in the potential for increased power and efficiency. Improved components can lead to faster cleaning times, allowing you to tackle larger areas with ease. Additionally, upgrades often result in reduced maintenance needs, ultimately saving you time and money.

Choosing the Right Components

When selecting components for enhancement, it is crucial to consider compatibility and quality. Investing in high-quality materials not only ensures better performance but also enhances the durability of your device. Consult the manufacturer’s guidelines or seek expert advice to make informed decisions that align with your specific needs.

In conclusion, upgrading your cleaning device can yield remarkable benefits, transforming your experience and effectiveness. Prioritizing quality and compatibility will help you achieve the best possible outcomes.