Understanding the Craftsman Pressure Washer Parts Diagram for Efficient Repairs

The functionality of any machine relies heavily on the intricate relationships between its various components. When seeking to optimize performance, a thorough understanding of these elements becomes essential. A visual representation can significantly enhance this comprehension, allowing users to identify and assess each integral piece.

By examining the layout of the unit, enthusiasts and professionals alike can quickly locate specific sections that may require attention or maintenance. This knowledge is not only valuable for troubleshooting but also for enhancing the overall longevity of the device.

Ultimately, mastering the configuration of these elements empowers users to make informed decisions, ensuring efficient operation and minimizing downtime. Whether for repair or enhancement, a detailed overview is an indispensable resource.

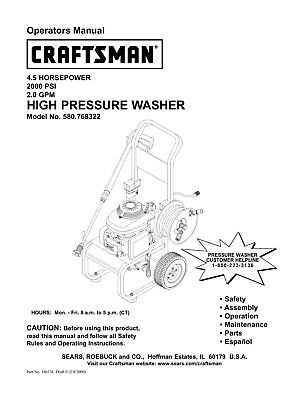

Understanding Craftsman Pressure Washers

This section aims to explore the essential elements and functionalities of a popular outdoor cleaning tool. By examining its components and how they work together, users can gain a deeper appreciation for its capabilities and maintenance needs.

- Functionality: This tool effectively removes dirt and grime from various surfaces.

- Components: Key elements include the motor, nozzle, and hose.

- Maintenance: Regular upkeep ensures longevity and efficiency.

- Usage: Ideal for tasks like cleaning driveways, patios, and vehicles.

By delving into these areas, users can maximize their understanding and experience with this valuable cleaning device.

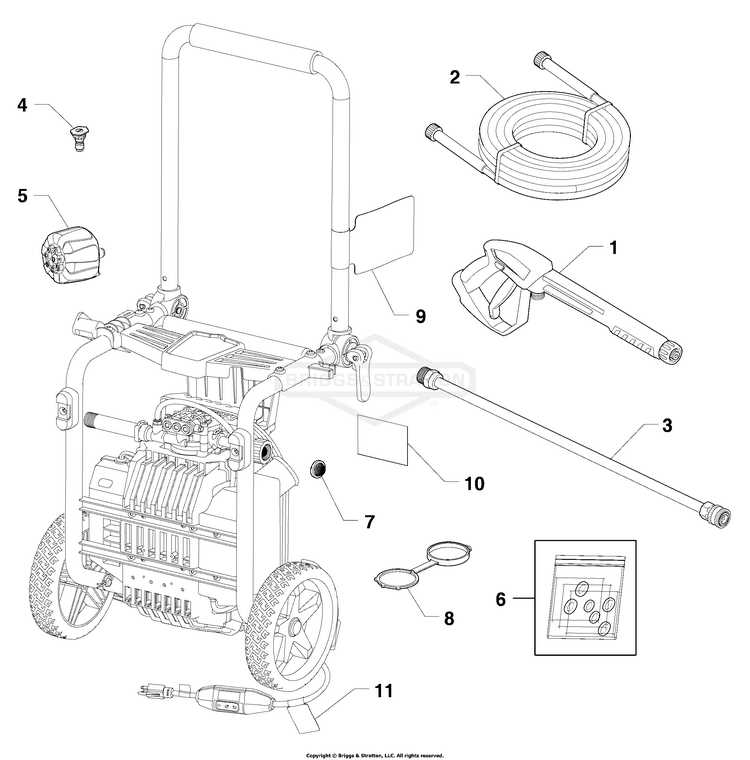

Key Components of Pressure Washers

Understanding the essential elements of these cleaning devices is crucial for optimal performance and maintenance. Each component plays a significant role in generating high-intensity streams that effectively remove dirt and grime from surfaces.

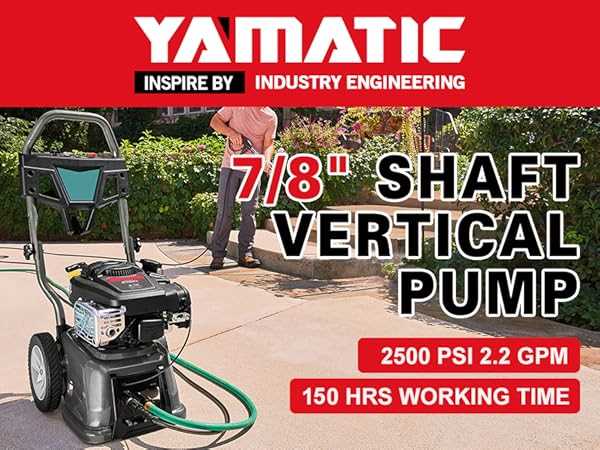

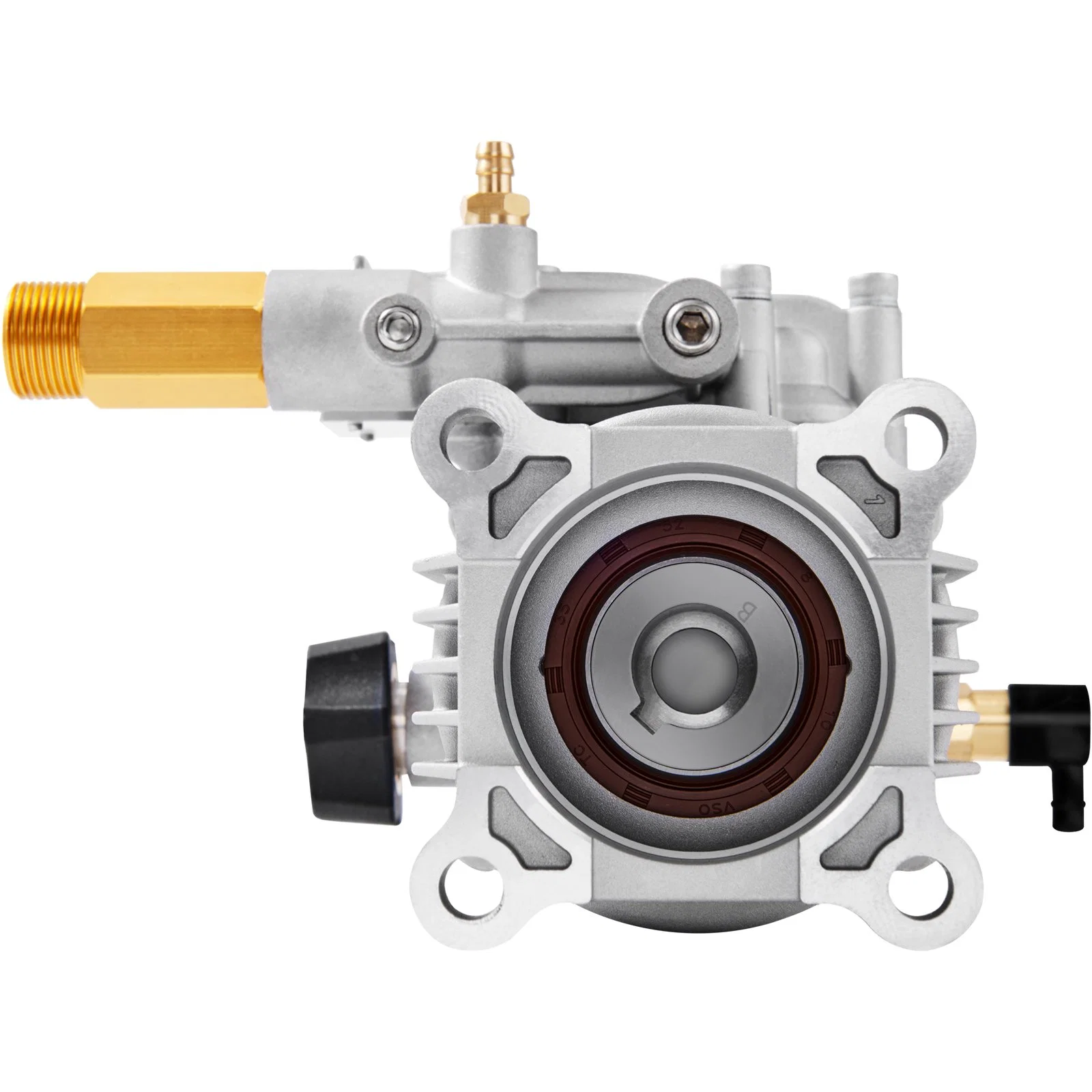

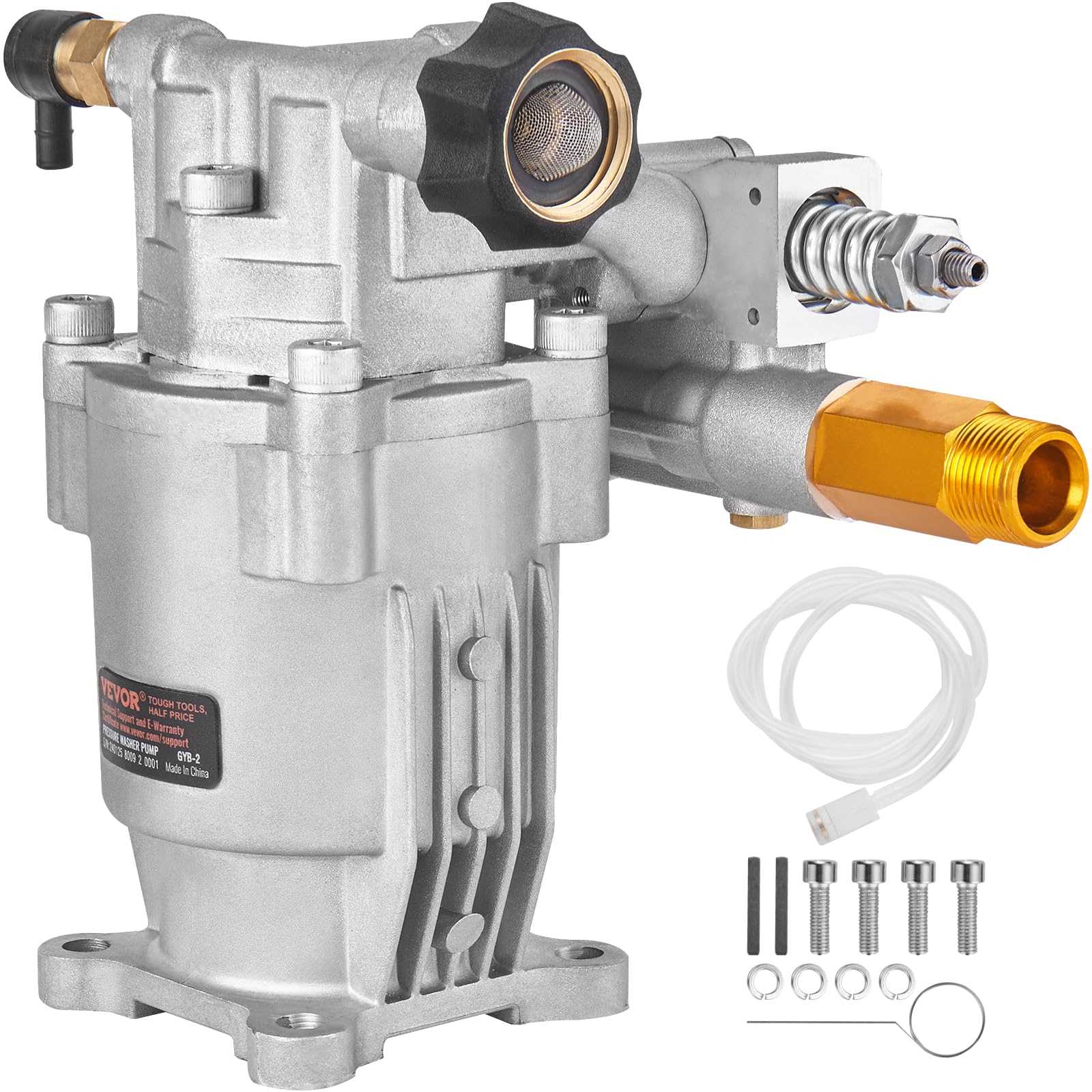

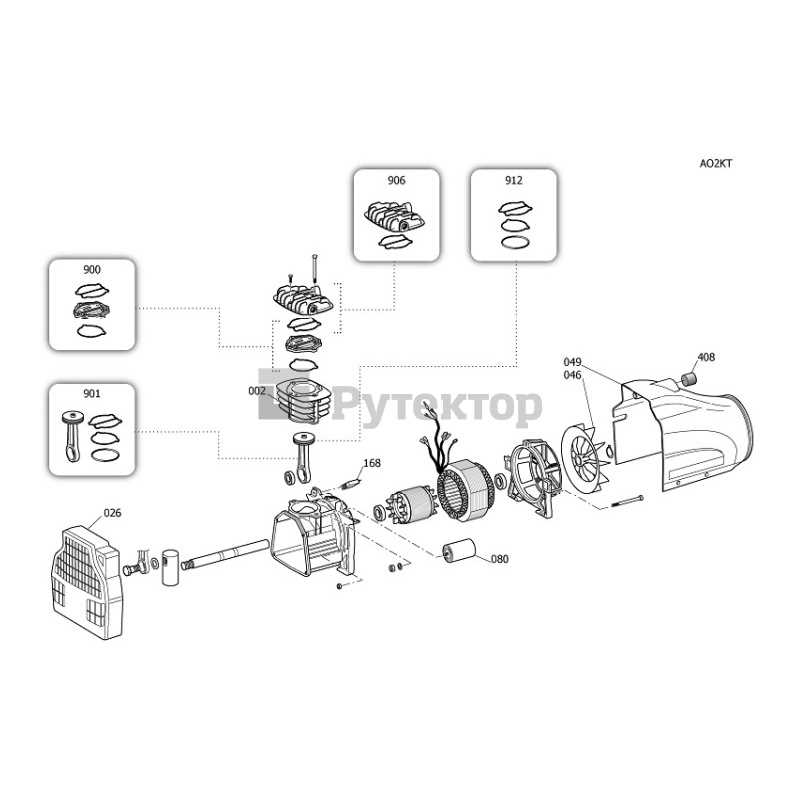

Motor and Pump

The motor serves as the driving force, converting electrical energy into mechanical energy. Coupled with the pump, it generates the necessary force to propel water through the system, enhancing the cleaning capabilities significantly.

Nozzle and Hose

The nozzle determines the flow and intensity of the water, allowing users to adjust the spray for different tasks. Meanwhile, the hose delivers the fluid efficiently, connecting the source to the nozzle while withstanding high pressures during operation.

Importance of Maintenance for Longevity

Regular upkeep is essential for extending the lifespan of any equipment. Proper care not only enhances performance but also prevents unexpected failures. By investing time in routine inspections and servicing, users can ensure their tools remain efficient and reliable over the years.

Benefits of Regular Upkeep

Consistent maintenance provides several advantages. Enhanced efficiency leads to better results, while early detection of issues can save time and money in the long run. Moreover, well-maintained tools often require fewer repairs, allowing for uninterrupted use.

Best Practices for Care

Establishing a regular maintenance schedule is crucial. This includes cleaning, lubrication, and checking components for wear. Keeping a detailed record of maintenance activities can also help in tracking performance and identifying patterns that may indicate the need for further attention.

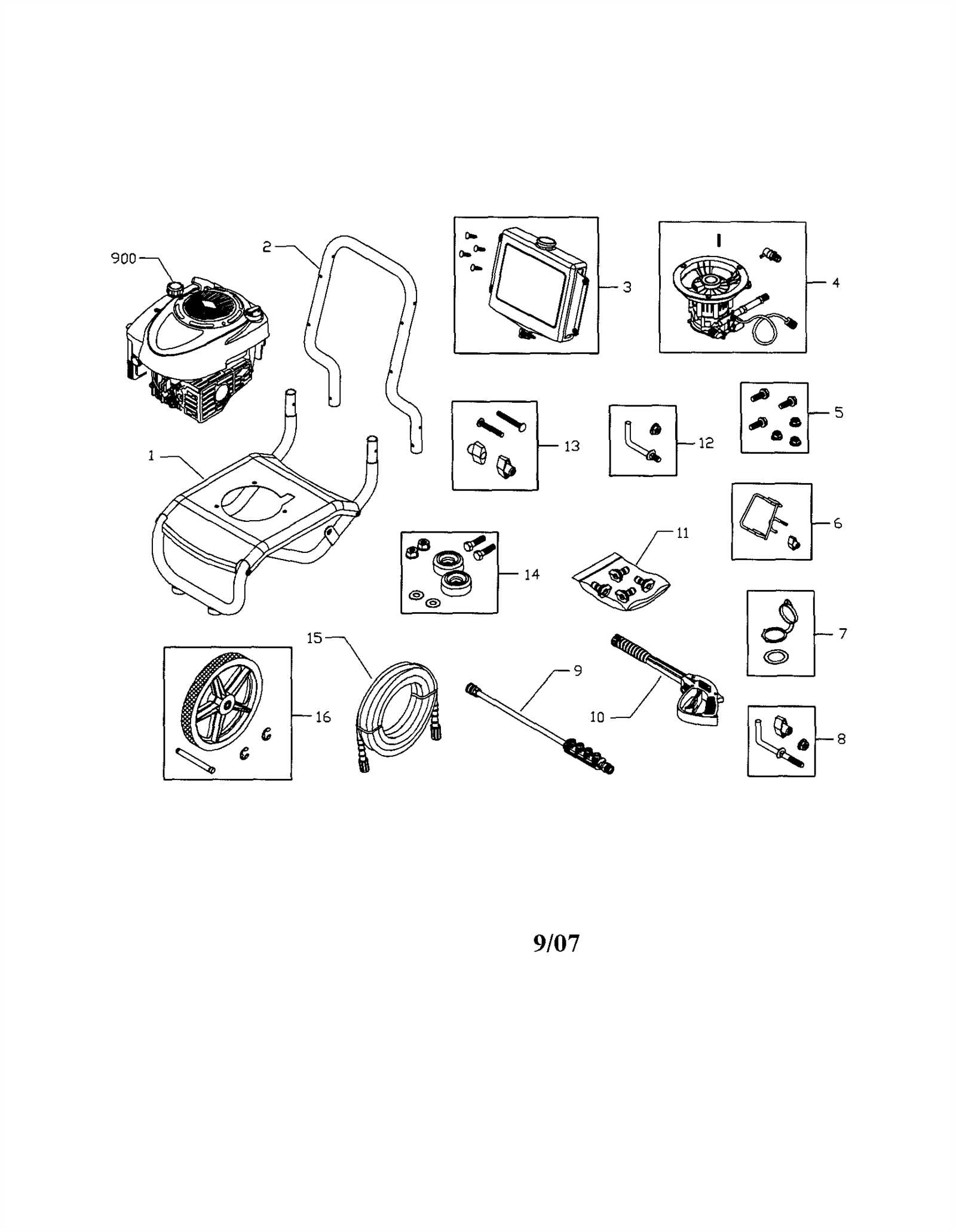

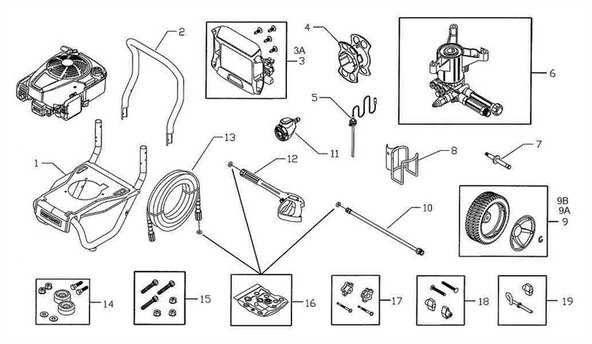

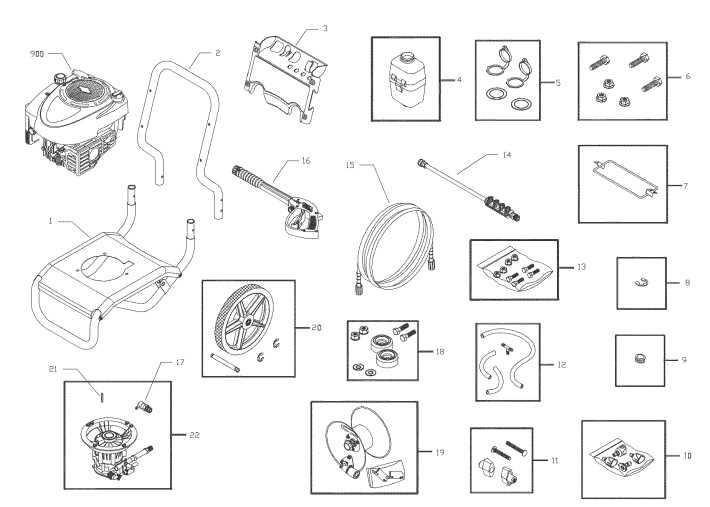

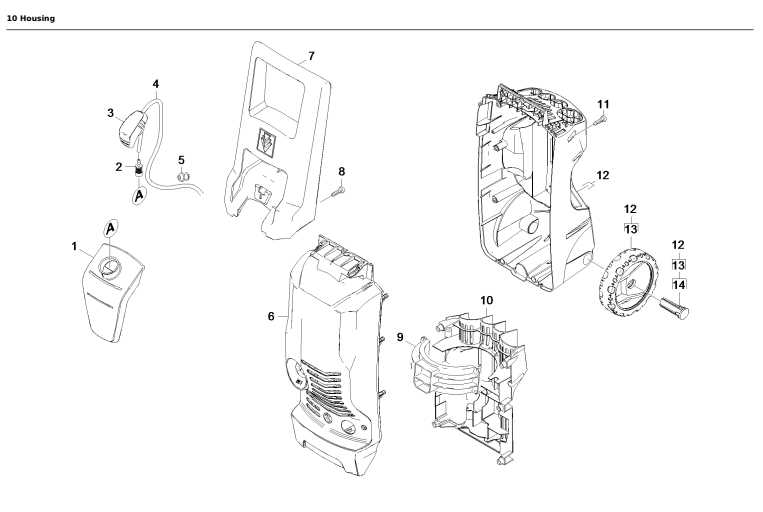

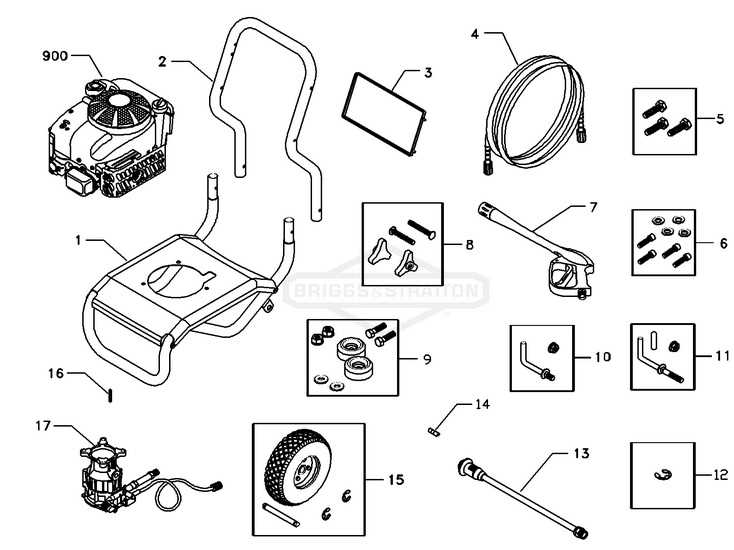

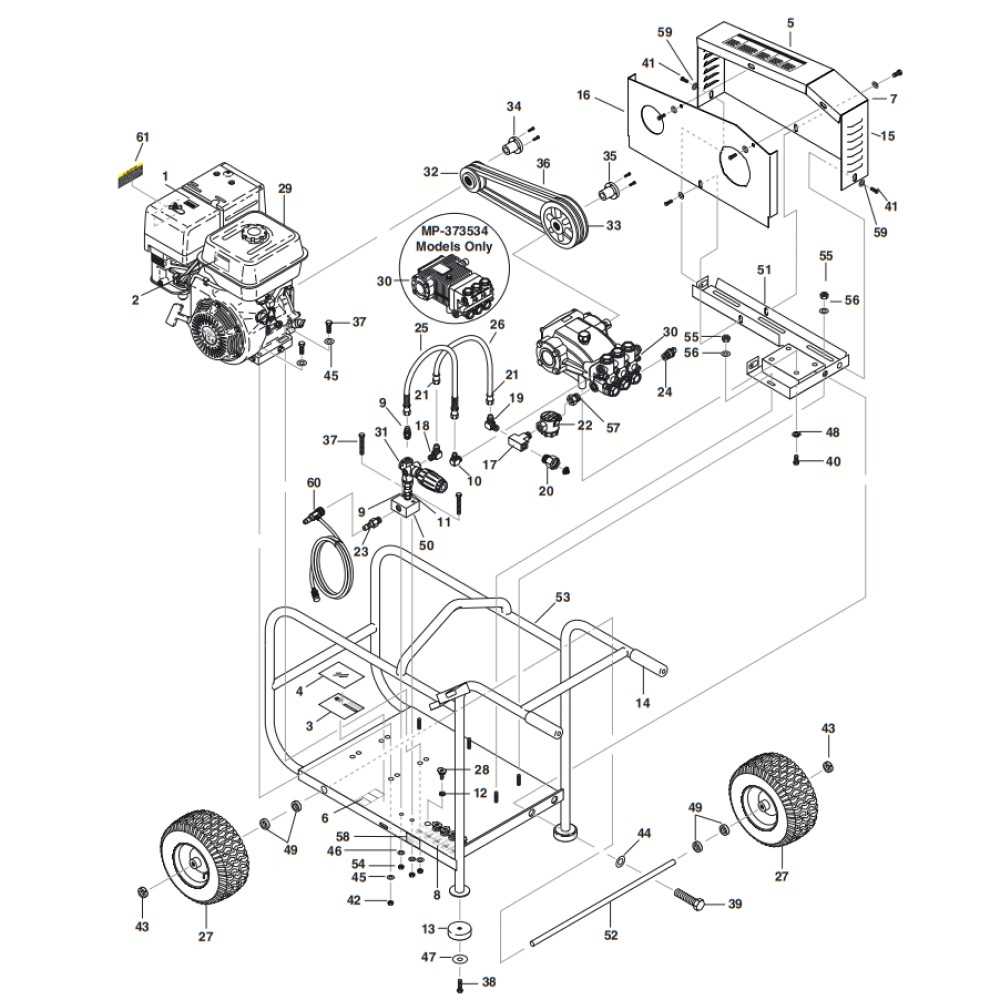

Identifying Parts in Diagrams

Understanding the components depicted in technical illustrations is essential for effective maintenance and repairs. Each element is crucial for the overall functionality, and recognizing them can streamline your troubleshooting process.

When examining an illustration, consider the following approaches:

- Familiarize Yourself with Common Terminology: Knowing the names of the components will help in identifying them more easily.

- Use a Legend: Most diagrams include a legend that explains the symbols and labels, aiding in clear identification.

- Focus on Shapes and Sizes: Components often have distinct shapes; take note of these characteristics to match them with their functions.

By employing these strategies, you can effectively navigate technical illustrations and enhance your repair skills.

Common Issues with Pressure Washer Parts

Understanding the frequent challenges encountered with various components of cleaning devices is essential for maintaining optimal performance. Many users experience similar malfunctions that can hinder efficiency and effectiveness.

Frequent Malfunctions

- Clogged filters that restrict water flow.

- Worn-out seals leading to leaks.

- Faulty connections causing pressure loss.

- Damaged hoses resulting in bursts.

Preventive Measures

- Regularly inspect and clean filters.

- Replace seals at the first sign of wear.

- Check connections for tightness.

- Avoid kinks in hoses during use.

How to Read Technical Diagrams

Understanding technical illustrations is essential for anyone involved in machinery or repair work. These visuals convey complex information succinctly, enabling users to identify components and their relationships efficiently.

Familiarize Yourself with Symbols

Each illustration features specific symbols representing various elements. Learning these symbols is crucial, as it allows you to interpret the diagram accurately and grasp the overall system structure.

Follow the Flow of Information

Diagrams often display a logical progression, guiding you through the assembly or functionality of the object. Pay attention to arrows and lines that indicate connections, as they reveal how parts interact and function together.

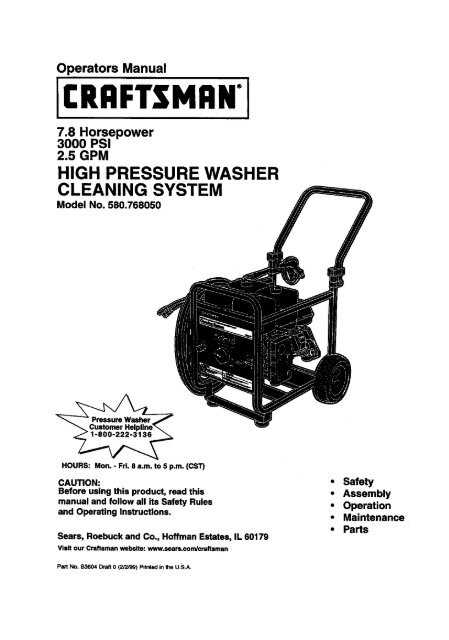

Replacement Parts for Craftsman Models

When it comes to maintaining your outdoor cleaning equipment, understanding the necessary components for replacement is crucial for optimal performance. These essential items can significantly enhance the longevity and efficiency of your machine, ensuring it operates at its best. Having access to reliable substitutes is vital for anyone looking to keep their unit in peak condition.

Several key elements are commonly required, including motors, hoses, and connectors, which may wear out over time. Identifying the right alternatives and sourcing them can make all the difference in restoring functionality. Additionally, referring to manufacturer specifications helps in selecting compatible options that fit seamlessly with your existing unit.

Regular maintenance and timely replacement of these crucial components will not only improve performance but also save you time and money in the long run. By keeping your equipment well-maintained, you ensure its readiness for any task, whether it’s a simple cleaning job or a more demanding project.

Tools Needed for Repairs

When it comes to maintaining and fixing your equipment, having the right tools is essential. A well-equipped workspace can significantly enhance your efficiency and ensure that repairs are carried out smoothly. Below are some of the vital instruments you may need to tackle common issues effectively.

Essential Tools

To start, a set of basic hand tools should be at your disposal. This includes screwdrivers, wrenches, and pliers, which are crucial for loosening and tightening various components. Additionally, a good quality socket set can make the process quicker, allowing for better leverage and access to tight spots.

Safety Equipment

Never underestimate the importance of safety gear. Using gloves can protect your hands from sharp edges and hot surfaces. Furthermore, safety goggles will shield your eyes from debris that might fly during the repair. Always ensure that you have these protective items on hand to promote a safe working environment.

Safety Precautions During Repairs

When undertaking maintenance or fixing machinery, it is crucial to prioritize safety to prevent accidents and injuries. Adhering to specific guidelines ensures a secure environment, allowing for effective repairs while minimizing risks.

First and foremost, always disconnect the equipment from its power source before starting any work. This simple step can prevent unexpected activation, which could lead to serious harm. Additionally, use appropriate protective gear, such as gloves, goggles, and masks, to shield yourself from potential hazards.

Moreover, maintain a clean workspace to avoid trips and falls. Ensure that tools are organized and materials are stored safely. Familiarizing yourself with the equipment’s manual can also provide vital information on safe handling and specific precautions needed for repairs.

Lastly, never hesitate to seek help if you’re uncertain about a repair. Consulting a professional can save time and ensure that the job is done correctly, ultimately enhancing your safety and the efficiency of the task at hand.

Where to Buy Replacement Parts

Finding suitable components for your equipment can be a straightforward process if you know where to look. Numerous options are available for sourcing the necessary items to keep your machinery running efficiently. Whether you prefer online shopping or local stores, understanding your choices can save you time and money.

Here are some recommended sources for obtaining replacement components:

| Source | Advantages | Considerations |

|---|---|---|

| Online Retailers | Wide selection, competitive prices, convenience | Shipping times, potential for incorrect parts |

| Manufacturer’s Website | Genuine components, reliability | Higher prices, limited availability |

| Local Hardware Stores | Immediate access, expert advice | Limited inventory, higher costs |

| Salvage Yards | Cost-effective options, unique finds | Quality concerns, less guarantee |

Assessing these options can help you make an informed decision, ensuring your equipment remains in optimal working condition.

Cost Considerations for Parts Replacement

When it comes to maintaining equipment, understanding the financial implications of replacing components is crucial. Many factors can influence the overall expenditure, ranging from the quality of the replacements to potential labor costs. Careful evaluation of these elements can lead to more informed decisions and ultimately save money in the long run.

Factors Influencing Costs

- Quality of Components: Higher quality items may have a higher upfront cost but can offer better durability and performance.

- Labor Expenses: If you opt for professional installation, factor in the cost of labor, which can vary significantly based on location and service provider.

- Availability: Rare or specialized components may come at a premium, while more common items may be readily available at lower prices.

- Warranty and Support: Investing in items with a warranty can provide peace of mind and potential savings on future repairs.

Strategies for Cost Management

- Research and compare prices from different suppliers to find the best deal.

- Consider purchasing used or refurbished items if quality is not compromised.

- Evaluate whether DIY installation is feasible to save on labor costs.

- Stay informed about promotions and discounts from suppliers to capitalize on savings opportunities.

By carefully considering these aspects, you can make cost-effective choices that ensure your equipment remains in optimal working condition without breaking the bank.

DIY Repair vs. Professional Help

When faced with equipment malfunctions, individuals often grapple with the decision to tackle the issue themselves or seek assistance from experts. This choice hinges on various factors, including personal skills, the complexity of the problem, and the potential costs involved.

Benefits of DIY Repair

Taking on repairs independently can foster a sense of achievement and save money. With the right tools and guidance, many issues can be resolved effectively. Moreover, engaging in self-repair allows for a deeper understanding of the equipment, which can be beneficial for future maintenance.

Advantages of Professional Assistance

On the other hand, enlisting a specialist ensures that the repair is performed correctly and safely. Experts possess the experience and knowledge to address intricate problems that may be daunting for the average person. Additionally, professional service often comes with warranties, providing peace of mind for the owner.

Tips for Efficient Pressure Washing

Achieving optimal results while cleaning surfaces requires a blend of technique, preparation, and the right equipment. Knowing how to maximize effectiveness not only saves time but also enhances the longevity of the surfaces being treated. Here are some practical suggestions to improve your cleaning process.

Preparation is Key

Before starting any cleaning task, ensure that the area is well-prepared. This involves removing obstacles, covering nearby plants or furniture, and ensuring safety measures are in place. A clean workspace can significantly enhance efficiency.

Choose the Right Nozzle

Utilizing the correct nozzle is crucial for varying cleaning tasks. Different nozzles offer various spray patterns and pressures, allowing you to tackle specific surfaces effectively. Refer to the table below to select the appropriate nozzle for your needs.

| Nozzle Color | Angle | Best For |

|---|---|---|

| Red | 0° | Heavy-duty cleaning, stubborn stains |

| Yellow | 15° | Paint stripping, heavy mildew |

| Green | 25° | General cleaning, decks, driveways |

| White | 40° | Light cleaning, cars, windows |

| Black | Soap | Applying soap solutions |

By following these guidelines, you can enhance the effectiveness of your cleaning tasks while ensuring that surfaces remain undamaged and pristine.