Understanding the Greenworks Pressure Washer Parts Diagram

In the world of outdoor maintenance, having a clear grasp of your cleaning tools is essential for effective operation and upkeep. This section delves into the intricate components that make up these high-performance devices, illuminating their function and significance. By familiarizing yourself with these elements, you can enhance your experience and ensure your equipment runs smoothly.

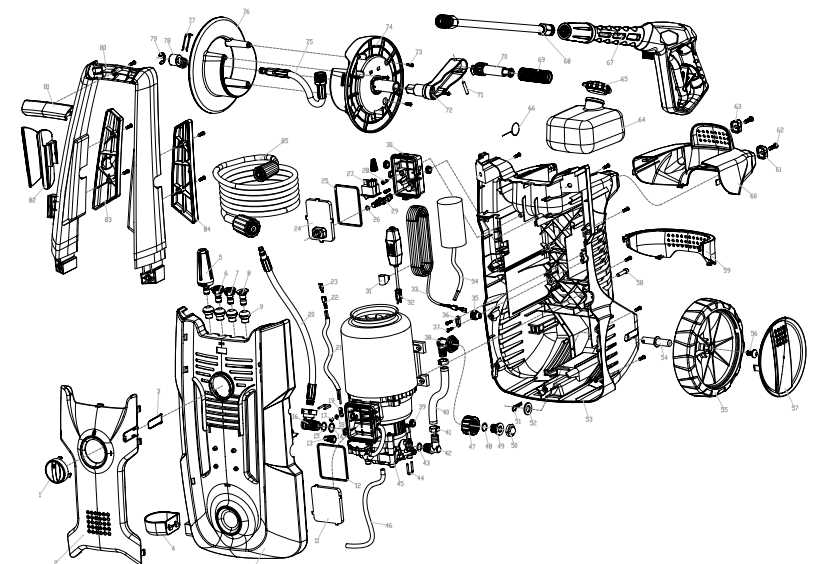

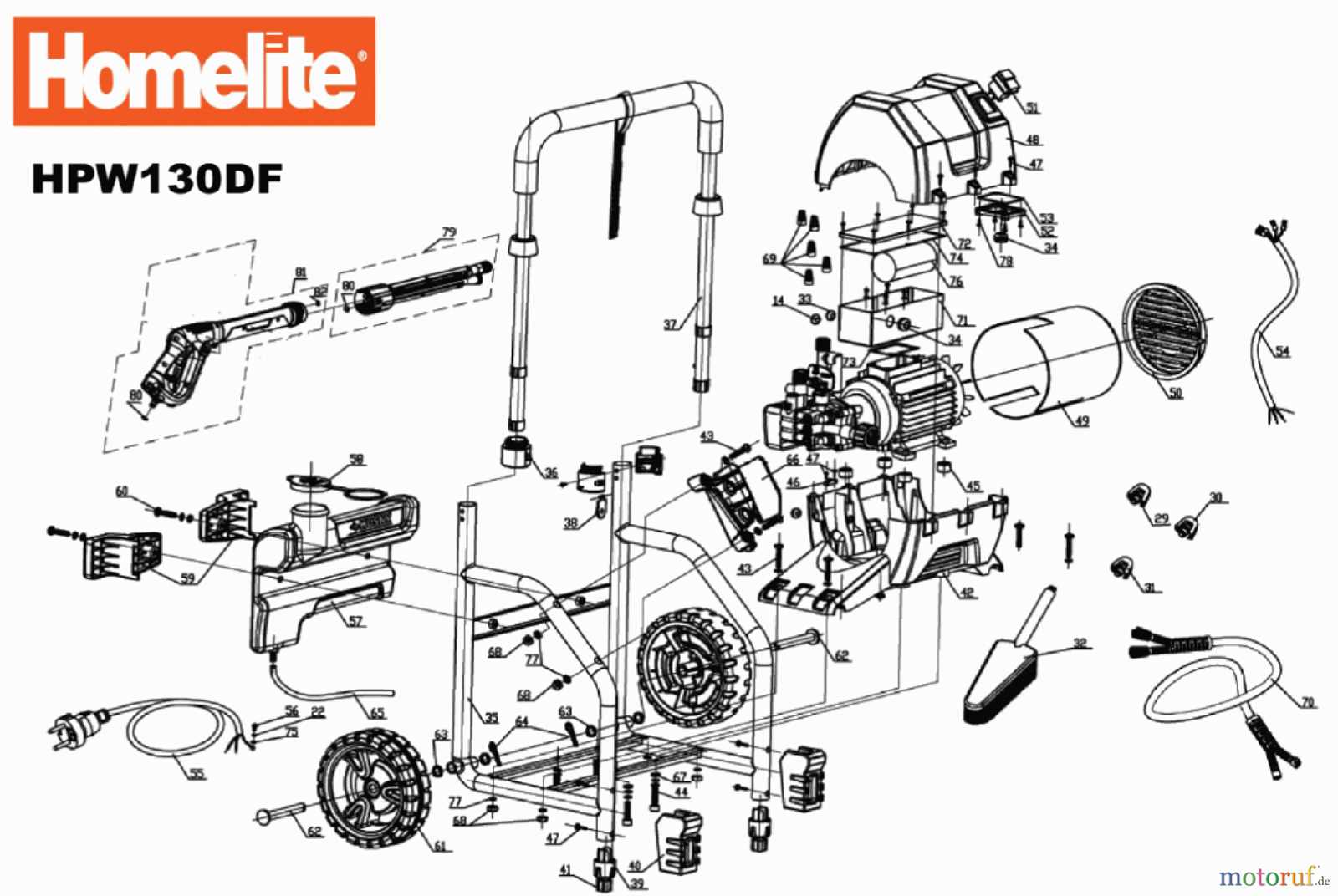

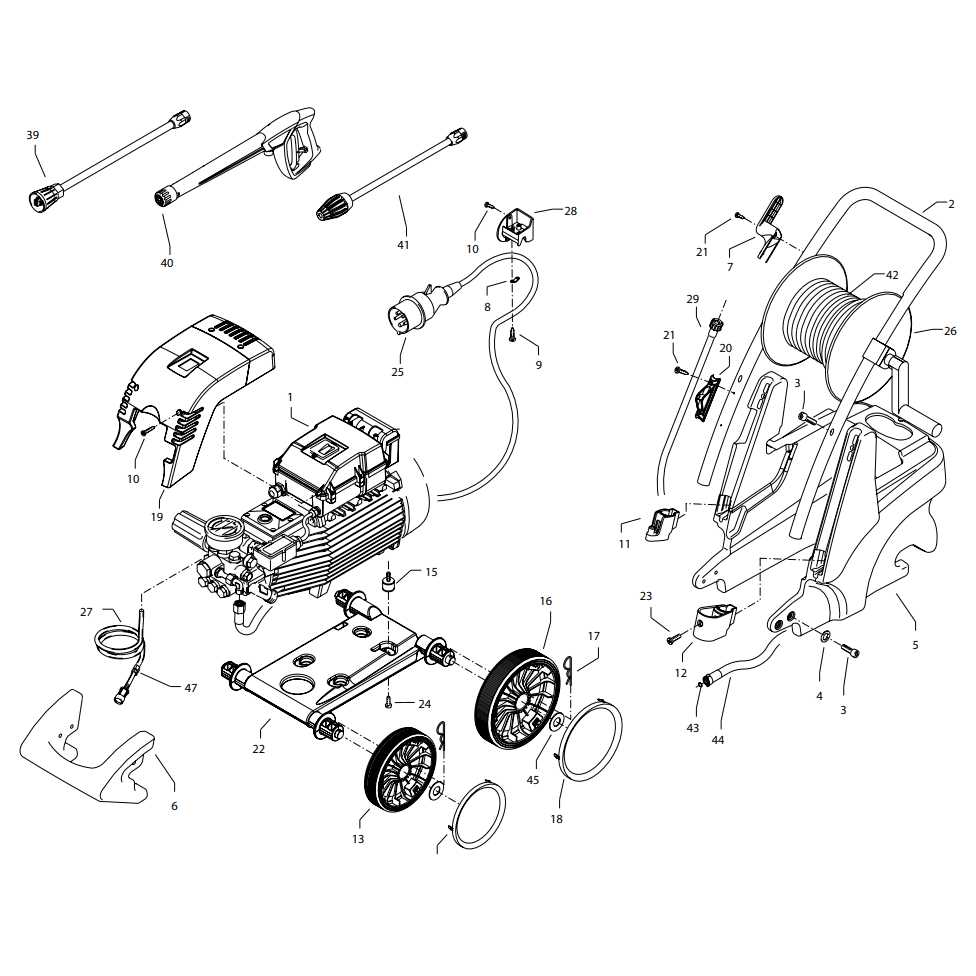

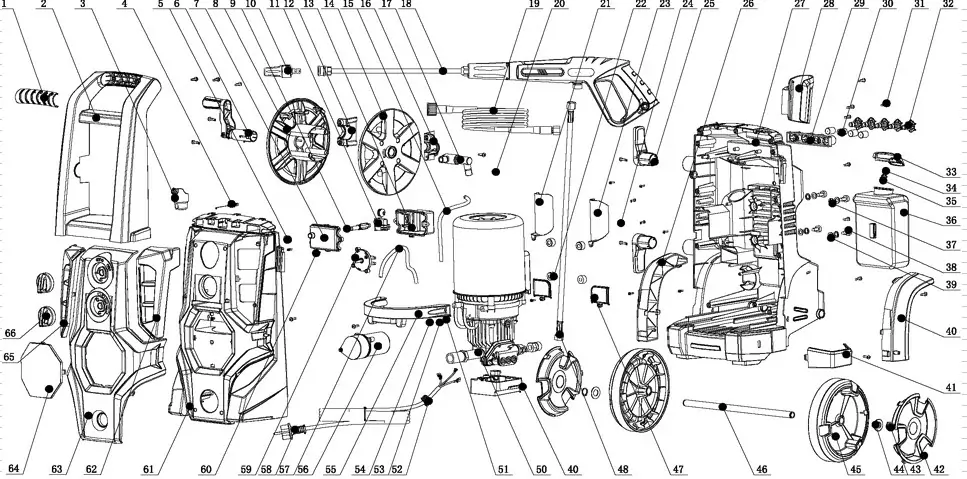

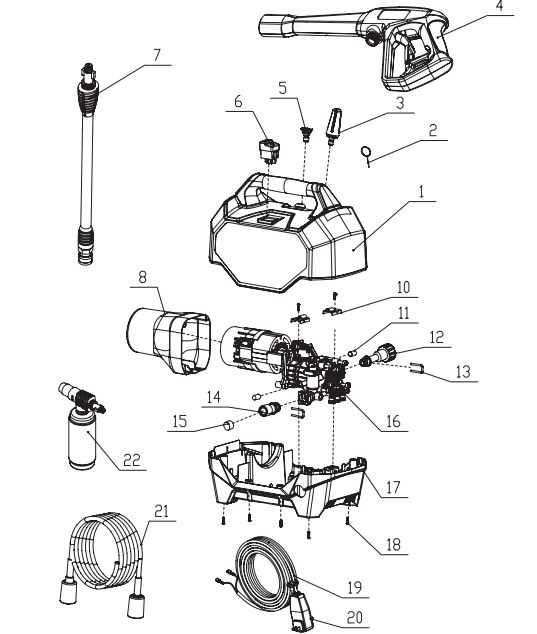

Visual aids play a crucial role in understanding the various components of your device. They provide a detailed representation that allows users to identify each segment, promoting informed maintenance and repair choices. Such insights can save time and reduce the risk of errors during handling.

Additionally, recognizing the relationships between different elements is vital for troubleshooting common issues. When users understand how each piece contributes to the overall functionality, they become better equipped to manage their equipment effectively. This knowledge empowers users to maintain their tools with confidence, ensuring optimal performance for all cleaning tasks.

Understanding Greenworks Pressure Washer Parts

Exploring the components of a cleaning machine can enhance your understanding of its functionality and maintenance needs. Each element plays a crucial role in ensuring efficient operation, and recognizing these roles can help in troubleshooting and repairs.

Key Components Overview

The main elements include the motor, hose, and spray nozzle. The motor serves as the driving force, converting electrical energy into mechanical energy. The hose facilitates the flow of liquid, while the nozzle determines the spray pattern and intensity, allowing for tailored cleaning approaches based on the surface being treated.

Maintenance and Troubleshooting

Regular inspection of each component is essential for optimal performance. Look for signs of wear, such as cracks in the hose or blockages in the nozzle. Addressing these issues promptly can extend the lifespan of the equipment and improve its efficiency. Understanding the functions of these key components empowers users to perform effective maintenance and make informed decisions when repairs are necessary.

Importance of a Parts Diagram

Understanding the intricate layout of components in any machine is crucial for effective maintenance and repair. A visual representation serves as a roadmap, guiding users through the various elements that make up the device. This tool not only simplifies the identification of each part but also enhances overall comprehension of the equipment’s functionality.

Clarity in Repairs: Having a well-illustrated representation allows for quicker and more accurate repairs. When users can easily locate specific elements, they can address issues promptly, reducing downtime and ensuring efficient operation.

Streamlined Maintenance: Regular upkeep is essential for longevity. A clear illustration aids in routine checks and part replacements, enabling users to follow best practices without confusion. This fosters a proactive approach to maintenance, preventing minor issues from escalating into major problems.

Enhanced Learning: For those new to machinery, visual aids are invaluable educational tools. They facilitate a deeper understanding of how components interact, allowing users to gain confidence and competence in handling repairs and maintenance.

Overview of Greenworks Pressure Washers

This section provides a comprehensive look at high-performance cleaning machines designed for outdoor use. These devices are engineered to tackle a variety of tasks, from removing dirt and grime from surfaces to enhancing the appearance of outdoor spaces. Understanding their components and functionality is essential for maximizing efficiency and ensuring longevity.

Key Features

- Powerful motors for effective cleaning.

- Variety of nozzle options for different applications.

- Lightweight and portable designs for ease of use.

- Eco-friendly operation with reduced energy consumption.

Benefits of Usage

- Enhanced cleaning efficiency saves time and effort.

- Versatile applications for home, garden, and vehicle maintenance.

- Improved aesthetics of surfaces leads to increased property value.

- Simple operation and maintenance make it user-friendly.

Main Components of Pressure Washers

Understanding the essential elements of high-performance cleaning devices is crucial for optimal usage and maintenance. Each component plays a vital role in ensuring efficiency and effectiveness during cleaning tasks.

- Motor: The heart of the device, providing the necessary power to operate the system.

- Pump: A critical mechanism that generates the force required to expel water at high velocity.

- Nozzle: The attachment that controls the spray pattern and pressure, allowing for versatility in cleaning.

- Hose: Facilitates the flow of water from the source to the cleaning area, often designed for flexibility and durability.

- Trigger Gun: The control interface that enables the user to start and stop the flow of water.

- Frame: The structure that houses all components, providing stability and ease of maneuverability.

Each of these elements must work harmoniously to deliver effective cleaning results, making familiarity with them essential for users.

How to Read a Parts Diagram

Understanding a schematic representation of components can significantly enhance your ability to repair and maintain equipment. By familiarizing yourself with the layout, you can quickly identify individual elements and their relationships to one another. This knowledge empowers you to troubleshoot issues and streamline the assembly process.

Identifying Symbols and Labels

The first step in interpreting a schematic is to recognize the various symbols and labels used. Each component is typically represented by a unique icon, accompanied by a reference number or name. Familiarizing yourself with these symbols will make it easier to locate specific parts and understand their functions within the overall system.

Understanding Relationships and Connections

Next, pay attention to how the components are connected. Lines often represent physical connections or pathways for energy and fluid. Understanding these relationships helps clarify how different elements interact and can guide you in troubleshooting potential problems. A clear grasp of the layout will enable more efficient repairs and modifications.

Common Issues with Pressure Washer Parts

When operating high-efficiency cleaning equipment, users often encounter various challenges that can hinder performance. Understanding these common difficulties can help maintain optimal functionality and extend the lifespan of the machine.

1. Clogged Filters: One frequent issue is the blockage of intake filters, which can restrict water flow and reduce efficiency. Regular cleaning or replacement of these components is essential to ensure smooth operation.

2. Leaks: Seals and hoses are prone to wear and tear, leading to leaks that can significantly impact performance. Inspecting these areas for cracks or damage is vital for effective maintenance.

3. Faulty Valves: Malfunctioning valves can cause inconsistent water pressure, affecting cleaning effectiveness. Identifying and repairing these components can restore proper function.

4. Pump Problems: The pump is crucial for generating the necessary pressure. Issues such as overheating or unusual noises may indicate underlying problems that require immediate attention.

5. Electrical Failures: Electrical components can also fail, leading to operational disruptions. Checking connections and components can help diagnose and rectify these issues quickly.

By being aware of these common challenges and conducting regular maintenance, users can enhance the reliability and efficiency of their cleaning equipment.

Maintenance Tips for Longevity

Ensuring the long-lasting performance of your equipment involves a few simple yet effective maintenance practices. Regular care not only enhances functionality but also extends the lifespan of your machinery. By following some basic guidelines, you can keep your unit in top condition for years to come.

Regular Cleaning: After each use, it is essential to remove any debris or residue that may accumulate. This prevents buildup that could hinder performance. Use a damp cloth or soft brush to wipe down surfaces, and ensure all nozzles are free from obstructions.

Check for Wear: Periodically inspect components for signs of wear or damage. Look for cracks, frayed hoses, or loose connections. Addressing these issues promptly can prevent more significant problems down the line.

Fluid Maintenance: Keeping fluid levels at optimal levels is crucial. Regularly check and replace any necessary fluids according to the manufacturer’s recommendations. Clean filters and ensure that all fluid passages are clear to promote efficient operation.

Proper Storage: When not in use, store your equipment in a dry, sheltered location. Protect it from extreme temperatures and direct sunlight, which can degrade materials over time. Consider using a cover for added protection against dust and moisture.

Follow Manufacturer Guidelines: Always adhere to the maintenance schedule and guidelines provided in the user manual. This includes recommended servicing intervals and any specific care instructions tailored to your model.

Implementing these practices will help ensure that your equipment remains reliable and efficient, ultimately saving you time and money in the long run.

Identifying Parts by Model Number

Understanding the components of your equipment is essential for effective maintenance and repairs. By recognizing the specific model number, users can access detailed information about each element, ensuring accurate replacements and optimal performance.

Importance of Model Number

The model number serves as a unique identifier, linking the device to its exact specifications. This information allows users to delve into the specific requirements for maintenance, helping to avoid mistakes when sourcing new components.

How to Locate Model Numbers

Typically, model numbers can be found on the equipment itself, often near the motor or base. Make sure to check the user manual for guidance on locating this crucial information, which ultimately facilitates a smoother repair process.

Where to Find Replacement Parts

Locating suitable components for your equipment can enhance its performance and longevity. Various resources are available to ensure you find the right items for your needs.

- Manufacturer’s Website: Check the official site for direct listings and specifications.

- Authorized Retailers: Visit local or online stores that are certified to sell your brand’s products.

- Online Marketplaces: Explore platforms like Amazon or eBay for a wide range of options.

- Repair Shops: Consult with local service centers that may offer parts and expert advice.

- Community Forums: Engage in online communities where users share experiences and sources for components.

By utilizing these avenues, you can effectively delve into your search for necessary items and ensure your equipment remains in top condition.

Tools Needed for DIY Repairs

Embarking on do-it-yourself maintenance tasks requires a specific set of instruments to ensure effective and safe repairs. Having the right tools at your disposal not only simplifies the process but also enhances the quality of your work. Below is a comprehensive list of essential implements for tackling common repair jobs.

Essential Tools

- Screwdrivers: A variety of flathead and Phillips screwdrivers will cover most fastening needs.

- Wrenches: Both adjustable and fixed wrenches are crucial for loosening or tightening bolts.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping and manipulating small components.

- Socket Set: A set of sockets and a ratchet will make working with nuts and bolts easier and more efficient.

- Hammer: A basic claw hammer is ideal for driving nails and performing light demolition work.

Additional Helpful Tools

- Utility Knife: Perfect for cutting various materials with precision.

- Measuring Tape: Ensures accurate measurements for fitting components together.

- Level: Useful for checking the alignment of surfaces.

- Multimeter: Essential for diagnosing electrical issues and checking voltages.

- Work Gloves: Protect your hands while ensuring a better grip on tools and materials.

Safety Precautions During Repairs

When undertaking maintenance on any equipment, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions not only protect the individual performing the repairs but also ensure that the equipment functions correctly after servicing. Here are essential measures to consider during your repair activities.

Personal Protective Equipment

Wearing the right gear is fundamental. This includes gloves, goggles, and sturdy footwear to shield yourself from potential hazards.

Work Area Safety

Maintaining a clean and organized workspace minimizes risks. Ensure that your area is free from clutter and that tools are stored properly when not in use.

| Precaution | Description |

|---|---|

| Disconnect Power Source | Always unplug the equipment before starting repairs to eliminate electrical hazards. |

| Read the Manual | Familiarize yourself with the equipment’s manual to understand specific safety instructions. |

| Use Tools Correctly | Employ the appropriate tools for the task to prevent damage and ensure safety. |

| Stay Alert | Concentrate on the task at hand to avoid distractions that could lead to accidents. |

Upgrading Your Pressure Washer Parts

Enhancing the components of your cleaning device can significantly improve its efficiency and longevity. By selecting high-quality replacements and upgrades, users can experience better performance and achieve optimal results in their cleaning tasks. This section explores various aspects of enhancing your equipment.

Benefits of Upgrading

Investing in superior components can lead to numerous advantages, including increased reliability, improved cleaning power, and reduced maintenance needs. Upgrades can also extend the lifespan of your machine, making it a worthwhile consideration for regular users.

Key Components to Consider

| Component | Upgrade Options | Benefits |

|---|---|---|

| Motor | High-efficiency models | Enhanced power and durability |

| Hoses | Reinforced materials | Resistance to wear and leaks |

| Gun | Ergonomic designs | Improved comfort and control |

Resources for Further Information

Exploring additional resources can greatly enhance your understanding and maintenance of cleaning equipment. Access to comprehensive guides and user manuals ensures optimal performance and longevity of your tools.

Online Manuals and Guides

Many manufacturers provide downloadable manuals on their websites, offering detailed instructions and troubleshooting tips. These resources are invaluable for anyone looking to deepen their knowledge.

Community Forums and Support Groups

Joining online communities dedicated to cleaning equipment can facilitate discussions and knowledge sharing. Engaging with experienced users can lead to practical insights and solutions to common issues.