Comprehensive Guide to Honda GC160 Pressure Washer Parts Diagram

Every effective cleaning machine is built from a range of essential elements that work harmoniously to deliver outstanding performance. Gaining insight into these individual components can significantly enhance your maintenance routine and extend the lifespan of your device. A clear visualization of how these parts interact with each other is crucial for anyone looking to troubleshoot or optimize their equipment.

Within this section, we will explore a detailed representation of the various components that contribute to the functionality of your device. By understanding each part’s role, you can make informed decisions regarding repairs and replacements. This knowledge is invaluable not only for enthusiasts but also for those who rely on their equipment for daily tasks.

Whether you’re a seasoned professional or a casual user, familiarizing yourself with these intricate details can lead to improved efficiency and reliability. Recognizing how each piece fits into the larger picture enables you to tackle issues more effectively and ensures that your cleaning tasks are completed with ease.

Understanding Honda GC160 Pressure Washer

This section explores the essential elements and components of a popular cleaning machine known for its reliability and efficiency. By gaining insight into its functionality, users can enhance their understanding and maintenance of this equipment.

Key Features

- Powerful engine designed for effective cleaning.

- Compact and lightweight design for easy maneuverability.

- User-friendly controls for straightforward operation.

- Versatile accessories for various cleaning tasks.

Maintenance Tips

- Regularly check and replace oil to ensure optimal performance.

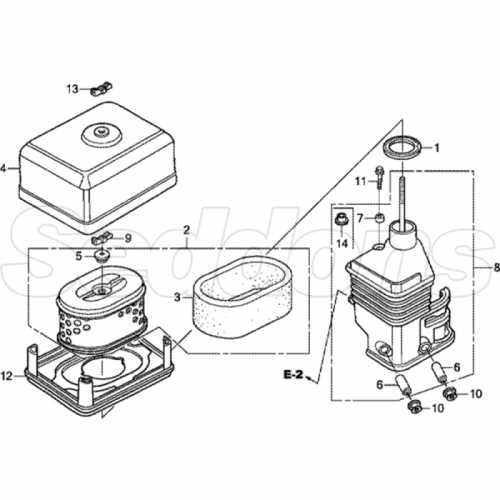

- Clean filters to maintain airflow and efficiency.

- Inspect hoses and connections for wear or damage.

- Store the unit in a dry place to prevent rust and corrosion.

Understanding these features and maintenance practices can significantly extend the lifespan and effectiveness of the cleaning device, making it an invaluable tool for various applications.

Key Features of Honda GC160

This engine is designed to deliver exceptional performance and reliability in various applications. It combines innovative engineering with user-friendly features, making it an ideal choice for both casual users and professionals alike. From its powerful output to its efficient operation, this model stands out in its category.

Powerful Performance

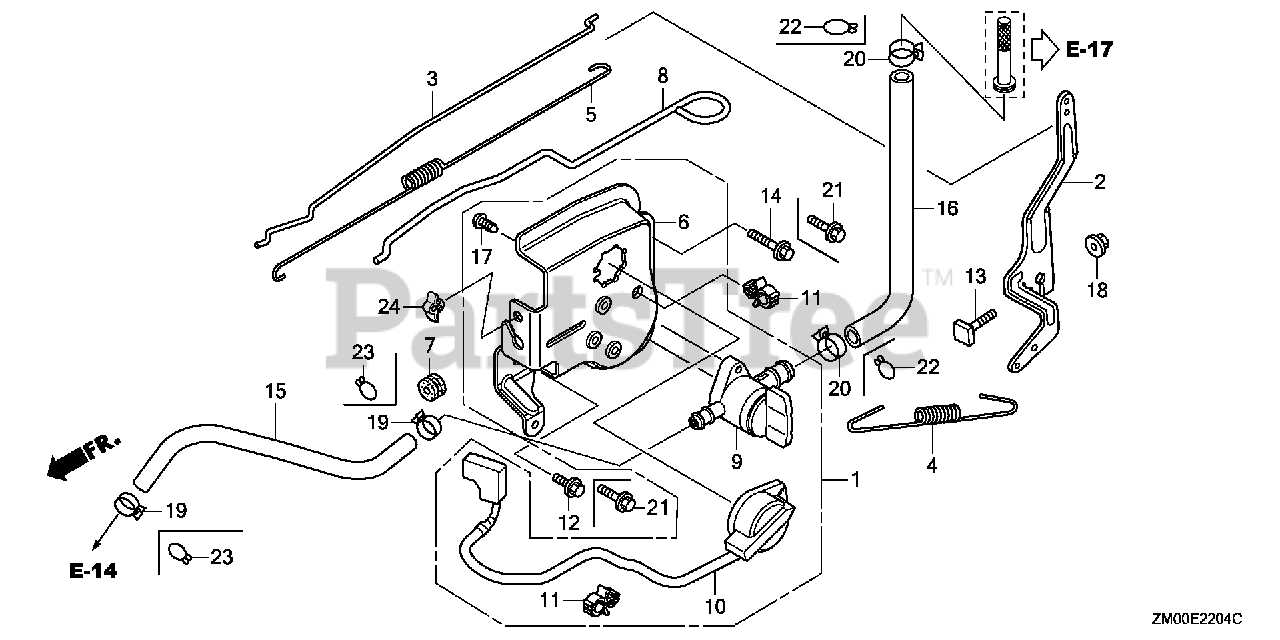

Equipped with a robust motor, this engine ensures consistent and strong performance. Its design allows for efficient combustion, resulting in a significant power-to-weight ratio. Users can expect quick start-ups and a smooth operation, making tasks more manageable and efficient.

User-Friendly Design

The layout of this model emphasizes ease of use. Key features include an accessible recoil starter and straightforward maintenance points, allowing users to keep the engine in top condition with minimal effort. Additionally, the lightweight construction enhances portability, making it easy to transport to various job sites.

In summary, this engine excels in performance and usability, ensuring reliable operation for a wide range of tasks.

Common Uses for Pressure Washers

These powerful cleaning machines are essential for tackling a variety of tasks around the home and garden. Their versatility allows users to effectively remove dirt, grime, and stains from numerous surfaces, making them invaluable for maintenance and restoration projects.

1. Driveway and Sidewalk Cleaning: Over time, driveways and walkways accumulate oil stains, dirt, and algae. A robust cleaning unit can effortlessly lift these blemishes, restoring the original appearance.

2. Deck and Patio Maintenance: Wooden and composite surfaces benefit greatly from a thorough wash. Removing debris and mildew not only enhances aesthetics but also prolongs the life of these outdoor areas.

3. Vehicle Detailing: These machines are also perfect for cleaning cars, trucks, and motorcycles. They can dislodge stubborn dirt and mud from wheel wells and undercarriages, providing a comprehensive clean.

4. Home Exterior Cleaning: Sidings, brick, and stucco can develop mold and mildew. Using a cleaning unit helps rejuvenate these surfaces, making them look fresh and new.

5. Fencing and Wall Restoration: Wooden fences and walls often attract dirt and biological growth. A deep clean can restore their natural beauty and prepare them for painting or staining.

6. Outdoor Furniture Cleaning: Garden chairs, tables, and cushions can accumulate dirt and mildew. A thorough wash makes them ready for use during the outdoor season.

By harnessing the power of these machines, users can maintain and enhance their property effectively, ensuring it looks its best year-round.

Importance of Maintenance for Longevity

Regular upkeep is crucial for ensuring the extended lifespan of any machinery. Neglecting routine care can lead to diminished performance, increased wear, and ultimately, costly repairs. By prioritizing maintenance, users can enhance efficiency and reliability, ensuring that their equipment remains in optimal working condition.

Consistent inspection allows for early detection of potential issues, preventing small problems from escalating into significant malfunctions. Furthermore, cleaning and lubricating components not only improves functionality but also reduces friction and heat buildup, which are common culprits of wear and tear.

In addition, adhering to a maintenance schedule cultivates a deeper understanding of the equipment. Users become familiar with its specific needs and performance characteristics, enabling them to make informed decisions about repairs and upgrades. Ultimately, a commitment to maintenance translates to enhanced reliability, cost savings, and a more satisfying user experience.

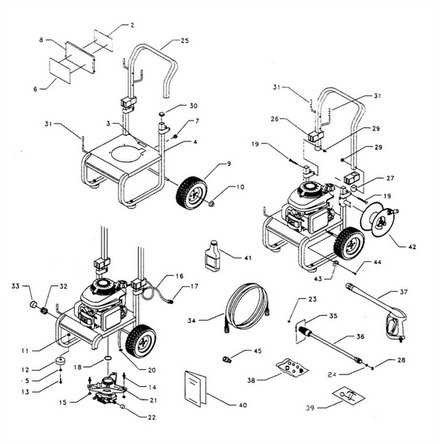

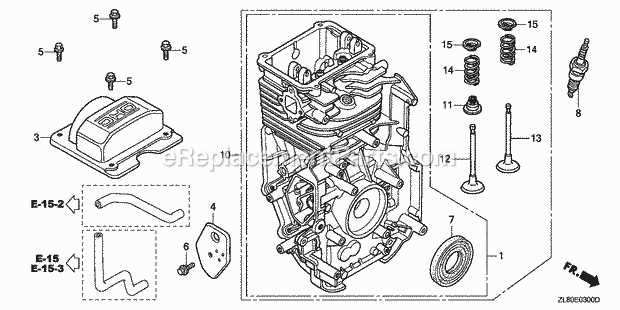

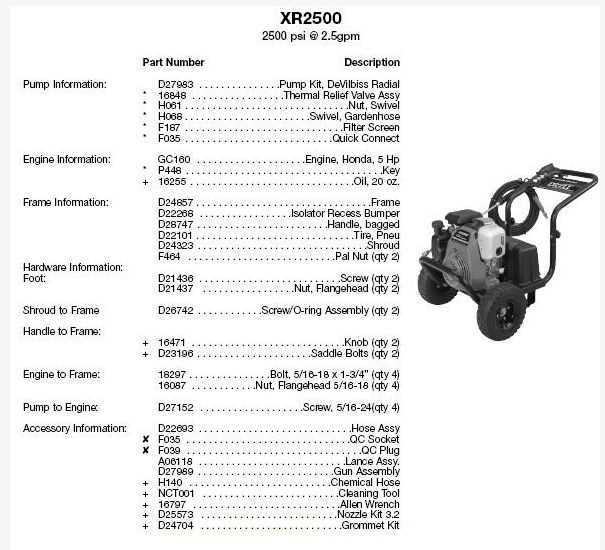

Identifying Parts in Diagrams

Understanding the components of machinery through visual representations is essential for effective maintenance and repairs. These illustrations serve as invaluable guides, allowing users to familiarize themselves with each element’s function and location. By breaking down complex systems into simpler visuals, one can easily pinpoint necessary replacements or adjustments.

When examining a visual guide, it’s important to recognize various types of components. Here’s a table that outlines common categories you might encounter:

| Component Type | Description |

|---|---|

| Engine | The core unit responsible for power generation. |

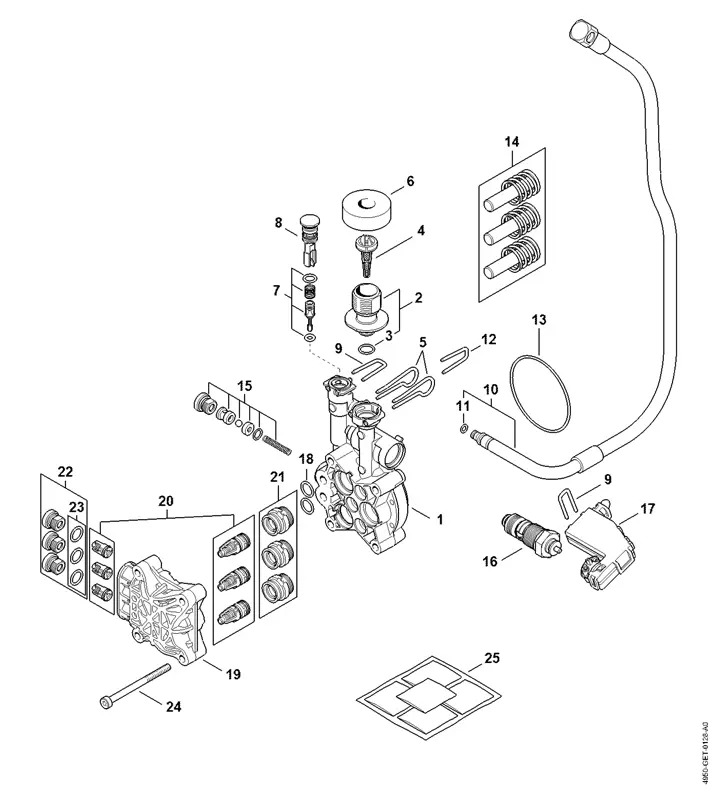

| Pump | Part that moves fluid through the system. |

| Hoses | Flexible tubes that transport liquids. |

| Nozzle | Attachment that directs the flow of liquid. |

| Frame | Structural base that supports all components. |

Familiarizing yourself with these categories can enhance your ability to navigate the visual aids effectively, ensuring that you can identify and address any issues that may arise in the system.

How to Read Parts Diagrams

Understanding assembly illustrations is essential for effectively maintaining and repairing machinery. These visuals provide a clear representation of components and their relationships, enabling users to identify each element and its function within the overall system. Familiarity with how to interpret these visuals can save time and enhance the accuracy of repairs.

Identifying Components

Each symbol or label within the illustration corresponds to a specific element of the equipment. Pay attention to numbers or letters that may be included, as they often reference parts in a corresponding list. This helps in locating the correct replacement items when necessary, ensuring compatibility and efficiency in repairs.

Understanding Relationships

Diagrams typically show how parts connect and interact with one another. Arrows may indicate movement or flow, while lines can represent connections or pathways. By recognizing these relationships, users can troubleshoot issues more effectively, understanding how a malfunction in one component can affect the overall operation.

Essential Components of Pressure Washers

Understanding the key elements that make up these cleaning machines is crucial for effective maintenance and optimal performance. Each component plays a specific role in the overall functionality, contributing to the device’s ability to deliver high-pressure water for a variety of cleaning tasks.

Key Elements

One of the primary components is the motor, which powers the entire system. Its efficiency directly affects the force and consistency of the water flow. Following closely is the pump, responsible for generating the necessary pressure. This unit transforms mechanical energy into hydraulic energy, enabling the machine to tackle tough stains and grime.

Additional Features

Another vital aspect includes the nozzle, which adjusts the spray pattern and pressure. Different nozzles can create a wide spray for gentle cleaning or a narrow jet for more challenging tasks. Additionally, the hose serves as the conduit for water, with durability being essential for long-term use. Understanding these fundamental parts ensures better care and extends the lifespan of your cleaning apparatus.

Where to Find Replacement Parts

Finding components for your equipment can be a straightforward process if you know where to look. Various resources offer a wide selection of items to ensure your machine runs smoothly. Whether you are seeking OEM replacements or aftermarket alternatives, understanding your options is key to making an informed choice.

Online Retailers

Many websites specialize in outdoor machinery and offer extensive catalogs of items. These platforms typically provide detailed descriptions, images, and customer reviews, allowing you to compare options easily. Search for reliable e-commerce sites that focus on tools and machinery to find the specific components you need.

Local Repair Shops

Your nearby repair shops can be an excellent resource for finding necessary components. Many shops maintain a stock of popular items and can order specific parts if they are not readily available. Additionally, speaking with knowledgeable staff can provide insights into the best alternatives and maintenance tips.

Remember, always double-check the compatibility of the components with your equipment model to ensure optimal performance. Seeking advice from experts or reading online forums can also enhance your purchasing experience.

Tips for DIY Repairs

Embarking on a do-it-yourself repair journey can be both rewarding and challenging. With the right approach, you can save time and money while gaining a deeper understanding of your equipment. Here are some valuable insights to help you tackle repairs effectively.

1. Gather Your Tools and Resources

Before starting any project, ensure you have the necessary tools at hand. A well-stocked toolbox can make a significant difference. Research is equally important; manuals and online tutorials can provide guidance and clarity on the steps involved.

2. Safety First

Always prioritize safety when performing repairs. Wear appropriate protective gear, such as gloves and goggles, to minimize risks. Additionally, ensure that the equipment is disconnected from any power source to prevent accidents. Taking these precautions can help you work more confidently and effectively.

Comparing Honda Models and Parts

When evaluating various engine models, it is essential to understand the differences in their components and functionalities. Each design comes with its own set of features that cater to specific needs, ensuring optimal performance across a range of applications. This section will delve into the nuances of these engines and highlight the distinctions that set them apart.

Engine Specifications

Different models boast unique specifications that influence their efficiency and power output. Power ratings, fuel consumption, and operational capabilities can vary significantly, making it crucial to select the right model for your requirements. For instance, some engines are tailored for heavy-duty tasks, while others excel in lighter applications.

Component Compatibility

Understanding the compatibility of various elements is vital for maintenance and repair. Internal mechanisms such as pistons, valves, and filters may differ across models, impacting overall functionality. Proper knowledge of these components can aid in making informed decisions when it comes to replacements and upgrades, ultimately enhancing the longevity of your equipment.

Common Issues and Troubleshooting Tips

When utilizing outdoor cleaning equipment, it’s not uncommon to encounter a range of challenges that may affect performance. Understanding these common problems can significantly enhance your troubleshooting skills, ensuring that your machine operates efficiently and effectively. Below are some prevalent issues and their solutions that can help restore functionality.

1. Engine Fails to Start

If the engine does not ignite, check the fuel level first. Ensure that you are using fresh fuel, as stale or contaminated fuel can hinder operation. Additionally, inspect the spark plug for wear or damage; replacing it may resolve the issue. Always confirm that the choke is in the correct position before attempting to start.

2. Insufficient Cleaning Power

When the equipment does not deliver adequate cleaning force, the nozzle might be clogged. Detach and clean it thoroughly to restore optimal flow. Also, verify that the hose is free from kinks and blockages. If the motor seems weak, consider checking the oil level and condition, as low or dirty oil can impact performance.

By identifying these issues early and applying the suggested solutions, you can prolong the lifespan of your equipment and maintain its effectiveness during use.

Upgrading Your Pressure Washer Performance

Enhancing the efficiency and effectiveness of your cleaning equipment can significantly improve your overall experience. By focusing on various components and their interactions, you can achieve remarkable results and make your tasks more manageable. A few key upgrades can transform the performance and durability of your device, making it suitable for various applications.

Key Components to Consider

Begin with the motor, as it directly influences the power and speed of your device. A high-performance motor can increase cleaning efficiency, allowing you to tackle tougher jobs with ease. Additionally, consider upgrading the nozzle. Different spray patterns and pressures can optimize cleaning for specific surfaces, ensuring you achieve the desired results without damaging the material.

Maintenance and Care

Regular maintenance is crucial for prolonging the lifespan of your equipment. Ensure that all components, such as filters and hoses, are in good condition and free from debris. Replacing worn-out parts promptly will not only enhance performance but also prevent further damage. Investing time in upkeep pays off by maintaining efficiency and saving costs in the long run.