LG Tromm Washing Machine Parts Overview

Understanding the structure and key elements of your home appliance can be crucial for ensuring its longevity and smooth operation. By familiarizing yourself with its internal setup, you can easily identify potential issues and know where specific adjustments or replacements are needed. This can not only save you time but also prevent costly repairs in the future.

Exploring the various elements that work together behind the scenes provides valuable insights into how different components interact. With this knowledge, users can better handle any complications that may arise during regular use. Whether it’s a small adjustment or a larger repair, having a solid grasp of the inner workings ensures smoother, more efficient upkeep.

LG Tromm Washing Machine Overview

The device from LG is designed to provide efficient fabric care while offering various advanced features for optimal performance. It caters to both delicate items and larger loads, making it versatile for different laundry needs. Its intuitive controls and modern design ensure user-friendly operation and effective results with minimal effort.

| Feature | Description |

|---|---|

| Capacity | Handles large loads for better energy and water efficiency. |

| Controls | Offers a range of settings tailored to various fabric types and care requirements. |

| Design | Sleek appearance combined with durable materials to enhance longevity and functionality. |

| Efficiency | Optimized for conserving energy while delivering high-quality cleaning performance. |

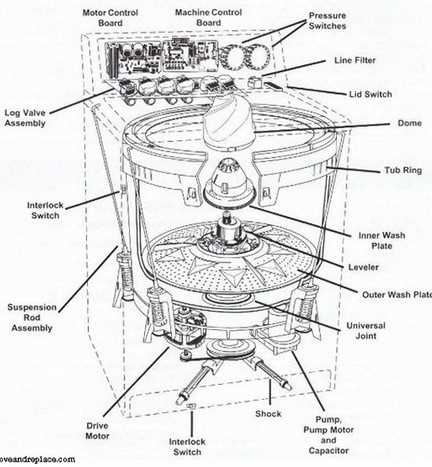

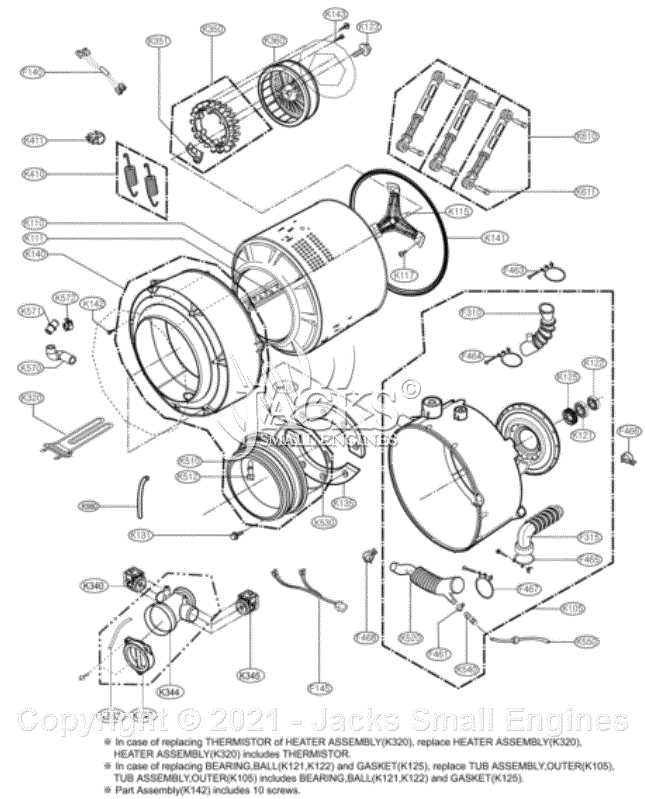

Main Components of LG Tromm

The key elements in this model are carefully designed to ensure efficient performance and user convenience. Each part plays a critical role in ensuring smooth operation and optimal functioning over time. The system is built for durability, with components working together to handle a range of tasks seamlessly.

Core mechanical units include a robust motor that drives the entire process, ensuring consistent power and speed. Additionally, specialized elements manage the flow and temperature, making sure the device operates at peak efficiency. These components provide the foundation for a reliable and efficient system.

Advanced control mechanisms allow for easy adjustments and custom settings, giving users flexibility in operation. This intuitive design ensures user-friendly handling while maintaining performance standards. Together, these features create a cohesive and reliable solution for modern needs.

Understanding the LG Tromm Control Panel

The control panel on this device is designed to provide a seamless and intuitive way to manage all the settings required for optimal operation. With a range of buttons and indicators, users can easily select the preferred functions and track the progress of ongoing tasks. Whether it’s adjusting the time, selecting a mode, or monitoring performance, the interface simplifies the process of interaction.

Key Buttons and Features

Several essential buttons are found on the control panel, each serving a specific purpose. These include options for setting temperatures, cycle durations, and special modes. The buttons are clearly labeled, making it straightforward to configure the unit according to personal preferences.

Progress Indicators and Feedback

A variety of lights or digital displays on the panel provide feedback on the current status. These indicators help track various stages of the process, from start to completion, ensuring users are informed about

Functions and Settings of the Display

The display provides users with an intuitive interface to manage and monitor various options. It shows essential information, helping to choose and adjust settings for optimal use. With a clear layout, the display offers easy access to all necessary functions.

Through the display, users can customize parameters like duration, intensity, and mode based on their preferences. It also provides notifications and feedback during use, making adjustments simple and efficient. Understanding how to interact with these features ensures smooth operation and maximizes the device’s potential.

Drum and Agitator Mechanism

The central components responsible for the movement and rotation within the system are the drum and agitator. These two elements work together to ensure efficient motion, guiding the contents through cycles of agitation and rotation. Their design and operation are key to ensuring effective performance, contributing to the overall functionality of the appliance.

Drum serves as the main container, where the rotation allows for consistent distribution and interaction of items during operation. The balanced movement it provides is essential for minimizing wear and tear while maintaining effectiveness.

The agitator, meanwhile, introduces additional motion within the system. It complements the drum’s rotation by creating targeted movement, enhancing the overall process. Its function ensures that all areas of the drum are utilized efficiently, promoting thorough interaction and optimal results.

How the Drum Rotates in LG Tromm

The spinning mechanism of the drum plays a crucial role in ensuring that clothes are effectively cleaned. This process relies on the coordination of several components that work together to achieve smooth and consistent movement. Understanding how these elements interact can help in maintaining efficiency and identifying potential issues.

- Motor Functionality: A specialized motor powers the drum, controlling its speed and direction. This motor is essential for the back-and-forth motion that ensures garments are evenly tumbled.

- Belt System: The motor is connected to the drum through a belt system. This belt transfers the motor’s energy, making sure the drum moves at the desired pace.

- Balancing Act: Sensors monitor the weight distribution inside the drum, ensuring that even with an uneven load, the movement remains stable, reducing wear and tear on the components.

- Speed Variation: The drum’s rotation speed can vary depending on the cycle, with faster spins used to remove excess water and slower speeds used during the washing process for delicate care.

By managing these processes effectively, the drum rotation mechanism ensures that garments are properly treated during every phase of the cycle, maintaining both performance and fabric care.

Water Inlet and Valve System

The water intake and valve assembly plays a crucial role in regulating the flow of liquid into the appliance. This system ensures that the appropriate amount of water is supplied during different cycles, contributing to the overall efficiency and performance of the equipment.

Functionality Overview

This assembly consists of various components that work in harmony to control water entry. The valves are responsible for opening and closing at specific times, allowing water to fill the drum while preventing any leaks. Proper operation of this system is essential for effective cleaning and rinsing.

Common Issues

Several problems can arise with the water inlet and valve system, including clogs, leaks, or valve malfunctions. Regular maintenance and inspection can help identify these issues early, ensuring optimal performance and prolonging the lifespan of the unit.

| Component | Function |

|---|---|

| Water Inlet Valve | Controls water flow into the unit. |

| Filter Screen | Prevents debris from entering the water system. |

| Pressure Switch | Detects water level and signals the valve to open or close. |

Controlling Water Flow in the Machine

Effective management of liquid movement is essential for optimal functionality. This process involves various components working in harmony to ensure the correct amount of fluid is utilized during each cycle. Understanding how to regulate this flow can lead to improved efficiency and performance.

Key Components for Water Regulation

Several critical elements contribute to controlling the flow of water:

- Inlet Valve: Regulates the entry of water into the system based on the programmed settings.

- Pressure Switch: Monitors the water level and activates the inlet valve as needed.

- Drain Pump: Ensures that excess water is expelled from the system at the appropriate times.

- Flow Meter: Tracks the amount of water used, allowing for accurate measurement and adjustments.

Adjusting Water Flow for Optimal Performance

To maintain peak efficiency, consider the following adjustments:

- Regularly inspect and clean the inlet valve to prevent blockages.

- Test the pressure switch to ensure it is functioning correctly.

- Check the drain pump for any obstructions to facilitate proper drainage.

- Monitor the flow meter readings for any discrepancies and make necessary calibrations.

Pump and Drainage System Explained

The pump and drainage system plays a crucial role in the effective functioning of any cleaning appliance. This setup ensures that water is efficiently circulated and removed during the cleaning cycle. Understanding how this system operates can help users troubleshoot potential issues and maintain optimal performance.

Components of the Pump and Drainage System

Several essential elements work together to facilitate water movement and drainage:

- Drain Pump: This component actively removes water from the appliance after the cleaning cycle.

- Drain Hose: The flexible tube directs the expelled water away from the appliance.

- Filters: These prevent debris from clogging the system, ensuring smooth water flow.

- Water Inlet Valve: This controls the amount of water entering the appliance, playing a vital role in the cleaning process.

Common Issues and Solutions

Users may encounter various challenges related to the pump and drainage system. Here are some typical problems and their potential solutions:

- Clogged Drain Hose: If the drainage tube is blocked, it can prevent water from exiting the unit. Regularly check and clean the hose to maintain proper flow.

- Faulty Pump: A malfunctioning pump can lead to inadequate water removal. If you notice unusual noises or water retention, consider inspecting or replacing the pump.

- Filter Blockage: Dirty filters can hinder water movement. Cleaning or replacing filters regularly helps avoid performance issues.

How the Pump Removes Water Efficiently

The mechanism responsible for extracting excess fluid operates with remarkable precision, ensuring optimal performance during the cleaning cycle. This essential component plays a vital role in facilitating the removal of water, contributing significantly to the overall efficiency of the process.

First, the fluid is directed into the pump chamber, where it is subjected to a series of actions designed to maximize extraction. The pump utilizes a combination of suction and pressure, allowing it to draw the liquid out rapidly.

Additionally, the design of the pump ensures that it can handle varying volumes of fluid, adapting to different load sizes effectively. This adaptability is crucial for maintaining performance consistency, regardless of the load type.

Moreover, efficient drainage not only prevents potential issues related to water buildup but also aids in reducing energy consumption. By minimizing the time taken to expel the fluid, the entire cycle can proceed without unnecessary delays.

In conclusion, the effectiveness of the fluid extraction system lies in its ability to perform under various conditions while ensuring that energy and time are used optimally. This sophisticated design highlights the importance of innovation in modern cleaning technology.

Motor and Belt Configuration

The performance of a laundry appliance significantly relies on the configuration of its motor and the associated drive components. These elements play a crucial role in the effective functioning of the equipment, ensuring that the load is properly handled and operational efficiency is maintained.

Motor Functionality

The motor is the heart of the device, providing the necessary torque and speed to facilitate various operations. It is designed to work in harmony with the other components, enabling smooth transitions during cycles. Understanding the motor’s role can help users appreciate its impact on the overall performance and longevity of the equipment.

Belt Characteristics

The belt serves as the connection between the motor and the drum, transferring power effectively. Its design and material influence both the durability and efficiency of the system. Regular inspection and maintenance of the belt are essential for optimal performance and to prevent potential issues.

| Component | Description |

|---|---|

| Motor | Drives the system, providing necessary power for operation. |

| Belt | Connects the motor to the drum, facilitating power transfer. |

| Idler Pulley | Maintains tension on the belt for consistent performance. |

| Mounting Bracket | Secures the motor in place, ensuring stability during operation. |

The Power Behind LG Tromm’s Operation

Understanding the core components of LG’s advanced appliance reveals the intricate system that ensures optimal performance. Each element is designed to work harmoniously, providing efficiency and reliability in daily tasks. This sophisticated setup enhances user experience while maintaining durability.

Key Components That Drive Efficiency

At the heart of this innovative design are essential mechanisms that facilitate smooth operation. These critical features contribute to energy conservation and effective cleaning cycles, adapting to various loads and fabrics. Enhanced technology allows for precise control, minimizing wear and tear while maximizing functionality.

Importance of Quality Materials

The longevity of LG’s appliances is significantly influenced by the materials used in their construction. High-grade components resist corrosion and wear, ensuring that the device remains in top condition over time. This commitment to quality not only improves performance but also supports sustainability by reducing the need for frequent replacements.

Detergent Dispenser and Its Role

The detergent dispenser plays a crucial role in the cleaning process of textiles, ensuring that the appropriate cleaning agents are released at the right time during the cycle. This component is designed to facilitate the effective distribution of detergents, softeners, and other additives, enhancing the overall efficiency of the cleaning procedure.

Typically located at the front or top of the unit, the dispenser features separate compartments for different types of detergents. This organization allows users to select the right products for specific loads, ensuring optimal performance. By managing the release of these substances, the dispenser contributes significantly to achieving clean and fresh results while also protecting the fabric quality.