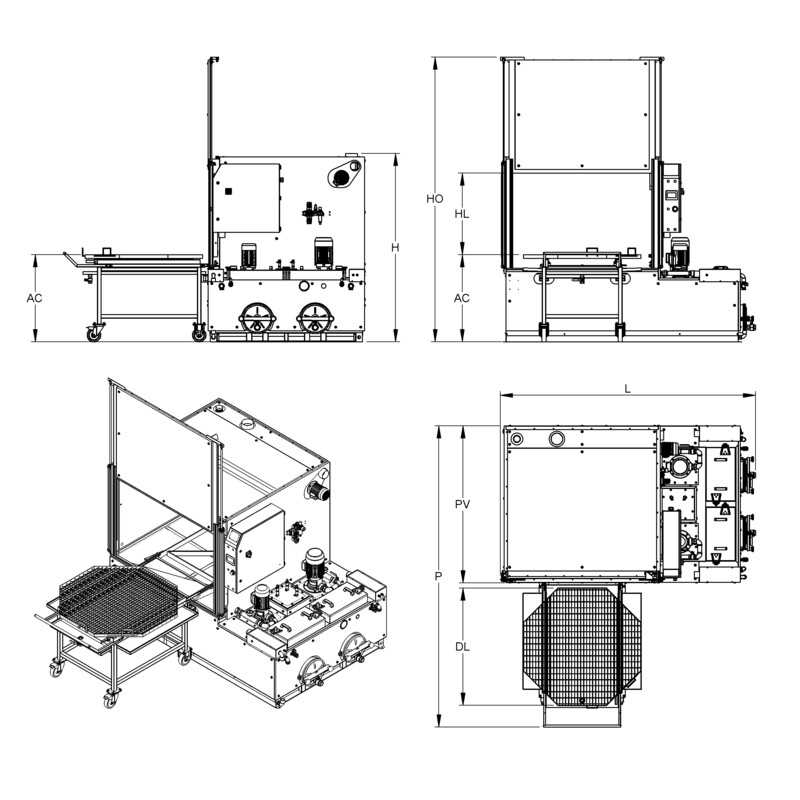

Comprehensive Parts Washer Parts Diagram for Optimal Maintenance

The intricacies of industrial cleaning solutions are crucial for maintaining efficiency and functionality. By examining the various elements involved, one can gain a deeper insight into their roles and interconnections within the system.

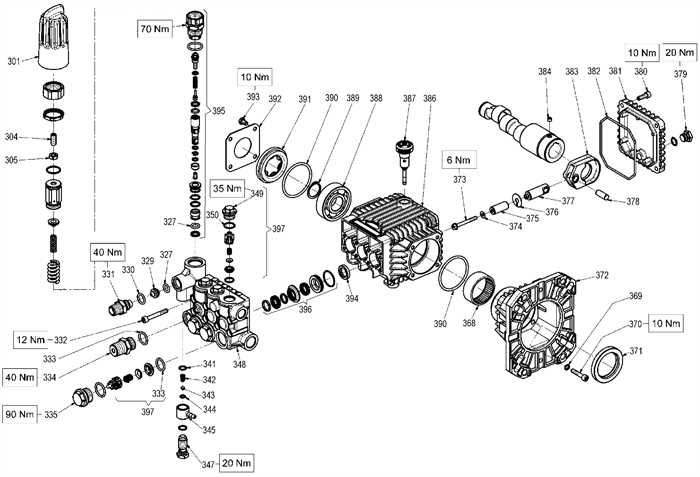

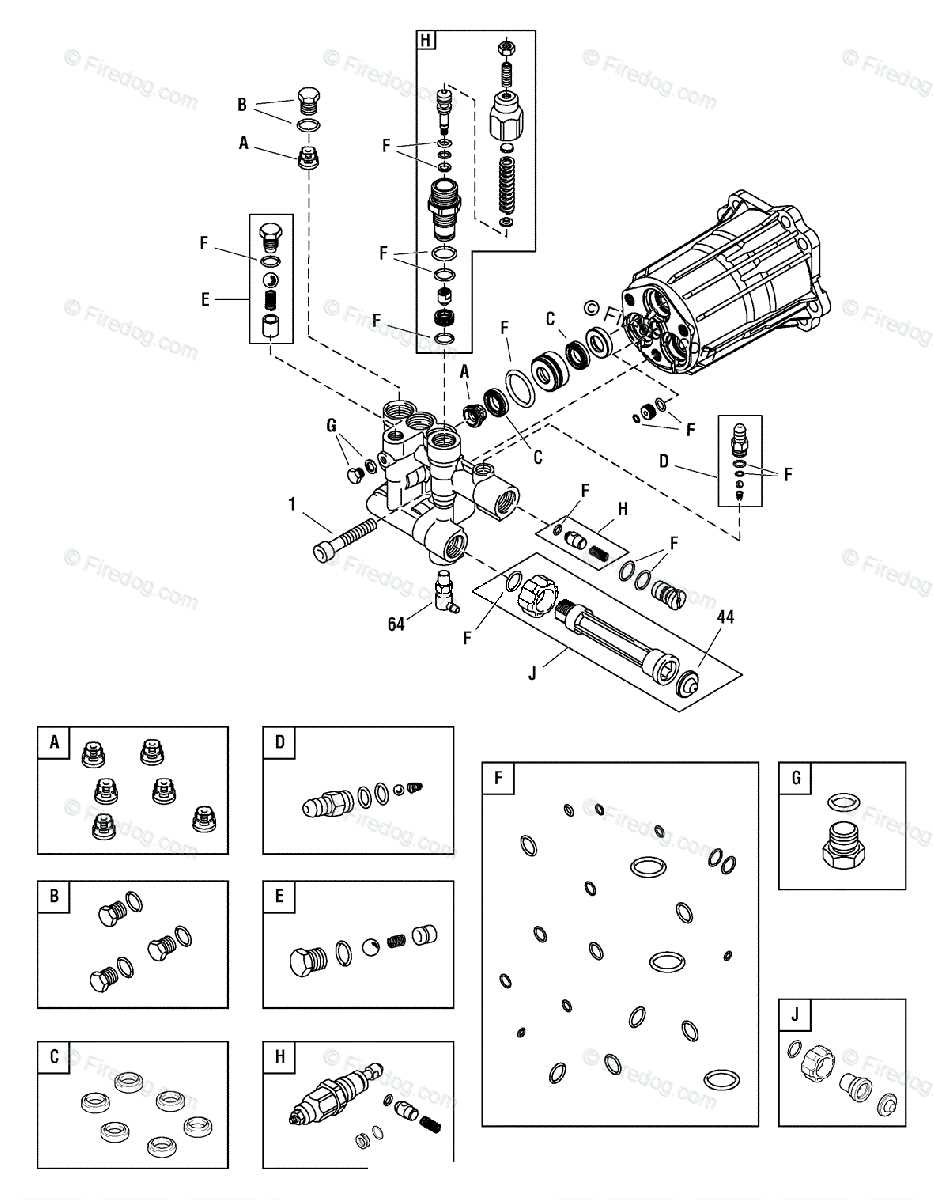

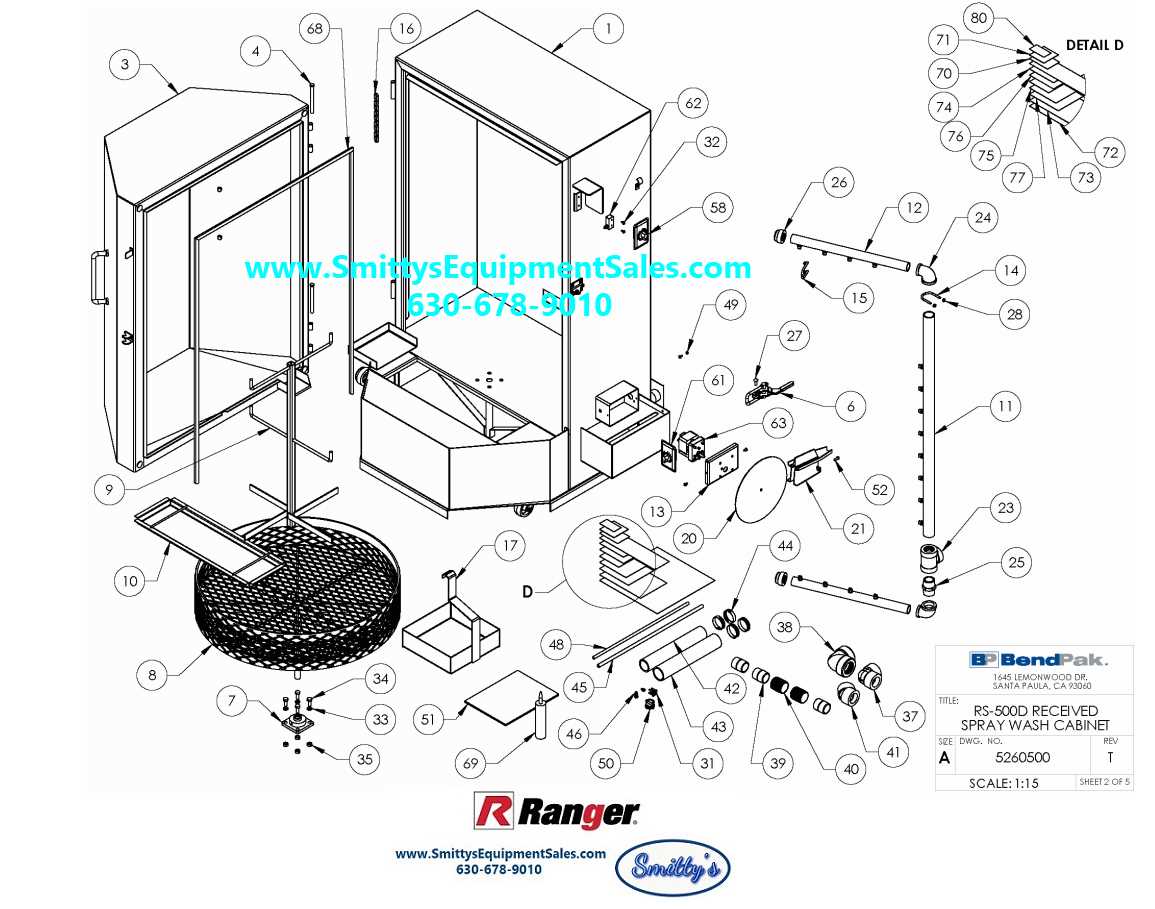

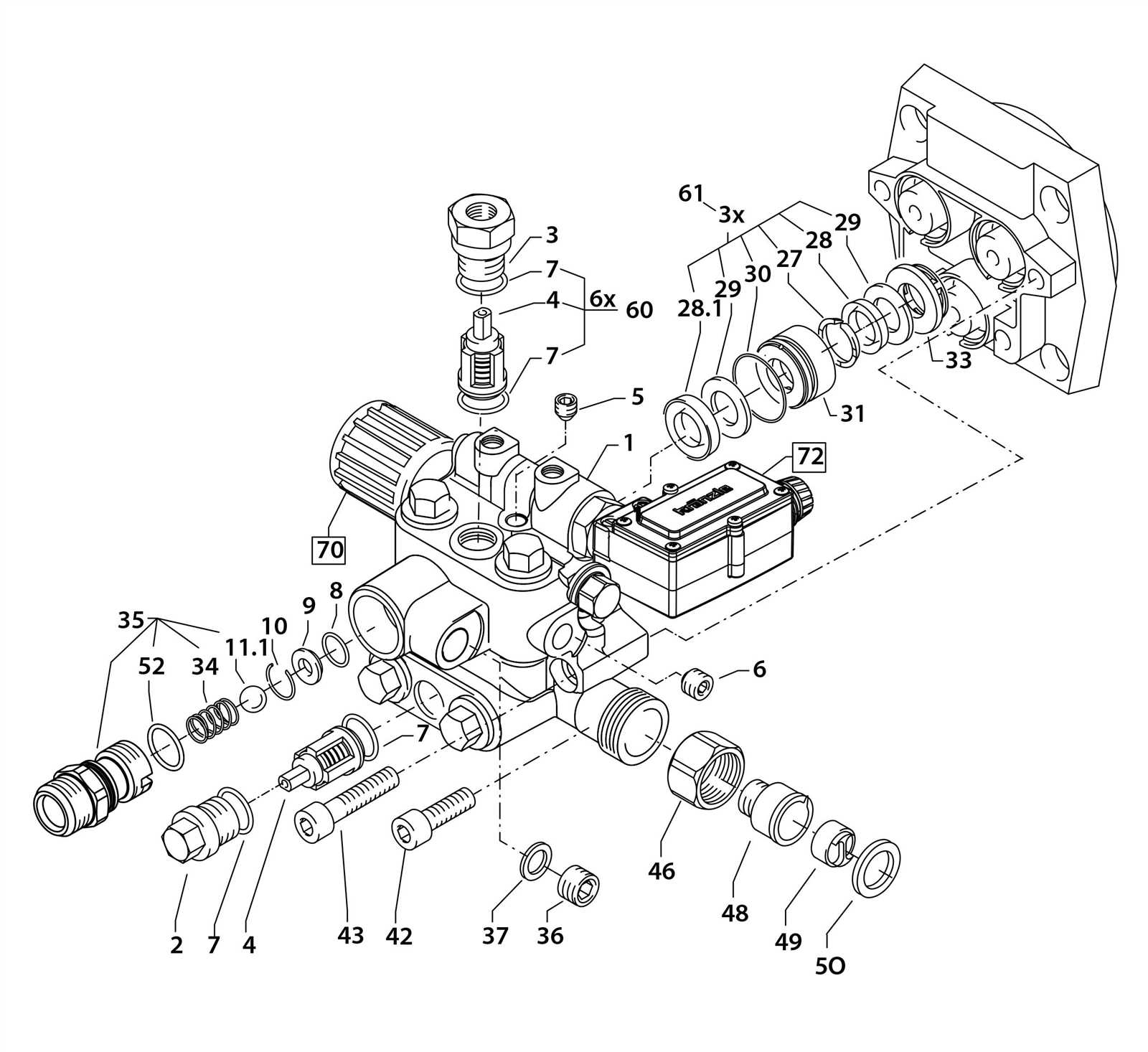

Visual representations serve as a valuable tool for comprehending how each segment interacts. They highlight the relationship between the different components, enabling users to grasp the overall structure and flow of operations.

To enhance performance and reliability, it is essential to familiarize oneself with each part’s characteristics. This knowledge not only aids in maintenance but also empowers users to make informed decisions when troubleshooting or upgrading their systems.

Understanding Parts Washer Basics

In the realm of maintenance and cleaning, there exists a system designed to efficiently remove contaminants from various components. This process not only enhances performance but also extends the lifespan of the items being treated. A fundamental grasp of how these systems operate is crucial for anyone involved in mechanical upkeep.

The core elements of these systems are integral to their effectiveness. Typically, they incorporate a reservoir for cleaning solutions, a mechanism for agitation, and various tools to facilitate the removal of dirt and grease. Understanding the interplay of these components is essential for optimizing the cleaning process.

Maintenance of the cleaning system itself is equally important. Regular checks on fluid levels, filters, and mechanical parts ensure optimal functionality. By delving into the maintenance aspects, users can avoid common pitfalls and enhance the longevity of their cleaning setup.

Ultimately, comprehending these basic principles empowers users to make informed decisions regarding cleaning techniques, resulting in superior outcomes and increased efficiency in their operations.

Importance of Parts Washer Diagrams

Understanding the layout and components of cleaning systems is crucial for efficiency and effectiveness in maintenance and repair tasks. Clear representations enable users to quickly identify elements, enhancing operational safety and performance.

- Facilitates quick identification of components.

- Improves safety by highlighting critical areas.

- Streamlines maintenance procedures.

- Reduces the risk of errors during assembly or disassembly.

Incorporating these visual aids ultimately enhances workflow and ensures that technicians can tackle issues promptly, maintaining optimal functionality.

Key Components of Parts Washers

Understanding the essential elements that facilitate effective cleaning can enhance maintenance efficiency and operational reliability. These critical components work together to ensure thorough cleansing and optimal performance.

Main Elements

- Cleaning Chamber

- Heating Element

- Filtration System

- Spray Nozzles

- Control Panel

Functional Importance

- Cleaning Chamber: The primary area where items are placed for treatment.

- Heating Element: Increases fluid temperature for more effective removal of contaminants.

- Filtration System: Maintains fluid clarity by removing debris and particles.

- Spray Nozzles: Disperse cleaning solutions evenly across surfaces.

- Control Panel: Allows users to adjust settings and monitor operation.

Types of Parts Washers Explained

Understanding the various cleaning solutions available in industrial and automotive settings is crucial for maintaining efficiency and ensuring longevity of equipment. Each option is tailored for specific tasks, utilizing different mechanisms and technologies to achieve optimal results. Below, we delve into the primary varieties of cleaning units, highlighting their unique features and applications.

| Type | Description | Best Used For |

|---|---|---|

| Manual Cleaning Stations | These require operator intervention to scrub and rinse components, often utilizing solvents. | Small to medium-sized items with stubborn residues. |

| Ultrasonic Cleaners | Employ high-frequency sound waves in a liquid solution to remove dirt and grime from intricate parts. | Delicate and complex geometries where precision cleaning is necessary. |

| Cabinet Systems | Enclosed units that provide a controlled environment for washing, minimizing splashes and waste. | Medium to large components that require thorough cleaning without environmental hazards. |

| Automated Cleaning Lines | Robotic systems that streamline the cleaning process, enhancing productivity and consistency. | High-volume production environments with repetitive cleaning needs. |

| Steam Cleaners | Utilize hot vapor to dissolve dirt, oils, and grease without the need for chemicals. | Eco-friendly cleaning in settings where solvent use is restricted. |

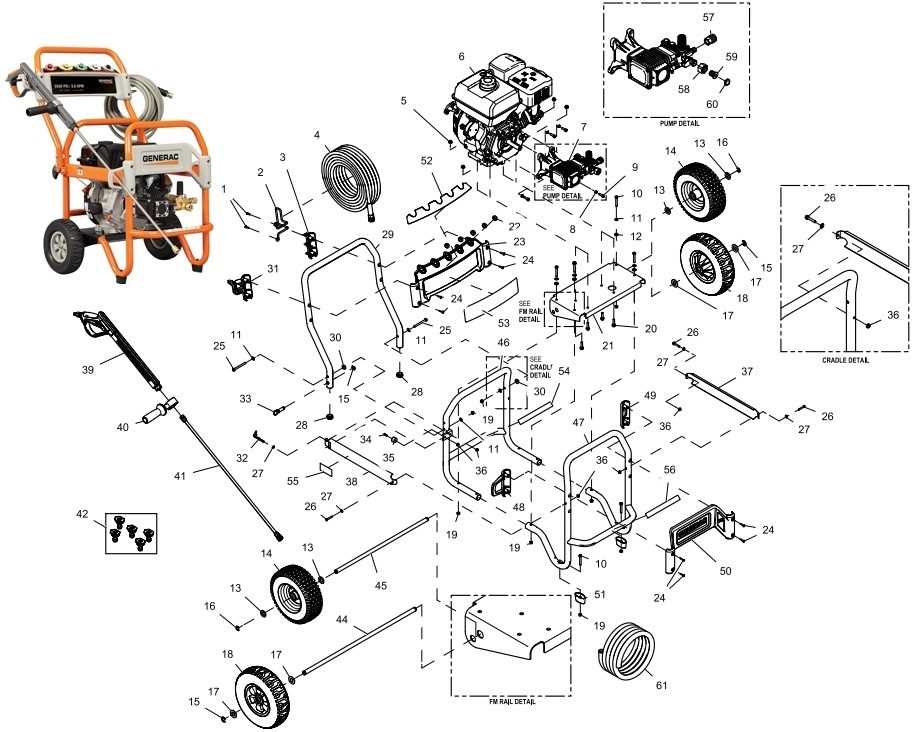

How to Read a Diagram

Understanding a visual representation of components can enhance your ability to assemble, repair, or maintain equipment effectively. This section will guide you through the essential elements to consider when interpreting these illustrations.

- Familiarize Yourself with Symbols: Various shapes and icons are used to denote specific items or functions. Recognizing these symbols is crucial.

- Check the Legend: Many representations include a legend that explains what each symbol means. Always refer to this for clarification.

- Follow the Flow: Look for directional arrows or lines that indicate movement or connection between elements. This helps in understanding how everything fits together.

Once you have grasped the basic elements, you can move on to more detailed interpretations:

- Identify Key Components: Start by pinpointing the major elements. This sets the foundation for understanding the overall structure.

- Analyze Relationships: Observe how components are interconnected. Understanding their relationships can help in troubleshooting issues.

- Refer to Specifications: If available, consult technical specifications or manuals that accompany the visual guide for in-depth information.

By mastering these steps, you will be better equipped to utilize these visuals for effective assembly or maintenance tasks.

Common Issues in Parts Washers

When it comes to cleaning machinery components, several challenges can arise that affect efficiency and performance. Understanding these common pitfalls can help in maintaining optimal functionality and prolonging the lifespan of the equipment.

Clogging and Blockages

One frequent issue is the accumulation of debris and contaminants that can lead to clogging. This not only impedes the flow of cleaning solutions but can also damage the internal mechanisms. Regular maintenance and monitoring are essential to mitigate this risk.

Chemical Imbalance

The effectiveness of cleaning agents is often compromised by improper chemical ratios. An unbalanced solution can either fail to clean effectively or cause harm to components. Regular testing and adjustment of chemical concentrations are necessary for optimal results.

| Issue | Symptoms | Solutions |

|---|---|---|

| Clogging | Poor cleaning performance, unusual noises | Regular filter cleaning, routine inspections |

| Chemical Imbalance | Residue on components, excessive wear | Regular testing, proper dilution ratios |

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your cleaning equipment involves regular upkeep and attention to detail. By implementing a consistent maintenance routine, you can significantly extend the life of your machinery and enhance its efficiency.

Here are some essential tips to help you maintain your equipment effectively:

| Tip | Description |

|---|---|

| Regular Cleaning | Remove any debris or residues after each use to prevent buildup that can impair functionality. |

| Inspect Seals | Check seals and gaskets for wear and tear, replacing them as needed to avoid leaks. |

| Lubrication | Apply appropriate lubricants to moving parts to reduce friction and wear. |

| Monitor Fluid Levels | Keep an eye on cleaning solutions and fluids to ensure optimal operation and prevent overheating. |

| Schedule Professional Servicing | Have your equipment professionally serviced periodically to catch any potential issues early. |

By following these guidelines, you can maintain the effectiveness of your cleaning apparatus and ensure it serves you well for years to come.

Choosing the Right Parts Washer

Selecting the appropriate cleaning equipment is crucial for maintaining efficiency and effectiveness in any industrial setting. The right choice can significantly enhance productivity and ensure optimal performance in cleaning tasks.

Key Considerations

- Size and Capacity: Assess the dimensions and volume requirements based on the items to be cleaned.

- Type of Cleaning Solution: Determine whether to use water-based or solvent-based cleaning agents based on the contaminants.

- Temperature Control: Evaluate the need for heated solutions to improve cleaning efficiency.

- Mobility: Consider if a stationary or portable unit best suits your workspace needs.

Final Thoughts

Ultimately, the decision should align with specific operational demands and maintenance requirements. Delve into the features and benefits of various models to ensure a wise investment that meets your cleaning challenges.

Upgrading Your Parts Washer

Improving your cleaning equipment can significantly enhance efficiency and performance. By selecting modern components and integrating advanced features, you can transform a standard unit into a powerful tool that meets contemporary demands. This not only saves time but also ensures a higher standard of cleanliness and safety in your workspace.

Choosing Modern Components

When considering enhancements, focus on selecting high-quality, durable elements that withstand frequent use. Upgrading to more effective filtration systems or incorporating automated controls can streamline operations and reduce manual labor. Researching the latest innovations in the market can provide insights into which enhancements are most beneficial for your specific needs.

Integrating Eco-Friendly Solutions

Adopting sustainable practices is becoming increasingly important. Consider incorporating biodegradable solvents or energy-efficient heating elements. These changes not only benefit the environment but can also lead to cost savings in the long run. Implementing such eco-friendly options reflects a commitment to responsible operation and can enhance your business’s reputation.

Safety Precautions to Consider

Ensuring a secure working environment is essential when handling cleaning equipment. Awareness of potential hazards and implementation of safety measures can significantly reduce the risk of accidents and injuries. By prioritizing safety, individuals can maintain not only their well-being but also the efficiency of their tasks.

1. Personal Protective Equipment (PPE): Always wear appropriate gear, such as gloves, goggles, and masks. This helps protect against harmful chemicals and debris that may be present during operation.

2. Ventilation: Adequate airflow is crucial when using cleaning substances. Ensure that the area is well-ventilated to minimize the accumulation of fumes, which can be harmful when inhaled.

3. Chemical Handling: Familiarize yourself with the properties of the substances in use. Read labels carefully and follow the manufacturer’s guidelines to prevent adverse reactions.

4. Equipment Maintenance: Regularly inspect and maintain machinery to ensure it operates safely and efficiently. Address any signs of wear or malfunction immediately to avoid accidents.

5. Emergency Procedures: Be prepared for unforeseen events. Familiarize yourself with emergency protocols, including first aid measures and evacuation routes, to respond swiftly in case of an incident.

By taking these precautions, individuals can create a safer workplace, ultimately enhancing productivity and minimizing risks.

Benefits of Regular Cleaning

Maintaining a clean environment is essential for optimal performance and longevity of equipment. Regular upkeep ensures that all components function efficiently and reduces the risk of unexpected breakdowns.

- Improved Efficiency: Clean systems operate more smoothly, enhancing overall productivity.

- Extended Lifespan: Routine maintenance can significantly increase the durability of machinery.

- Safety: A clean workspace minimizes hazards and promotes a safer environment for personnel.

- Cost Savings: Preventative care reduces the likelihood of costly repairs and replacements.

- Enhanced Performance: Regular cleaning ensures that equipment operates at peak efficiency.

Finding Replacement Parts Easily

Locating the right components for your cleaning equipment can significantly enhance its efficiency and longevity. Understanding where to search and how to identify what you need simplifies the process immensely.

- Check manufacturer websites for official listings.

- Utilize online marketplaces that specialize in industrial supplies.

- Join forums or communities dedicated to maintenance and repair.

Additionally, consider these tips to ensure a smooth experience:

- Keep a record of model numbers for easy reference.

- Compare prices across different retailers to find the best deal.

- Consult customer reviews to assess the reliability of products.

By following these strategies, you can effortlessly acquire the necessary elements to maintain optimal performance.