Understanding the Parts Diagram of a Pressure Washer Gun

In the realm of effective cleaning solutions, the intricate design and functionality of various tools play a crucial role. A thorough grasp of how these devices operate can significantly enhance their efficiency and prolong their lifespan. By examining the various elements that comprise this essential apparatus, users can optimize their cleaning experience and achieve better results.

Key components of the tool each serve a specific purpose, contributing to the overall performance and usability. From the trigger mechanism to the various attachments, understanding these elements allows for a more informed approach to maintenance and operation. This knowledge is invaluable for both novice users and seasoned professionals alike.

Moreover, recognizing the interconnection between these components can help users troubleshoot any issues that may arise during use. Familiarity with the individual parts not only aids in effective cleaning but also empowers users to make necessary adjustments or repairs, ensuring the tool remains in top working condition for years to come.

Understanding Pressure Washer Gun Components

In the realm of high-efficiency cleaning tools, the various elements that come together to facilitate effective operation are essential for optimal performance. A thorough comprehension of these components allows users to appreciate their roles and ensure proper maintenance and functionality.

At the core of the assembly lies the trigger, which serves as the user interface for controlling the flow of liquid. This mechanism allows for precise adjustments, enabling the user to manage the intensity of the spray. Additionally, the handle is designed for comfort and stability, ensuring that users can operate the tool with ease during extended cleaning sessions.

Connecting these elements is the body, which houses internal mechanisms and provides a robust structure. This component often includes fittings that allow for the attachment of various nozzles, each designed for specific tasks. The choice of nozzle can significantly impact the effectiveness of the cleaning process, highlighting the importance of understanding this aspect.

Another vital element is the valve, which regulates fluid flow and pressure within the system. A properly functioning valve ensures that the right amount of liquid reaches the surface being cleaned, preventing both waste and damage. Finally, the hose connects the assembly to the main supply, allowing for mobility and versatility during operation.

Recognizing how these various components interact not only enhances user knowledge but also fosters a greater appreciation for the technology that drives efficient cleaning solutions.

How Pressure Washer Guns Work

This section explores the mechanics behind high-pressure cleaning tools, focusing on their efficiency and functionality. Understanding the components and how they interact can enhance the cleaning experience and improve maintenance practices.

Basic Components and Their Functions

At the core of these tools is a mechanism that generates a powerful stream of fluid. When the trigger is engaged, it allows the fluid to flow from the reservoir through a specialized nozzle. This nozzle is designed to concentrate the flow, transforming it into a forceful jet. The intensity of the spray can often be adjusted, providing versatility for different cleaning tasks.

Operation Mechanism

The operation begins with a motor that pumps fluid into the system. As the fluid travels through various channels, it gains momentum, creating pressure. This stored energy is released when the trigger is activated. Safety features are incorporated to prevent accidental discharge and ensure user protection, while the ergonomic design facilitates ease of use. Understanding these mechanisms can help users troubleshoot issues and optimize performance.

Key Parts of a Pressure Washer Gun

The functionality of a high-pressure cleaning tool relies on several essential components that work together to deliver effective performance. Understanding these elements can enhance user experience and maintenance, ensuring optimal operation during cleaning tasks.

| Component | Description |

|---|---|

| Trigger | The mechanism that activates water flow, allowing for easy control during operation. |

| Handle | The part that provides grip and comfort, enabling the user to maneuver the device effortlessly. |

| Connection Nozzle | The interface that links the cleaning attachment, determining the spray pattern and intensity. |

| Safety Lock | A crucial feature that prevents accidental activation, ensuring safe handling when not in use. |

| Trigger Safety | A mechanism that adds an extra layer of security, requiring intentional pressure to engage. |

| Body | The main structure that houses internal components and provides durability to withstand high pressure. |

Familiarizing oneself with these key components will not only facilitate effective usage but also assist in identifying any potential issues that may arise during operation.

Common Issues with Pressure Washer Guns

When using high-performance cleaning tools, users often encounter various challenges that can affect functionality and efficiency. Understanding these issues can help in troubleshooting and maintaining optimal performance. From inadequate output to unexpected leaks, several common problems can arise during operation.

Insufficient Water Flow

One frequent issue is the lack of adequate water flow, which can result from clogged nozzles or blocked hoses. Debris buildup can restrict the passage, leading to reduced cleaning effectiveness. Regular maintenance and cleaning of these components can prevent this problem and ensure a smooth operation.

Leakage Problems

Another prevalent concern is leakage, which often occurs at connection points or seals. Over time, wear and tear can cause these areas to deteriorate, leading to unwanted water escape. Inspecting seals and replacing damaged components promptly can help mitigate this issue and prolong the lifespan of the equipment.

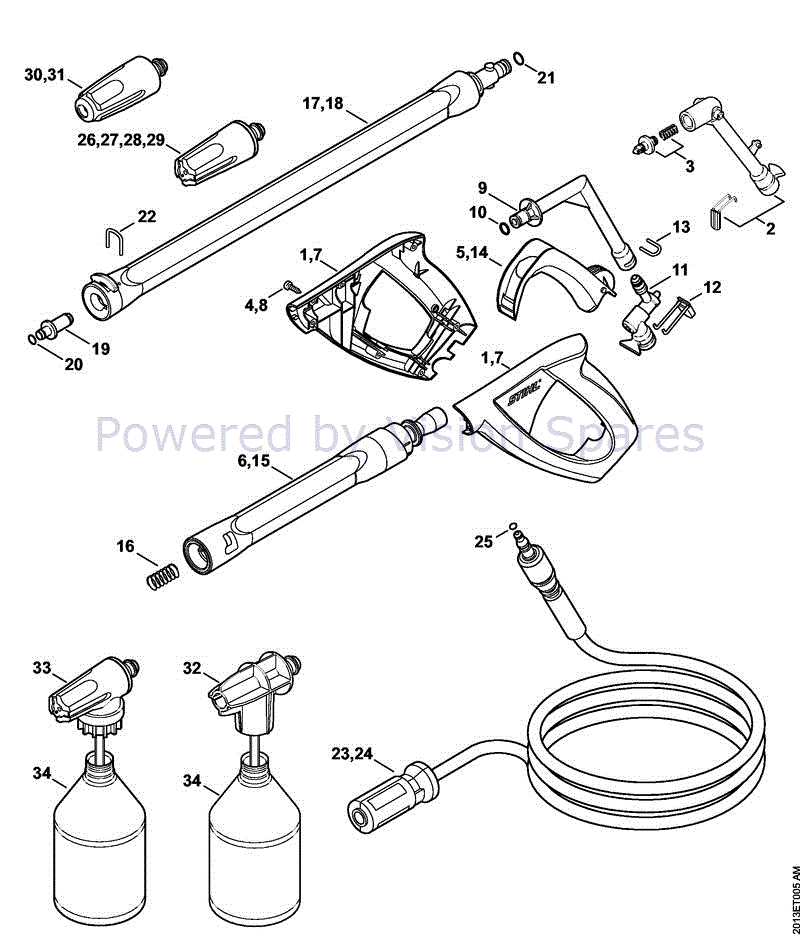

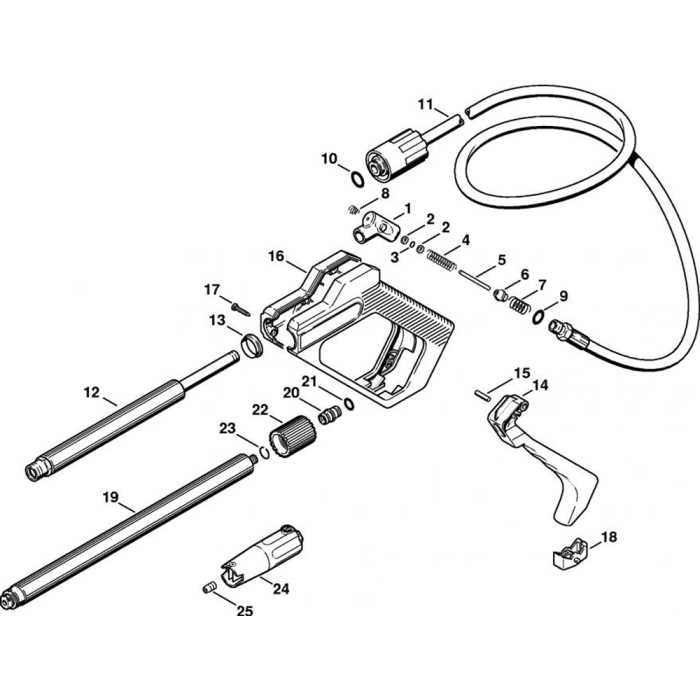

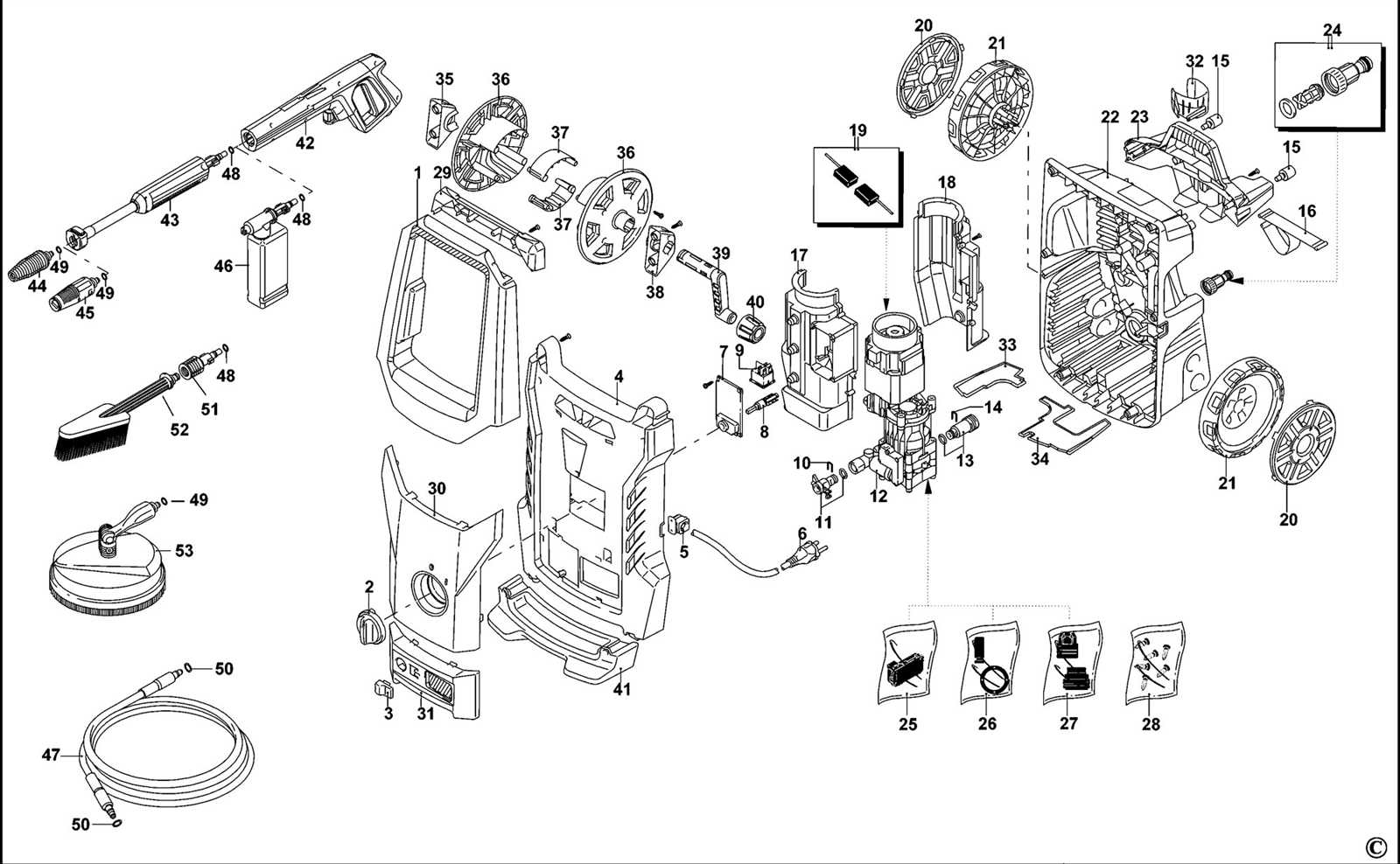

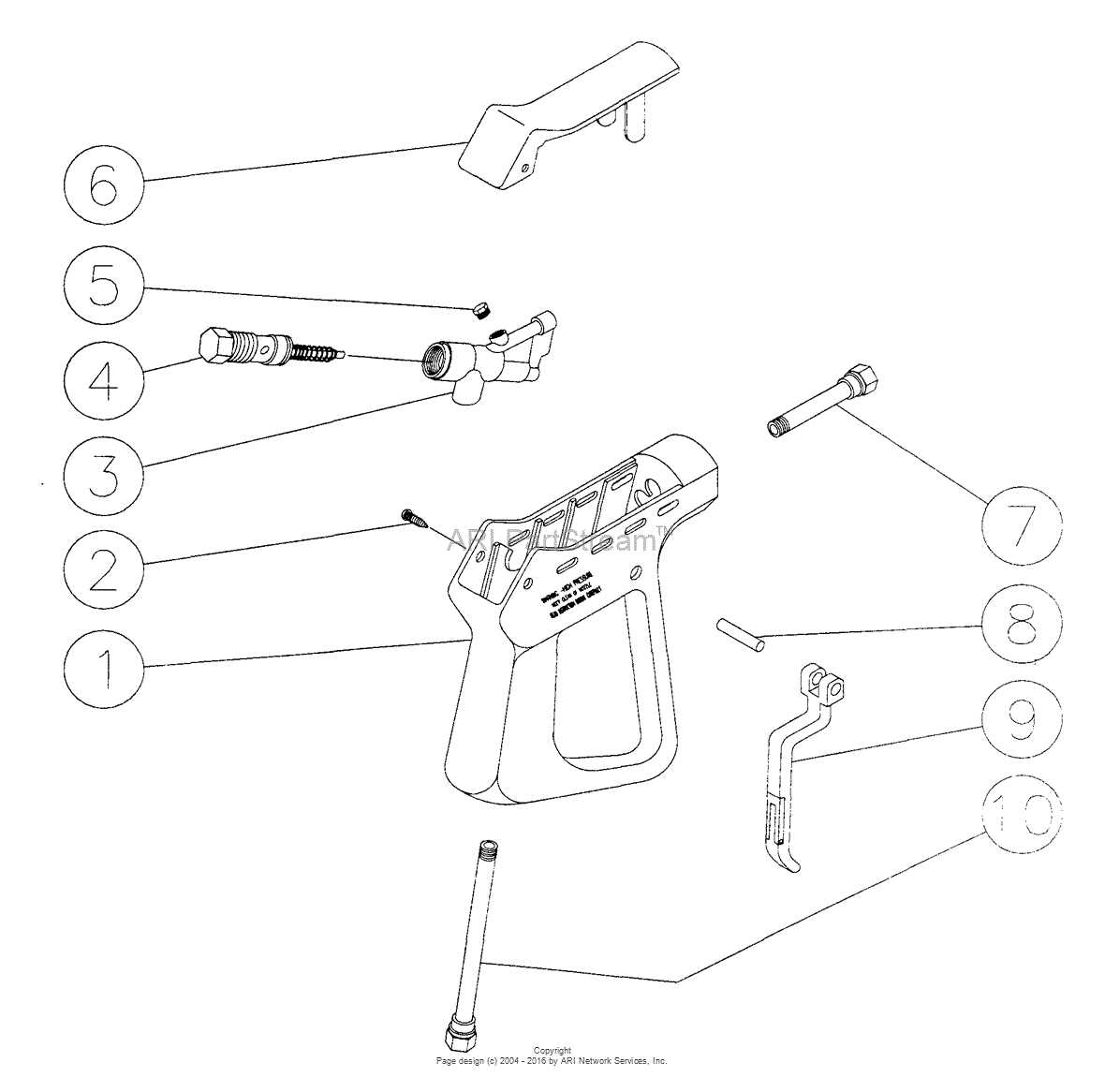

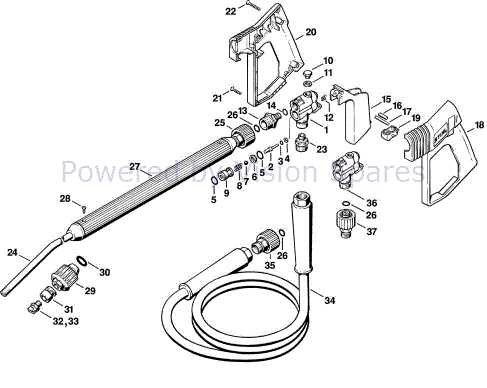

Identifying Pressure Washer Gun Diagrams

Understanding the components of a high-pressure cleaning device is essential for effective maintenance and troubleshooting. Familiarizing oneself with the various sections and their functions can significantly enhance the user experience and ensure optimal performance.

To accurately recognize the layout of these tools, it is helpful to refer to a comprehensive illustration that labels each section. Key elements often include the handle, trigger mechanism, and nozzle attachments, which are crucial for controlling the flow and intensity of the liquid. Visual representations serve as invaluable resources, allowing users to pinpoint specific areas that may require attention or repair.

Moreover, understanding the connection points and how they interact can assist in effective assembly and disassembly. Proper identification of these components not only aids in repairs but also extends the lifespan of the equipment by promoting regular upkeep. By utilizing clear visuals, one can enhance their proficiency and ensure that their cleaning tasks are carried out efficiently.

Maintenance Tips for Pressure Washer Guns

Proper care and upkeep of your cleaning equipment is essential to ensure optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents unexpected failures during use. Here are some effective strategies to keep your cleaning device in top shape.

Routine Inspection

Performing regular checks on your equipment can help identify issues before they escalate. Look for signs of wear and tear, such as cracks or leaks, and ensure that all connections are secure. A visual inspection can save you time and money in the long run.

Cleaning and Storage

After each use, make it a habit to clean the equipment thoroughly. Remove any debris or residue that may have accumulated during operation. Store the device in a dry, sheltered location to protect it from environmental factors that could cause damage.

| Maintenance Task | Frequency |

|---|---|

| Visual Inspection | Before each use |

| Cleaning | After each use |

| Lubrication | Monthly |

| Deep Cleaning | Every 3 months |

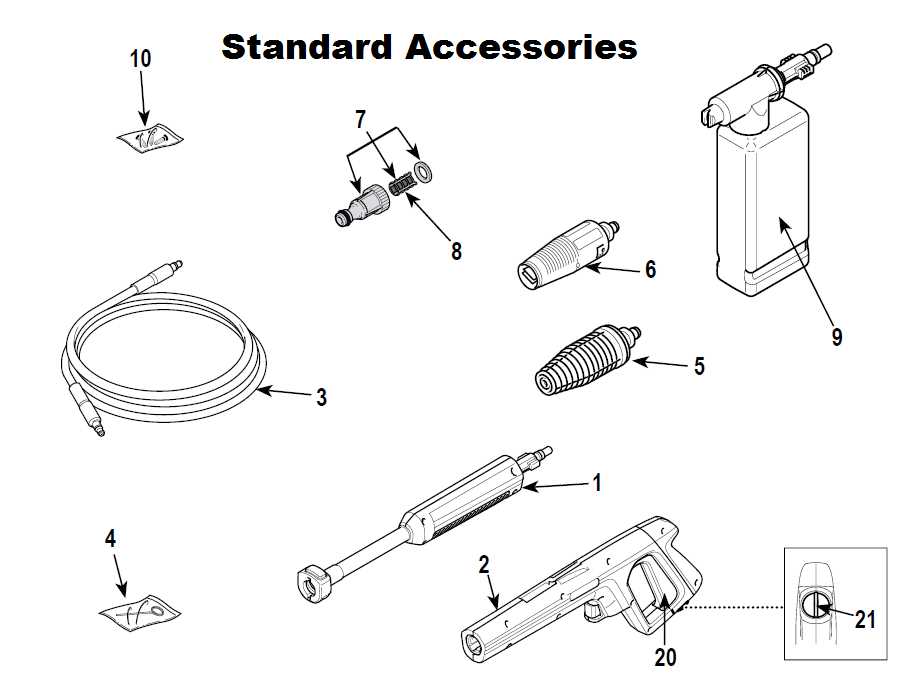

Replacement Parts for Pressure Washer Guns

Ensuring optimal performance of your cleaning equipment often requires timely updates to its components. Understanding the significance of each element in the assembly can help you identify which ones may need replacement. This section explores various components essential for maintaining efficiency and effectiveness.

Common Components and Their Functions

Every cleaning tool consists of several integral elements, each playing a critical role. For instance, seals and o-rings prevent leaks, while nozzles determine the spray pattern and intensity. Regular inspection can reveal wear and tear, making it crucial to have replacement options on hand.

Where to Find Quality Replacements

When it comes to sourcing new components, consider reputable suppliers that specialize in cleaning equipment. Online marketplaces and local hardware stores often carry a range of options, from basic elements to more advanced features. Always verify compatibility with your specific model to ensure optimal performance.

Safety Features of Pressure Washer Guns

Ensuring user safety during high-intensity cleaning tasks is paramount. The design of these tools incorporates various mechanisms aimed at minimizing risks associated with their powerful operation. Understanding these safety features can significantly enhance the overall user experience and prevent accidents.

One of the primary safety mechanisms is the trigger lock, which prevents unintentional activation. This feature ensures that the device remains inactive when not in use, reducing the likelihood of accidental discharge. Additionally, many models are equipped with a safety nozzle that limits the spray’s intensity and direction, helping to avoid injury to both the user and surrounding objects.

Furthermore, several cleaning devices include an automatic shut-off system that activates when the trigger is released. This not only conserves energy but also eliminates the risk of overheating. Reinforced construction materials are often used to withstand high pressure and prevent any potential leaks, further enhancing safety during operation.

Regular maintenance is also crucial for safe operation. Users are encouraged to follow manufacturer guidelines to ensure all safety features are functioning correctly. By prioritizing these aspects, operators can enjoy a more secure and efficient cleaning experience.

Choosing the Right Nozzle for Your Gun

Selecting the appropriate attachment for your cleaning device is essential for achieving optimal results. The right choice can greatly impact the efficiency and effectiveness of your cleaning tasks, allowing you to tackle a variety of surfaces and materials with ease.

There are several factors to consider when making your selection:

- Type of Surface: Different surfaces require different approaches. For example, delicate materials like glass may need a gentler touch, while tougher surfaces like concrete can handle a more intense stream.

- Cleaning Task: Consider the specific job at hand. Are you removing dirt, grime, or mold? Each task may necessitate a different nozzle design to maximize performance.

- Water Flow Rate: The flow rate of your device can influence the choice of nozzle. Ensure compatibility to achieve the desired pressure and coverage.

- Nozzle Angle: Nozzles come in various spray angles, such as 0°, 15°, 25°, and 40°. A narrower angle offers a concentrated stream, ideal for stubborn stains, while a wider angle is better for broader cleaning areas.

When you understand these factors, you can make an informed decision that enhances your cleaning efficiency and delivers outstanding results. Experimenting with different attachments may also help you find the perfect fit for your needs.

Upgrading Your Pressure Washer Gun

Enhancing your cleaning equipment can significantly improve performance and efficiency. By investing in better components, you can achieve superior results and extend the lifespan of your device. Here are some key areas to consider when upgrading.

- Handles: Look for ergonomic designs that provide comfort during extended use. Materials with non-slip grips can also enhance control.

- Trigger Mechanism: Upgrading to a smoother trigger can reduce fatigue and improve accuracy. Consider options with adjustable flow control.

- Connection Fittings: High-quality connectors can prevent leaks and ensure a secure fit. Look for materials that resist corrosion for long-term durability.

- Spray Nozzles: Different nozzle types offer varied spray patterns. Investing in a set of nozzles can make your equipment more versatile for different cleaning tasks.

By focusing on these components, you can elevate your cleaning experience, making it more efficient and enjoyable. Each upgrade contributes to a noticeable difference in performance, leading to better results overall.

Frequently Asked Questions about Pressure Washer Guns

This section addresses common inquiries regarding high-pressure cleaning devices, focusing on their operation, maintenance, and troubleshooting. Understanding these elements can enhance user experience and prolong the lifespan of the equipment.

What are the essential components of a high-pressure cleaning device?

The key elements typically include the trigger mechanism, nozzle types, and hose connectors. Each component plays a crucial role in ensuring efficient performance and safety during use.

How can I maintain my cleaning tool for optimal performance?

Regular cleaning and inspection of the components are vital. Lubricating moving parts and checking for leaks can significantly enhance the longevity and functionality of the device. Following manufacturer guidelines is essential for effective upkeep.