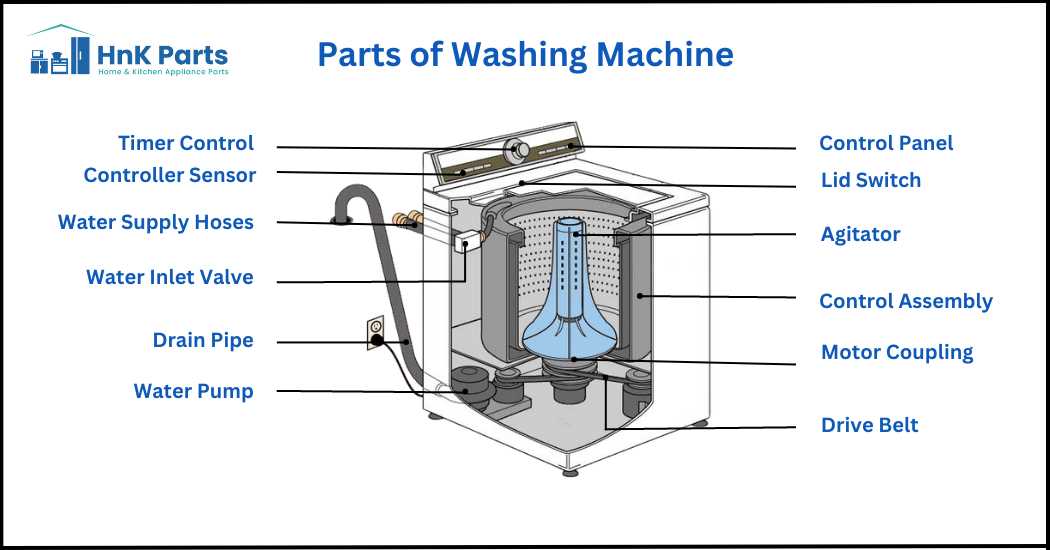

Understanding the Components of a Washing Machine Diagram

Every household device designed for laundry relies on a sophisticated arrangement of elements, each serving a distinct purpose to ensure efficient operation. Grasping how these components interact can significantly enhance the user experience and facilitate better maintenance practices.

Familiarity with the internal and external structures of these machines is crucial for troubleshooting common issues. Recognizing the role of each section allows users to diagnose problems quickly and efficiently, saving time and money in repairs.

Moreover, an in-depth understanding can empower users to optimize the performance of their equipment. Whether it involves selecting the appropriate settings or performing routine checks, knowing the layout of these essential components is a key step towards prolonging the lifespan of your appliance.

Understanding the Basics of Washing Machines

Exploring the fundamental components of a laundry appliance can enhance your knowledge and optimize its usage. This section aims to provide insights into the essential elements that contribute to effective cleaning.

- Drum: The central chamber where garments are placed.

- Agitator: A mechanism that facilitates movement for thorough cleaning.

- Pump: Responsible for draining water during cycles.

- Motor: Powers the entire operation, ensuring smooth performance.

By grasping these core aspects, users can better appreciate the ultimate function of their laundry equipment.

Essential Components of a Washing Machine

Understanding the critical elements that contribute to the efficiency of a laundry device is fundamental for effective operation and maintenance. Each component plays a unique role, ensuring optimal performance and longevity.

Main Elements

- Drum: Holds the garments during the cleaning cycle.

- Motor: Powers the rotation and agitation processes.

- Pump: Removes used water from the container.

- Control panel: Provides user interface for settings and adjustments.

Supportive Mechanisms

- Suspension system: Stabilizes the drum during movement.

- Heating element: Warms water for effective cleansing.

- Water inlet valve: Regulates the flow of fresh water into the unit.

- Drain hose: Facilitates the expulsion of wastewater.

How the Washing Cycle Works

The process of cleansing textiles involves a series of coordinated actions that ensure effective removal of dirt and stains. This intricate sequence is designed to optimize performance while maintaining the integrity of the fabric.

After sufficient time has elapsed, the system drains the soiled water, preparing for the rinsing stage. Here, clean water is circulated to eliminate any residual cleaning agents, ensuring that garments emerge fresh and free from chemical traces.

The final phase involves extracting excess moisture, effectively preparing the items for subsequent drying. This entire operation exemplifies a carefully orchestrated approach to maintaining fabric cleanliness while considering various material types and their specific needs.

Diagrams: Visualizing Machine Parts

Visual representations play a crucial role in understanding complex systems. They enable users to grasp the interconnections and functions of various components, enhancing comprehension and facilitating maintenance.

| Component | Function |

|---|---|

| Drum | Houses the load and rotates during cycles. |

| Pulley | Transfers motion from the motor to the drum. |

| Control Panel | Allows user interaction for cycle selection. |

| Drain Pump | Removes excess water post-cycle. |

| Agitator | Moves items within the drum for effective cleaning. |

Common Issues and Solutions

In any household appliance, various problems may arise over time. Understanding these issues and their resolutions can greatly enhance the longevity and performance of your device. This section addresses frequent complications and suggests practical solutions to maintain optimal functionality.

Frequent Complications

- Unusual Noises

- Inconsistent Cycle Performance

- Leakage Problems

- Insufficient Cleaning Results

Effective Resolutions

- Unusual Noises: Check for foreign objects lodged in the drum or inspect the drive belt for wear.

- Inconsistent Cycle Performance: Ensure that the load is balanced and not overloaded.

- Leakage Problems: Examine hoses for cracks and tighten any loose connections.

- Insufficient Cleaning Results: Clean the filters regularly and use the appropriate detergent for your load type.

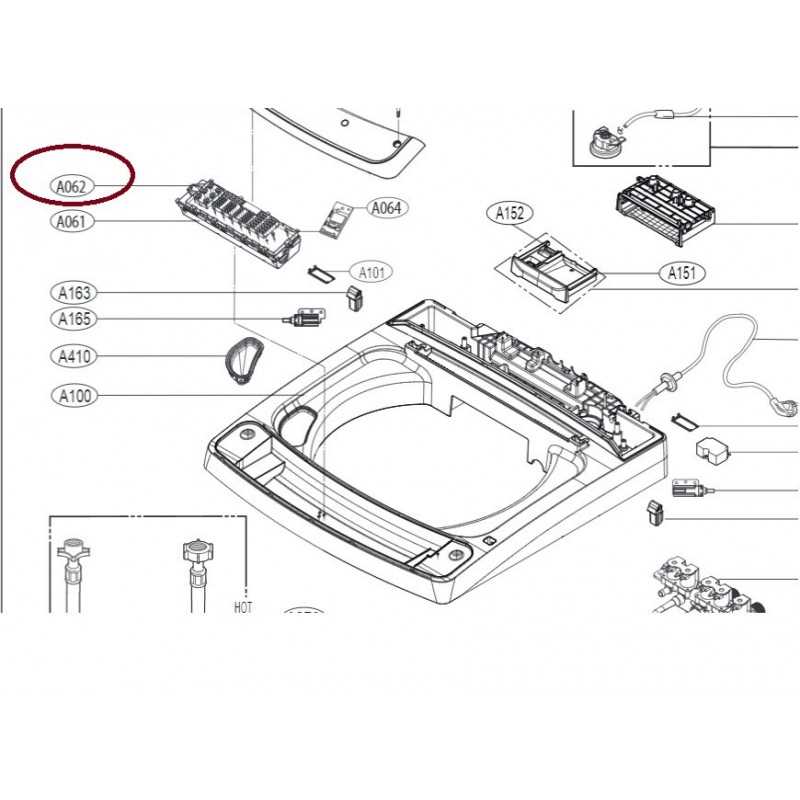

Wiring Diagrams Explained

Understanding the intricacies of electrical connections is essential for effective troubleshooting and repair. These visual representations provide a clear overview of how various components interact within a system, allowing users to identify potential issues and streamline maintenance efforts. By studying these layouts, one can gain insight into the flow of electricity and the roles different elements play.

Importance of Clarity

Clarity in electrical schematics is paramount. A well-structured illustration simplifies complex relationships, making it easier to follow the connections between wires, switches, and other components. Each symbol in the schematic serves a distinct purpose, and understanding these can significantly enhance the efficiency of repairs.

Decoding Symbols and Functions

Every element in these visuals is represented by a specific symbol, denoting its function. For example, circuits, resistors, and relays all have unique icons that convey their roles within the overall framework. Familiarity with these symbols empowers technicians to diagnose faults swiftly, ensuring that systems remain operational with minimal downtime.

Water System Mechanics in Machines

The intricate mechanics governing fluid circulation in appliances play a crucial role in their overall functionality. Understanding these components reveals how they work in harmony to ensure efficient performance.

| Component | Function |

|---|---|

| Inlet Valve | Regulates water flow into the system based on demand. |

| Pressure Switch | Monitors water levels and signals the valve to open or close. |

| Pump | Circulates water throughout the unit for various cycles. |

| Drain Hose | Facilitates the expulsion of used water after cycles. |

| Filtration System | Removes impurities from water before use. |

Each of these elements is vital for optimal operation, ensuring that fluid dynamics are maintained for various processes.

Motor Function and Placement

The functionality of the central component is crucial for the overall operation of the appliance, providing the necessary movement and energy. Understanding its role and location helps in troubleshooting and maintenance.

- Function:

- Drives the drum or tub for effective cleaning and rinsing.

- Controls the speed and rotation direction.

- Facilitates different cycles for various fabric types.

- Placement:

- Typically situated at the rear or bottom of the unit.

- Mounted securely to minimize vibrations during operation.

- Connected to other critical components for efficient energy transfer.

Understanding the Control Panel Layout

The control interface is crucial for user interaction with the appliance. It serves as the command center, allowing individuals to customize settings and monitor the operation. Familiarity with its arrangement can significantly enhance the experience and efficiency of usage.

Typically, the layout consists of various components, each serving a specific function:

- Buttons: These are used to initiate cycles or adjust settings.

- Knobs: Often utilized for selecting programs or adjusting temperature and duration.

- Display Screen: Provides real-time feedback and notifications about the ongoing processes.

- Indicators: Lights that signal the status of different functions, such as readiness or completion.

Understanding each element helps users operate the appliance more effectively. Here’s a brief overview of common features found on the control interface:

- Program Selector: This allows users to choose different cycles based on fabric type or desired outcome.

- Start/Stop Button: A vital control for initiating or halting a process at any point.

- Delay Start Option: Enables scheduling of operations for a later time, adding convenience.

- Child Lock: A safety feature that prevents unintended changes during operation.

By becoming acquainted with these elements, users can maximize the functionality of their appliance and ensure optimal performance for a variety of tasks.

Drum Types and Their Functions

The heart of any cleaning appliance lies in its rotating cylinder, which plays a crucial role in the overall effectiveness of the process. Different varieties of these cylinders serve unique purposes, influencing everything from fabric care to energy efficiency. Understanding the distinctions among them can enhance the user experience and prolong the lifespan of garments.

Types of Drums

| Type | Description |

|---|---|

| Stainless Steel | Durable and resistant to rust, providing a smooth surface for delicate fabrics. |

| Plastic | Lightweight and often less expensive, but can be prone to scratching over time. |

| Porcelain Enamel | Offers a sleek finish and is resistant to stains but may chip if mishandled. |

Functionality and Efficiency

Each type of cylinder contributes differently to the cleaning cycle. For instance, stainless steel is ideal for high-performance tasks, while plastic variants can be suitable for lighter loads. The choice of cylinder can significantly impact energy consumption and garment care, making it essential for users to select the right option based on their specific needs.

Maintenance Tips for Machine Longevity

Proper care and regular upkeep are essential for extending the lifespan of your appliance. By following a few simple practices, you can ensure that it operates efficiently and avoids unnecessary breakdowns. This section offers practical suggestions to enhance durability and performance.

Regular Cleaning

Keeping the interior and exterior clean is crucial. Residue buildup can lead to inefficiency and unpleasant odors. Use a mild detergent and soft cloth to wipe surfaces regularly. Additionally, check and clean filters to prevent clogs and ensure optimal performance.

Check Connections and Hoses

Inspecting connections and hoses is vital to avoid leaks and potential damage. Ensure that all fittings are secure and that there are no signs of wear or cracks. Replace any damaged components promptly to maintain smooth operation and prevent further issues.

Replacement Parts: When and Why

In the realm of household appliances, understanding the timing and reasons for substituting components is crucial for maintaining efficiency and prolonging lifespan. Regular usage can lead to wear and tear, necessitating timely interventions to prevent further issues. Recognizing when to replace elements can save both time and money in the long run.

Signs of Wear

Several indicators suggest that it’s time to consider new components. Look for performance degradation, unusual noises, or leaks, which often signal underlying problems. Addressing these signs promptly can prevent more significant damage.

Benefits of Timely Replacement

Replacing worn elements not only enhances functionality but also improves energy efficiency. New components can lead to a more consistent performance, ensuring your appliance operates at its best while reducing utility costs.

| Indicator | Recommended Action |

|---|---|

| Unusual noises | Inspect and consider replacing components |

| Decreased efficiency | Evaluate and replace outdated elements |

| Visible damage | Replace damaged items immediately |

| Frequent breakdowns | Assess all components for potential replacement |