Understanding the Components of a GE Water Softener

In the realm of home enhancement, the significance of effective treatment systems cannot be overstated. These innovative setups play a crucial role in ensuring that the fluid utilized in daily activities is of the highest quality. By comprehending the various elements involved in these mechanisms, users can better appreciate their functionality and maintenance requirements.

The intricate assembly of these systems consists of several key components, each serving a distinct purpose. From filtration to regeneration, understanding how these individual elements interact contributes to a comprehensive grasp of the entire process. This knowledge empowers homeowners to make informed decisions regarding installation and upkeep.

As we delve into the specifics of these systems, we will explore the various roles of each component, shedding light on how they work together to deliver optimal performance. This insight not only aids in troubleshooting potential issues but also enhances the overall user experience, ensuring longevity and efficiency.

Understanding GE Water Softeners

GE’s systems for treating household liquids are designed to improve the quality of the supply. These devices effectively minimize the presence of hard minerals, enhancing the overall experience of using water in various applications, from bathing to laundry. By understanding their components and functionality, users can better appreciate their benefits and maintain optimal performance.

Key Components

Each unit consists of several essential elements that work together to achieve the desired results. Familiarizing oneself with these components is crucial for effective operation and maintenance.

| Component | Description |

|---|---|

| Mineral Tank | This is where the exchange process occurs, removing unwanted minerals from the supply. |

| Brine Tank | Holds the salt solution used for regenerating the resin in the mineral tank. |

| Control Valve | Regulates the flow and timing of the treatment cycle, ensuring efficiency. |

| Resin Beads | Small beads that facilitate the ion exchange process, capturing hard minerals. |

Benefits of Using GE Systems

Implementing these treatment solutions offers numerous advantages. They can prolong the lifespan of appliances, enhance the effectiveness of cleaning products, and provide a more enjoyable experience when using treated fluids. Understanding the mechanics behind these systems empowers users to make informed decisions and maintain their units effectively.

Components of Water Softener Systems

This section explores the essential elements that contribute to the effective functioning of a system designed to reduce hardness. Understanding these components can enhance performance and longevity.

| Component | Description |

|---|---|

| Tank | Primary container for holding the medium that filters impurities. |

| Resin | Material that captures hardness ions, replacing them with softer alternatives. |

| Brine Tank | Storage unit for salt solution used in the regeneration process. |

| Control Valve | Mechanism that regulates flow and manages cycles within the unit. |

| Bypass Valve | Allows water to circumvent the system during maintenance or repairs. |

Importance of Water Softener Parts

The components of a conditioning system play a crucial role in ensuring its efficient operation and longevity. Each element serves a specific function, contributing to the overall effectiveness of the system. Understanding the significance of these individual pieces can help users maintain their equipment and achieve optimal performance.

Functionality and Efficiency

Each component is designed to perform a unique task, from filtration to regeneration. When these elements work together seamlessly, they enhance the efficiency of the entire system. For instance, a properly functioning control valve is essential for regulating the flow and timing of the treatment process, ensuring that the system operates as intended.

Maintenance and Longevity

Regular inspection and maintenance of each element are vital for extending the lifespan of the equipment. Neglecting any component can lead to malfunction and decreased performance. Timely replacement of worn or damaged items not only prevents costly repairs but also promotes reliable operation. Investing attention in these critical pieces ensures a consistent supply of high-quality treated fluid.

Identifying Common Water Softener Issues

Understanding the typical problems that arise in these systems is essential for effective maintenance. Many users may encounter difficulties that affect performance and efficiency, leading to unsatisfactory results.

One frequent concern involves inadequate filtration, which can manifest as persistent mineral buildup. This issue often results from a malfunctioning regeneration cycle or an exhausted medium.

Another notable problem is unexpected leaks, which may indicate worn seals or connections that require attention. Regular inspection can help prevent water damage and ensure proper function.

Finally, unusual noises during operation can signal mechanical issues, such as a malfunctioning motor or obstructed pathways. Addressing these symptoms promptly can extend the lifespan of the unit.

Functionality of Resin Tanks

Resin tanks play a crucial role in the purification process by utilizing specialized materials to exchange ions, effectively reducing unwanted substances. This process is essential for achieving optimal clarity and quality.

The primary functions of these tanks include:

- Ion exchange: Replacing harmful ions with beneficial ones.

- Filtration: Capturing impurities and enhancing overall effectiveness.

- Regeneration: Restoring resin to maintain performance over time.

Understanding these functions helps in appreciating how they contribute to the ultimate goal of providing high-quality liquid for various applications.

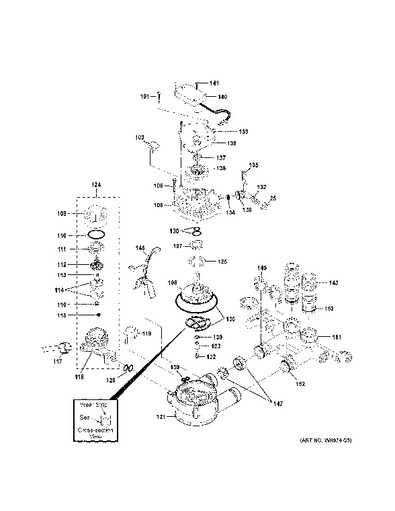

Understanding Control Valves

Control valves are essential components that play a pivotal role in regulating fluid movement within various systems. Their primary function is to manage the flow rate, pressure, and direction of the liquid, ensuring optimal operation and efficiency.

These devices can be categorized based on their design and functionality:

- Manual Valves: Operated by hand, allowing for direct control.

- Automatic Valves: Function based on external signals, providing automated regulation.

- Servo-Controlled Valves: Utilize feedback systems for precise control in complex applications.

Understanding the components that make up these devices is crucial for effective maintenance and troubleshooting:

- Actuator: Drives the valve open or closed.

- Body: Contains the flow pathway and ensures durability.

- Seat: Provides a sealing surface to prevent leaks.

By exploring these aspects, one can delve deeper into the significance of control valves in various systems and their impact on overall performance.

Role of Brine Tanks Explained

Brine tanks play a crucial role in the overall functionality of certain filtration systems. They serve as reservoirs for a concentrated saline solution, essential for the regeneration process that enhances the efficiency of the entire setup. This mechanism is vital for maintaining optimal performance and longevity.

The primary function of these tanks is to hold the brine solution, which is created by dissolving salt in water. During regeneration, this solution is drawn into the main unit, where it aids in removing impurities from the filtration medium. This process ensures that the system can effectively continue to provide cleaner and more purified results.

Moreover, brine tanks are designed with specific features to optimize their performance. They often include float switches to prevent overflow and maintain the right levels of saline solution. Regular maintenance of these tanks is essential to ensure that the brine concentration remains effective, thereby supporting the overall efficiency of the filtration process.

Salt Usage in Water Softeners

Understanding the role of sodium in treating hard minerals is essential for optimizing performance and ensuring longevity. This element plays a crucial part in the regeneration process, effectively helping to maintain efficient functionality.

Key points about sodium usage include:

- It aids in removing calcium and magnesium ions.

- Regular replenishment is necessary for consistent operation.

- Types of salt vary in purity and effectiveness.

Considerations for optimal usage:

- Monitor salt levels regularly to prevent shortages.

- Choose high-quality sodium products to enhance efficiency.

- Store sodium properly to avoid contamination.

In summary, effective management of sodium contributes to the ultimate performance of the system, leading to improved results in mineral removal and system reliability.

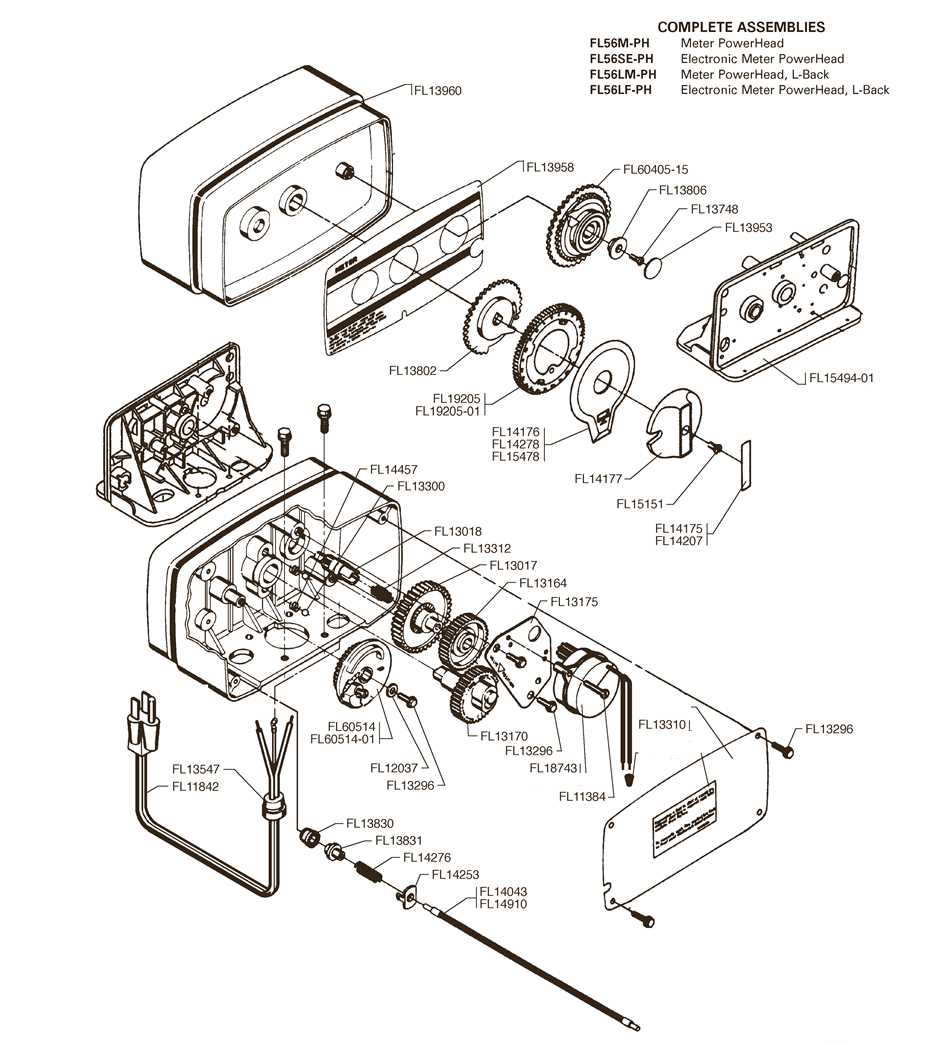

How to Read Parts Diagrams

Understanding visual representations of components can greatly enhance your ability to maintain and repair systems effectively. Familiarizing yourself with the various symbols and layouts will allow for quicker identification of elements, making troubleshooting and assembly more straightforward.

Key Elements to Look For

- Labels: Most illustrations include names or numbers that correspond to specific elements. Always check the legend for clarification.

- Connections: Arrows or lines often indicate how components interact. Pay attention to these connections for proper assembly.

- Scale: Some diagrams may include a scale or dimensions, helping you understand the size and relation of each part to others.

Steps for Effective Interpretation

- Start by identifying the main components highlighted in the visual.

- Refer to the accompanying legend or key to match labels with their descriptions.

- Trace connections to visualize how each element fits within the overall system.

- Use any provided scale to grasp the relative sizes, which can aid in selecting appropriate replacements.

By mastering these skills, you’ll be better equipped to handle repairs and maintenance tasks efficiently.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your system requires regular upkeep and attention. By following a few simple guidelines, you can extend its lifespan and optimize performance, ultimately saving time and resources.

First, regularly check for any signs of wear or damage. Early detection of issues can prevent more significant problems down the line. It’s advisable to inspect all connections and fittings to ensure they are secure and functioning properly.

Next, maintain a clean environment around the unit. Dust and debris can accumulate, affecting performance. A gentle cleaning routine will help keep the area tidy and prevent potential obstructions.

Periodic replenishment of essential substances is crucial. Follow manufacturer recommendations for the correct schedule and type of materials needed. This practice ensures that the system operates efficiently and remains effective over time.

Lastly, consider scheduling professional evaluations. Regular assessments by a qualified technician can identify potential concerns and provide peace of mind. Investing in expert care will contribute to the longevity of your equipment.

Replacing Parts for Optimal Performance

Maintaining efficiency and longevity of your system relies heavily on timely substitutions of its components. Over time, various elements may wear out or become less effective, leading to suboptimal functioning. Regularly assessing and refreshing these critical components ensures that your setup operates at peak capacity, providing the best results for your needs.

When considering replacements, it’s essential to identify the specific elements that have shown signs of deterioration. This might include filters, resin beads, or seals that can degrade due to prolonged usage. Keeping track of these parts’ conditions helps prevent unexpected failures and promotes a smoother operation.

Utilizing quality replacements is crucial for preserving the overall integrity of your unit. Opt for manufacturer-approved or high-grade alternatives to guarantee compatibility and performance. Proper installation and adherence to maintenance schedules can also extend the life of new components, ensuring that your equipment continues to deliver reliable service.

By proactively addressing component wear, you not only enhance efficiency but also save on potential repair costs down the line. A well-maintained system can lead to better outcomes, ultimately improving the experience and satisfaction of users. Regular check-ups and timely replacements are key to achieving this goal.