Understanding the Parts Diagram of Whirlpool Gas Water Heaters

When exploring the intricate workings of a heating unit, it becomes vital to grasp the various elements that contribute to its efficient operation. Each component plays a significant role, ensuring optimal performance and reliability. Understanding these parts can lead to better maintenance and troubleshooting, ultimately enhancing the overall experience.

Knowledge of the layout of these components allows users to navigate their systems with confidence. Whether you’re a novice or an experienced technician, familiarizing yourself with the arrangement and function of these elements is crucial. This understanding can help prevent common issues and facilitate timely repairs.

In this guide, we will delve into the individual sections of the heating unit. By highlighting their functions and interactions, we aim to provide you with the ultimate insights needed to manage and maintain your system effectively.

Understanding Whirlpool Gas Water Heaters

This section provides an overview of a popular appliance that provides heated liquid for various domestic needs. It is essential to comprehend the components and functionality of these units to ensure optimal performance and maintenance.

Key Components

- Burner assembly

- Thermostat

- Ventilation system

- Storage tank

- Gas control valve

How It Operates

- The thermostat detects the temperature of the stored liquid.

- When the temperature drops below a set point, the gas control valve opens.

- The burner ignites, heating the liquid within the storage tank.

- Once the desired temperature is reached, the thermostat signals the gas control valve to close, stopping the heating process.

Understanding these elements will assist users in troubleshooting issues and ensuring the longevity of the appliance.

Key Components of Gas Water Heaters

In heating systems designed to provide warm household liquids, various elements work together to ensure efficient operation and temperature regulation. These components contribute to maintaining a stable flow, control mechanisms, and safety measures. Understanding each of these elements helps in identifying issues and ensuring proper maintenance.

Burner Assembly

The burner assembly is responsible for generating the heat necessary to warm the liquid. This section includes ignition elements, flame control, and fuel regulation. Its performance is critical for efficient heating and overall functionality.

Control Valve

The control valve regulates the flow of energy to the system. It ensures safe operation by maintaining correct pressure levels and allowing for user adjustments. This component often includes safety mechanisms to prevent overheating or pressure build-up.

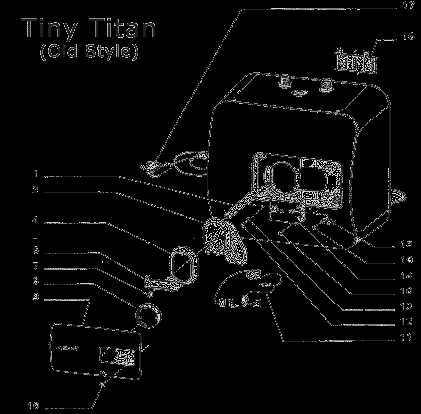

How to Read Parts Diagrams

Understanding technical illustrations is crucial for anyone working with complex equipment. These visual representations provide a clear guide to the layout and connections of various components, making it easier to identify and replace specific elements. By following the structure and labeling within these drawings, you can efficiently navigate the assembly or repair process.

Each drawing is organized to show how individual pieces fit together. Key sections are often highlighted, and labels or numbers are used to reference specific components. Cross-referencing these details with a guide or manual ensures accuracy during repairs or installations.

Common Issues with Water Heater Parts

Malfunctions in thermal appliances can be a source of frustration, especially when essential components fail to perform as expected. These problems often arise due to wear, improper installation, or poor maintenance practices, leading to reduced efficiency or complete failure of the system.

One frequent issue involves faulty temperature controls, which may cause the system to overheat or underheat. Another common problem is sediment buildup inside the tank, which can hinder performance and shorten the lifespan of the unit. Leaks are also a concern, particularly around connection points and seals, potentially resulting in water damage if left unaddressed.

Electrical malfunctions or pilot light issues may also lead to inconsistent performance, requiring timely intervention to restore normal operation. Regular inspections and proper care are crucial for preventing these issues from becoming severe.

Maintenance Tips for Gas Models

Proper upkeep is essential to ensure efficient performance and longevity of your equipment. Regular inspection and cleaning of key components help prevent malfunctions and extend the lifespan of the system.

Regular Inspections

- Check for leaks or unusual noises during operation.

- Inspect the control valves to ensure they are functioning correctly.

- Verify that the connections and fittings are tight and secure.

Cleaning Recommendations

- Periodically clean the venting system to avoid blockages.

- Remove sediment buildup from the tank to maintain efficiency.

- Ensure burner components are free from

Identifying Replacement Parts Easily

Maintaining an efficient home system often requires understanding the various components involved. Knowing how to locate the correct substitute items is crucial for quick repairs and avoiding downtime.

To simplify the process of finding the right components, follow these steps:

- Check the model number: Every system is equipped with a unique identifier that links directly to specific components.

- Consult the user manual: Manuals typically include detailed charts that list corresponding elements and their functions.

- Use online resources: Many websites offer searchable databases where you can input system details to find exact replacements.

- Inspect the original components: Often, the removed element has a label or code that can guide you toward the correct match.

By following these methods, finding the appropriate items becomes a straightforward task, reducing time spent on repairs and ensuring your system runs smoothly.

Safety Features in Gas Water Heaters

Modern thermal systems are equipped with various mechanisms designed to ensure user protection and reliable operation. These features help prevent accidents, protect the system from malfunctions, and extend its overall lifespan. The focus on safety allows for more efficient energy use while reducing potential risks associated with system failure.

One of the essential components is the automatic shut-off feature, which activates if the system detects an issue, such as overheating or lack of proper ventilation. Additionally, temperature and pressure relief valves are critical in maintaining safe operating conditions by releasing excess heat and pressure to prevent dangerous buildups.

Tools Needed for Repairs

When it comes to fixing common issues, having the right set of instruments is essential for efficient and safe work. Preparing ahead with the appropriate tools ensures that the process goes smoothly, and potential complications are minimized. Below is a list of equipment typically required to address standard maintenance tasks.

Basic Tools

For most repair jobs, you will need fundamental tools such as screwdrivers, pliers, and a wrench. These help in accessing various fasteners and components without causing damage. A multimeter is also essential to test electrical connections and ensure safety during repair procedures.

Specialized Instruments

In addition to basic tools, certain fixes may require more specific instruments. For example, a pipe wrench or adjustable spanner might be necessary to handle fittings, while a tube cutter could be essential for adjusting pipe lengths or removing sections. These specialized items help ensure precision during more intricate repair tasks.

Wiring and Electrical Connections Explained

Understanding how the electrical setup functions is essential when working with thermal appliances. The correct configuration ensures safe and efficient operation, preventing potential issues caused by improper installation or faulty connections.

Main Electrical Components

Key components involved in the electrical system include power wires, connectors, and control units. These elements work together to manage the flow of electricity and ensure proper operation of the unit. Each part must be connected securely to avoid short circuits or malfunctions.

Safety Considerations

Proper insulation, grounding, and alignment of the electrical wiring are critical for the safe functioning of the system. It’s vital to check all connections and ensure that the power supply adheres to the manufacturer’s specifications for optimal performance and safety.

Best Practices for Efficient Operation

Maintaining the optimal performance of your system relies on following key operational guidelines. Implementing these strategies ensures long-lasting use and reduces the likelihood of disruptions.

- Regular maintenance checks: Periodic inspections of the system are essential for identifying and addressing potential issues before they become serious.

- Temperature settings: Ensure the temperature is set to an appropriate level to avoid excessive energy consumption and wear on components.

- Proper ventilation: Good airflow around the unit promotes efficiency and prevents overheating, which could lead to damage.

- Cleaning components: Dust and debris can accumulate over time, so it’s crucial to clean key parts regularly for optimal functionality.

- Timely replacements: Replace any worn or faulty elements promptly to prevent larger system failures and costly repairs.

By adhering to these

When to Call a Professional Technician

There are certain situations when reaching out to a certified specialist is crucial to ensure both safety and efficiency in the operation of your home’s equipment. Although some issues can be resolved with basic troubleshooting, others demand the skills of a trained expert.

Complex Installation or Repairs

If the installation process or the required fix involves advanced steps, it’s best to rely on a professional. Incorrect handling of electrical connections or mechanical components can lead to more serious damage or even hazardous conditions. Professional technicians are equipped with the knowledge to perform these tasks safely and correctly.

Unusual Noises or Malfunctions

Strange sounds, unexpected shutdowns, or failure to start are clear indicators that an experienced technician is needed. These signs can point to deeper problems that are not easily identifiable without the right tools and experience. In these cases, immediate assistance from a professional can prevent