Comprehensive Guide to Whirlpool Water Softener Parts Diagram

In the realm of home maintenance, comprehending the intricacies of your treatment unit is essential. This device plays a crucial role in ensuring the quality of your supply, ultimately impacting everything from appliance longevity to the comfort of your daily routine. A clear grasp of its components can lead to more informed decisions regarding upkeep and troubleshooting.

Visual representation of the various elements within this system can significantly enhance your understanding. By exploring a schematic layout, you can identify each section’s function and importance. Recognizing how these components interact enables you to address potential issues effectively, promoting efficiency and performance.

Additionally, familiarity with the individual sections can empower you during maintenance tasks or when seeking assistance from professionals. Knowing the terminology and layout will facilitate clearer communication and help you achieve optimal results. Engaging with the mechanics of your treatment unit opens the door to greater control over your household environment.

Understanding Whirlpool Water Softeners

Household systems designed to reduce mineral content play a crucial role in improving the quality of water used for various purposes. These mechanisms help to prevent the buildup of scale, ensuring that appliances function efficiently and prolonging their lifespan. By maintaining optimal water conditions, these systems contribute to a more comfortable living environment and enhance the effectiveness of cleaning agents.

How They Work

At the core of these devices is a process that involves the exchange of ions. Hard minerals, primarily calcium and magnesium, are replaced with sodium ions. This ion exchange process is fundamental to achieving the desired level of purity and softness in the liquid. Understanding the internal components is essential for efficient operation and maintenance.

Key Components

Critical elements within these systems include the resin tank, control valve, and brine tank. The resin tank houses the ion-exchange resin, where the critical transformation occurs. The control valve regulates the flow and timing of the regeneration process, while the brine tank contains the salt solution necessary for replenishing the resin’s capacity. Regular inspection and timely replacement of these components are vital to ensuring optimal performance.

Components of Water Softener Systems

Understanding the essential elements of a conditioning system is crucial for maintaining optimal performance and efficiency. Each component plays a significant role in the overall functionality, ensuring that the system effectively addresses hardness and impurities in the supply.

Resin Tank is where the ion exchange process occurs. This tank is filled with resin beads that attract and hold onto minerals like calcium and magnesium, replacing them with sodium ions.

Brine Tank serves as the reservoir for the salt solution. This component is vital for regenerating the resin beads, allowing them to continue their work in mineral removal. The concentration of the salt solution is crucial for effective regeneration.

Control Valve regulates the flow of water through the system. It manages the various cycles, including service, backwash, and regeneration, ensuring that the entire process operates smoothly and efficiently.

Bypass Valve allows for the diversion of water around the conditioning system. This feature is useful during maintenance or repairs, ensuring that other plumbing fixtures remain operational without interruption.

Drain Line is essential for removing waste water and excess brine from the system during the regeneration cycle. Proper drainage is necessary to maintain efficiency and prevent system overload.

Flow Meter measures the amount of water passing through the system. This information is crucial for determining when regeneration is needed, optimizing the performance of the entire setup.

Each of these components works in harmony to ensure the effectiveness of the conditioning system, providing a reliable solution for managing hardness and enhancing the quality of the treated supply.

How Water Softeners Function

Understanding the mechanisms behind the removal of hardness minerals from liquid supplies is essential for optimizing household systems. The process not only improves the quality of the fluid but also enhances the efficiency of appliances and plumbing infrastructure.

Core Principles of Operation

The fundamental concept revolves around exchanging ions. The primary components involved are:

- Minerals: Predominantly calcium and magnesium, responsible for hardness.

- Resin: A medium that facilitates the ion exchange process.

- Regeneration: A method used to refresh the resin after it becomes saturated.

When the liquid flows through the resin bed, the hardness minerals adhere to the resin while releasing sodium ions. This exchange diminishes the presence of hard elements, resulting in a more efficient and smooth liquid flow.

Regeneration Process

Once the resin reaches its capacity, a regeneration cycle is initiated. This involves:

- Brine Solution: A concentrated sodium solution is introduced to the resin bed.

- Ion Exchange: Sodium ions displace the accumulated hardness minerals from the resin.

- Flushing: The discarded minerals are washed away, preparing the system for renewed service.

Through this cycle, the system maintains its efficiency, ensuring long-term effectiveness in reducing hardness and enhancing overall performance.

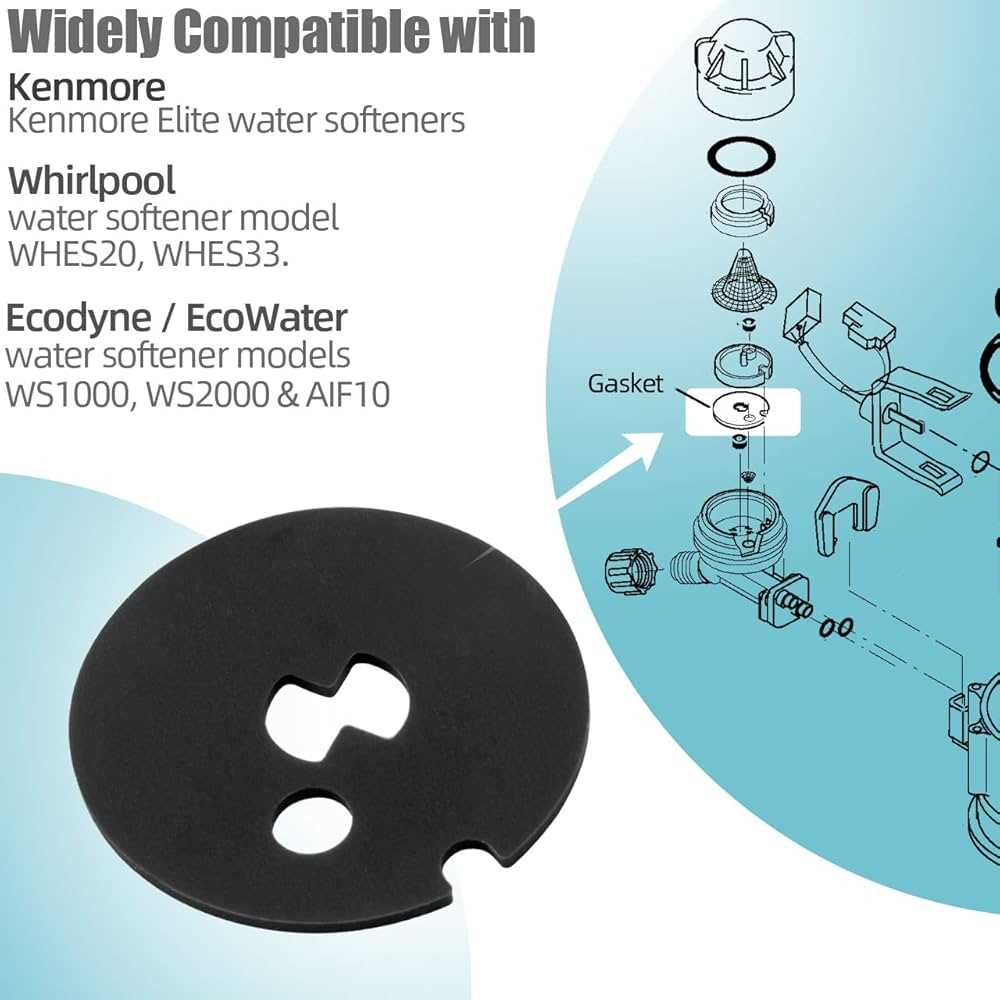

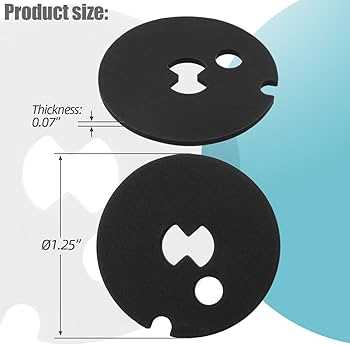

Common Parts in Whirlpool Models

Understanding the essential components of these systems is crucial for maintenance and efficient operation. Each unit is designed with specific elements that contribute to its overall functionality. Familiarity with these features can help in troubleshooting and ensuring optimal performance.

Brine Tank: This container holds the salt needed for regeneration. It plays a vital role in the ion exchange process, ensuring the system operates effectively.

Control Valve: The control valve regulates the flow of water through the system. It is responsible for directing the water during various cycles, such as regeneration and service.

Resin Bed: The resin bed contains tiny beads that facilitate the ion exchange process. This is where hard minerals are removed from the water, providing a softer output.

Bypass Valve: This component allows users to divert water away from the system when needed. It is useful during maintenance or when soft water is not required.

Salt Level Sensor: This sensor monitors the amount of salt in the brine tank. Maintaining the correct salt level is essential for effective regeneration and overall system health.

Being aware of these fundamental components can greatly enhance your understanding of unit operation and maintenance, ensuring longevity and efficiency.

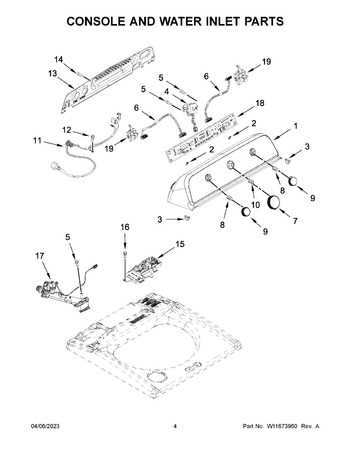

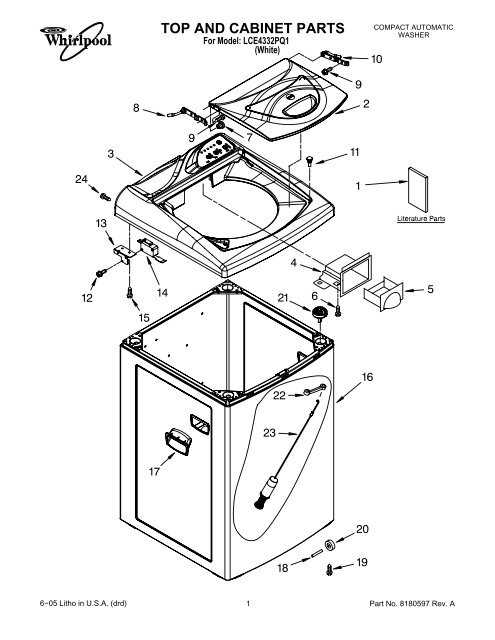

Reading the Parts Diagram

Understanding the layout of components within a system is crucial for effective maintenance and troubleshooting. A detailed illustration provides a visual representation, allowing users to identify various elements and their relationships. By familiarizing oneself with this schematic, one can navigate the intricacies of assembly and functionality with greater ease.

When examining the illustration, it’s essential to focus on the labeling of each item. Color coding and symbols often aid in differentiating parts, making it simpler to follow the flow of operation. Pay close attention to the orientation and positioning, as these factors significantly influence performance.

In addition to recognizing components, understanding their roles within the overall mechanism is vital. Each element works in harmony with others, contributing to the efficiency of the entire unit. By grasping how each piece interacts, users can better diagnose issues and implement appropriate solutions.

Ultimately, a thorough comprehension of the schematic empowers users to take informed action, whether performing routine maintenance or addressing specific concerns. Familiarity with the intricacies presented in the illustration is a valuable skill for anyone involved in the upkeep of such systems.

Identifying Key Components

Understanding the essential elements of a conditioning system is crucial for effective maintenance and troubleshooting. Each component plays a vital role in ensuring the unit operates efficiently and prolongs its lifespan. Familiarity with these integral parts enables users to address issues promptly and make informed decisions about repairs or replacements.

Core Elements

- Resin Tank: This is where the filtration process occurs, allowing ions to be exchanged effectively.

- Brine Tank: A storage space for the salt solution, which aids in the regeneration of the resin.

- Control Valve: Responsible for regulating the flow of fluid and timing of the regeneration cycles.

- Bypass Valve: Allows users to divert flow away from the conditioning system during maintenance.

- Drain Line: Facilitates the expulsion of waste water during regeneration.

Additional Features

- Salt Level Indicator: Monitors the amount of salt in the brine tank, ensuring optimal performance.

- Timer: Controls the scheduling of regeneration processes based on usage patterns.

- Overflow Tube: Prevents flooding by directing excess liquid away from the system.

Recognizing these components can enhance your understanding of how the system functions and simplify maintenance tasks. Regular inspections and knowledge of these features contribute significantly to the unit’s efficiency and reliability.

Maintenance Tips for Water Softeners

Proper upkeep is essential for ensuring the longevity and efficiency of your purification system. Regular maintenance not only enhances performance but also helps in avoiding costly repairs in the future. Here are some practical tips to keep your system running smoothly.

1. Check Salt Levels: Regularly inspect the salt levels in your reservoir. Maintaining an adequate amount prevents operational issues and ensures optimal functionality. Refill with the recommended type of salt when levels are low.

2. Clean the Brine Tank: Periodically, it’s important to clean the brine tank to prevent the buildup of sediment and debris. A clean tank enhances the regeneration process and improves overall effectiveness.

3. Inspect for Leaks: Regularly check connections and hoses for any signs of leaks. Addressing leaks promptly can prevent water damage and maintain system efficiency.

4. Schedule Professional Maintenance: Consider arranging for professional service at least once a year. Experts can perform thorough inspections, identify potential issues, and ensure your system operates at its best.

5. Monitor System Performance: Keep an eye on the performance of your unit. Unusual sounds, changes in water quality, or increased salt usage may indicate underlying problems that need attention.

By following these maintenance tips, you can extend the life of your purification equipment and ensure that it functions effectively for years to come.

Common Issues with Water Softener Parts

Many homeowners encounter challenges with their treatment systems, which can lead to inefficiency and increased maintenance costs. Understanding the typical problems associated with these devices is essential for effective troubleshooting and repair. This section explores some frequent issues that users may face, along with potential solutions.

One prevalent concern is the accumulation of debris within the unit, which can obstruct flow and reduce effectiveness. Regular cleaning and maintenance can help mitigate this issue. Another common problem is the failure of resin beads to function properly, often due to aging or contamination, which can lead to hard minerals not being adequately removed from the fluid supply.

Malfunctioning valves are also a significant source of trouble, potentially causing leaks or improper regeneration cycles. Ensuring these components are inspected regularly can prevent larger issues down the line. Additionally, fluctuating salt levels in the brine tank can affect overall performance, so monitoring and replenishing salt is crucial for optimal operation.

Electrical problems, such as faulty timers or control boards, may also arise, leading to operational inconsistencies. Identifying these issues early on can save time and money in repairs. By being aware of these common difficulties and implementing routine maintenance, users can enhance the longevity and efficiency of their systems.

Replacing Faulty Components

Maintaining optimal performance of your system often involves addressing defective elements. Identifying and replacing these components promptly can significantly enhance efficiency and prolong the lifespan of the entire unit. This section will guide you through the process of recognizing signs of wear and ensuring that replacements are executed effectively.

Identifying Defective Elements

Common indicators of malfunction may include unusual noises, decreased functionality, or visible damage. Regular inspections can help in detecting these issues early on. Key components to monitor include valves, filters, and resin tanks, as these are critical for maintaining performance.

Replacement Procedure

Once you have pinpointed the problematic parts, follow these steps for replacement:

| Step | Description |

|---|---|

| 1 | Disconnect power supply and water source to ensure safety. |

| 2 | Carefully remove the defective component, taking note of its orientation and connections. |

| 3 | Install the new part, ensuring a secure fit and proper alignment. |

| 4 | Reconnect the water supply and power, then test the system to confirm functionality. |

Following these guidelines can help ensure a smooth replacement process, restoring your unit to optimal operation.

Tools Needed for Repairs

When tackling any maintenance task, having the right instruments at your disposal is crucial for efficiency and effectiveness. Proper tools not only simplify the repair process but also ensure that the job is done safely and correctly. Understanding what is needed before you begin can save time and prevent frustration.

Essential Hand Tools

Start with a set of screwdrivers of various sizes, including both flathead and Phillips. These will help you access components that may be secured with screws. Additionally, a reliable wrench or socket set is vital for loosening and tightening nuts and bolts. Don’t forget to include a pair of pliers for gripping and bending tasks.

Specialized Equipment

For more intricate repairs, having a multimeter can assist in diagnosing electrical issues effectively. A tubing cutter may also come in handy for replacing any pipes, ensuring clean cuts. Finally, consider using a drain pan to catch any spills during your work, protecting your space from unnecessary mess.

Water Softener Installation Guide

This section provides a comprehensive overview of the setup process for a system designed to reduce mineral content in liquids. Proper installation ensures optimal performance and longevity, ultimately improving the quality of the treated fluid.

Preparation Steps

- Identify a suitable location with easy access to plumbing.

- Gather necessary tools such as wrenches, screwdrivers, and tubing cutters.

- Ensure you have all components, including tanks, brine containers, and fittings.

Installation Process

- Shut off the main supply and drain the existing line.

- Connect the unit to the inlet pipe, ensuring a secure fit.

- Install the drain line following the manufacturer’s guidelines.

- Set up the brine tank, ensuring it is level and easily accessible.

- Fill the brine container with the recommended salt type.

- Power on the system and configure settings as per the instructions.

- Check for leaks and ensure all connections are tight.

Following these steps carefully will help you achieve a successful installation, paving the way for enhanced efficiency in treating your liquids.

Where to Find Replacement Parts

Locating suitable components for your appliance is crucial to ensuring its longevity and efficient operation. Whether you are looking to replace a faulty element or upgrade to a newer version, there are several reliable sources available. Understanding where to seek these items can save time and provide peace of mind during your repair process.

Authorized Retailers

One of the most dependable avenues for sourcing components is through authorized retailers. These establishments often stock genuine items that guarantee compatibility and performance. Visiting a local store can provide the added benefit of expert advice from knowledgeable staff who can assist in identifying the correct item needed for your specific model.

Online Marketplaces

The internet offers a plethora of options when it comes to acquiring replacement components. Reputable e-commerce websites host a wide array of selections, making it easy to compare prices and availability. Ensure you check customer reviews and seller ratings to avoid subpar products. Additionally, specialized online platforms dedicated to home appliances often feature comprehensive catalogs, making your search more efficient.